Patents

Literature

68results about How to "Improve rust removal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

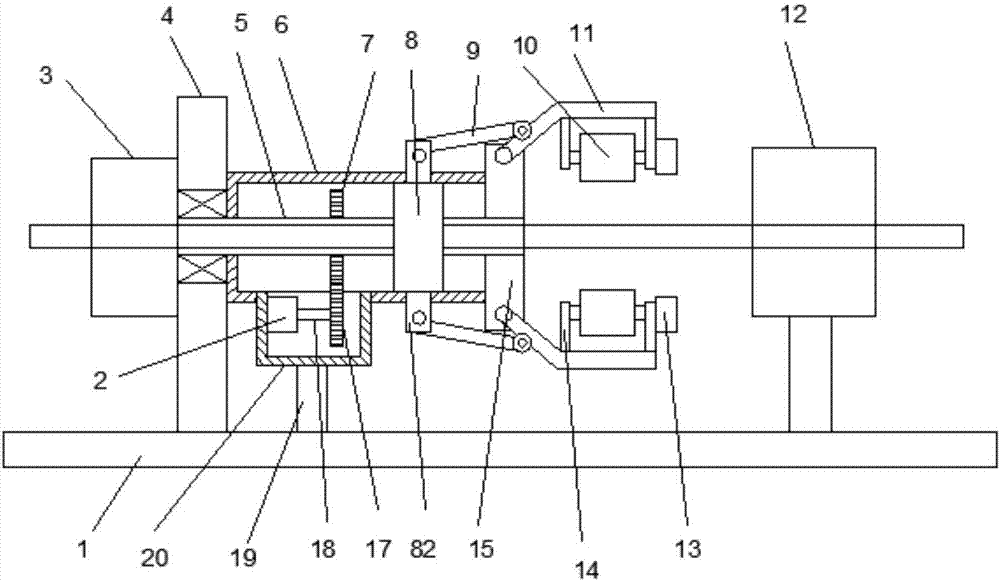

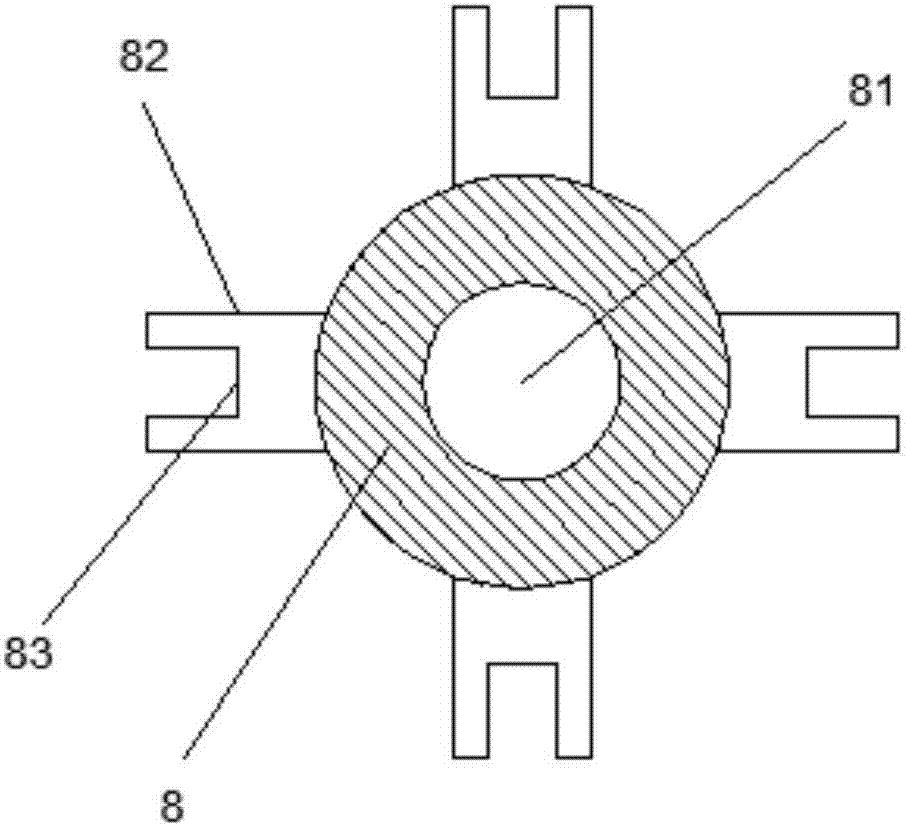

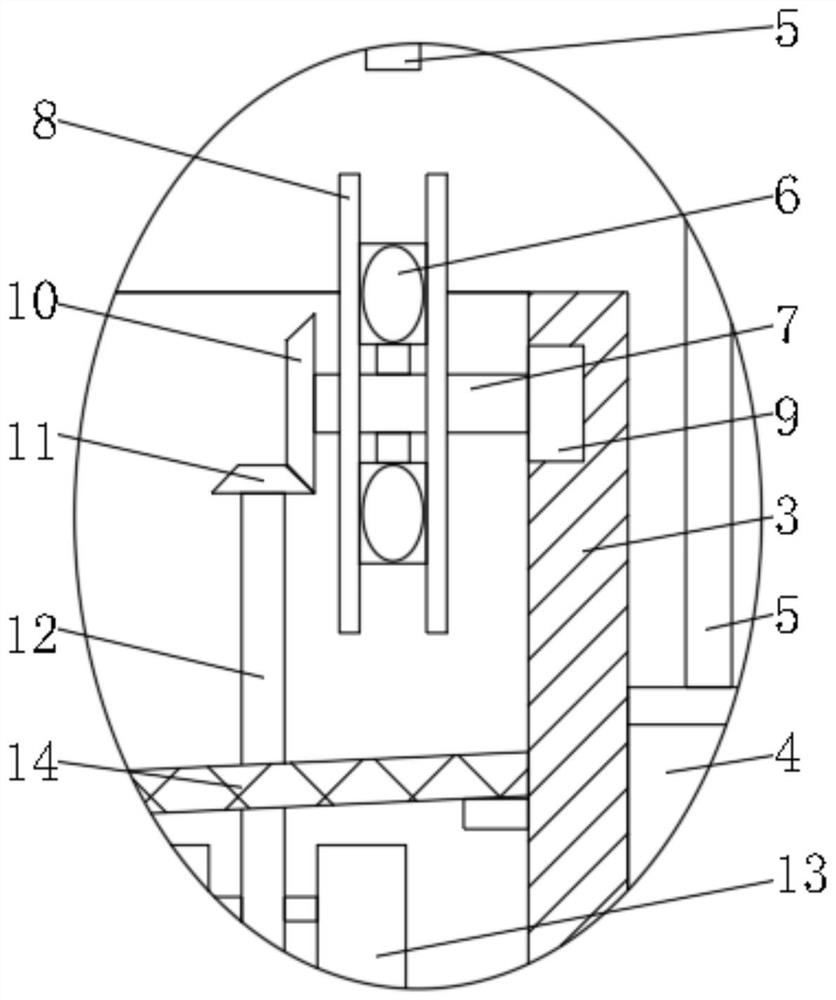

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

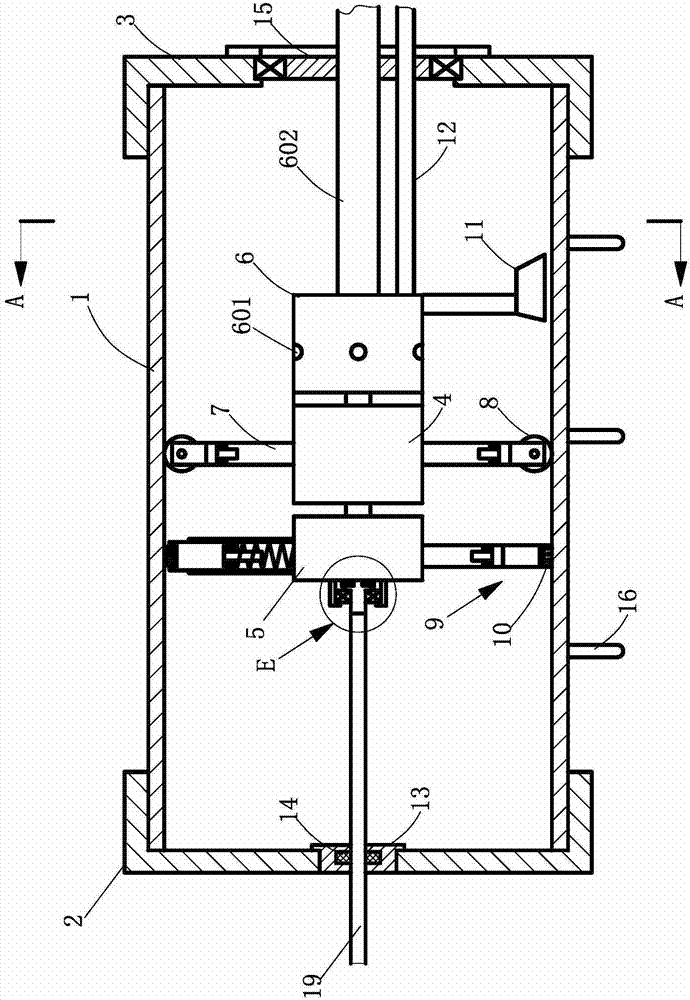

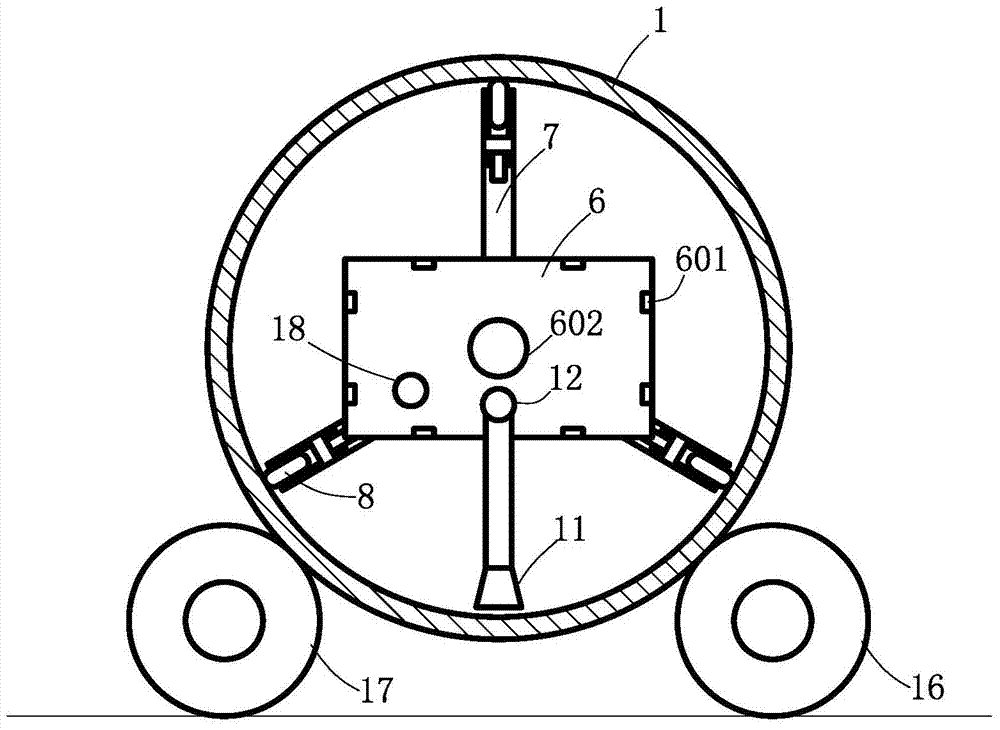

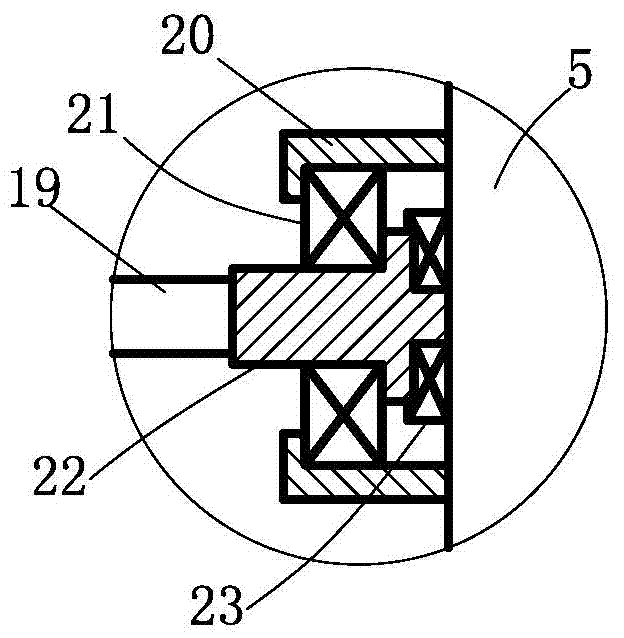

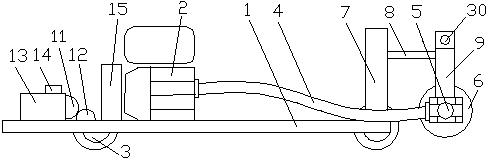

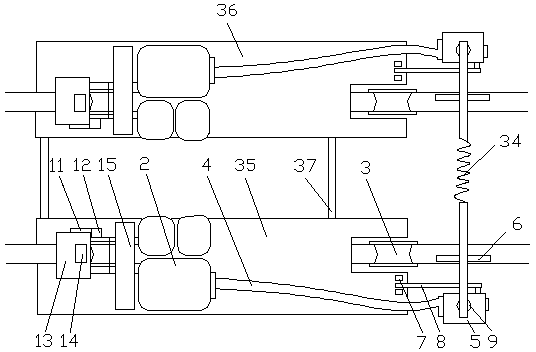

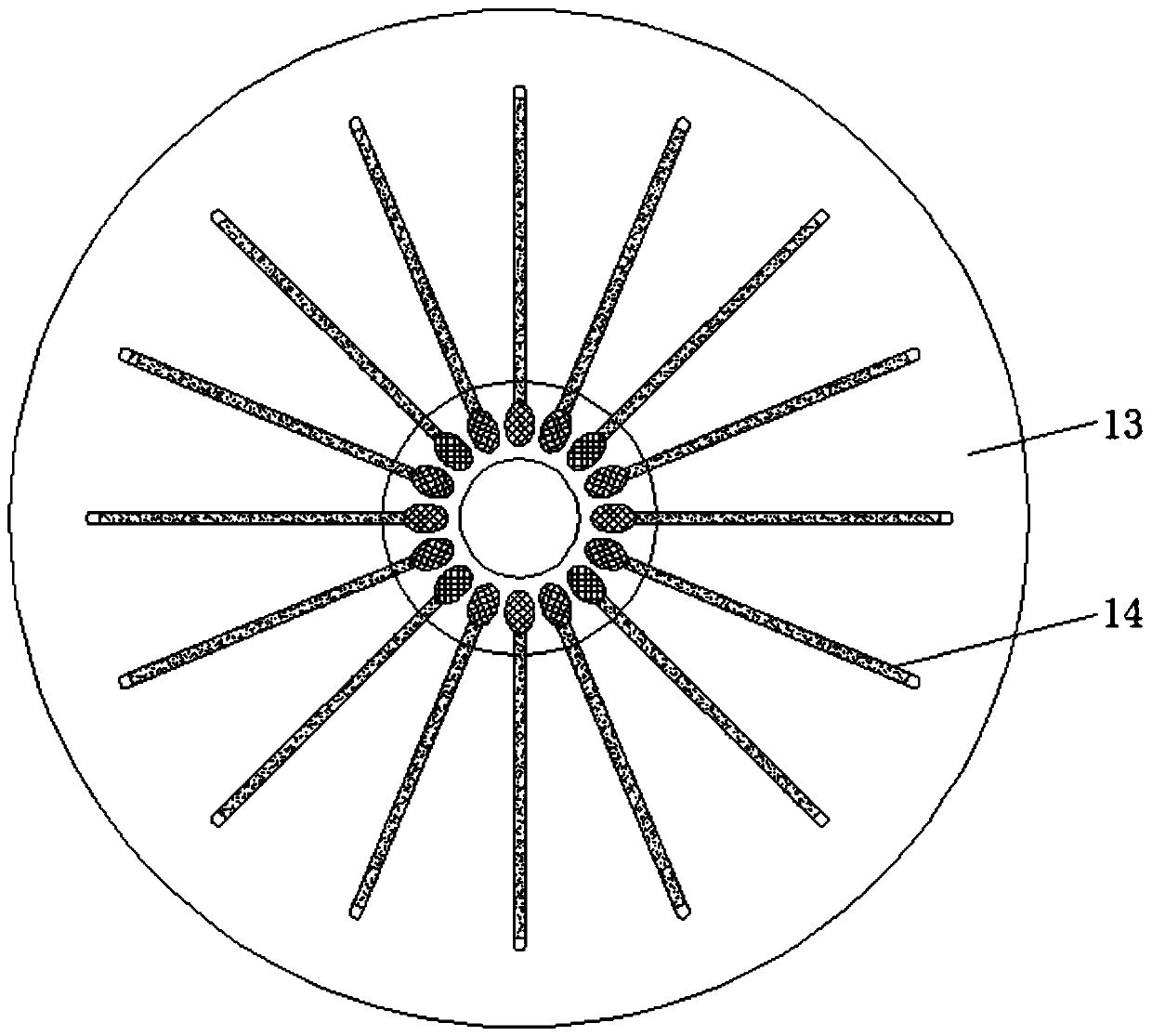

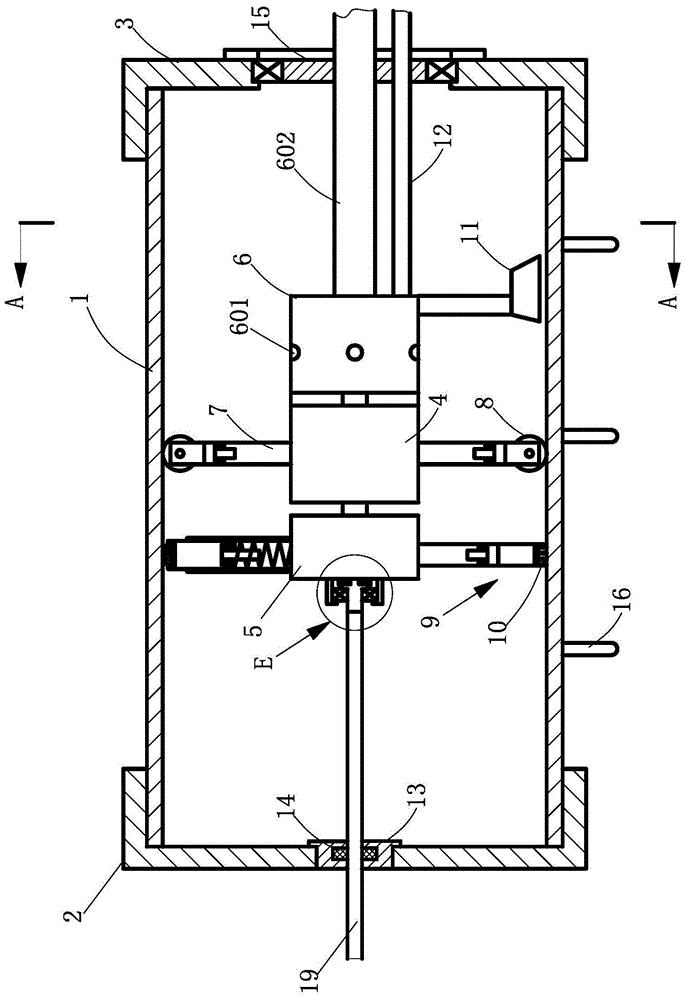

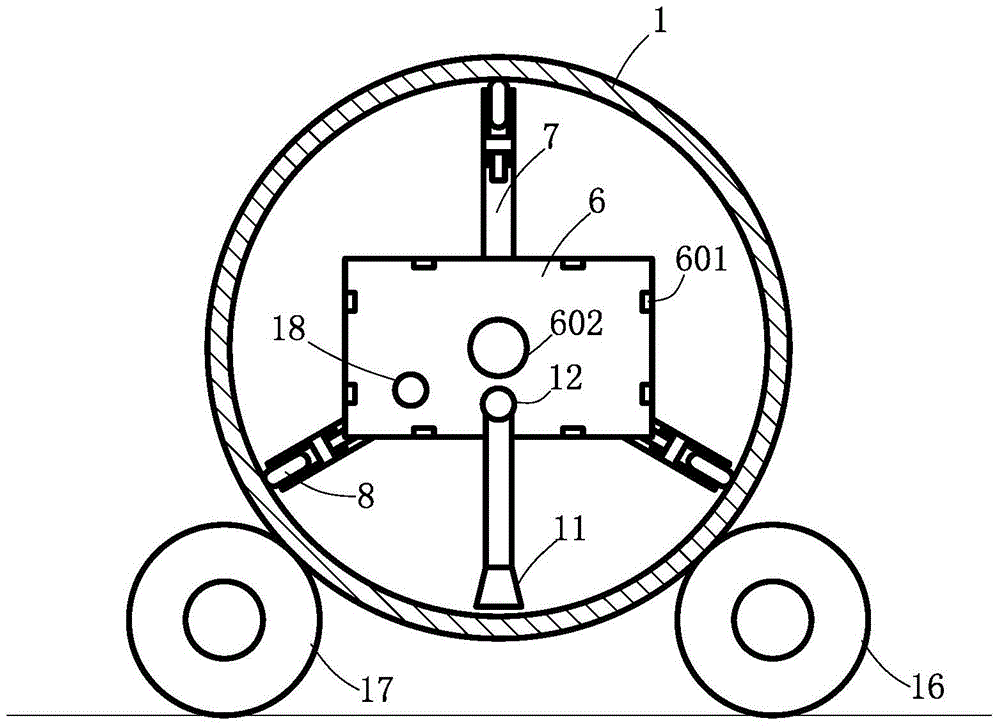

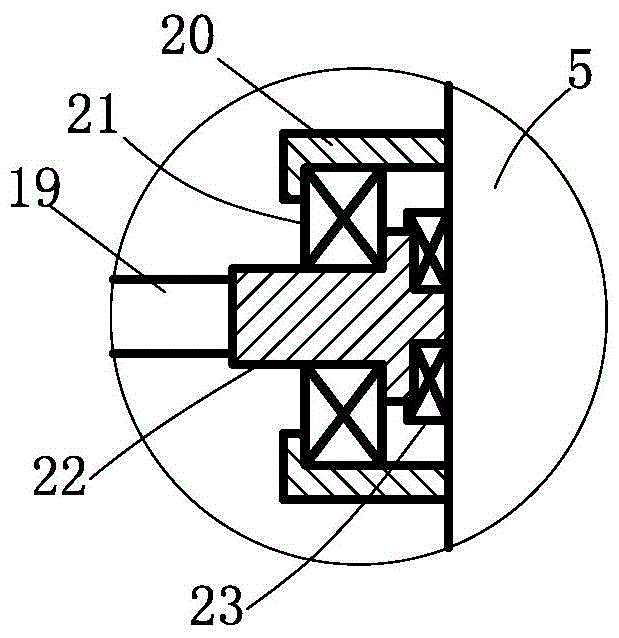

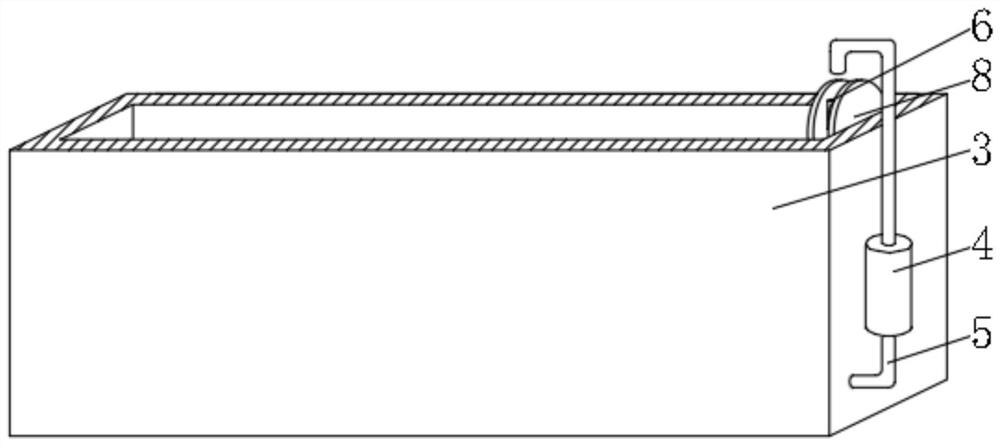

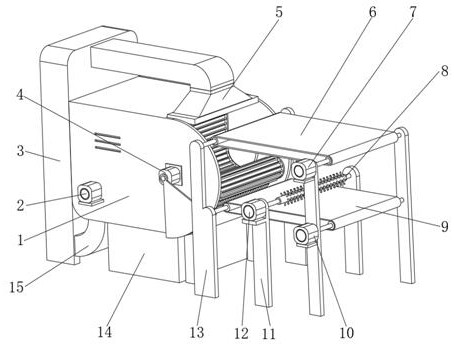

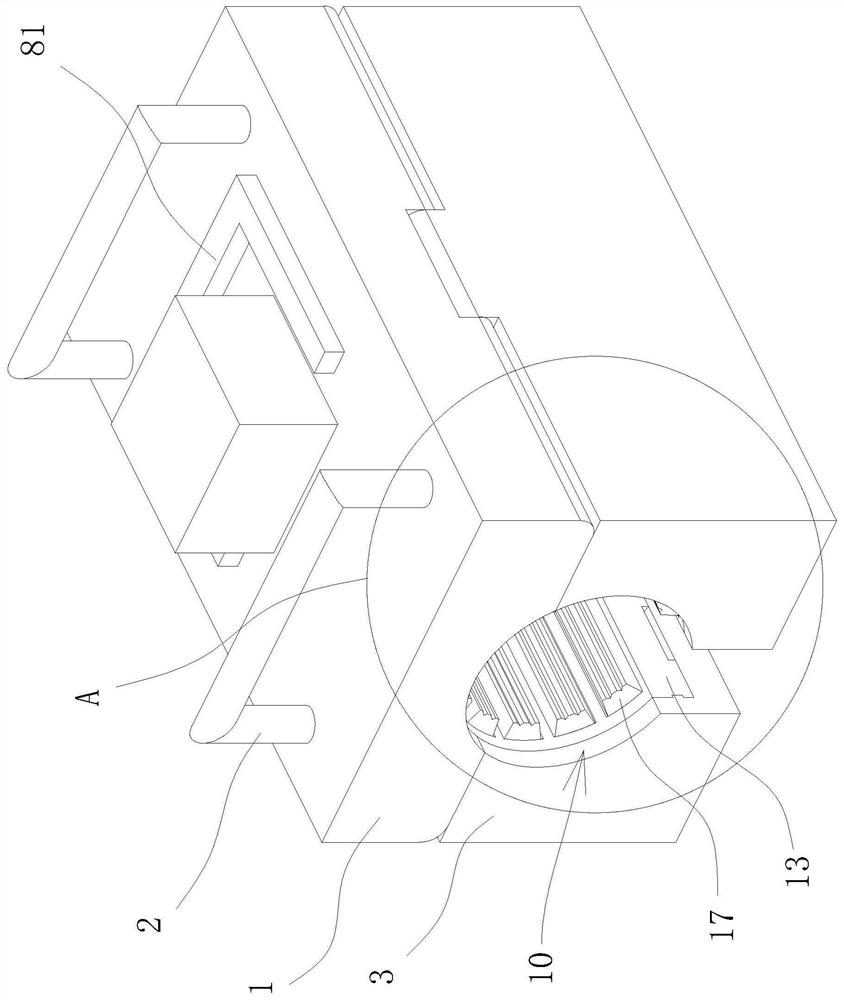

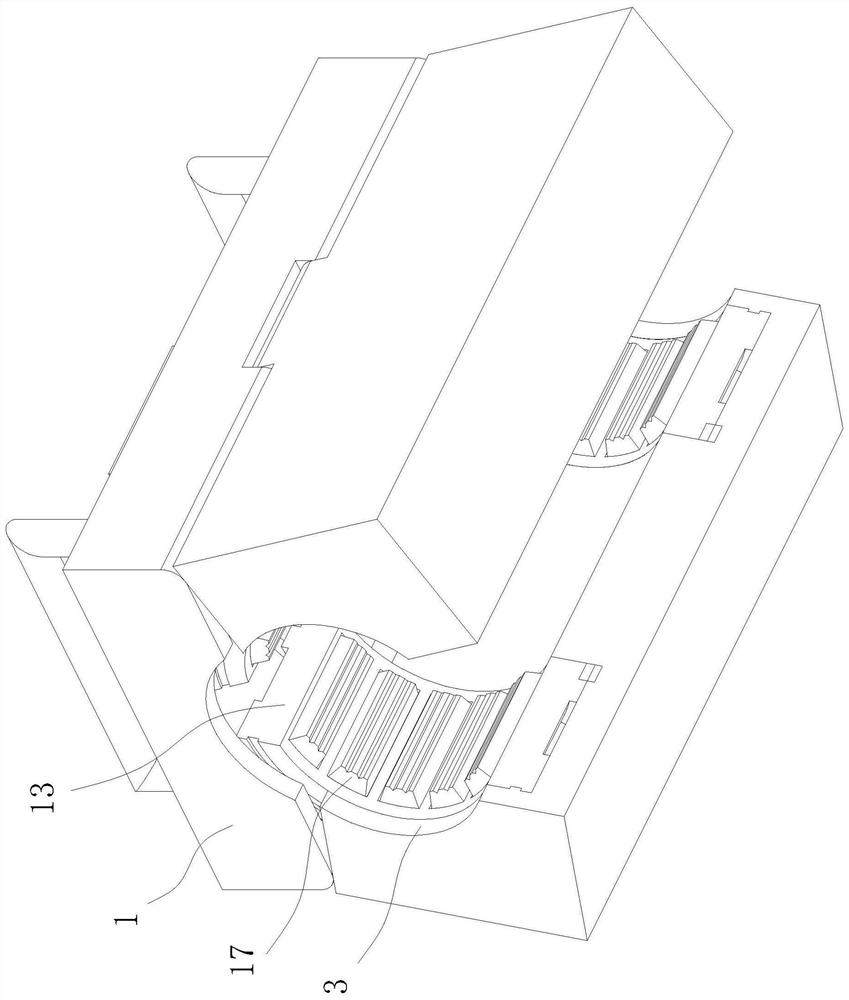

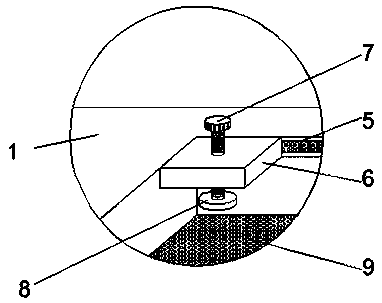

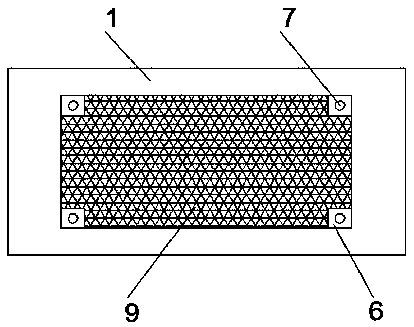

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

Carriage trucks water under high pressure jet stream rust cleaning production line and technique

InactiveCN101249639AImprove rust removal qualityHigh speedBlast gunsAbrasive machine appurtenancesWater filterHigh pressure water

The invention discloses a freight car high pressure water jet derusting production line and a process thereof, comprising high-pressure pump units, the power and control system, a water container and a prepositive centrifugal pump as well as a precise filter positioned in front of the high-pressure pump inlet; the high-pressure pump is connected with high pressure water jet cleaning devices through a high-pressure hose and a control valve. The high pressure water jet cleaning devices refers to the high pressure water rotating nozzle or spray gun. The high pressure water rotating nozzle is provided with a cover or without a cover outside. The cover is communicated with a vacuum recovery system. The sewage in the vacuum tin and the sewage collected are all sent to the water filter recovery system. The production line has the advantages of high derusting efficiency, good effect and dryness on derusting.

