Sand blasting machine and sand blasting system provided therewith

A sandblasting machine and sandblasting technology, applied in the direction of abrasive jet machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high working intensity, steel sand splashing, poor sandblasting effect, etc., and achieve labor intensity Large, improve production efficiency, improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

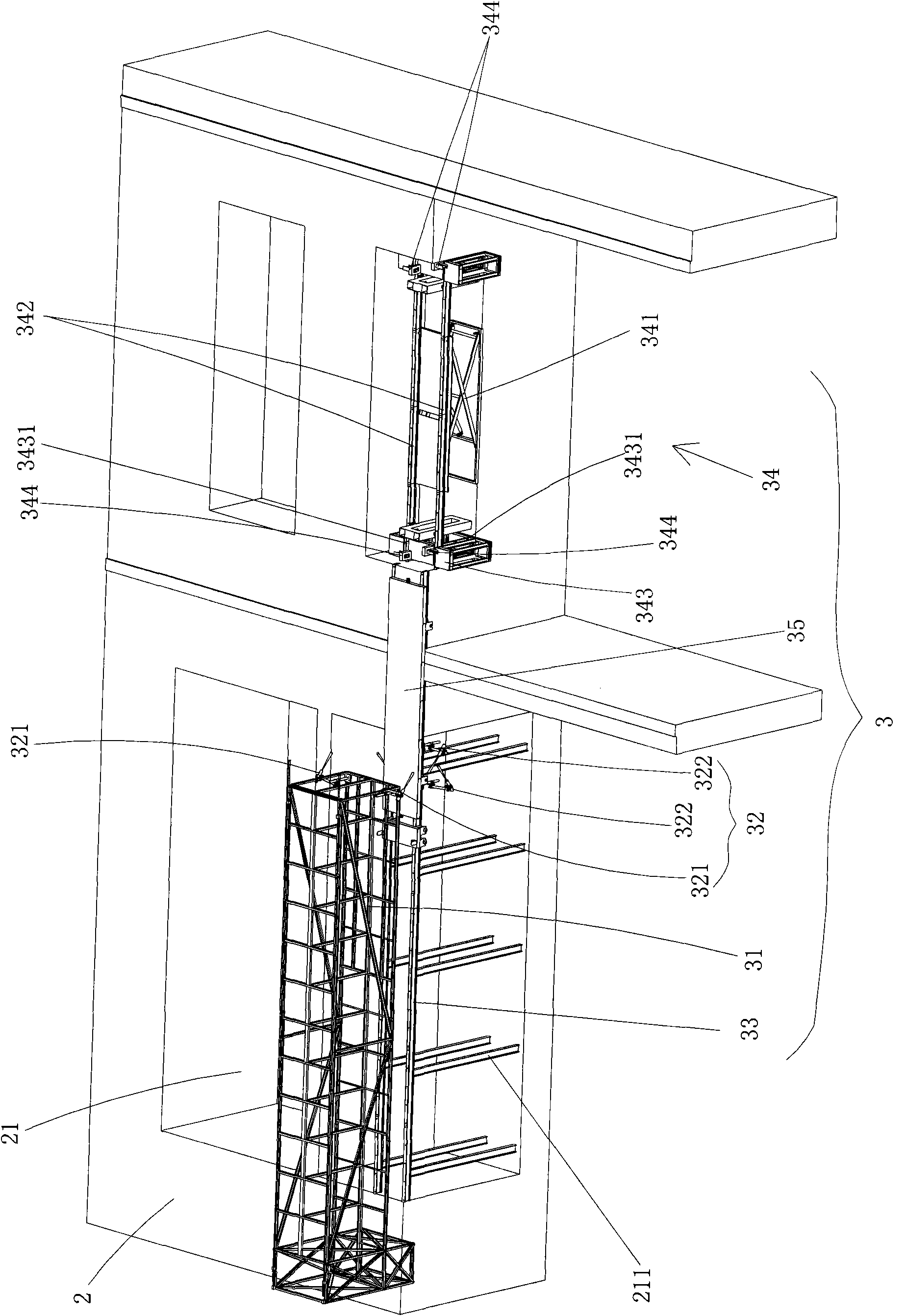

[0014] figure 2 It is a structural schematic diagram of the sandblasting system of the present invention. As shown in the figure, the sandblasting system includes: a sand room 2 and a sandblasting machine 3 . A pit 21 is arranged in the sand room 2, and the pit 21 extends to the top surface of the sand room 2, so that an opening is formed on the top of the sand room 2. This sandblasting machine 3 is installed on the sand room 2, and it comprises: a truss 31, two first rails 33, multi-rod sand gun 32, a lifting platform device 34, a loading platform 35 and at least one driving mechanism (not shown Show).

[0015] The truss 31 is set on the top of the sand room 2 and corresponds to the opening of the pit 21 in the sand room 2. The truss 31 is designed as a rectangular frame structure approximately matching the internal storage space of the container. The container can be integrated under the support of the loading platform 35. Insert the truss 31. The truss 31 is suspended a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com