Rolling wheel fixing clamp in sand-blasting machine

A technology for fixing fixtures and sandblasting machines, which is applied in the direction of manufacturing tools, used abrasive processing devices, abrasives, etc. It can solve the problems of fixed rollers and inconvenient sandblasting operations, so as to improve efficiency and reduce defects. effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

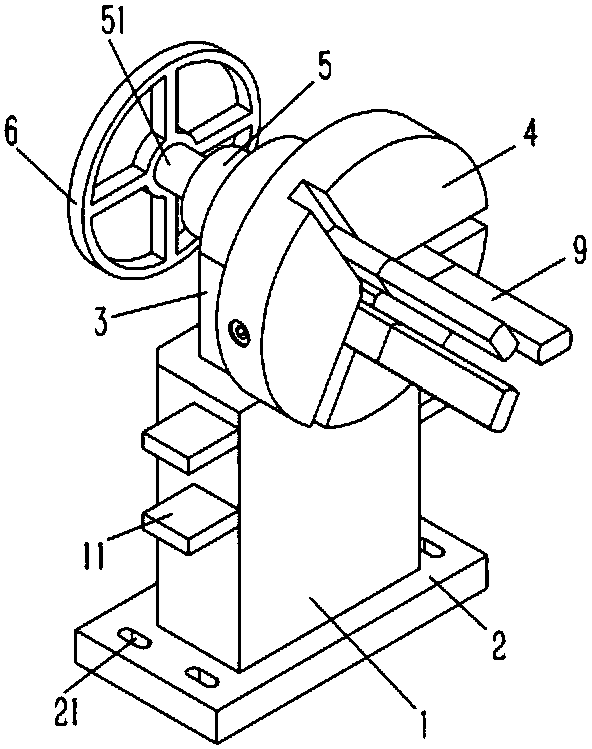

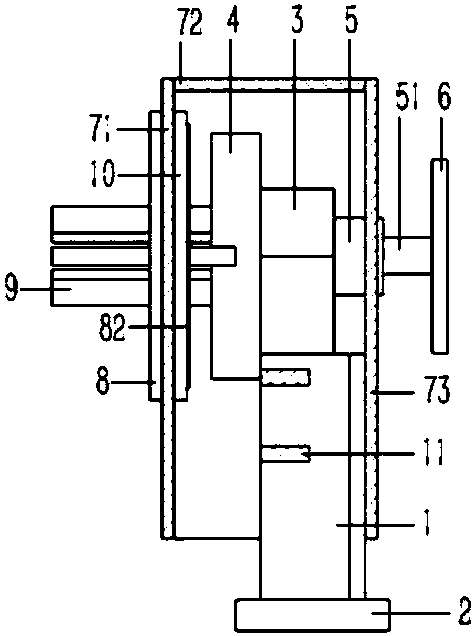

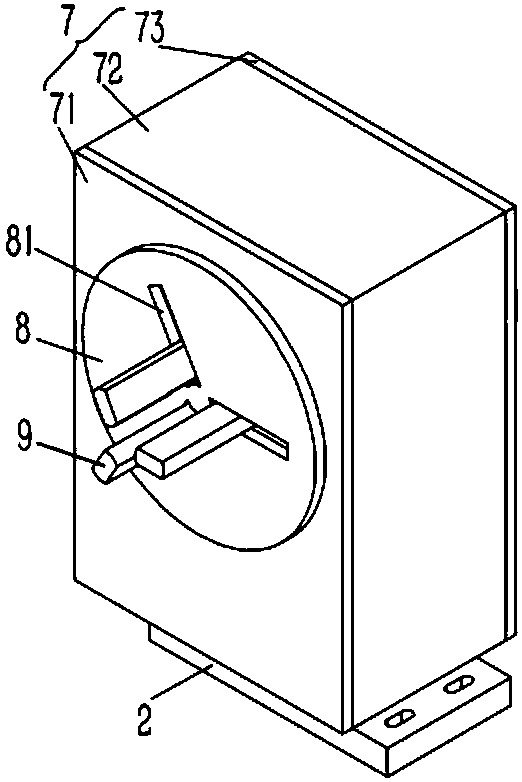

[0017] Example: see figure 1 , 2 . As shown in 3, a roller fixing fixture in a sandblasting machine includes a fixed seat 1, a bottom plate 2 is fixed on the lower end surface of the fixed seat 1, a bearing seat 3 is fixed on the upper end of the fixed seat 1, and the front side of the bearing seat 3 There is a side-standing three-jaw chuck 4, and the center of the bottom surface of the three-jaw chuck 4 is fixed with a main shaft 5. The rear end is fixed with a hand wheel 6; the jaws of the three-jaw chuck 4 are fixed with an extended clamping rod 9; the outer cover of the three-jaw chuck 4 is provided with a sand-proof cover 7, and the sand-proof cover 7 includes a front panel 71. "The font cover 72 and rear panel 73, the front panel 71 and the rear panel 73 are respectively fixed on the front and rear end surfaces of the cover body 72, the rear panel 73 is fixed on the rear end surface of the holder 1, the both sides of the holder 1 A number of supporting brackets 11 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com