Owner:HEFEI GENERAL MACHINERY RES INST

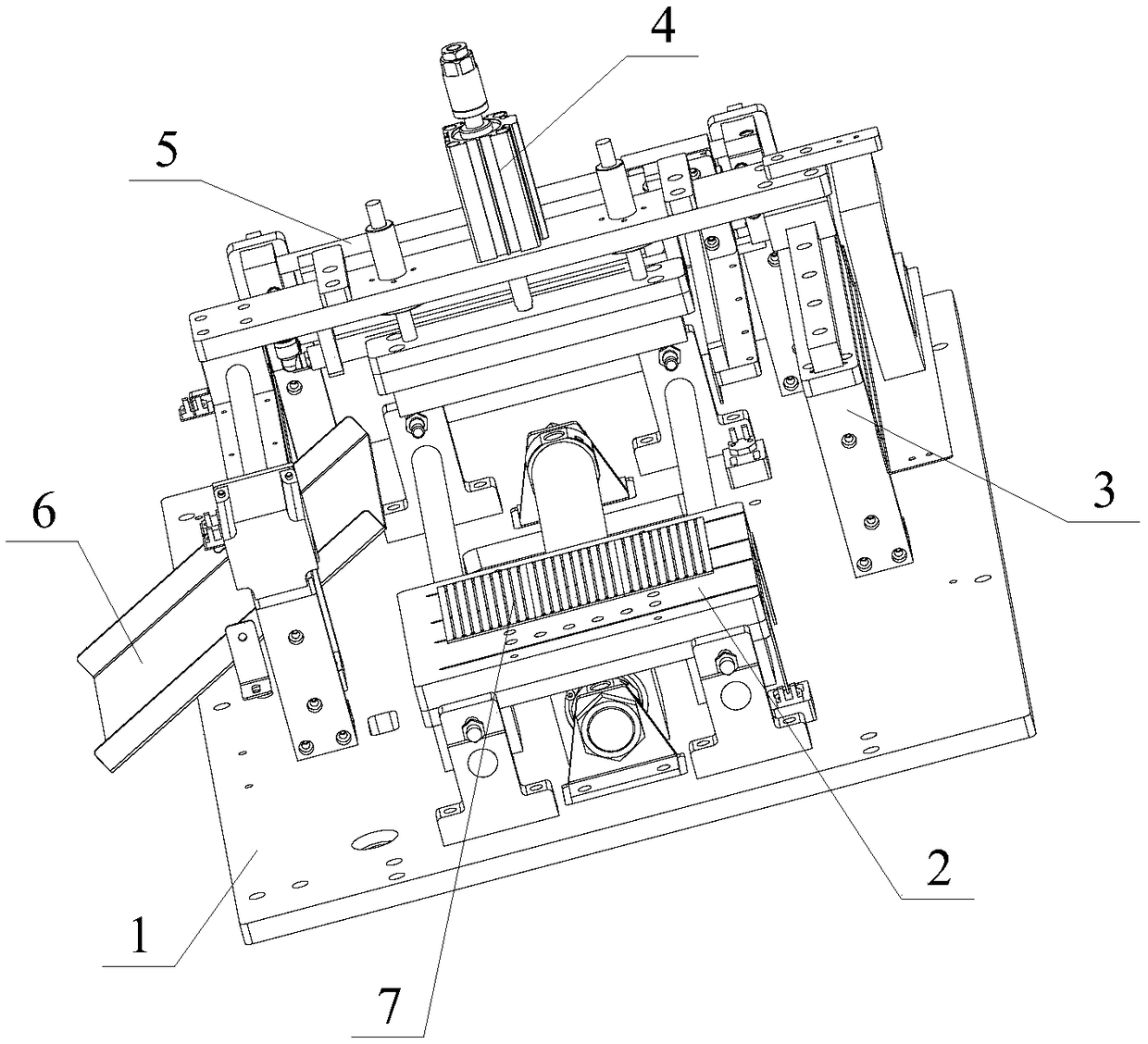

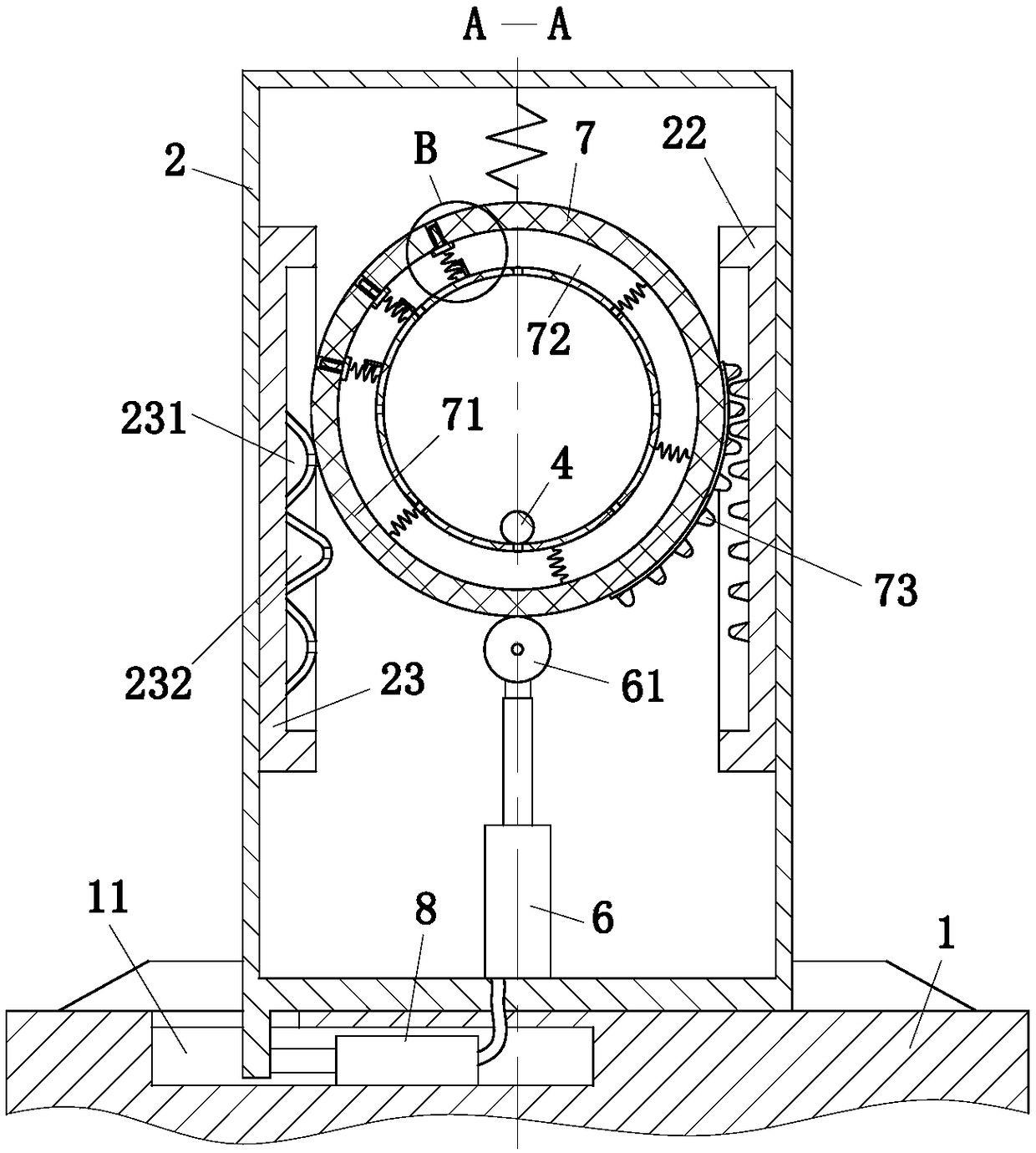

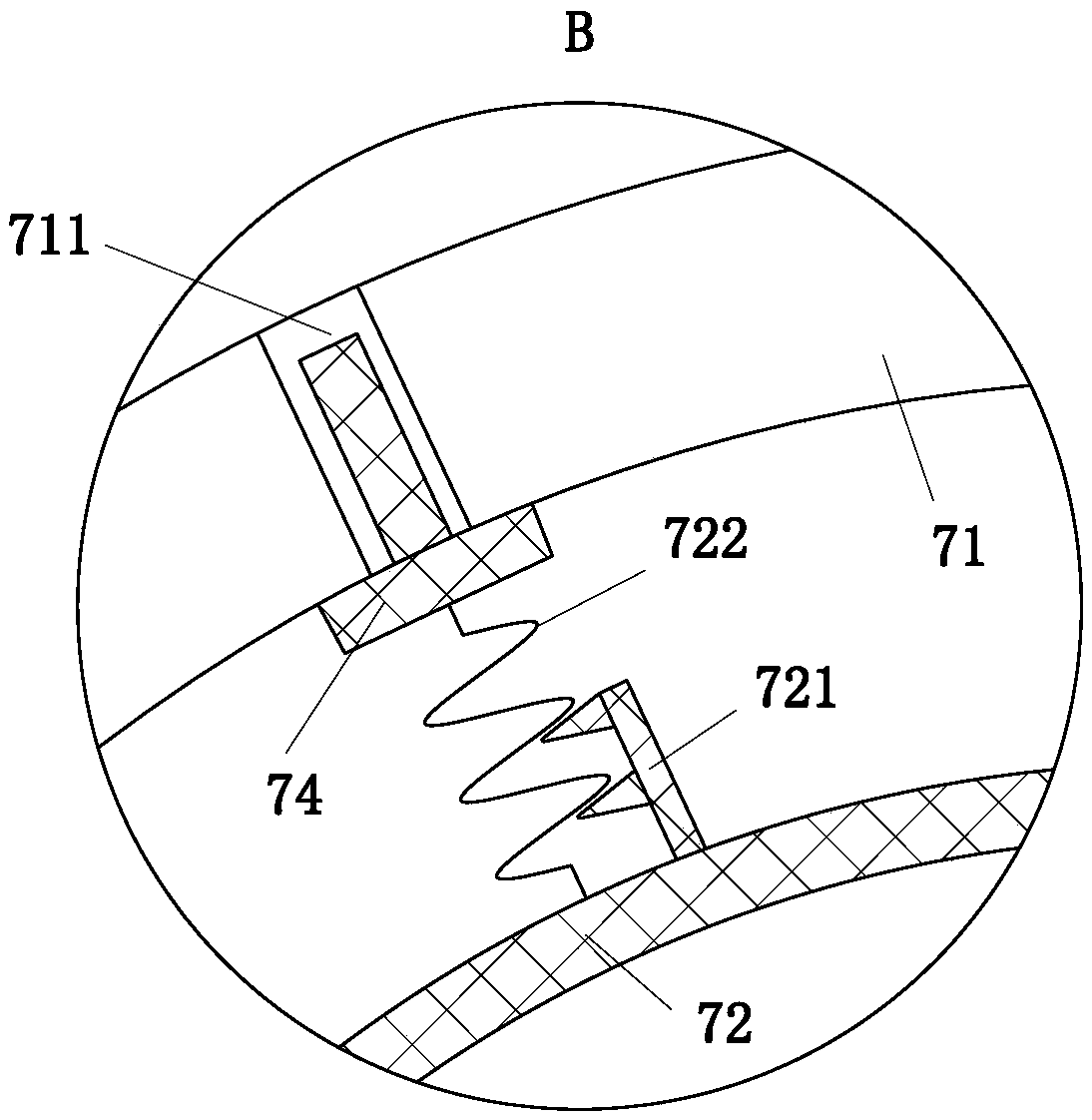

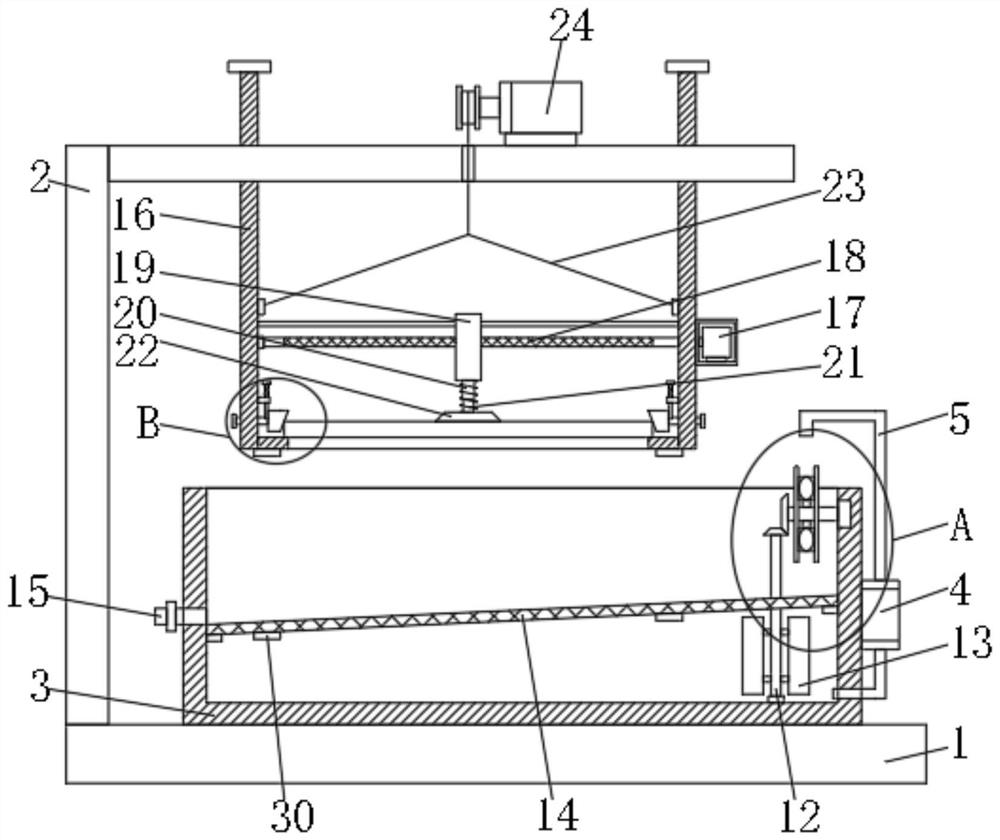

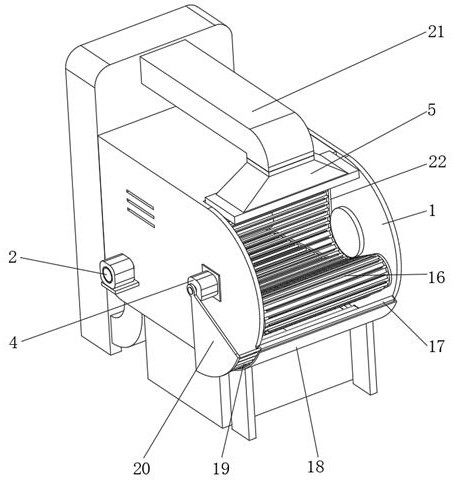

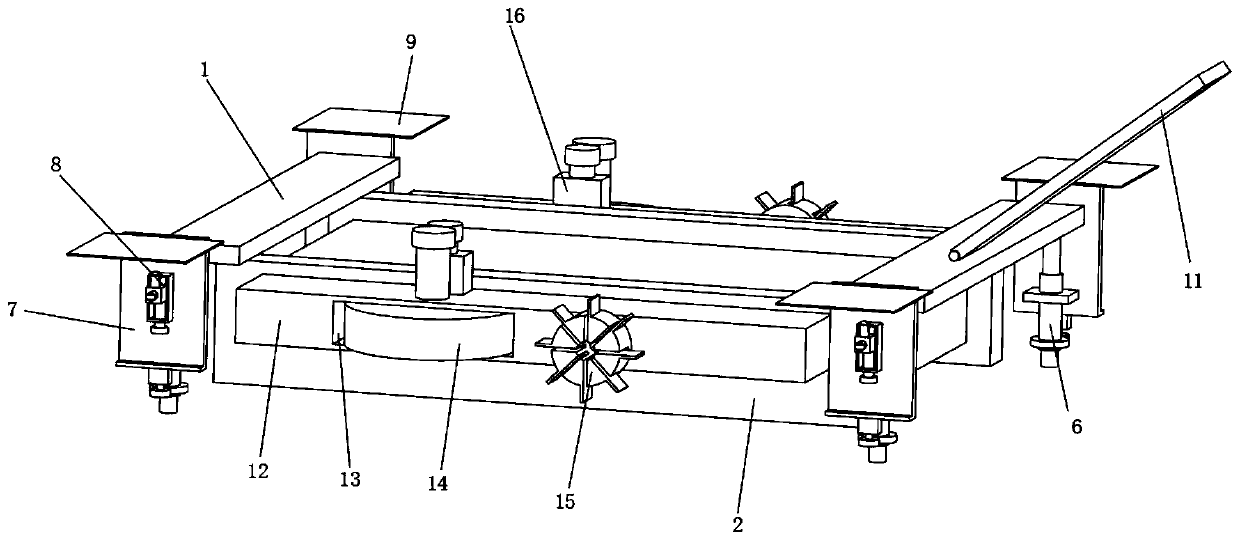

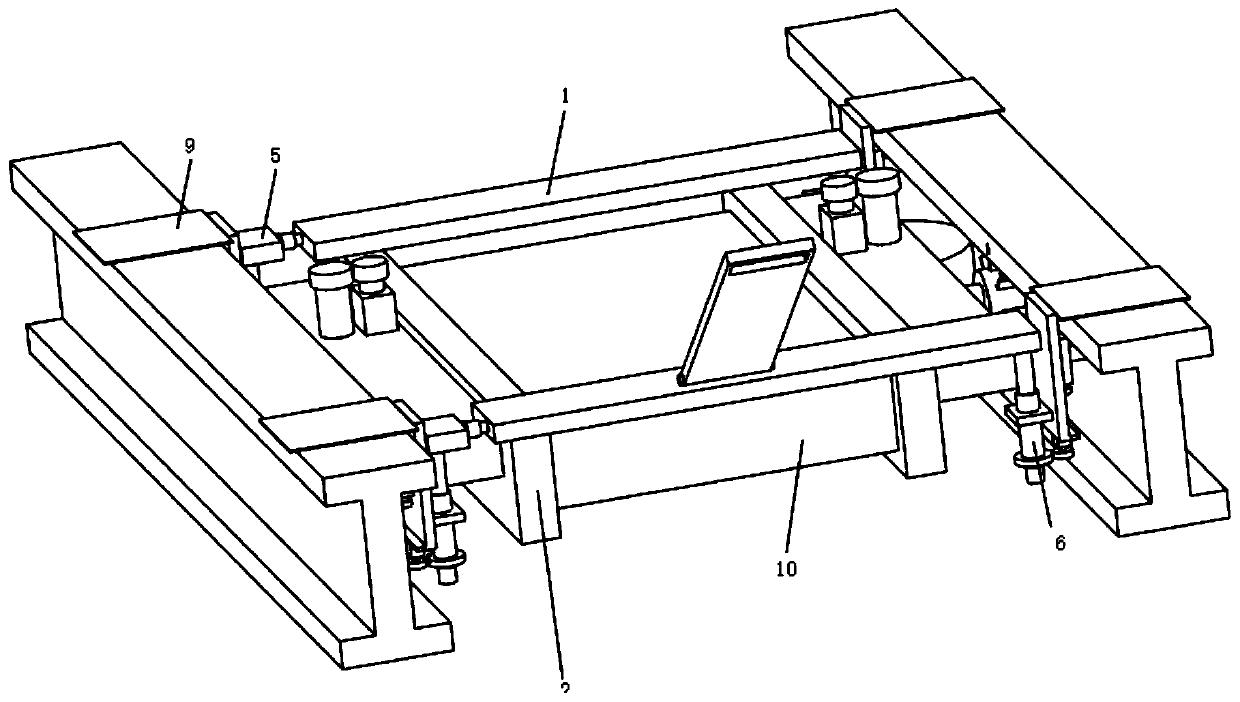

Steel bar grinding and descaling equipment for building construction

InactiveCN110216569AImprove rust resistanceAvoid secondary rustRevolution surface grinding machinesLiquid spraying apparatusArchitectural engineeringEngineering

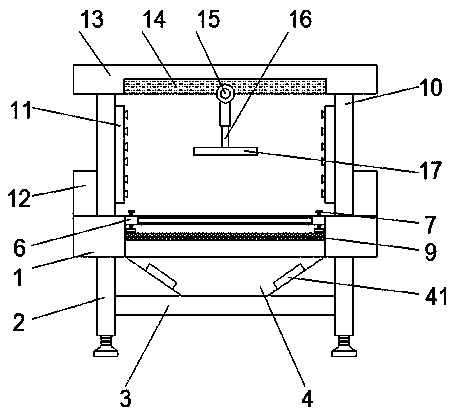

The invention discloses steel bar grinding and descaling equipment for building construction. The equipment comprises a descaling box; the descaling box is internally provided with a descaling cavitywhich is through left and right; the descaling cavity is internally provided with a descaling device for conveying steel bars and preliminarily descaling the steel bars; the descaling cavity is internally provided with a grinding device located on the right side of the descaling device; the descaling cavity is internally provided with a spraying device located on the right side of the grinding device; and the end surface of the upper side of the descaling cavity is provided with a mixing device located on the upper side of the spraying device. The conveying device and the descaling device canautomatically adapt to the steel bars of different diameters through a telescopic mechanism, steel wire brushes are adopted by the descaling device for rapidly and preliminarily descaling the steel bars, the steel bars are further ground and descaled through a grinding wheel mechanism, thus, the descaling uniformity and descaling quality can be improved, and descaling liquid is sprayed to the descaled steel bars through the spraying device, so that the equipment has good descaling quality and can descale the steel bars.

