A method for improving the brazing strength of tungsten-copper parts

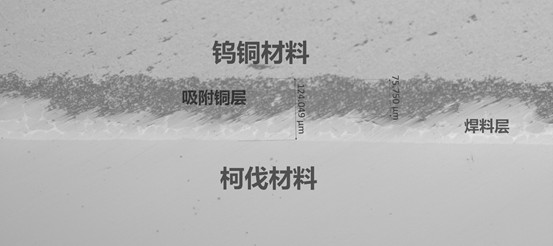

A technology for brazing and parts, which is applied in the field of improving the brazing strength of tungsten-copper parts, can solve the problems that the brazing rate is difficult to exceed 80%, the surface quality of materials is poor, and the wettability is not good, so as to avoid welding defects and weld area The effect of increase and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

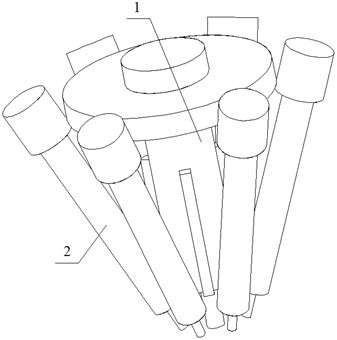

Image

Examples

Embodiment 1

[0032] A method for improving the brazing strength of tungsten-copper parts, comprising the following steps:

[0033] S1 pressed tungsten billet: press 100g tungsten powder into 10g / cm 3 tungsten billet;

[0034] S2 Forming: Put the pressed tungsten billet into the graphite crucible, put the copper block that needs to be infiltrated on the tungsten billet, the mass of the copper block is 50g, lay a layer of corundum powder in the graphite crucible in advance, and then use 160-220 mesh The corundum powder is buried and compacted, and the thickness of the corundum powder covered on the top and bottom of the tungsten billet is 2cm. The thickness of the corundum powder covered by the tungsten billet from the front and rear edges of the graphite crucible and the left and right edges is the same, and the thickness is 2cm. The pre-sintered part, the corundum powder It is white corundum, and the mass of corundum powder is 8 times that of tungsten billet;

[0035] S3 sintering: put t...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, except that the density of the tungsten billet is different, so the quality of copper that can penetrate into the tungsten billet is different, and the quality of the copper added under the same quality tungsten billet is also different. At the same time, the amount of corundum powder added also changed.

[0040] S1 pressed tungsten billet: press 100g tungsten powder into 13g / cm 3 tungsten billet;

[0041] S2 Forming: Put the pressed tungsten billet into the graphite crucible, put the copper block that needs to be infiltrated on the tungsten billet, the mass of the copper block is 30g, lay a layer of corundum powder in the graphite crucible in advance, and then use 220-260 mesh The corundum powder is buried and compacted, and the thickness of the corundum powder covered on the top and bottom of the tungsten billet is 3cm. The thickness of the corundum powder covering the tungsten billet from the front and rear edge...

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 1, except that the density of the tungsten billet is different, so the quality of copper that can penetrate into the tungsten billet is different, and the quality of the copper added under the same quality tungsten billet is also different. At the same time, the amount of corundum powder added also changed.

[0047] S1 pressed tungsten billet: press 100g tungsten powder into 15g / cm 3 tungsten billet;

[0048] S2 Forming: Put the pressed tungsten billet into the graphite crucible, put the copper block that needs to be infiltrated on the tungsten billet, the mass of the copper block is 15g, lay a layer of corundum powder in the graphite crucible in advance, and then use 260-320 mesh The corundum powder is buried and compacted, and the thickness of the corundum powder covered on the top and bottom of the tungsten billet is 4cm. The thickness of the corundum powder covering the tungsten billet from the front and rear edges ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com