Owner:LISHUI ZHONGYING MACHINERY TECH CO LTD

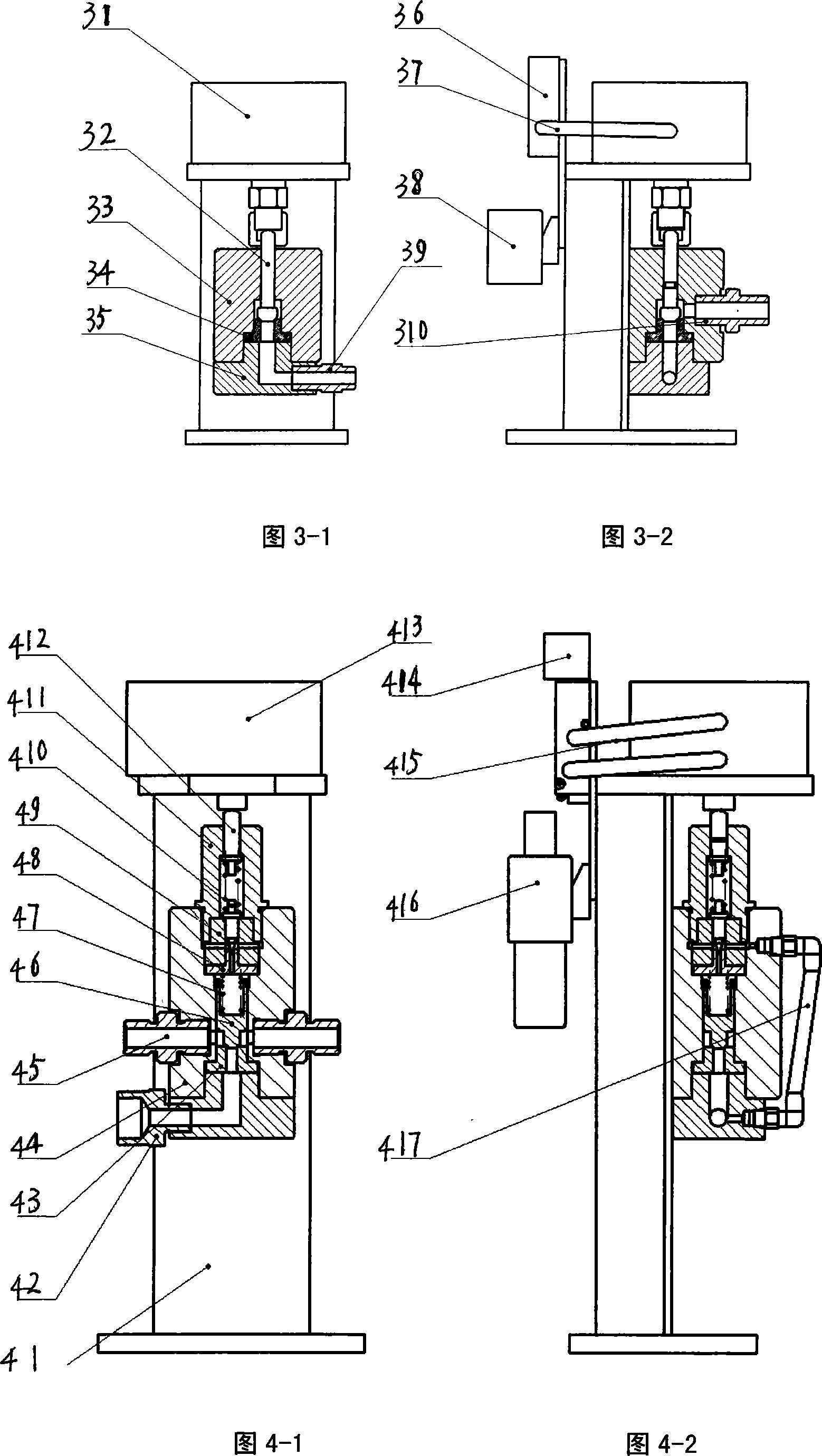

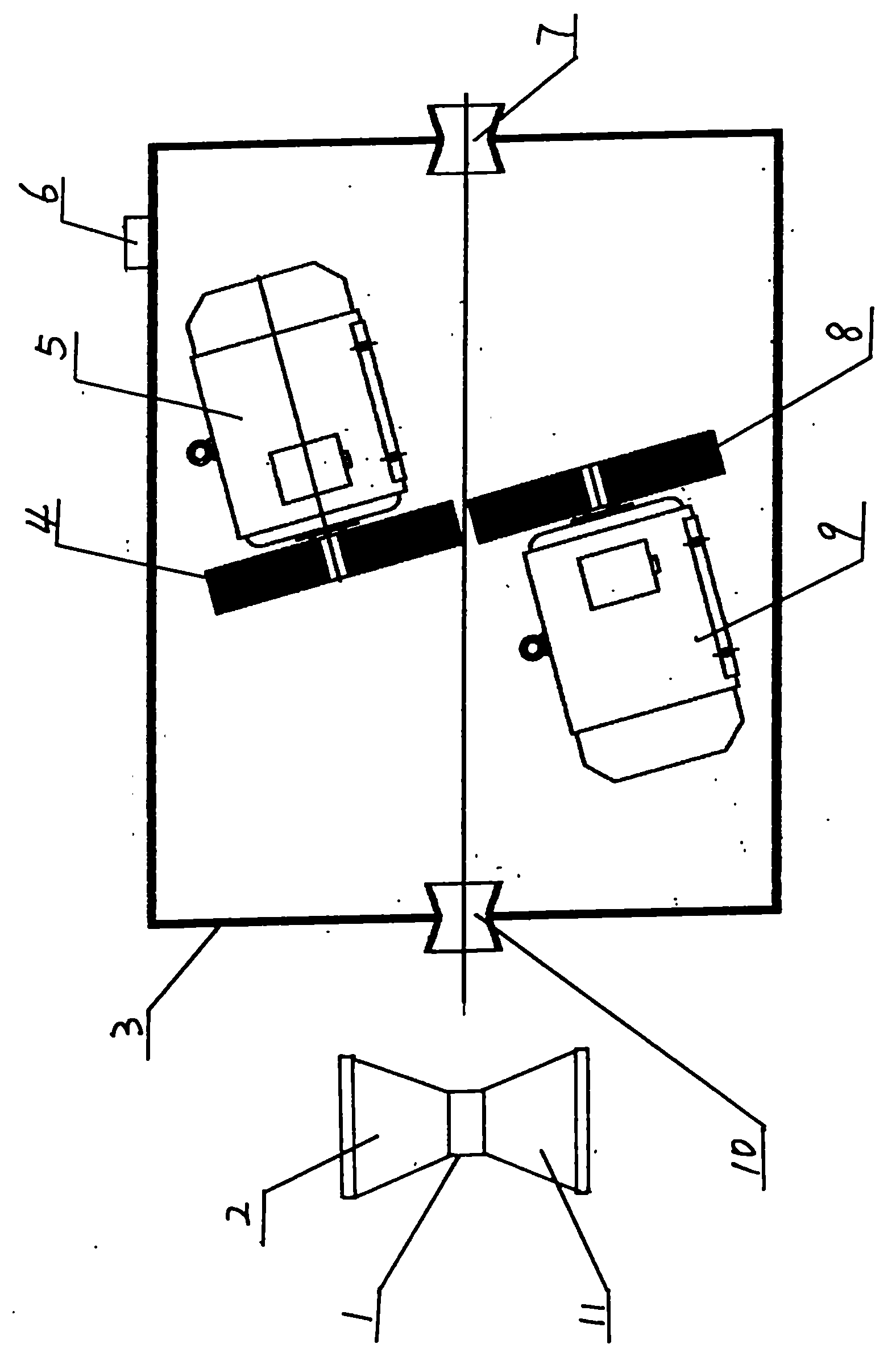

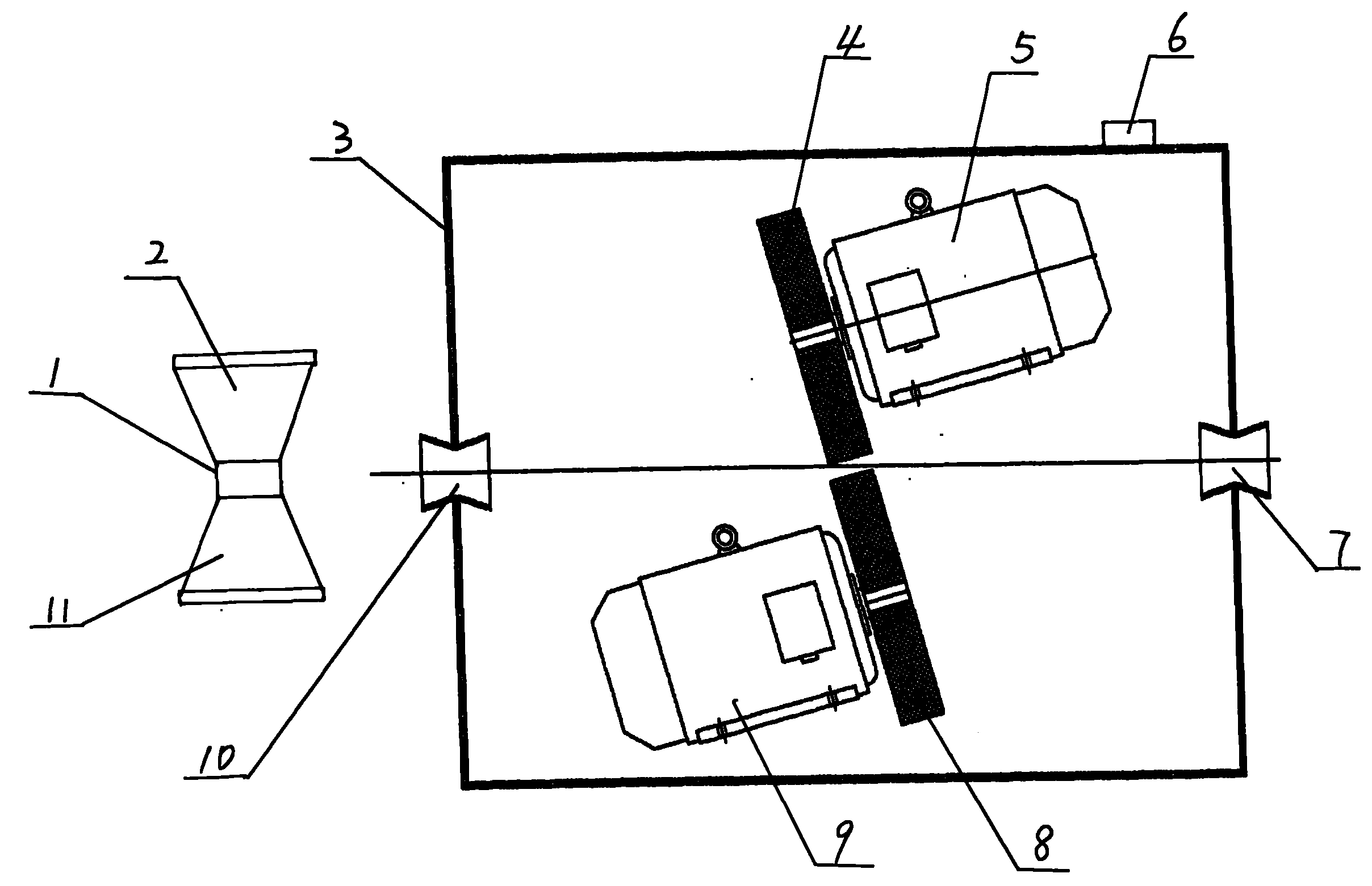

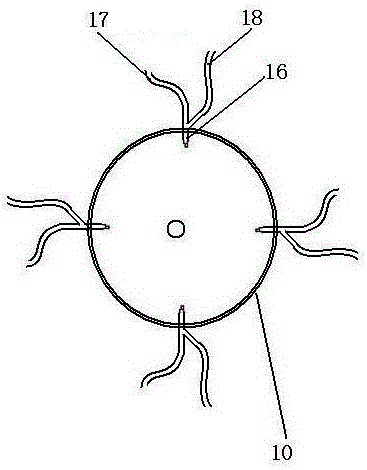

Rust removing device for circular tube

The invention discloses a rust removing device for a circular tube, and aims to provide a rust removing device which can ensure that the circular tube can rotate during polishing to remove rust in all directions and improves rust removing quality. The device comprises a circular tube conveying roller and a box; the transmission shaft of the circular tube conveying roller is connected with a motor through a transmission mechanism; the two ends of the box are provided with a circular tube inlet and a circular tube outlet respectively; the centers of the circular tube inlet and the circular tube outlet are positioned on the same centre line; the two ends of the box are provided with a circular tube inlet and a circular tube outlet respectively; a first motor and a second motor are arranged in the box; the first motor is connected with a first rust removing brush through the transmission mechanism; the second motor is connected with a second dust removing brush through the transmission mechanism; the middle part of the circular tube conveying roller is provided with a circular tube groove; and the roll surfaces of the two sides of the circular tube groove are spiral inclined surfaces. The dust removing device can ensures that the circular tube rotates, polishes the tube wall in all directions, avoids dead corners and rust residual, improves rust removing quality and facilitates the use of the next procedure.

Owner:TIANJIN LIQIANG STEEL PIPE

Automatic steel rail duplex rust removing machine

ActiveCN104631234AHard and wear-resistant working surfaceEasy to attachTrack superstructureRailway track constructionCouplingEngineering

The invention discloses an automatic steel rail duplex rust removing machine. The automatic steel rail duplex rust removing machine comprises a rack, engines and wheels connected to the lower portion of the rack, and is characterized in that the two engines are adopted and distributed on steel rails on the two sides respectively, the automatic steel rail duplex rust removing machine further comprises two soft shafts and two steering gears, one ends of the soft shafts are connected with rotating shafts of the engines through couplers, the other ends of the soft shafts are connected with input shafts of the steering gears, output shafts of the steering gears are connected with blade grinding wheels, the rack is fixedly connected with two connecting pieces, vertical adjusting pieces are arranged above the steering gears and elastically connected with the steering gears, connecting rods of the connecting pieces are connected with the vertical adjusting pieces, a transverse spring pull rod is connected between the vertical adjusting pieces of the steel rails on the two sides, and the rack is connected with a drive component. The kinetic energy of the engines is directly transmitted to the blade grinding wheels through the soft shafts, a duplex structure is adopted, synchronous automatic constant-speed rust removing can be carried out on pedal faces of the two steel rails at the same time, and the rust removing quality and efficiency are greatly improved.

Owner:德阳路安恒轨道技术开发有限公司

Centring and self-generating fixing device for environment-friendly steel pipe rust removal

ActiveCN110883668AEven contactTo achieve a calming effectGrinding drivesGrinding machinesEngineeringMechanical engineering

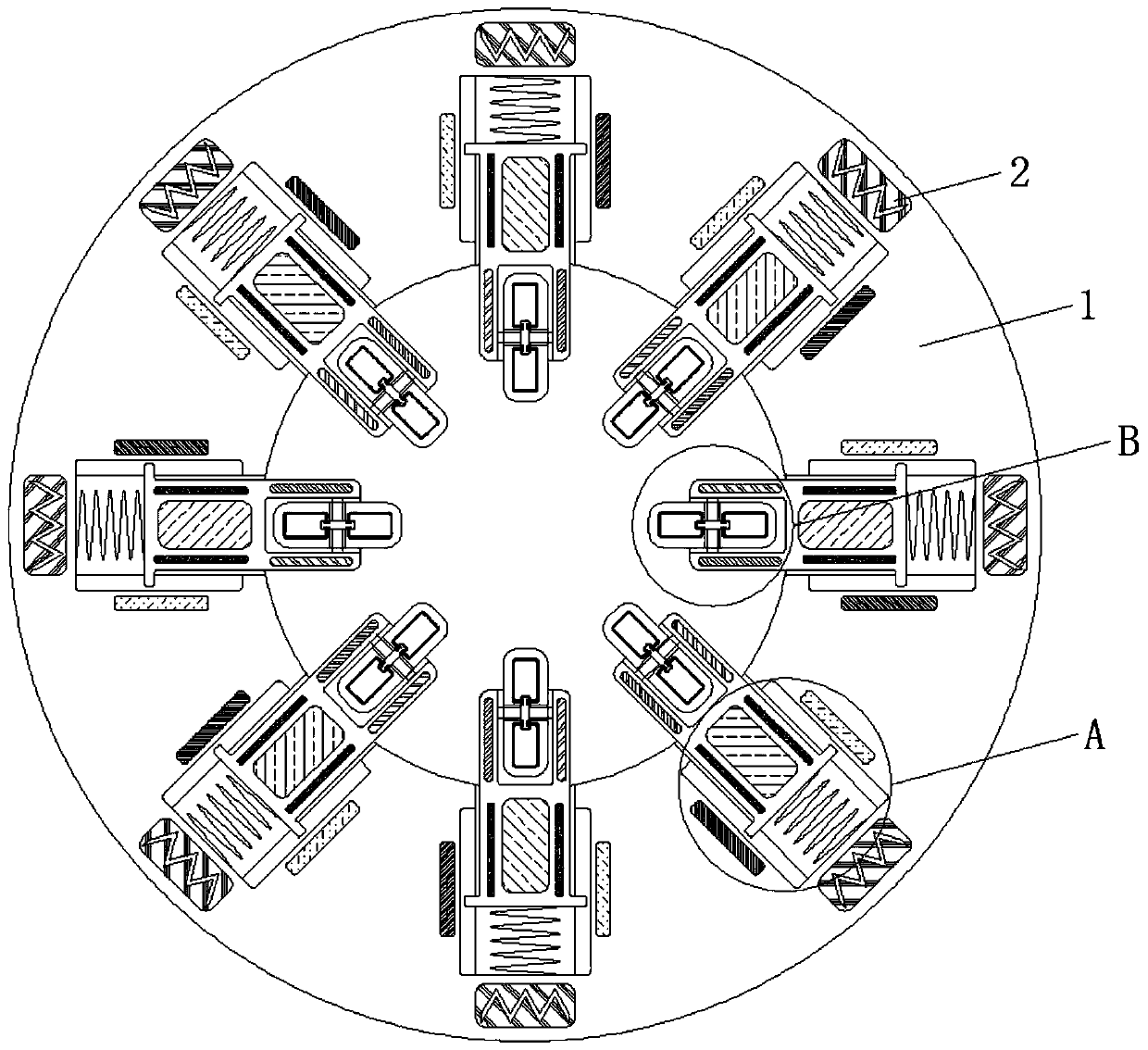

The invention provides a centring and self-generating fixing device for environment-friendly steel pipe rust removal relates to the technical field of environmental protection. The device comprises afixing pipe, an inner wall of the fixing pipe is fixedly connected with uniformly distributed electromagnetic devices 1, and the inner wall of the fixing pipe is provided with uniformly distributed movable grooves. According to the fixing device, the electromagnetic devices 2 and electromagnetic devices 2 are matched for use, since all the electromagnetic devices 1 have the same magnetism, the electromagnetic devices 2 have the same magnetism and the magnetism of inner sides of the electromagnetic devices 1 is the same as that of the outer sides of the electromagnetic devices 2, the electromagnetic devices 1 and the electromagnetic devices 2 repel each other, meanwhile, movable blocks can move towards the inner sides by the same length under the repulsive action of the electromagnetic devices 1 and the electromagnetic devices 2 such that rolling wheels are clamped and located in the center of the fixing pipe, the centering effect is achieved, the rust removal work is effectively guaranteed, an outer side of a steel pipe makes uniform contact with the rust removal device, and the rust removal quality is improved.

Owner:山东东正钢构有限公司

Rust removal device of environment-friendly steel pipe end surface

ActiveCN109159006AReduce pollutionProtect your bodyRevolution surface grinding machinesPlane surface grinding machinesEngineeringWaste treatment

The invention discloses a rust removal device of an environment-friendly steel pipe end surface, and belongs to the field of environmental protection engineering equipment. An exhaust device is fixedbehind a third support, a motor is fixed at the top of a motor base, a grinding device is fixed on a main shaft of the motor, a magnet is fixed at the top of a second support, is positioned right below the grinding device, and a limiting support is fixed at the top of a first support. According to the device, a steel pipe is clamped by a first pressing block and a second pressing block, the grinding device is driven by the motor to rotate at a high speed, an end eliminating device and a surface eliminating device are used for grinding an end head and an outer surface of the steel pipe, and thecompletion of steel pipe derusting operation is replaced with manual operation, iron scraps generated by the magnet attraction and grinding are prevented from splashing to hurt people, poisonous smoke dust generated in a grinding process is adsorbed by the exhaust device, and the poisonous smoke dust is discharged into a waste treatment device, the environment pollution is reduced, the damage tothe body of workers is reduced, and the safety of the workers is guaranteed.

Owner:佛山市南海岐丰钢管有限公司

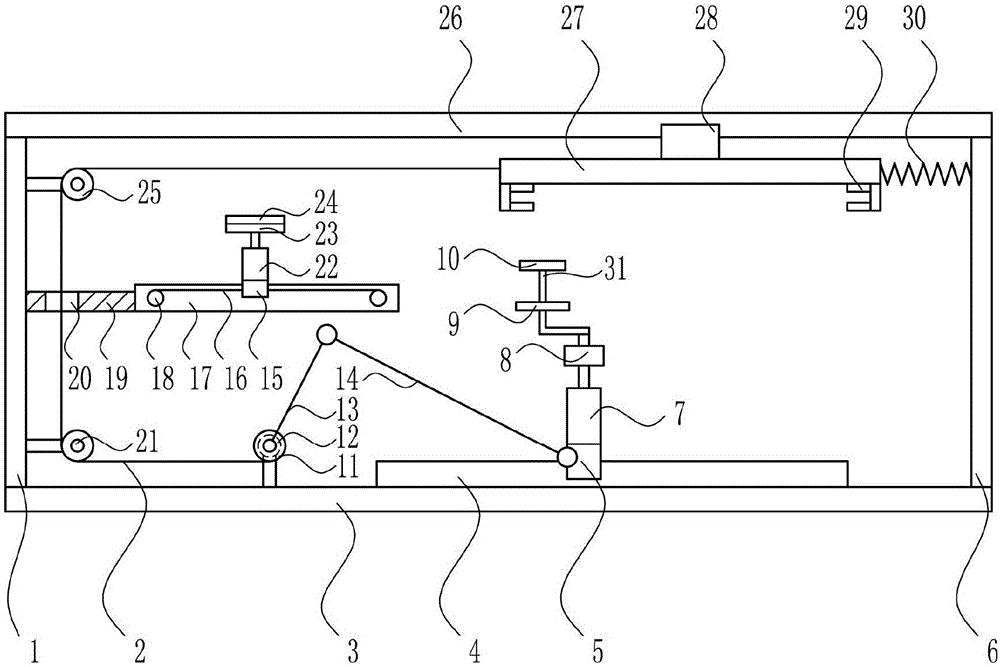

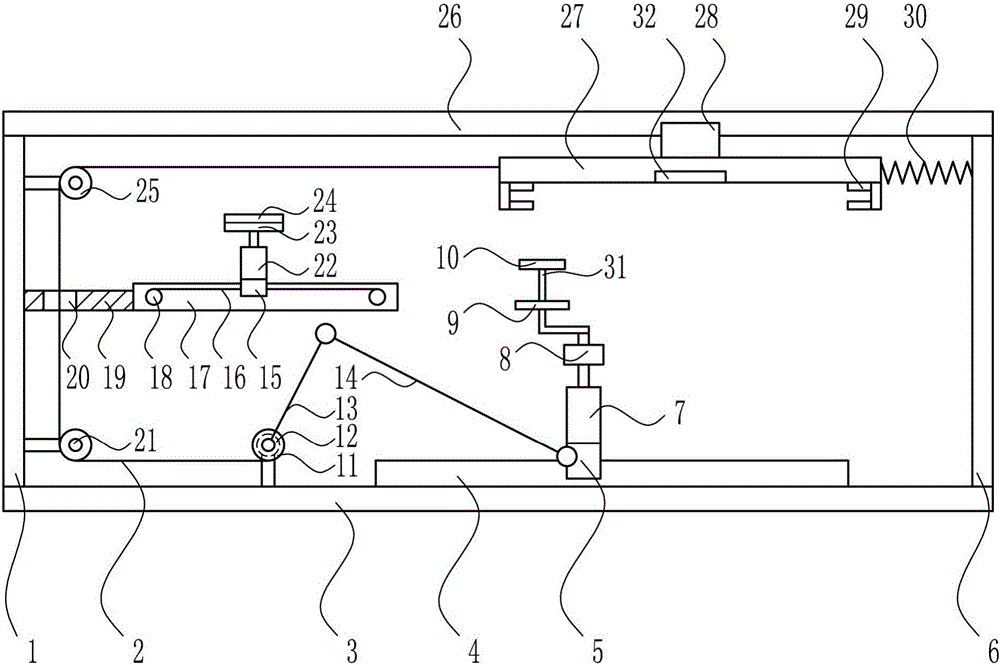

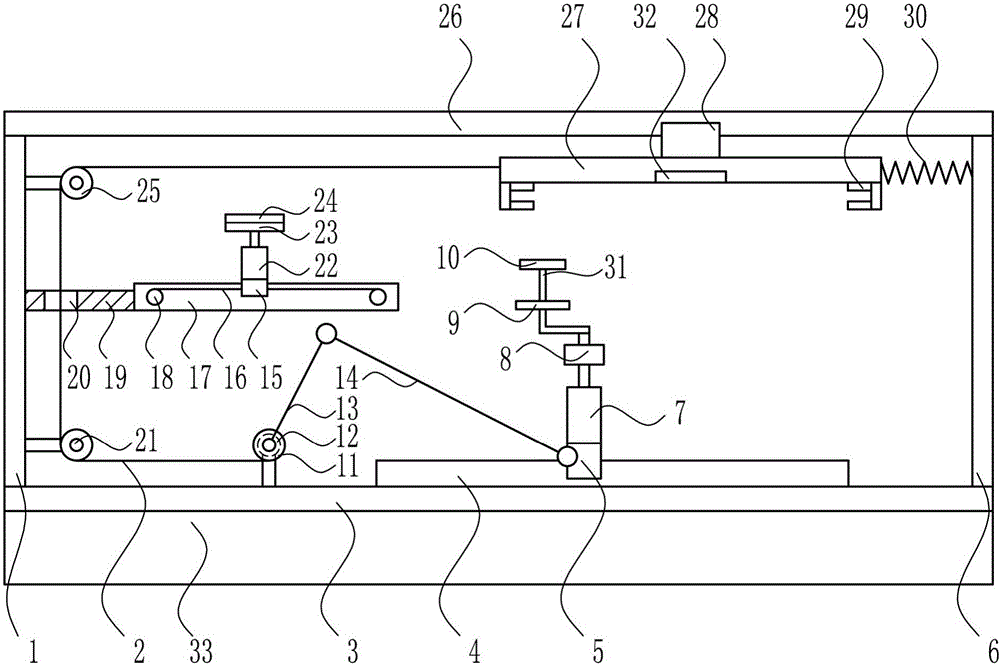

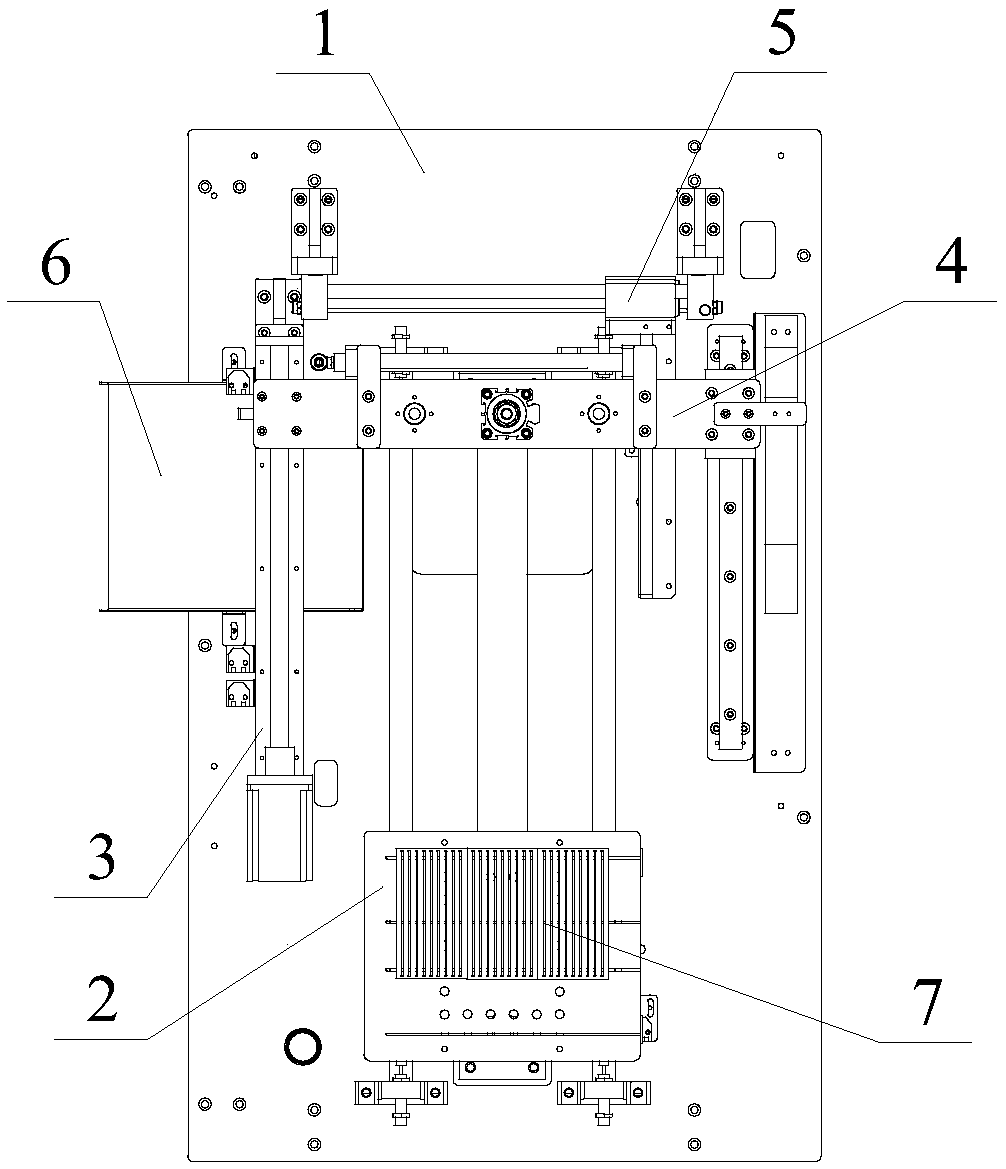

Hardware strip derusting device

ActiveCN106112767AReduce laborComplete rust removalGrinding carriagesGrinding machinesMechanical engineeringEngineering

The invention relates to a derusting device, and particularly relates to a hardware strip derusting device. The invention aims to solve the technical problem of providing the hardware strip derusting device, which has the advantages of less labor, completeness in derusting and simplicity in operation. In order to solve the technical problem, the invention provides the hardware strip derusting device. The hardware strip derusting device comprises a left bracket, a pull rope, a base, a first sliding rail, a first sliding block, a right bracket, a first electric push rod, a first motor, a rotary table, a steel brush, a winding wheel, a second motor, a second connecting rod, a first connecting rod, a second sliding block, a pull wire, a second sliding rail, an electric wheel, a guide plate, a first guide wheel, a second electric push rod, a first moving plate, a piece of abrasive paper, a second guide wheel, a third sliding rail and the like, wherein the left bracket and the like are arranged on the top of the base in sequence from left to right. According to the hardware strip derusting device, the effects of less labor, completeness in derusting and simplicity in operation are achieved, and additionally, secondary derusting can be performed by the device, so that the derusting quality and effect can be increased, and benefits can be increased.

Owner:平湖永鑫五金制品股份有限公司

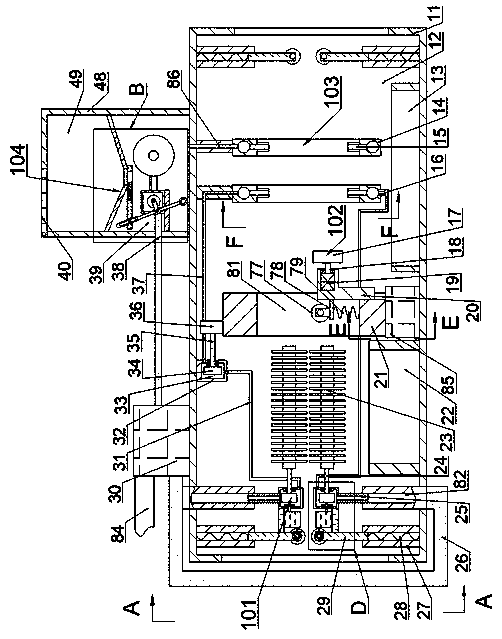

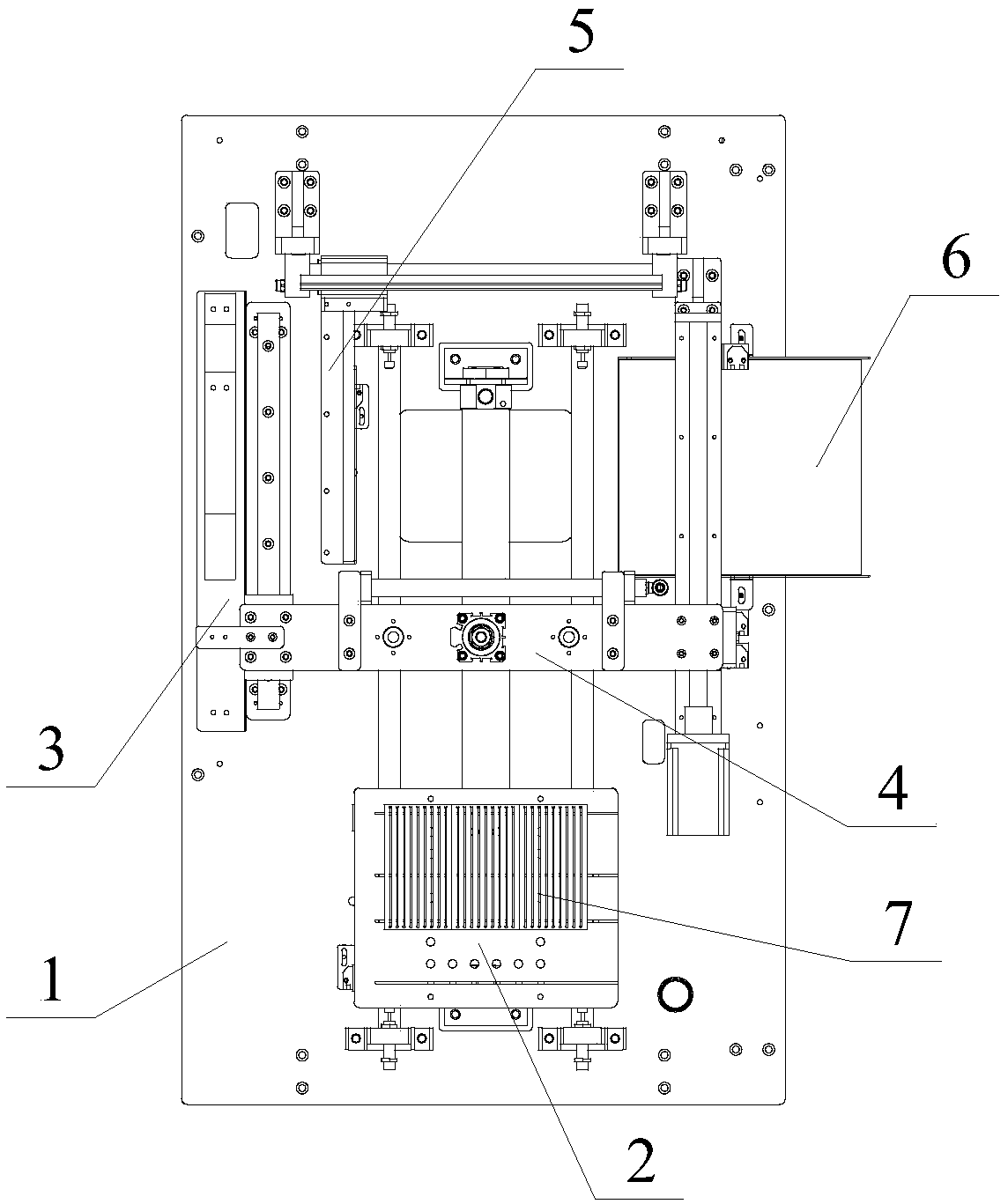

A PCB automatic derusting machine

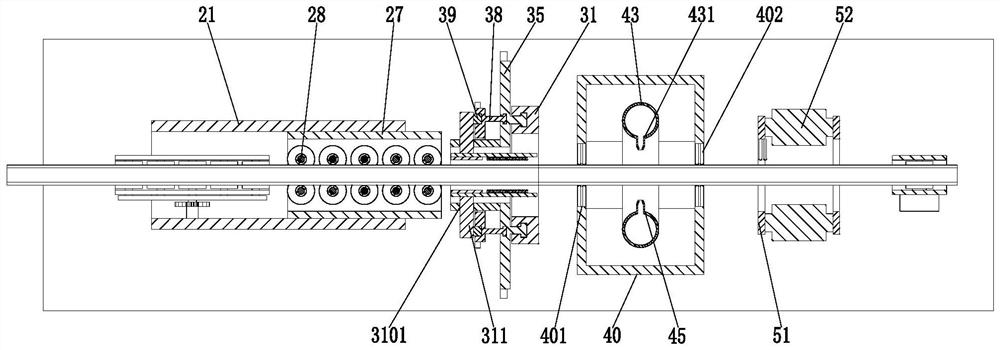

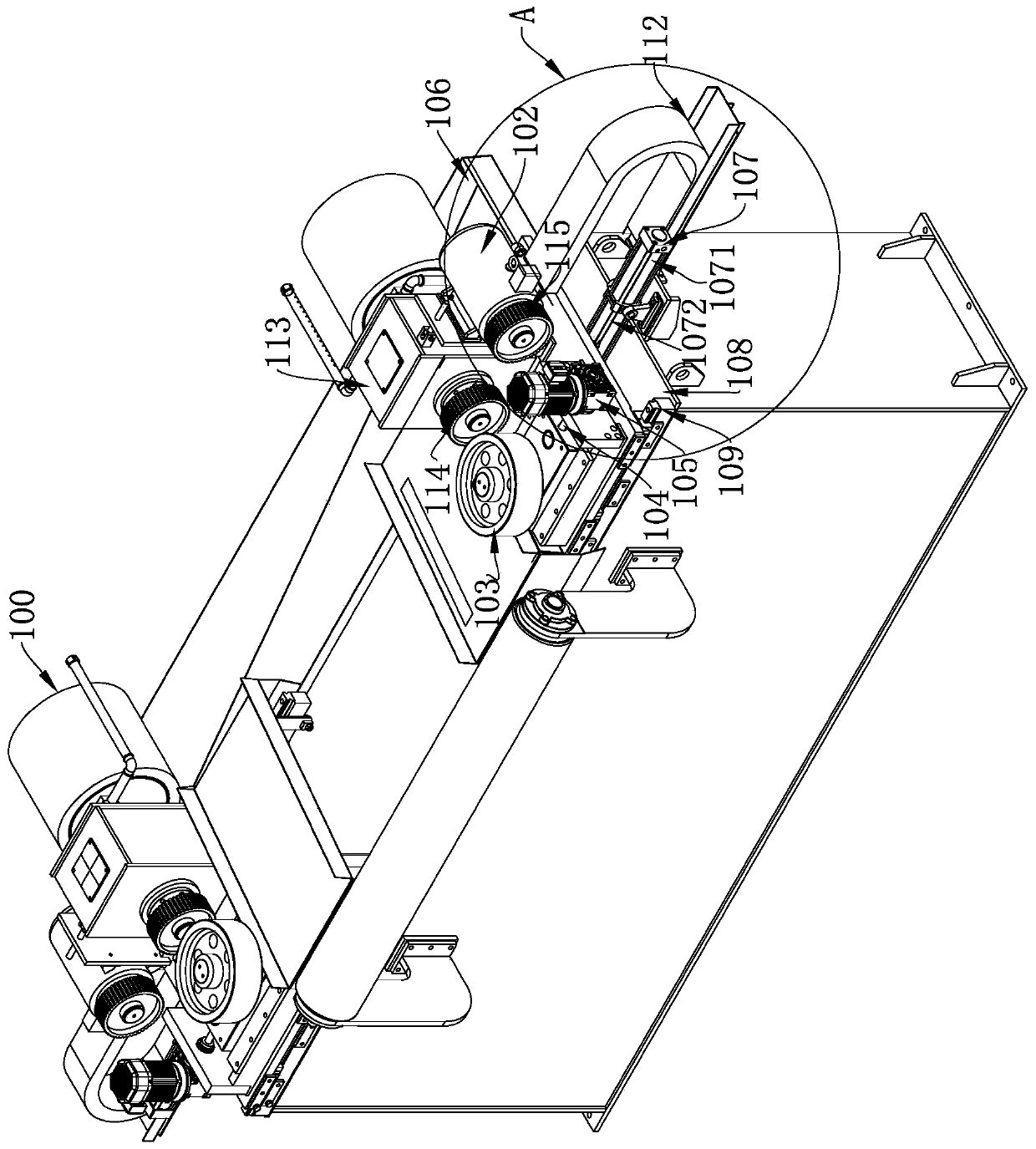

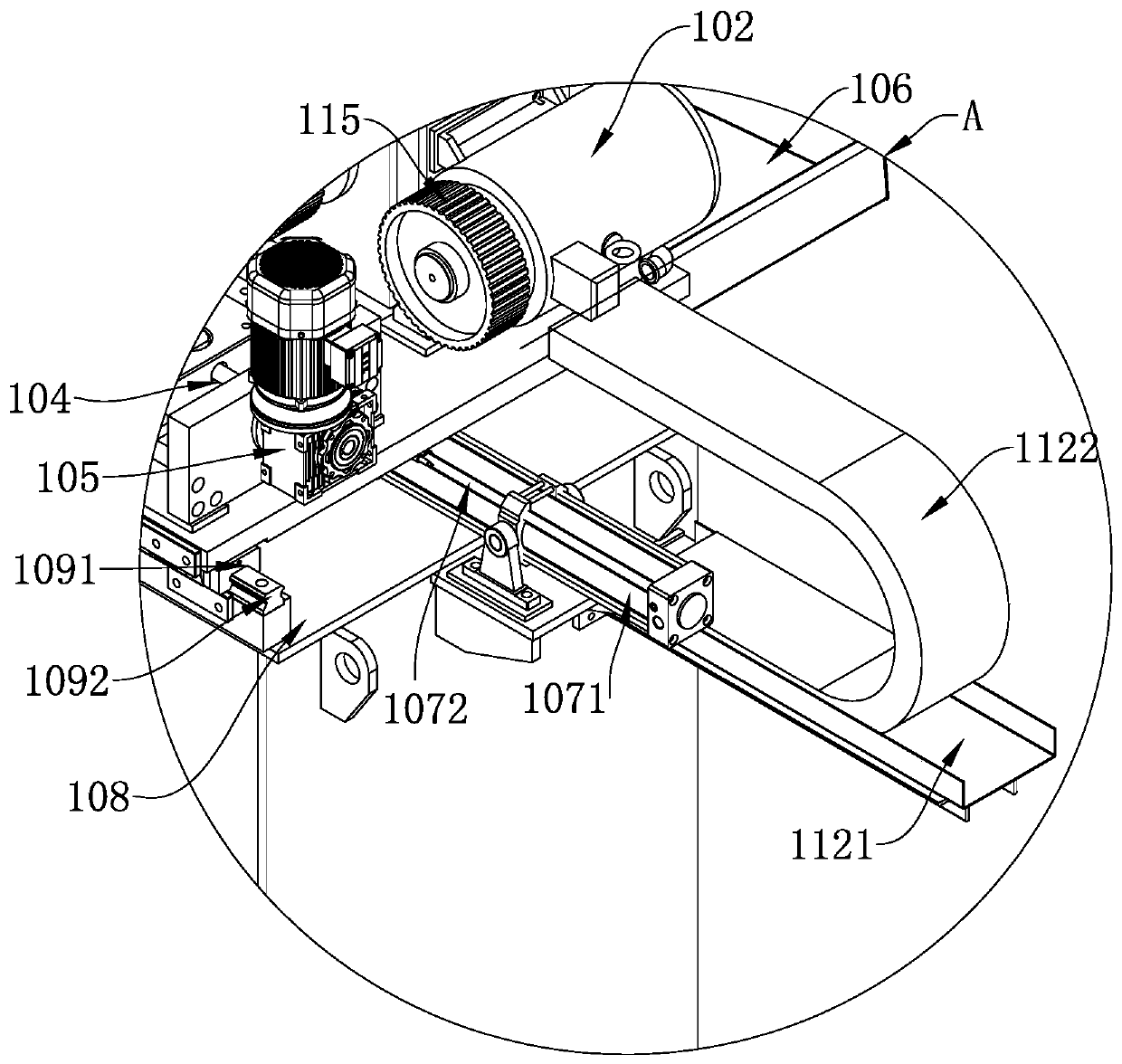

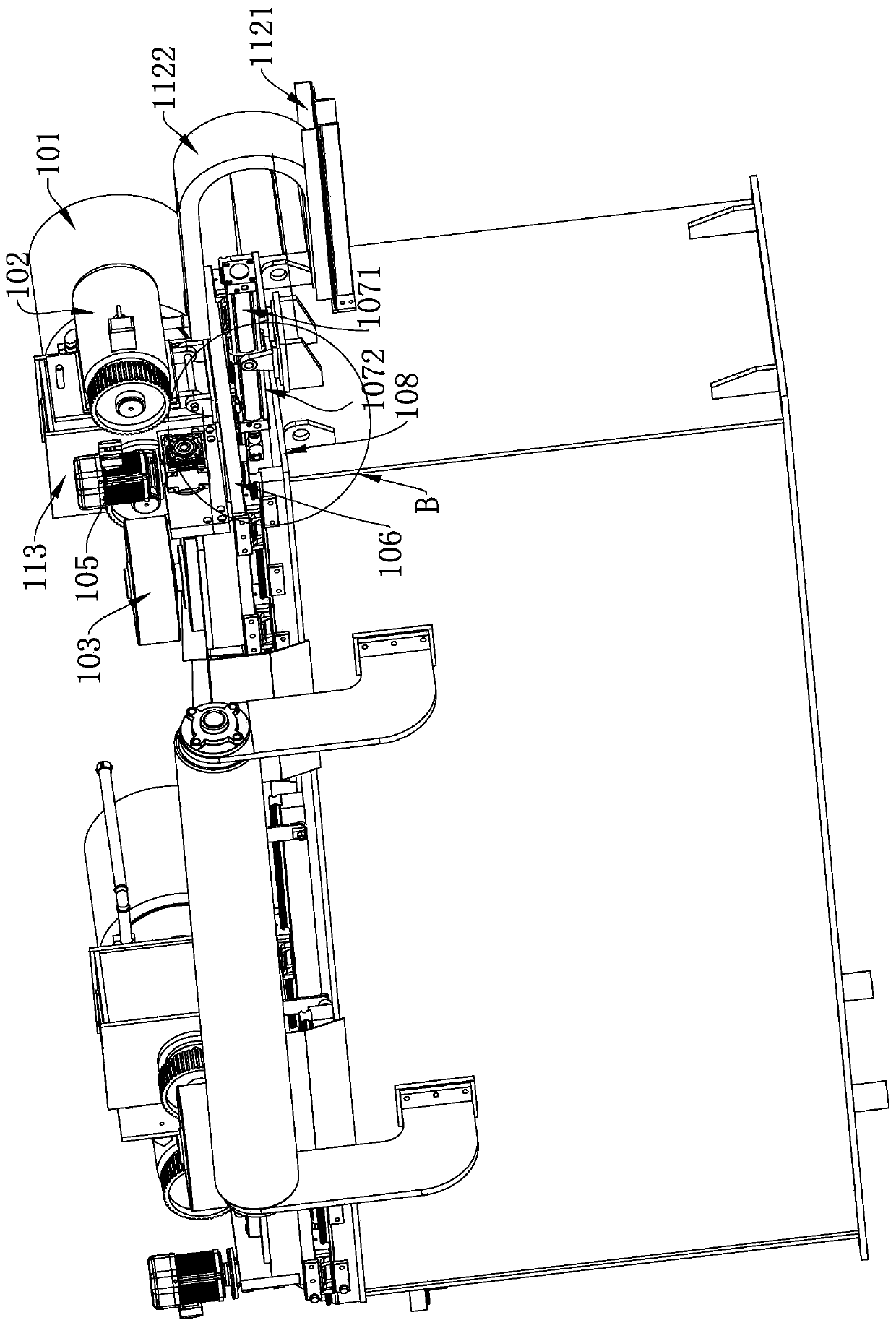

InactiveCN108890497AEfficient rust removalImprove rust removal efficiencyGrinding machinesGrinding feedersMaterial resourcesEngineering

The invention discloses a PCB automatic derusting machine, which comprises a frame, wherein a feeding unit, a support moving unit, a derusting unit, a pushing unit and a discharging bin are arranged on the frame; The rust removing unit is arranged on the support moving unit, the rust removing unit is arranged above the feed unit to remove rust from the PCB board on the feed unit, The pushing unitis arranged behind the rust removing unit to push out the PCB board on the feeding unit from the feeding unit, the discharge bin is arranged on one side of the supporting mobile unit, and the PCB board enters the discharge bin after being pushed out from the feeding unit. The automatic rust remover of the PCB board of the invention has the advantages of reasonable functional division, simple structure and convenient operation, is not limited by the site, improves the rust removing and cleaning efficiency, strengthens the surface of the board, is favorable for maintenance, loading and unloading, saves manpower and material resources, and improves the working efficiency.

Owner:俞斌

Adjustable rust removal paint spraying device for building steel tubes

InactiveCN107344154AReasonable structureInnovative designPretreated surfacesCoatingsDrive shaftArchitectural engineering

The invention discloses an adjustable rust-removing and painting device for building steel pipes, which comprises a bottom plate, a support frame is connected to the upper left side of the bottom plate, a feeding box is connected to the left end of the support frame, and a fixing frame is connected to the upper and lower ends of the inside of the feeding box to fix There is a feed roller in the middle of the frame, a fixed cylinder is connected to the right end of the support frame, a rotating screw is installed inside the fixed cylinder, a rotating gear is connected to the outer middle of the rotating screw, a driving gear is meshed at the lower end of the rotating gear, and a driving shaft is connected to the middle of the left end of the driving gear , the left end of the drive shaft is connected to the drive motor, the middle part of the rotating screw is connected to the slider, the outer side of the slider is evenly connected to the guide block, the outer side of the guide block is connected to the installation groove, the middle part of the installation groove is connected to the connecting rod, the right end of the connecting rod is connected to the tie rod, and the middle part of the tie rod A grinding wheel frame is connected, a grinding wheel is connected to the middle part of the grinding wheel frame, and a paint spraying box is connected to the upper right side of the bottom plate. The invention satisfies the needs of derusting steel pipes with different diameters, and at the same time realizes automatic painting of the derusted steel pipes.

Owner:阮霞伟

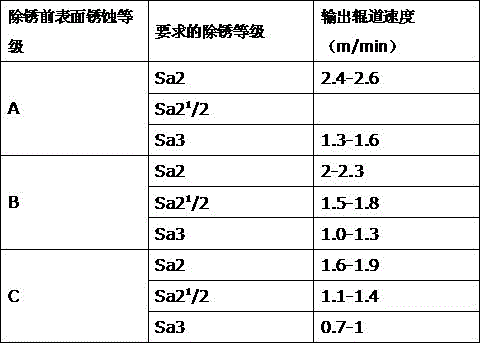

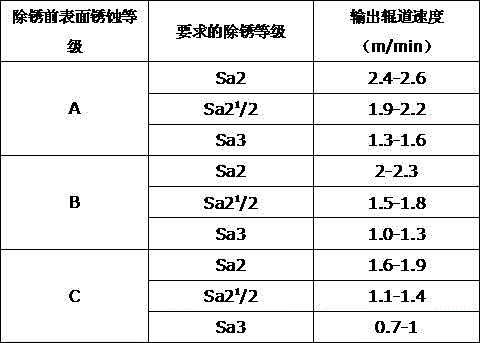

Steel structure shot blasting and rust removing method

InactiveCN106670977AGuaranteed surface roughnessImprove adhesionAbrasion apparatusEnergy consumptionRust

The invention provides and relates to a steel structure shot blasting and rust removing method to improve the rust removing efficiency of steel and reduce energy consumption. According to the method, a method for controlling surface roughness by selecting proper shot kinds and different shot grades, a method for controlling the casting time by adopting different conveying roller way speeds on steel surfaces of different rust grades and a method for controlling energy consumption through adjustment of casting angles and stopping of a casting device are adopted, and therefore the purposes of ensuring the rust removing grade, improving the rust removing quality, improving the production efficiency, reducing energy consumption and reducing the production cost are achieved. The method is suitable for construction for steel material surface cleaning and friction surface treatment of welding H steel, steel materials, sectional materials, steel pipes and steel structure nodes.

Owner:SHANXI WUJIAN GRP CO LTD

Power transmission line inspection device

ActiveCN111769476AAchieve cleanupRealize reciprocating frictionFault location by conductor typesCable installation apparatusDrive wheelStructural engineering

The invention discloses a power transmission line inspection device and a using method thereof, and belongs to the technical field of pipeline inspection equipment. The power transmission line inspection device comprises a controller, a first substrate and a second substrate. The first substrate and the second substrate are both composed of center plates and connecting plates, the connecting plates are distributed on the outer edges of the center plates at equal intervals, and driving lead screws are connected between the center plates. The end of the connecting plate is fixedly connected witha limiting block, and the limiting block is slidably connected with a telescopic adjusting assembly. The adjusting end of the telescopic adjusting assembly is connected with a driving wheel assemblymatched with the inner wall of the pipeline. A reciprocating mechanism is connected to the side, away from the driving lead screw, of the center plate on the first base plate. The device can be suitable for walking of pipe diameters of different sizes and is excellent in stability, the hollowed-out air pipe adsorbs dust in a pipeline and on the surface of a cable and rust chippings falling off from polishing of the cleaning piece, cleaning of impurities in the pipeline is achieved, a basis is provided for accurate collection of a camera shooting mechanism, and the inspection quality is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY

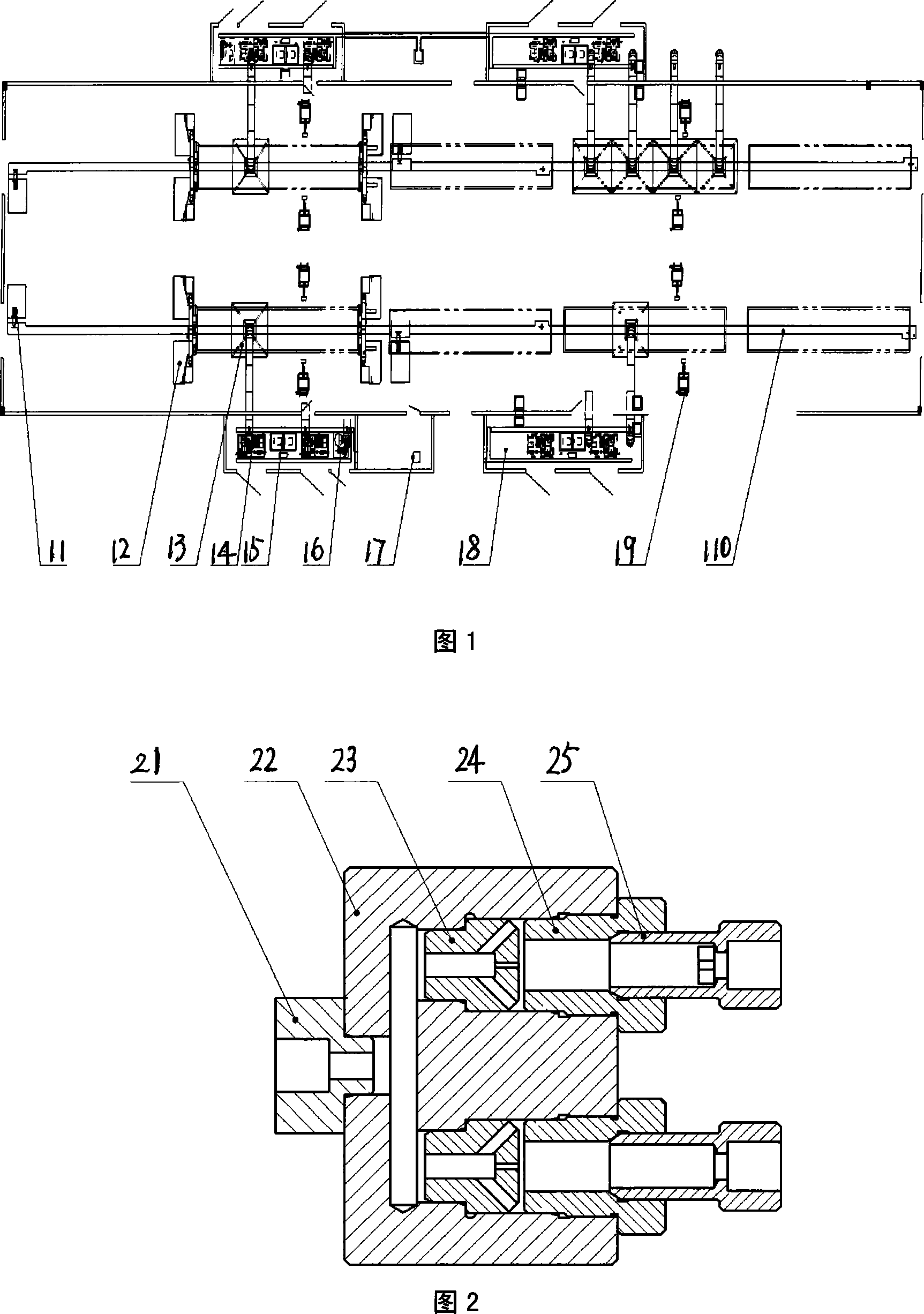

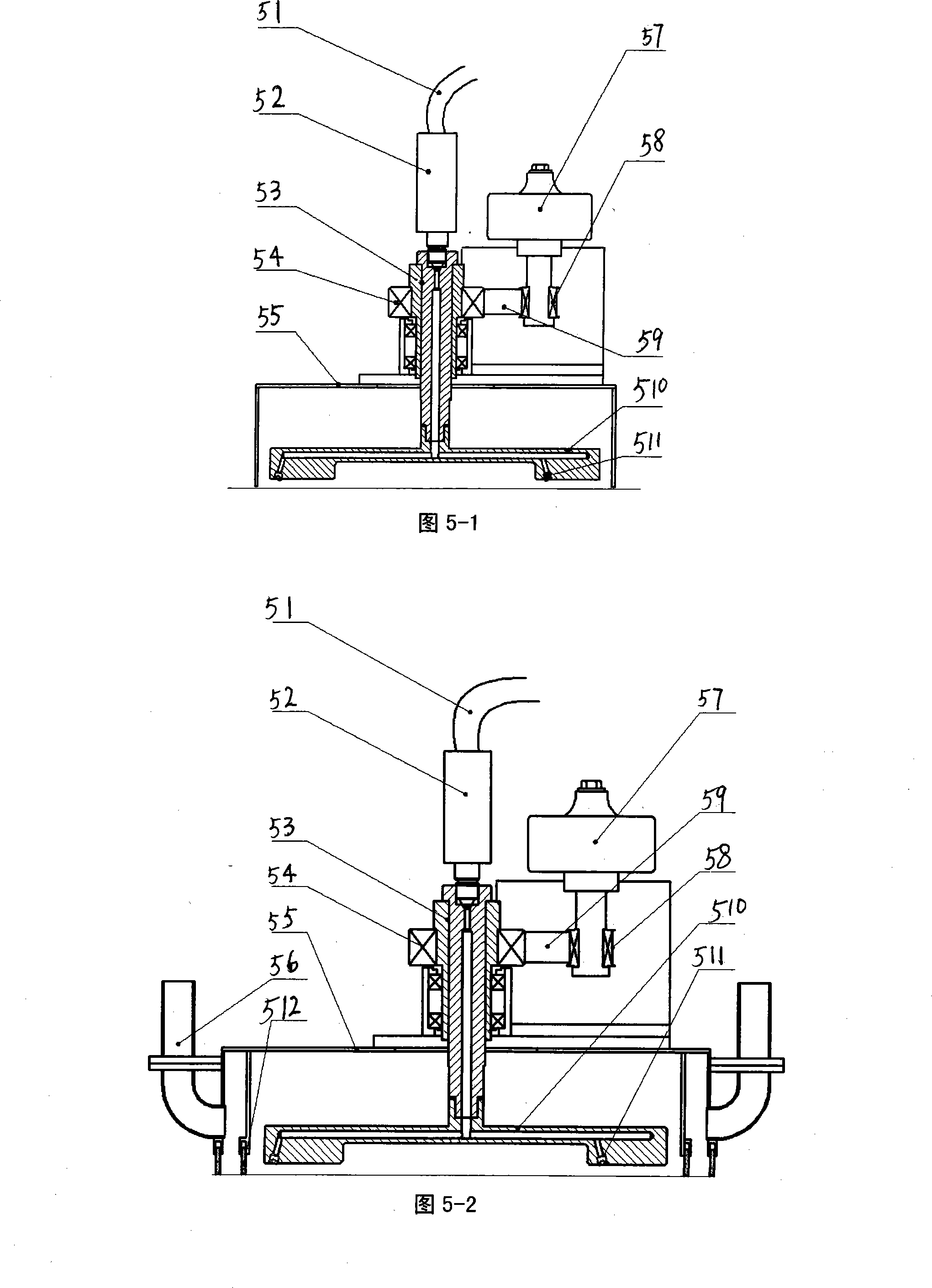

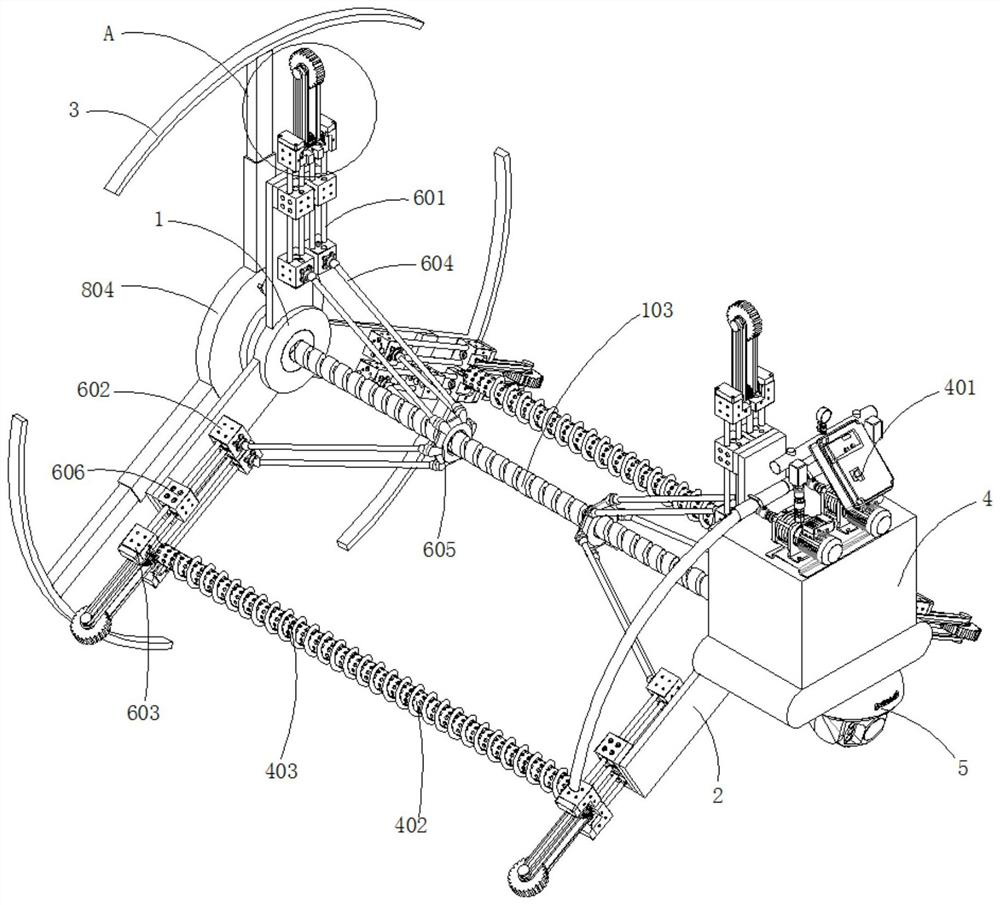

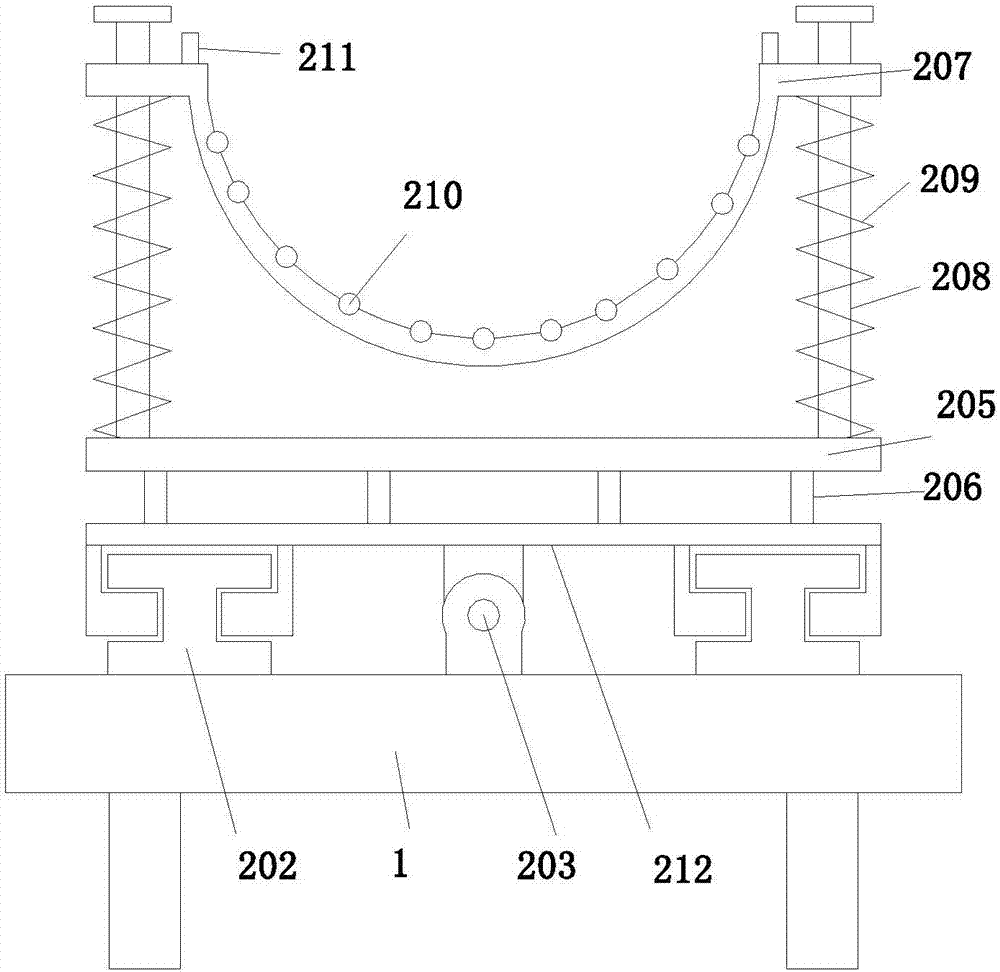

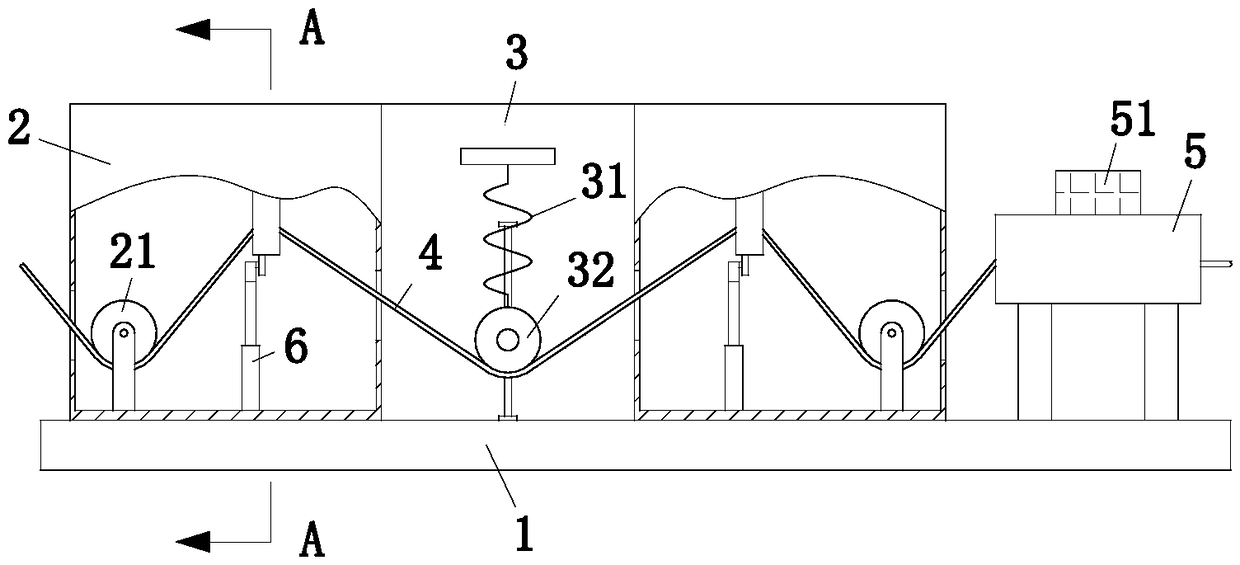

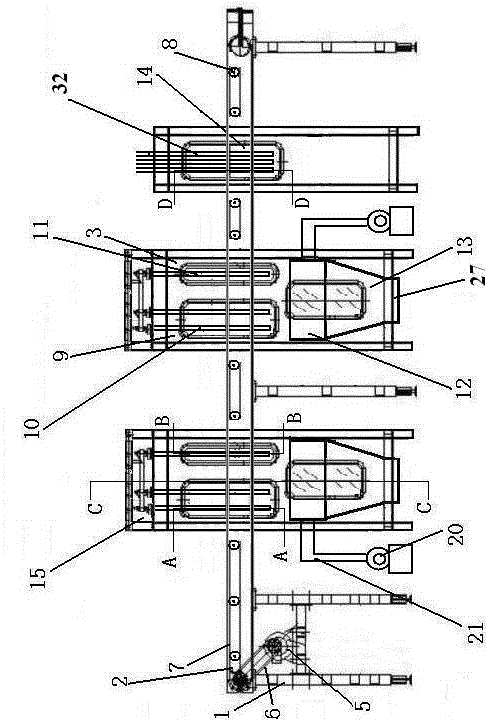

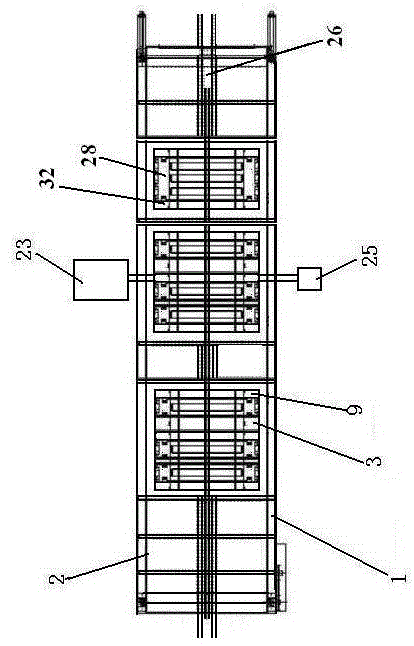

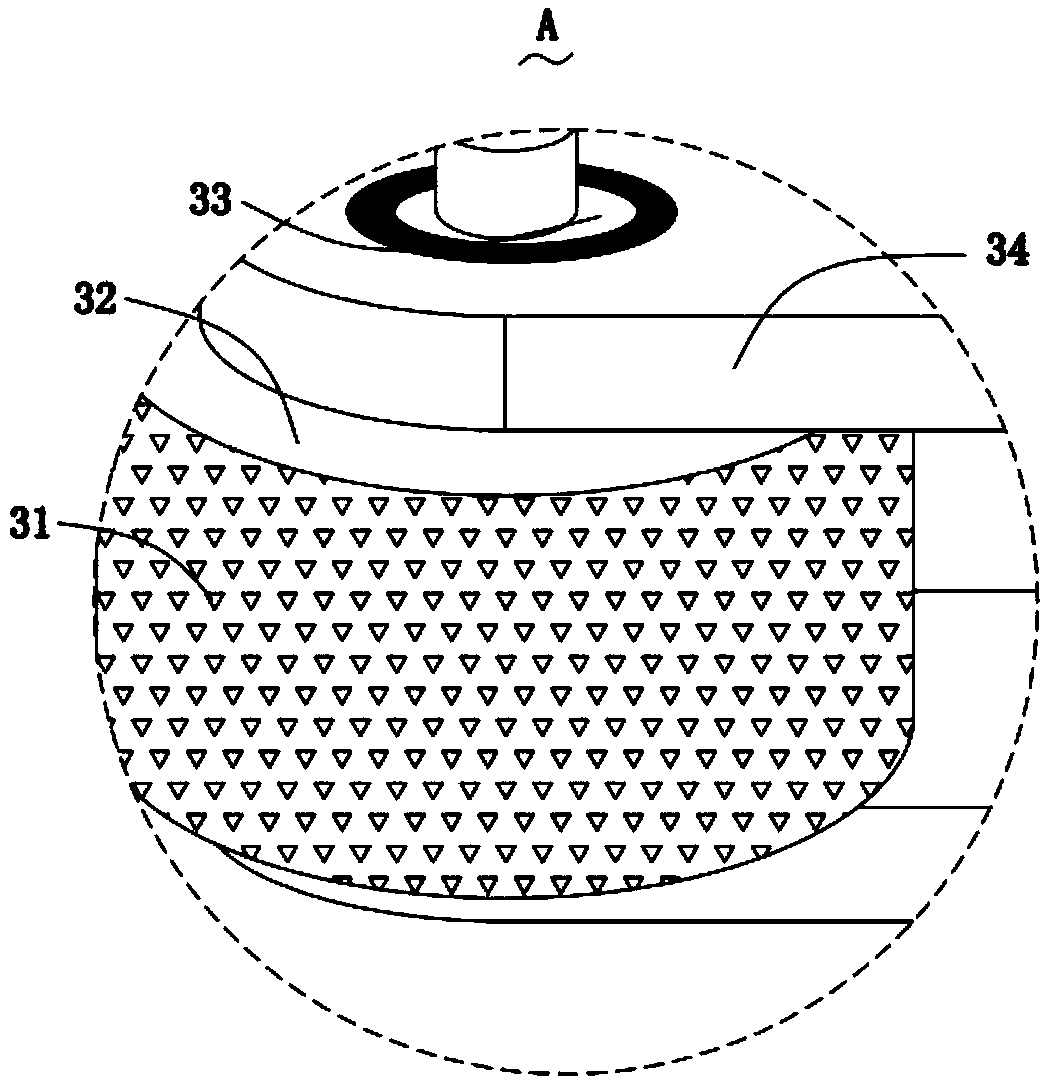

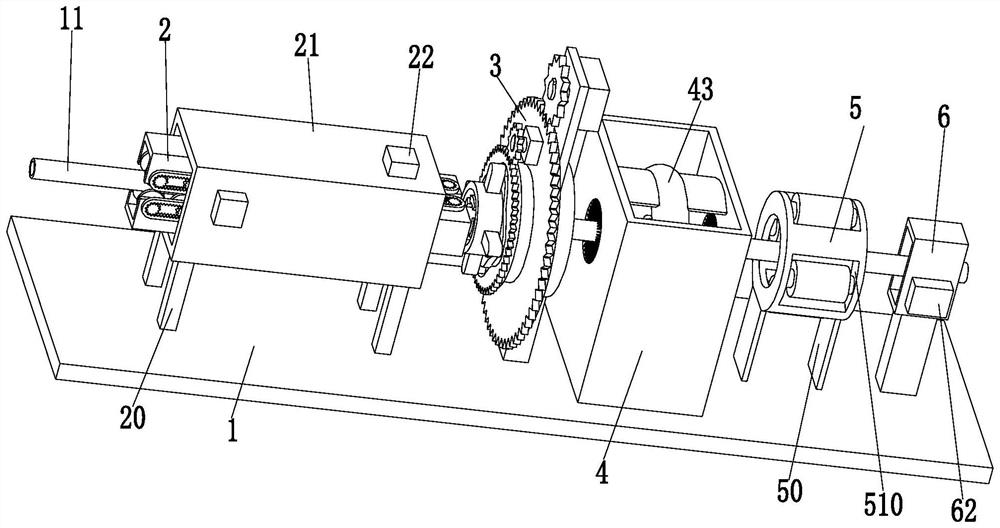

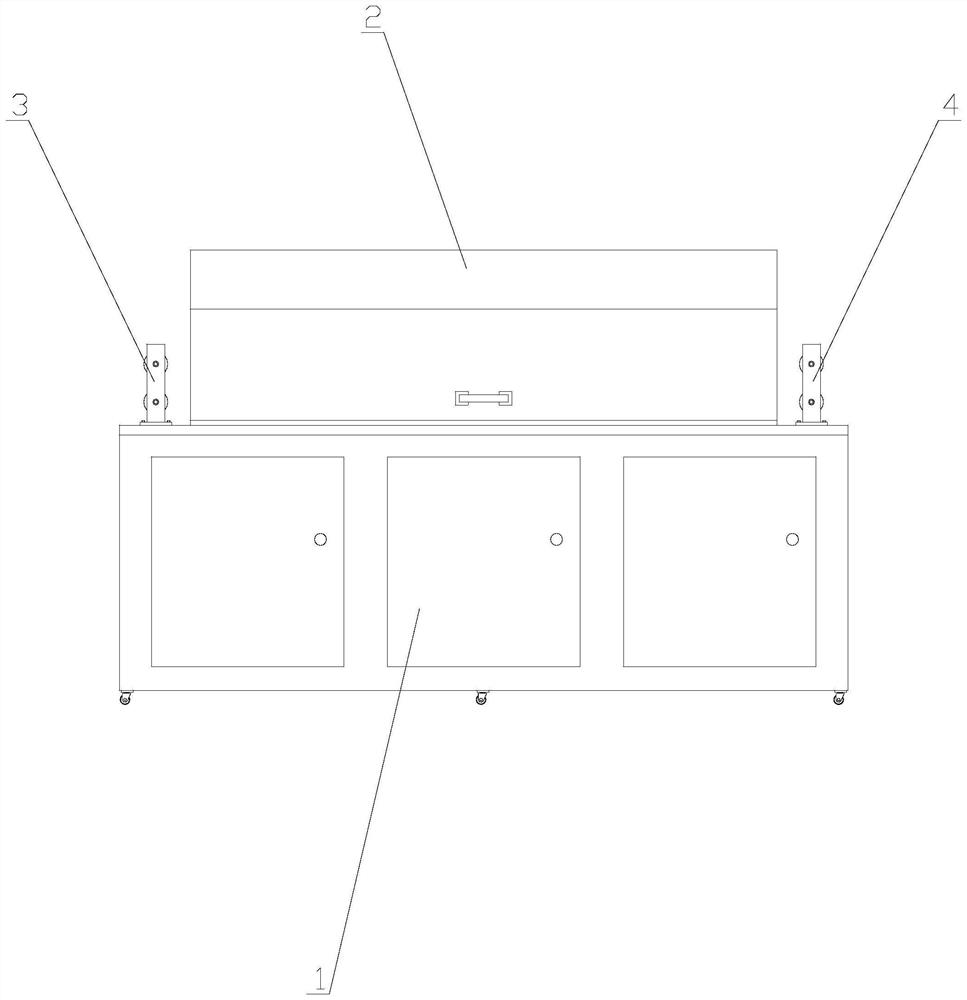

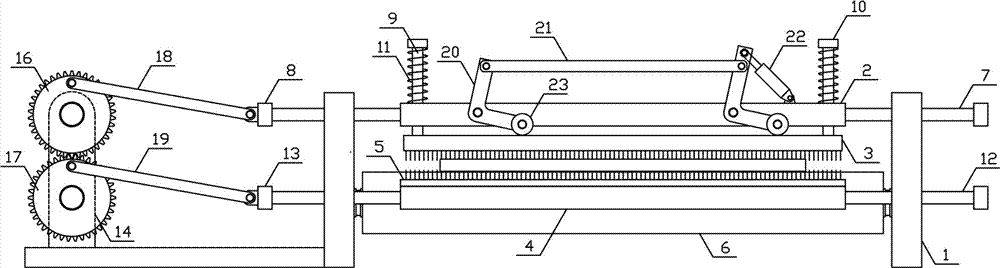

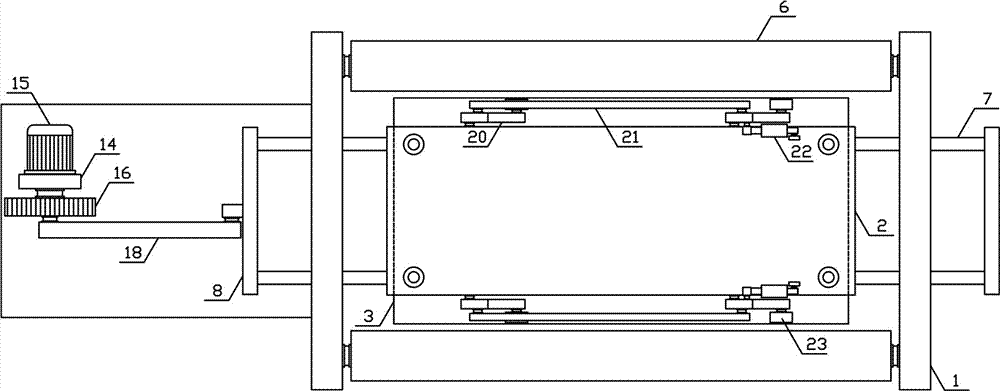

Automatic feeding device for lift guide rail bracket production

InactiveCN107335691AEasy to transportEasy to installGrinding machinesExtrusion cleaning devicesSurface cleaningWaste material

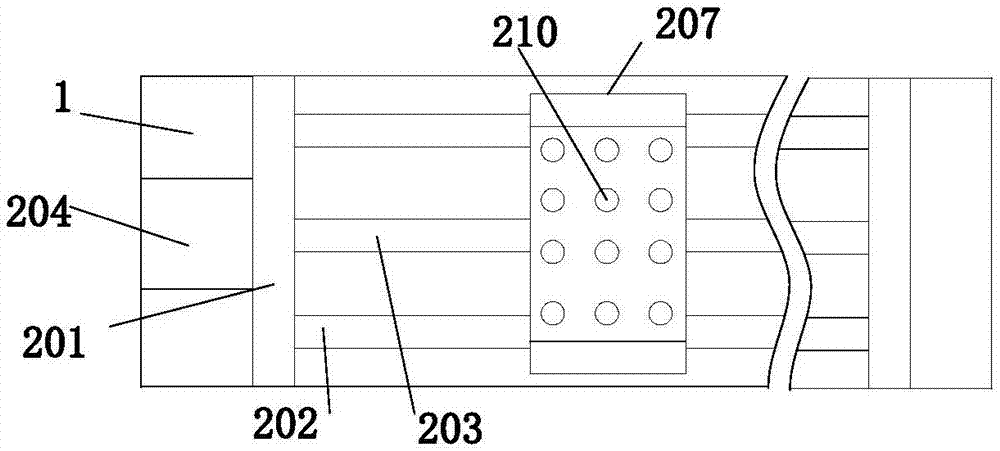

The invention discloses an automatic feeding device for lift guide rail bracket production. The automatic feeding device comprises a machine frame (1). A coiled steel conveying device (2), a coiled steel overturning device (3), a straightening device (4) and a coiled steel surface cleaning device (5) are sequentially arranged on the machine frame (1). A waste material recycling device (6) is arranged below the coiled steel surface cleaning device (5). The waste material recycling device (6) comprises a conical recycling hopper (601) fixed to the machine frame (1). The inner surface of the conical recycling hopper (601) is evenly provided with multiple electromagnets (602). The coiled steel conveying device (2) is connected with a controller (7). The controller (7) is connected with the coiled steel overturning device (3), the straightening device (4), the coiled steel surface cleaning device (5) and the waste material recycling device (6). The automatic feeding device has the advantages that coiled steel is convenient to convey, install and rotate, the labor intensity is lowered, the rust removal effect is improved, and the straightening effect is improved.

Owner:湖州南浔电梯配件配送中心有限公司

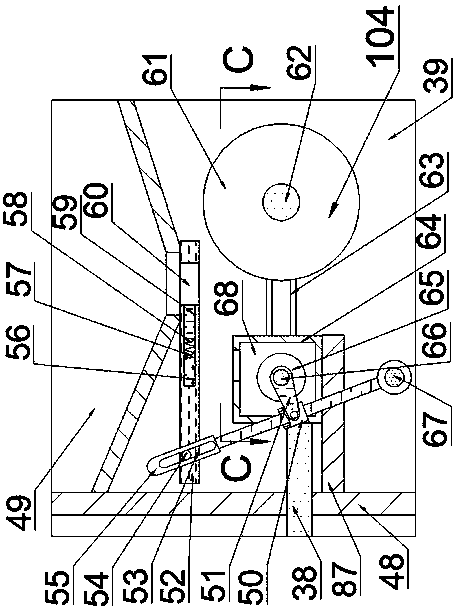

A kind of pipeline inner wall derusting device

ActiveCN104723223BAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesEngineeringPneumatic motor

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

Steel wire surface rust removing equipment

ActiveCN109366329AImprove rust removal efficiencyImprove rust removal qualityGrinding drivesGrinding machinesArchitectural engineeringRust

The invention belongs to the technical field of steel wire rust removing equipment, in particular to steel wire surface rust removing equipment. The steel wire surface rust removing equipment comprises a frame, cleaning boxes, a vertical plate, a steel wire and a straightening machine; two cleaning boxes are mounted on the frame; one cleaning box is slidingly connected with the frame through a guide rail; the straightening machine is mounted at the right end of the top of the frame; fixed guide wheels are fixedly connected to baseplates in the cleaning boxes; first guide plates and second guide plates are fixedly connected to the inner walls on two sides of the cleaning boxes; rust removing modules are arranged between the first guide plates and the second guide plates; an extrusion springis fixedly connected to the top of the front side of the vertical plate; a movable guide wheel is slidingly connected to the bottom of the front side of the vertical plate; and one end of the steel wire passes through the fixed guide wheel in the cleaning box on the left side of the frame, the rust removing modules and the movable guide wheel outside the cleaning box on the left side in sequence,passes through the rust removing module and the fixed guide wheel in the cleaning box on the right side of the frame in sequence, and finally penetrates through the straightening machine. As the steel wire performs up-down and left-right reciprocating swing, the rust removing efficiency and quality are improved, and the secondary rust removing workload is reduced.

Owner:东台市菲亚达金属丝网有限公司

Sand blasting derusting and online heat treatment method for reinforcing steel bar

ActiveCN106272092AShorten processing lengthAvoid too long gapsFurnace typesAbrasive machine appurtenancesSand blastingRebar

The invention discloses a sand blasting derusting and online heat treatment method for a reinforcing steel bar. Firstly, the reinforcing steel bar is placed on a conveying device, and the reinforcing steel bar is placed in a reinforcing steel bar conveying groove; and sand blasting devices are started, a heat treatment device is then started, and the surface of the reinforcing steel bar is covered with a dense oxide protection layer. The sand blasting derusting and online heat treatment method has the beneficial effects that sand blasting derusting can be conducted on the reinforcing steel bar in all directions, the dense oxide protection layer is formed under the high temperature, and the derusting quality is improved; meanwhile, the internal environment and the external environment can be cleaned, a rack passes through the outer sides of sand blasting compartments, conveying carrier rollers do not enter the sand blasting compartments either, and therefore the rack and the carrier rollers can be prevented from being damaged; the sand blasting devices are increased so that the process length of each sand blasting device is shortened, it can be avoided that the vacancy of the conveying carrier rollers is too long, and the reinforcing steel bar can obtain continuous conveying drive force; after sand blasting is conducted in a hierarchical manner, rough steel sand is recovered and then cleaned and reused, and fine steel sand can be directly recycled; and with the comprehensive effect, the production efficiency can be improved, cost is reduced, and the labor protection measures are enhanced.

Owner:重庆市晟庄建材有限责任公司

Steel plate surface derusting device for manufacturing hardware

InactiveCN111850580AEasy to remove rustImprove rust removal qualityCleaning using liquidsCirculating pumpBevel gear

The invention discloses a steel plate surface derusting device for manufacturing hardware. The device comprises a base, a bracket and a rust remover box, wherein the bracket is arranged on the left side of the upper end of the base, and the rust remover box is arranged at the upper end of the base. When the device is used, a winding engine lowers a support frame through a digging rope, the supportframe drives a steel plate to lower down into the rust remover box, a solution in the rust remover box immerses the steel plate to remove rust, derusting of the entire steel plate is conveniently carried out, the derusting efficiency is good, a filter screen filters rust stains in the solution, a circulation pump circularly uses the solution in the rust remover box through a circulation pipe, thesolution is sprayed from the circulation pipe and flows into a water receiving ladle to drive a rotating shaft, a bevel gear I, a bevel gear II, a stirring shaft and a stirring blade to rotate, and the solution in the rust remover box is convenient to stir, so that the steel plate and the rust remover solution are fully contacted, and the derusting quality of the steel plate is improved.

Owner:程勋振

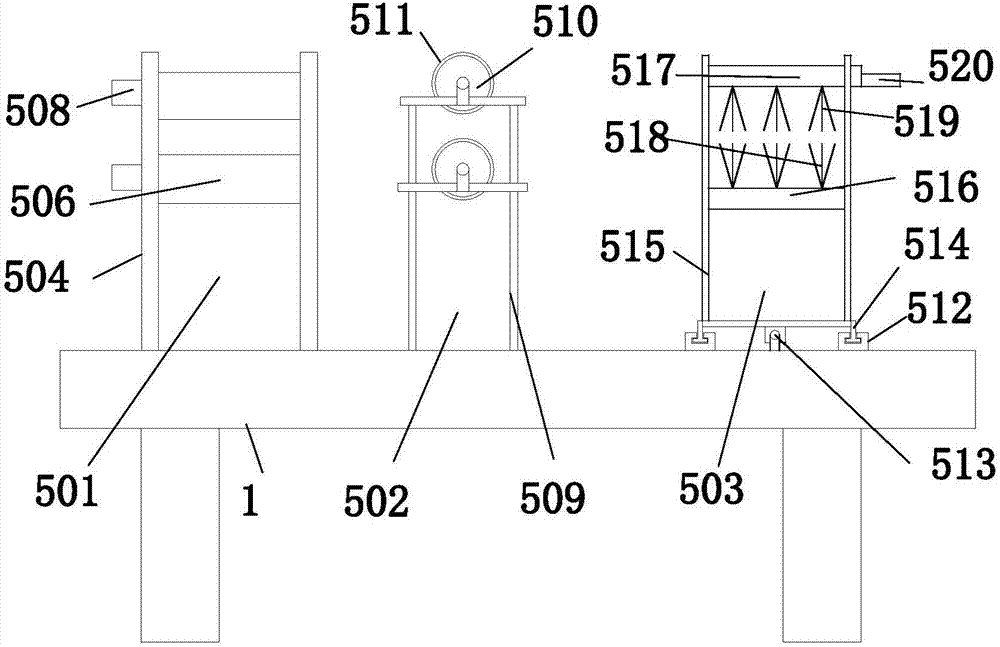

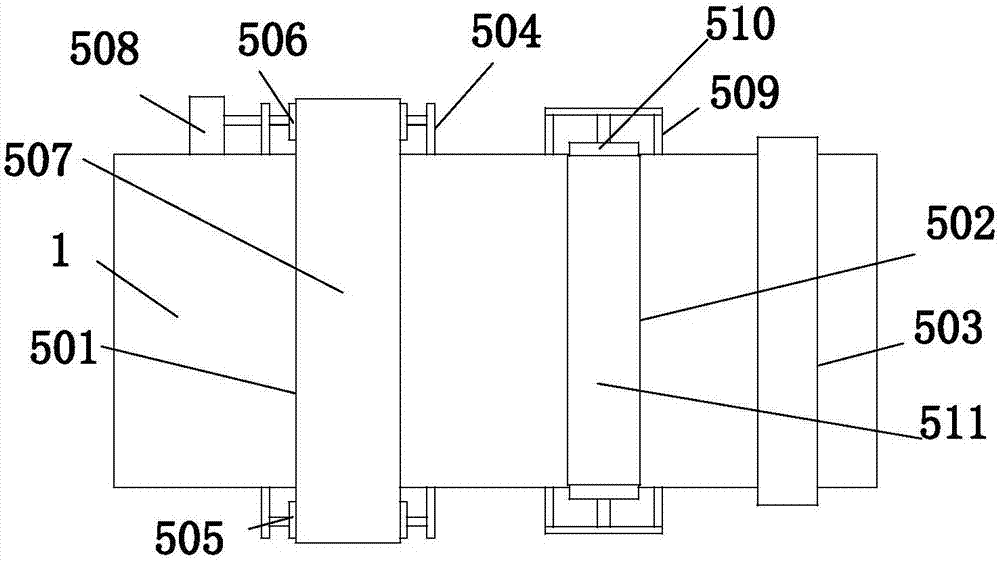

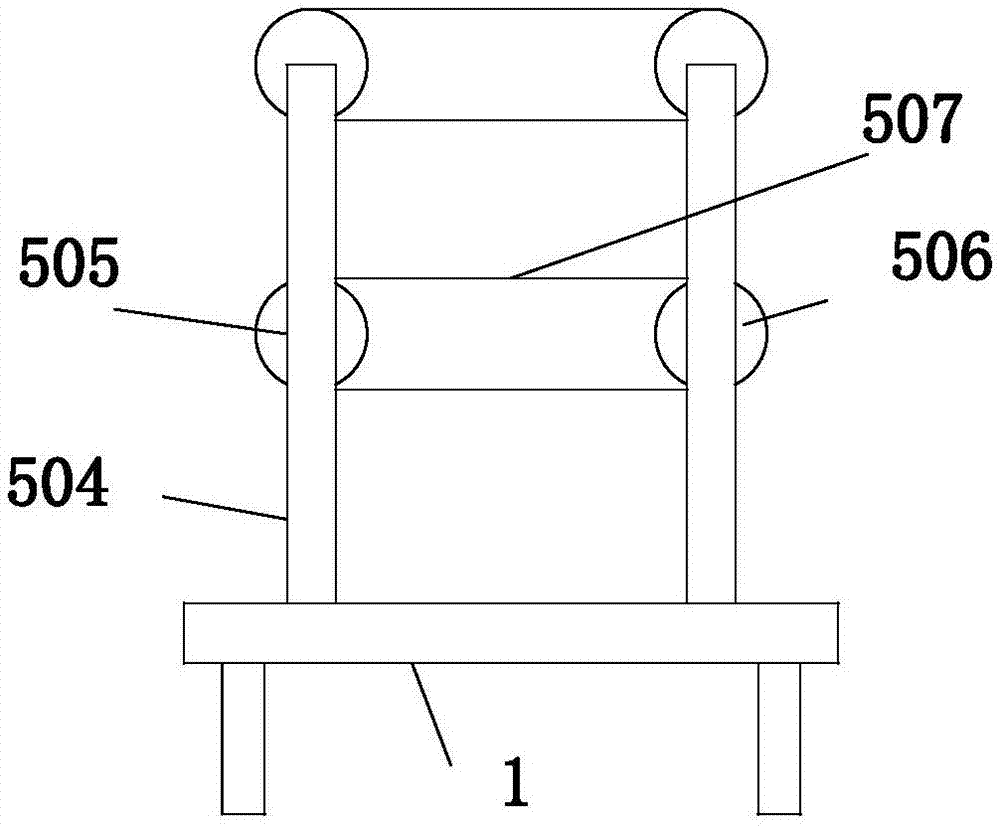

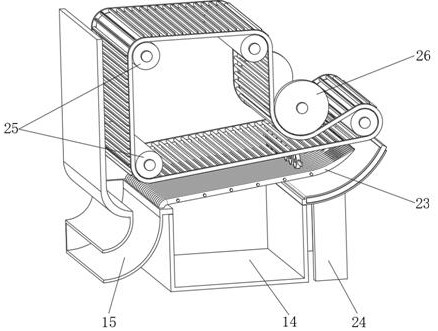

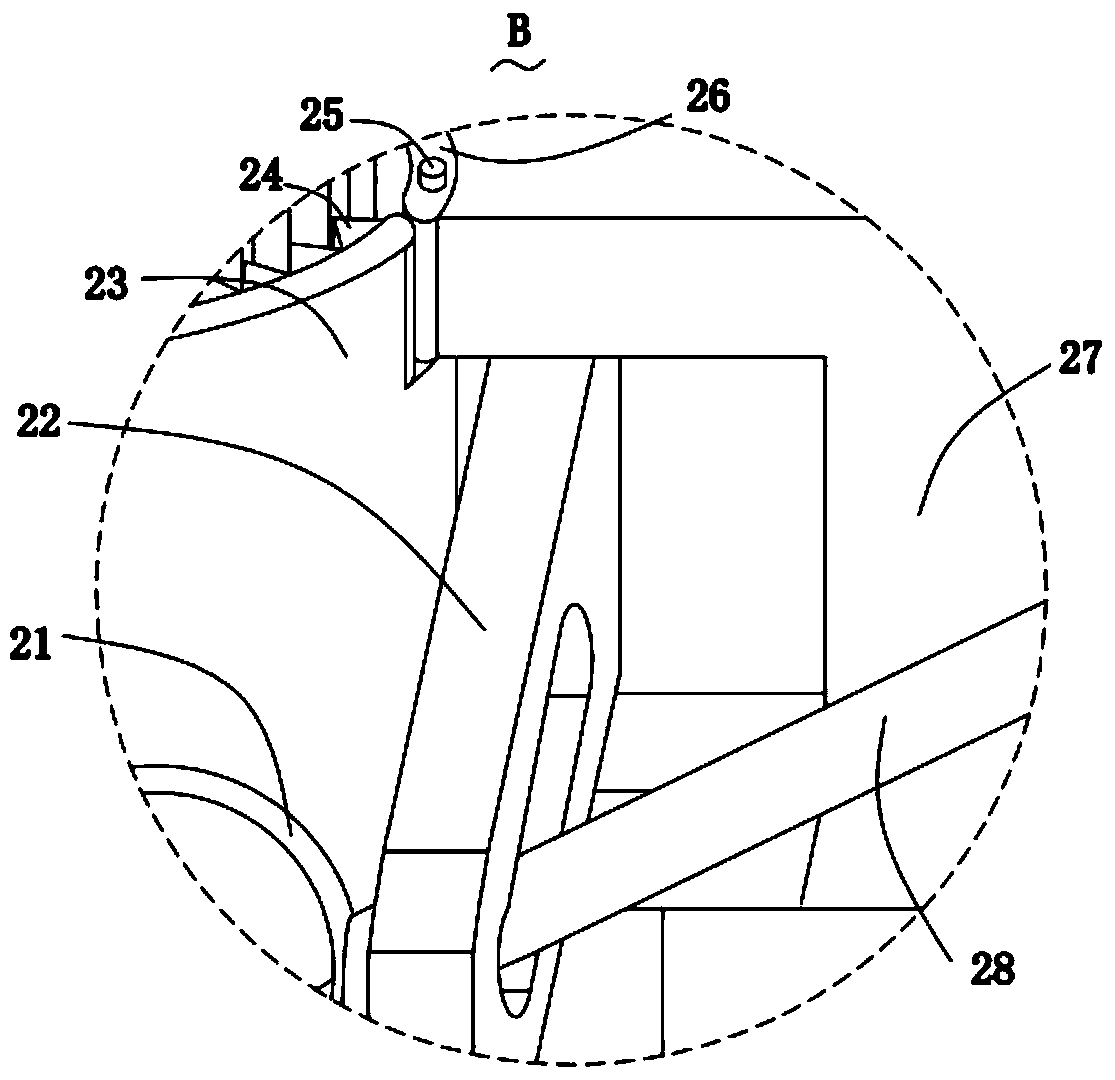

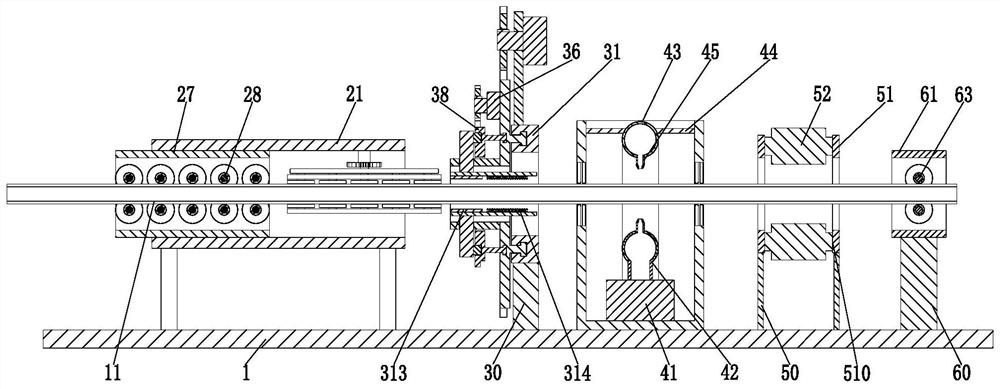

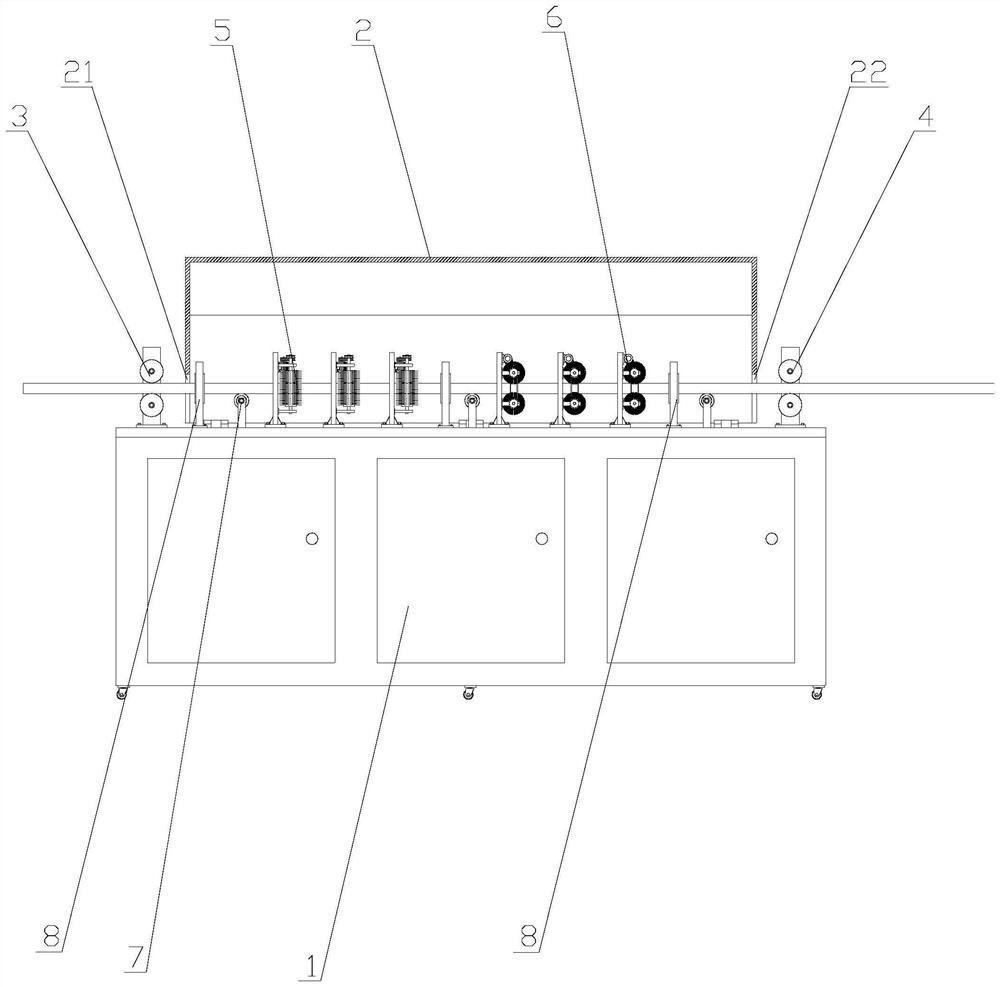

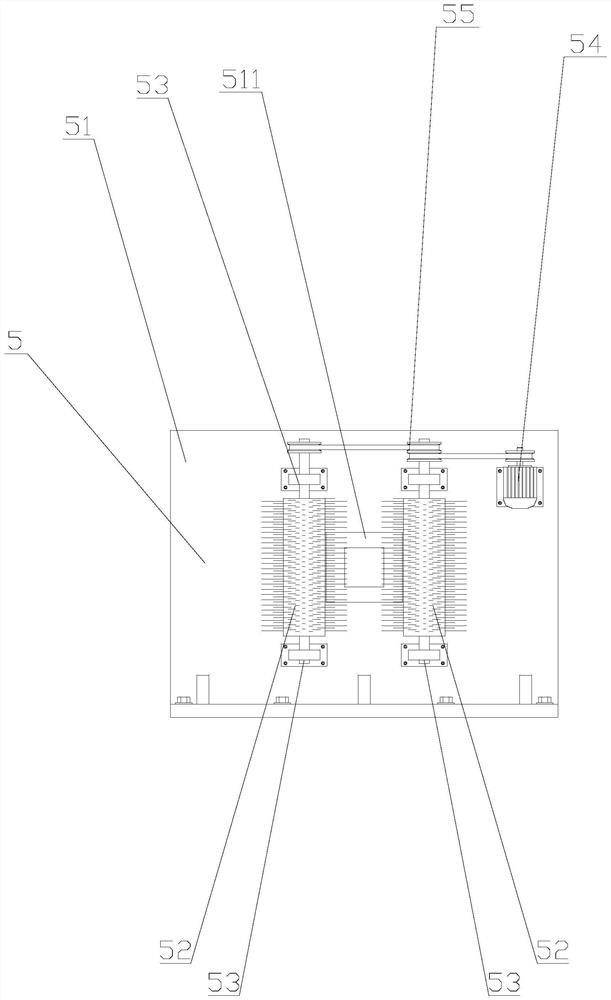

Coil steel surface cleaning equipment for production of elevator guide rail bracket

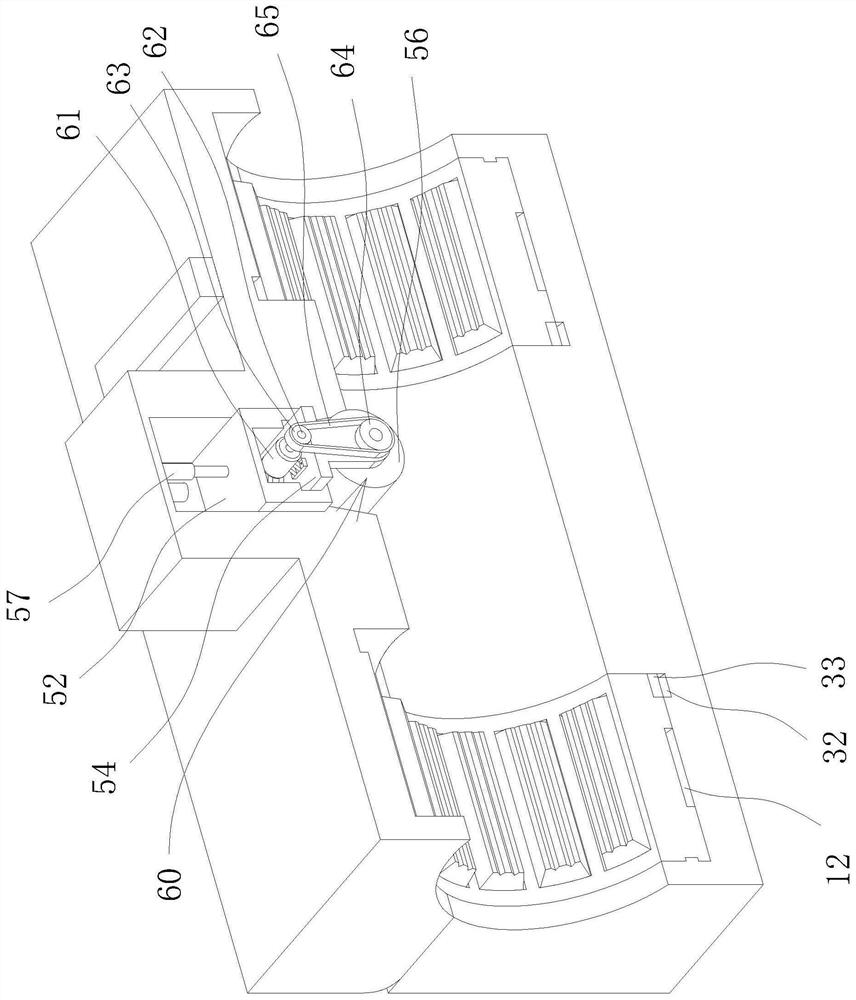

InactiveCN107378718AImprove the finishReduce labor intensityBelt grinding machinesCleaning using toolsSurface cleaningEngineering

The invention discloses coil steel surface cleaning equipment for production of an elevator guide rail bracket. The coil steel surface cleaning equipment comprises a rack (1), wherein the rack (1) is sequentially provided with a longitudinal cleaning mechanism (501), a transverse cleaning mechanism (502) and a surface sweeping mechanism (503). The longitudinal cleaning mechanism (501) comprises longitudinal supports (504) which are arranged on the front side and the rear side of the rack (1) correspondingly, and two longitudinal grinding devices which are distributed in the vertical direction are arranged between the two adjacent longitudinal supports (504). Each longitudinal grinding device comprises a driven roll shaft (505) and a drive roll shaft (506) which are arranged on the two longitudinal supports (504) correspondingly, wherein an abrasive belt (507) is arranged between the drive roll shaft (506) and the driven roll shaft (505), and the drive roll shaft (506) is connected with a rotary motor (508). The coil steel surface cleaning equipment has the beneficial effects that the derusting effect can be improved, and the labor intensity of workers is lowered.

Owner:湖州南浔电梯配件配送中心有限公司

High-efficiency shot blasting and derusting device for machining steel structure

InactiveCN111805437APrevent slippingEven contactAbrasive blasting machinesGrinding/polishing apparatusTransmission beltElectric machinery

The invention discloses a high-efficiency shot blasting and derusting device for machining a steel structure, and relates to the technical field of shot blasting and derusting devices. In order to improve the derusting effect, the device specifically comprises a main body, wherein a feeding conveyor belt and a discharging conveyor belt are separately arranged on one side of the main body through two first installation frames; a feeding motor and a discharging motor are separately fixed on the outer walls of one sides of the first installation frames through screws; and the output ends of the feeding motor and the discharging motor are respectively connected with the feeding conveyor belt and the discharging conveyor belt in a transmission mode. According to the high-efficiency shot blasting and derusting device, a supporting rod, a driving roller and other structures are arranged, the supporting rod can be driven by a driving motor after feeding through the feeding conveyor belt, thena product with a surface to be derustized is driven to overturn, a shot falls from a shot blasting opening to impact the surface of the product for derusting, and by arranging a shifting convex strip,slipping between the product and the supporting rod can be effectively avoided, so that the overturning effect of the product is guaranteed.

Owner:六安市汇鑫钢结构有限公司

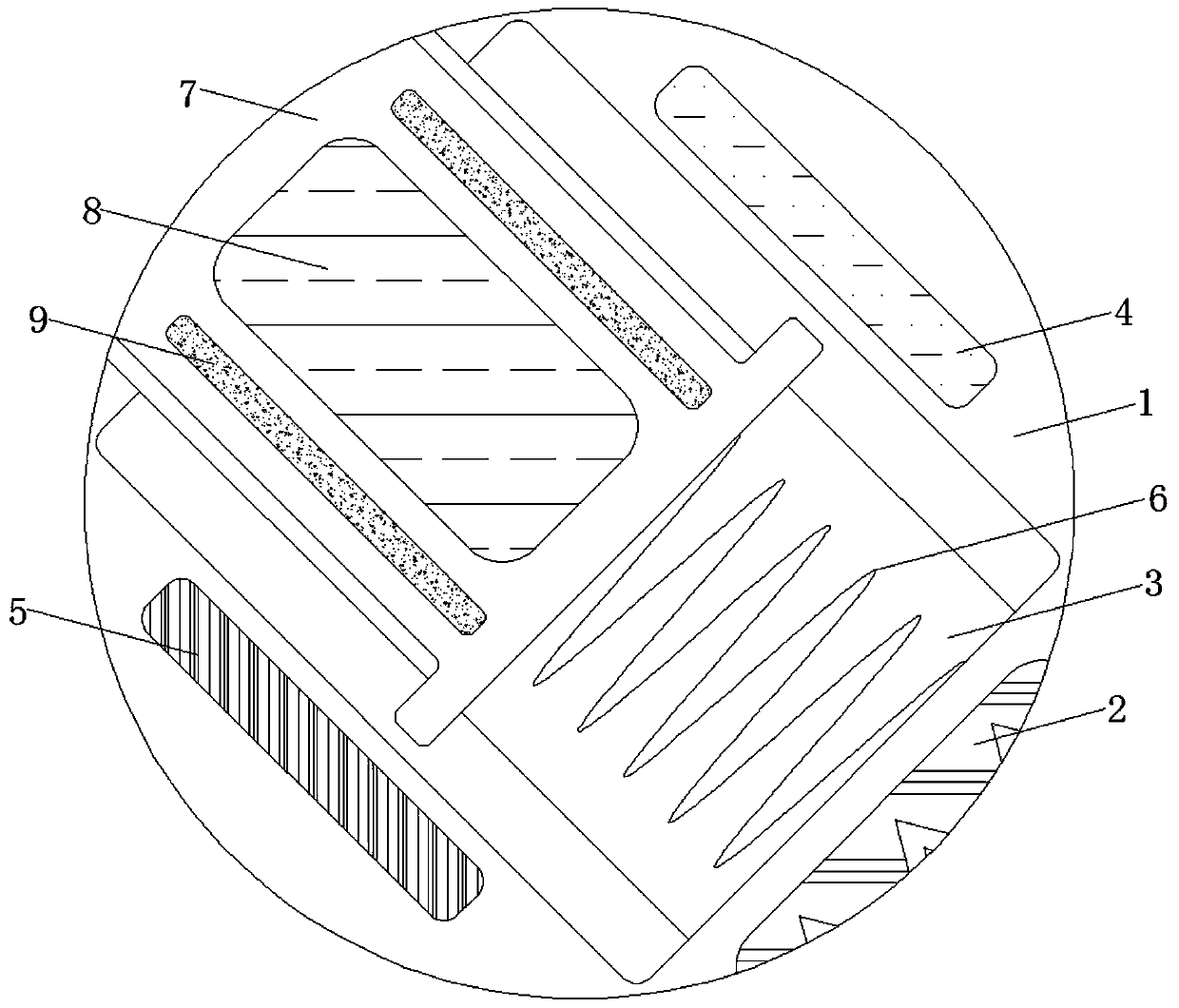

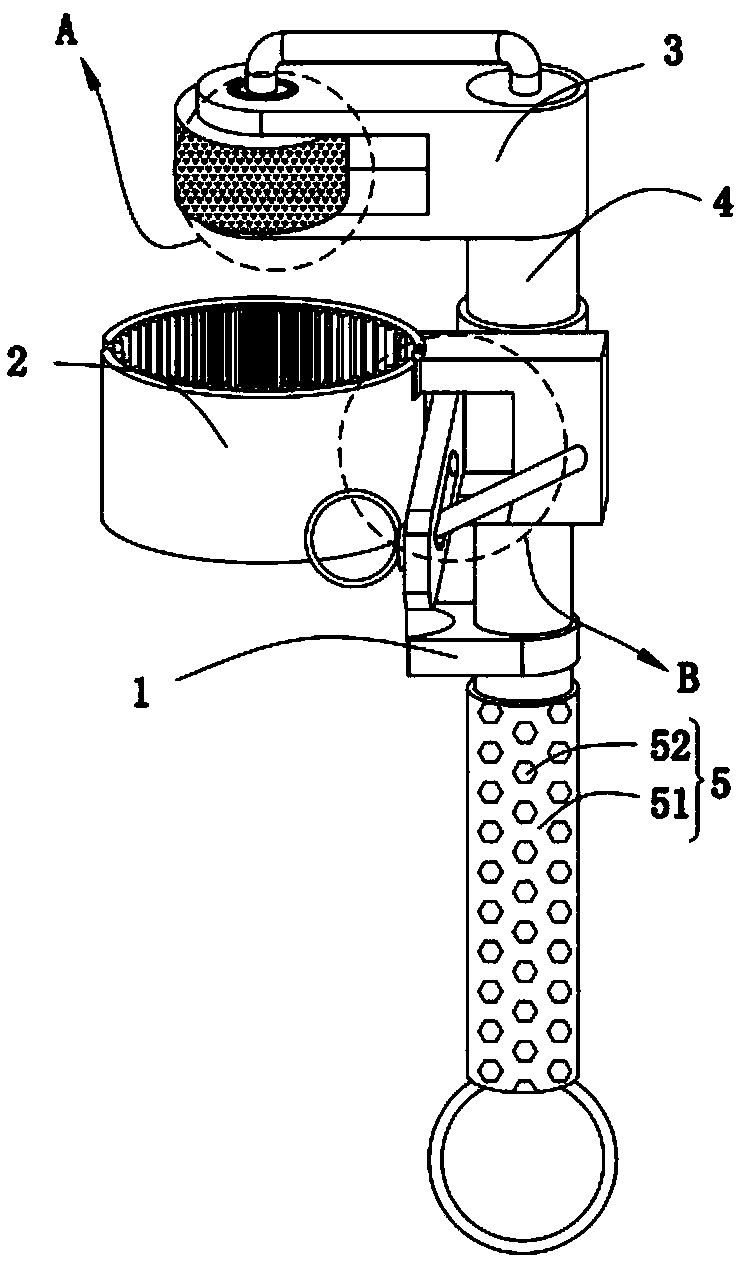

Scaffold steel pipe maintaining method

The invention relates to the technical field of steel pipe rust removal and maintenance, in particular to a scaffold steel pipe maintaining method. According to the method, a rust removal device is adopted and comprises a first rust removal structure, a second rust removal structure, a lubricating structure and an anti-skid structure. The anti-skid structure is provided with the lubricating structure for applying of rust removal oil. The lubricating structure is provided with the first rust removal structure for wrapping and grinding a steel pipe. The lubricating structure is provided with thesecond rust removal structure for conducting secondary grinding and polishing on the steel pipe. The first rust removal structure wraps the outer side of the steel pipe, rust slag on the surface of the steel pipe is rapidly removed through rotation of the first rust removal structure, and rust removal can be conveniently conducted on steel pipes different in size. Through cooperative usage of thesecond rust removal structure and the first rust removal structure, the preliminarily-ground steel pipe can be further ground, and the steel pipe surface smoothness is improved. Through cooperative usage of the second rust removal structure and the lubricating structure, the steel pipe obtained after secondary rust removal can be conveniently subjected to protection oil liquid applying, and the steel pipe rust removal efficiency is greatly improved.

Owner:ANHUI HUATENG AGRI TECH CO LTD

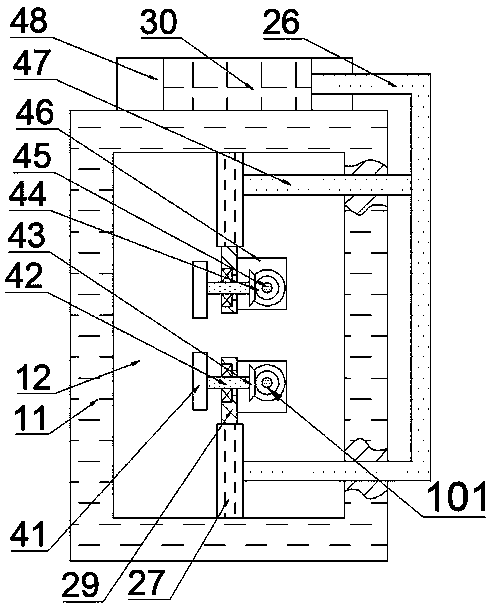

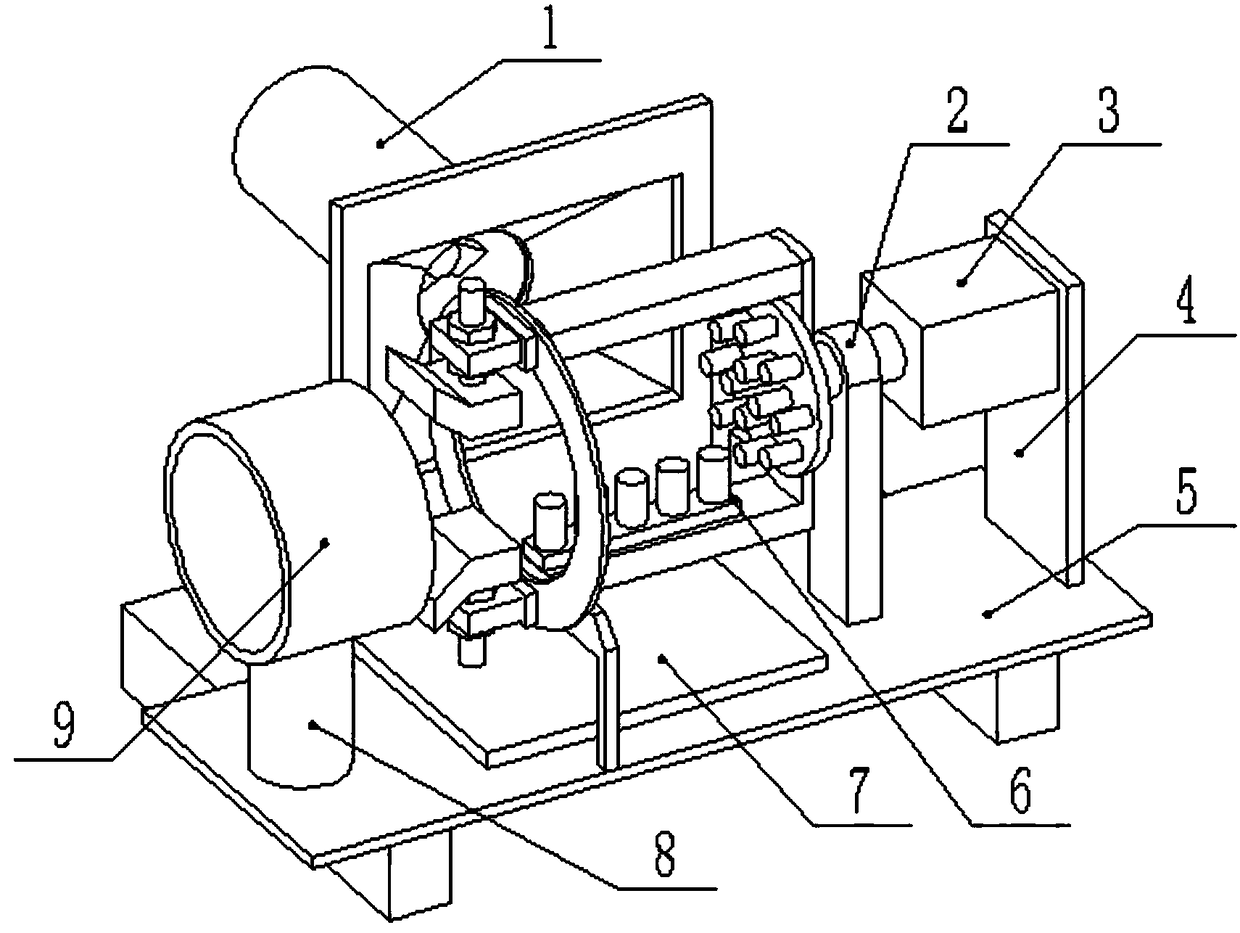

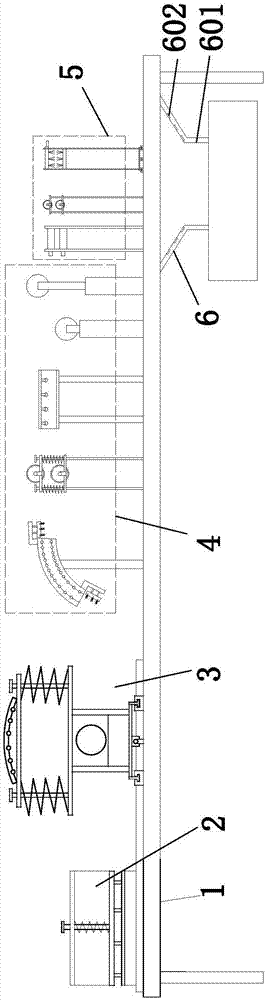

Scaffold steel pipe repairing and maintaining device

ActiveCN113618583AImprove drying efficiency and qualityImprove rust removal efficiency and qualityPretreated surfacesGrinding machinesSteel tubeManufacturing engineering

The invention relates to a scaffold steel pipe repairing and maintaining device. The device comprises a bottom plate, a straightening mechanism, a rust removal mechanism, a paint spraying mechanism, a drying mechanism and a discharging mechanism; and the straightening mechanism, the rust removal mechanism, the paint spraying mechanism, the drying mechanism and the discharging mechanism are sequentially installed on the bottom plate from the left end to the right end. The scaffold steel pipe repairing and maintaining device can solve the following problems during repair and maintenance of a scaffold steel pipe: 1, when a traditional scaffold steel pipe is subjected to rust removal, the steel pipe needs to be subjected to manual rust removal operation by the aid of a rust removal tool, and due to the fact that manual rust removal is not complete and repeated rust removal operation is required, the rust removal efficiency of the steel pipe is low, and the repair quality of the steel pipe is influenced; and 2, traditional steel pipe straightening equipment cannot conduct straightening operation and paint smearing operation on the steel pipe at the same time, so that the maintenance efficiency of the steel pipe is low, and follow-up use of the steel pipe is affected.

Owner:JIANGSU SUZHONG CONSTR GROUP

Steel plate side edge rust removal device and method

InactiveCN110802494AEnsure consistencyGuaranteed accuracyGrinding drivesGrinding machinesEngineeringAnalog signal

The invention relates to a steel plate side edge rust removal device and method. The rust removal device includes steel plate side brushing mechanisms oppositely arranged on the left side and the right side of the steel plate, wherein each steel plate side brushing mechanism includes a rack, a placing platform arranged on the rack and moving oppositely to the placing rack, a scale breaking rollerarranged on the placing platform and performing synchronously translational movement with the placing platform, and a guide roller arranged on the placing platform and moving oppositely to the placingplatform. The method includes the following steps: S1: setting the numerical value section of a'-a; S2: adopting a current analog signal acquisition module to acquire current analog signals and sending the current analog signals to a processing module; S3: enabling the processing module to convert the current analog signals into digital signals and sending the digital signals to a control module;S4, judging whether the digital signals are in the threshold value section of a'-a by the control module; S5: if yes, not issuing an order, if no, issuing an order; and S6, issuing an order, and adjusting the positions of the scale breaking rollers. Compared with the prior art, the invention has the following advantages: the positions of the scale breaking rollers can be adjusted according to thepolishing and brushing intensity and the clearances between the scale breaking rollers and the side edges of the steel plate, and the fact that the scale breaking rollers can be used for efficientlypolishing and brushing the side edges of the steel plate in real time, is guaranteed, and the production efficiency and the yield are improved.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

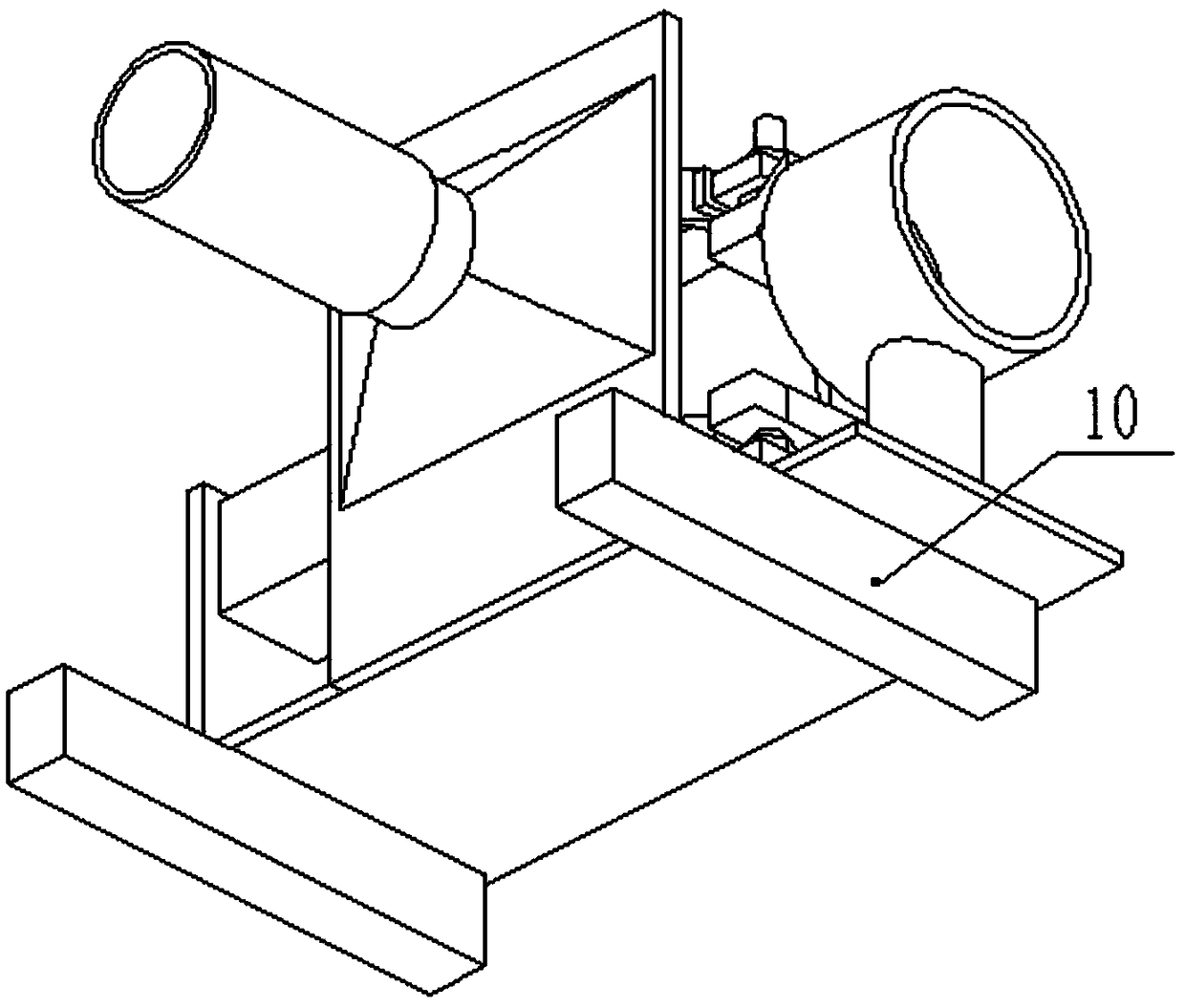

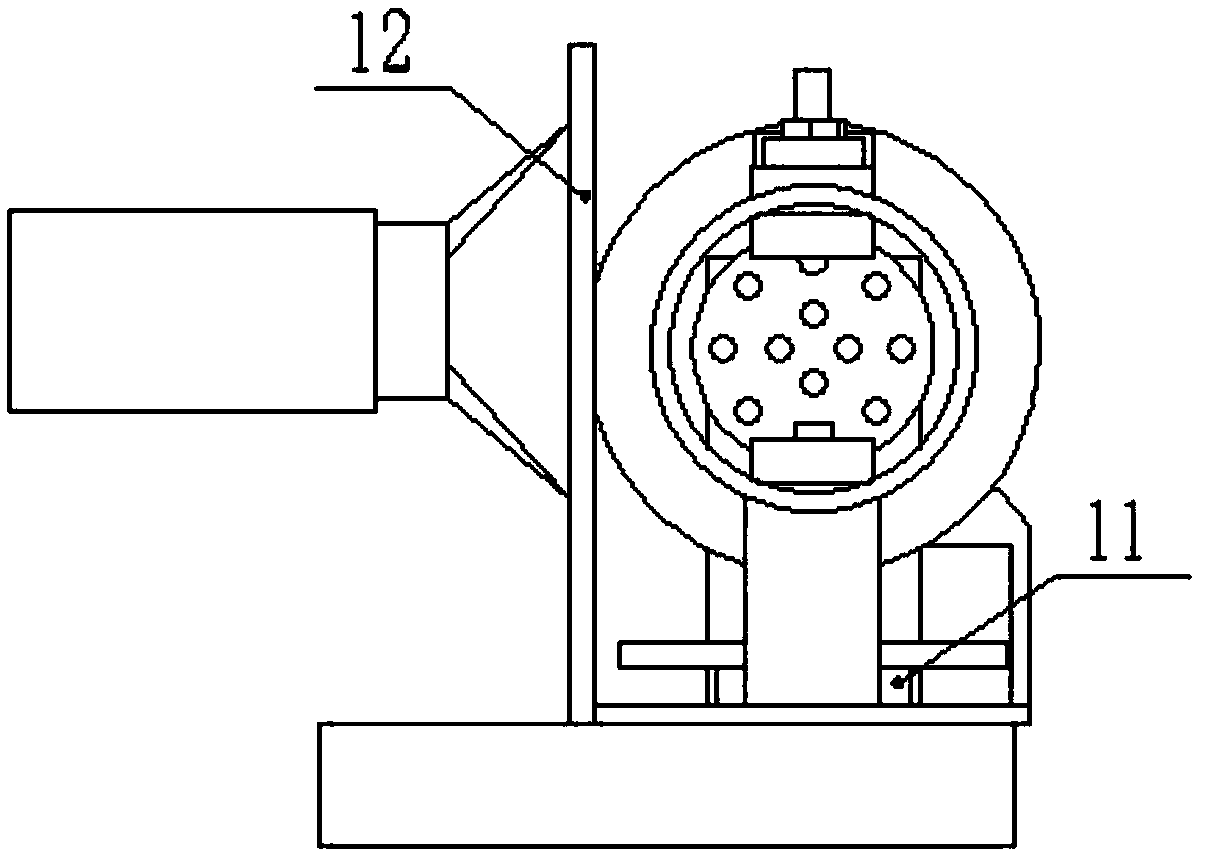

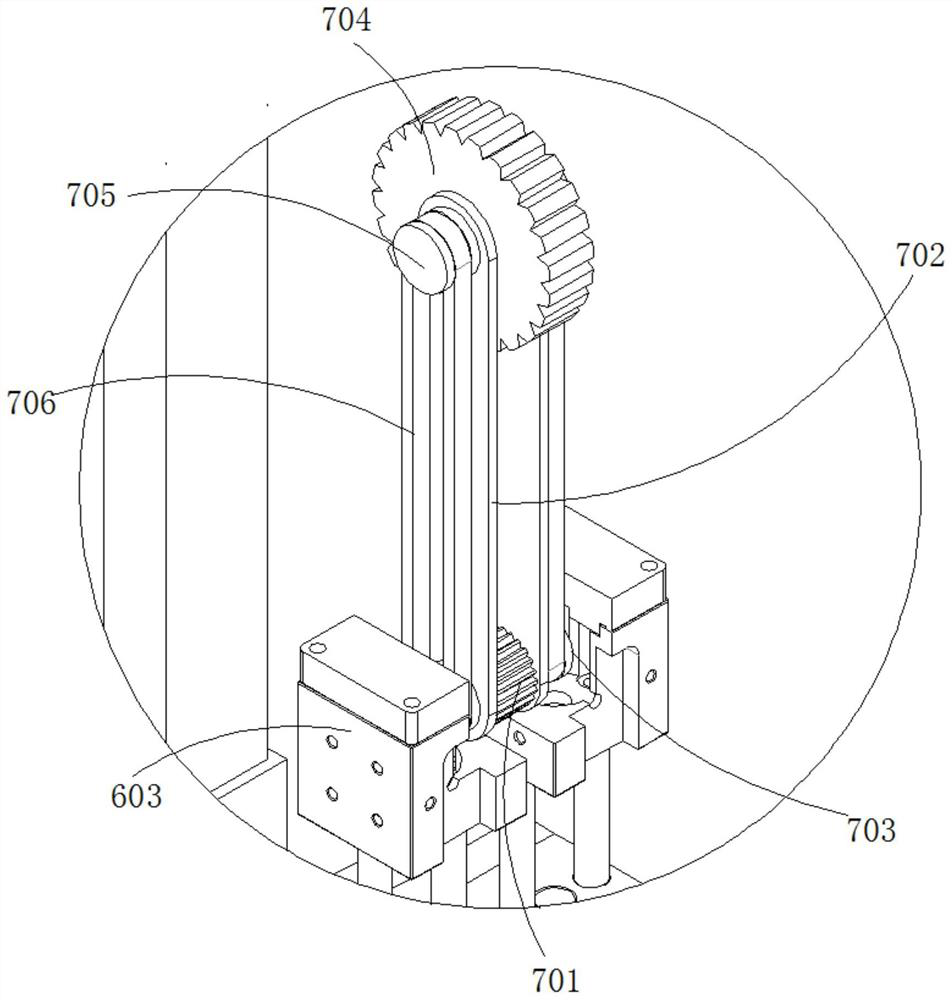

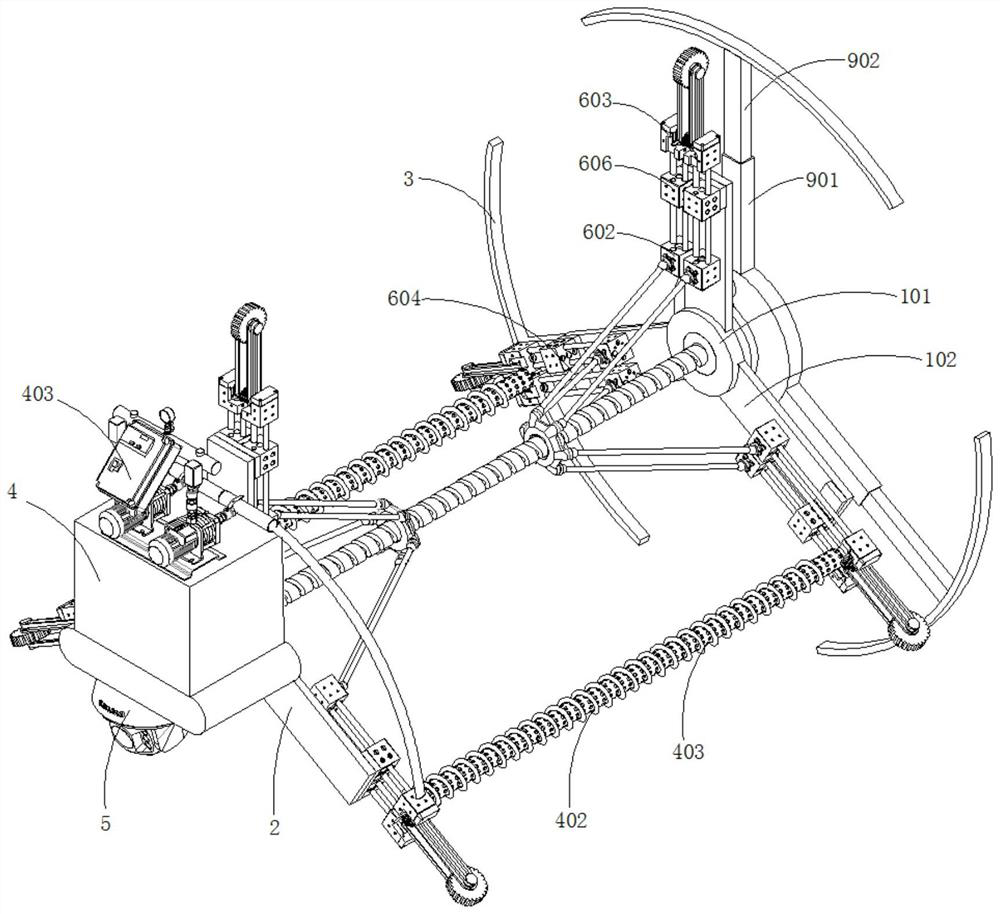

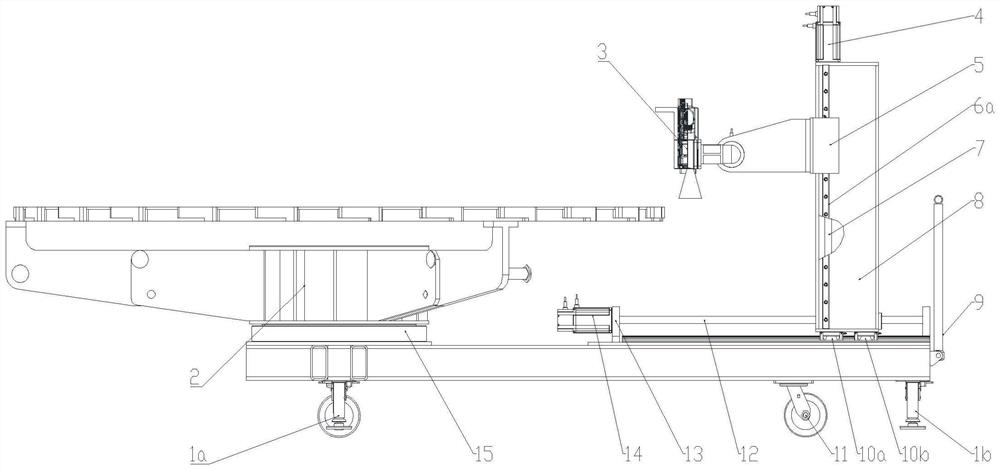

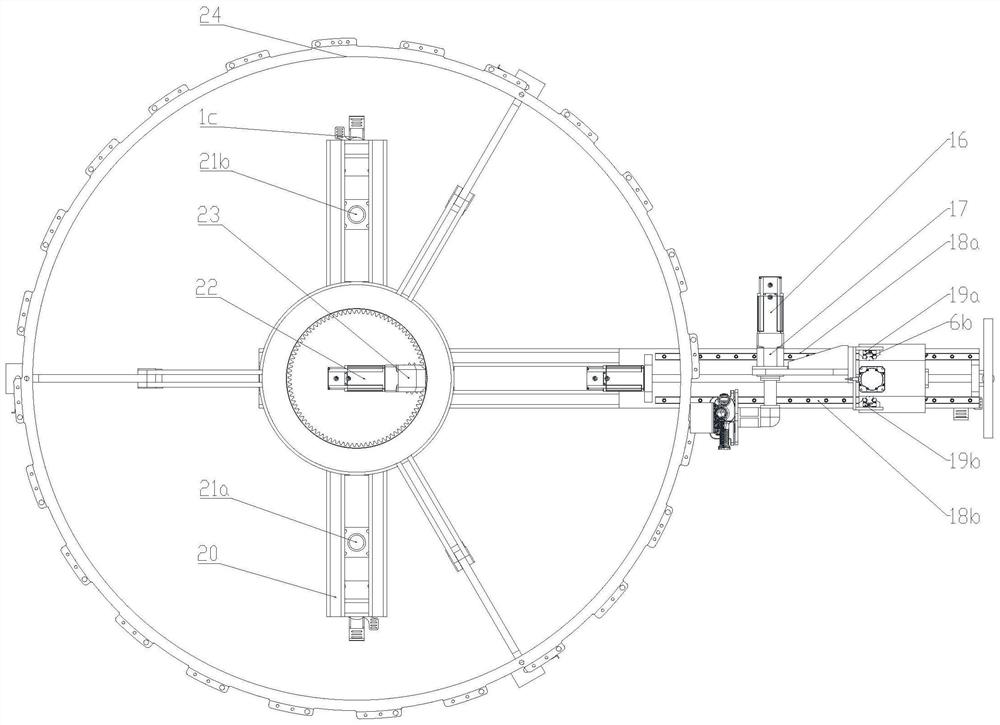

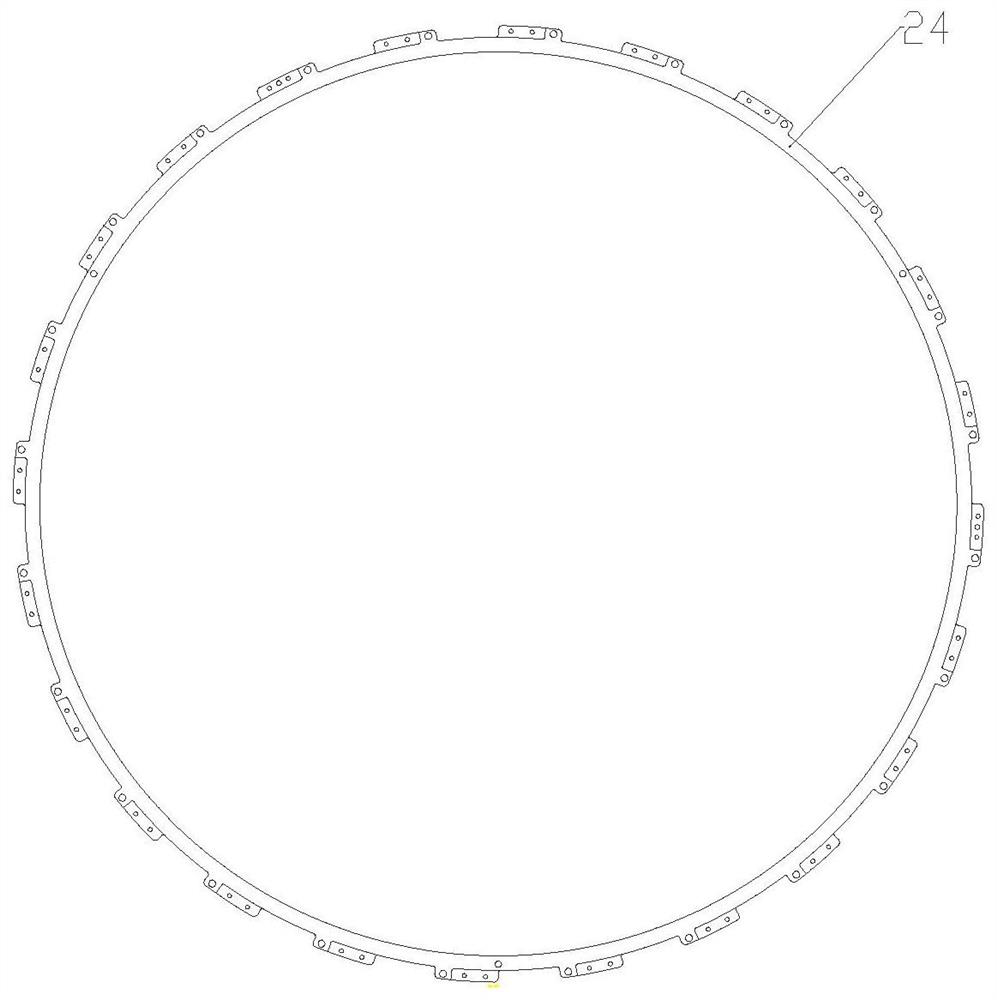

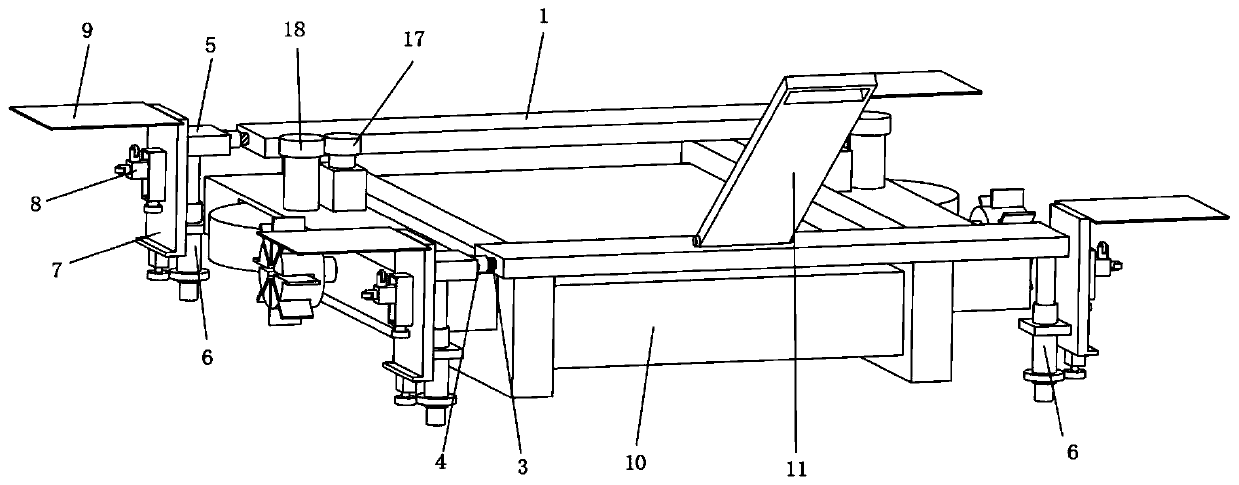

Automatic laser rust removal device for convex film pressing ring of underwater missile launching shaft

InactiveCN111673286AImprove rust removal efficiencyImprove rust removal qualityLaser beam welding apparatusControl theoryMechanical engineering

The invention discloses an automatic laser rust removal device for a convex film pressing ring of an underwater missile launching shaft. The device comprises a rotary supporting mechanism used for fixing the convex film pressing ring, a laser rust removal head and a three-degree-of-freedom moving mechanism used for driving the laser rust removal head to act; the rotary supporting mechanism comprises a rotary support, a rotary driving device and a convex film bracket, wherein the convex film bracket is fixedly connected to the outer circumference of the inner ring of the rotary support, the rotary driving device is connected with the inner ring of the rotary support and drives the inner ring of the rotary support to drive the convex film bracket to rotate relative to the outer ring of the rotary support, and the convex film pressing ring is fixed at the upper end of the convex film bracket; and the three-degree-of-freedom moving mechanism is connected with the laser rust removal head and drives the laser rust removal head to move to different stations to perform rust removal on the convex film pressing ring. According to the device, the automatic rust removal on the convex film pressing ring can be achieved, the rust removal efficiency is improved, and the labor cost is reduced.

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP +1

Treatment device for realizing continuous derusting work of steel rail for rail inner side cleaning

ActiveCN111576108AAvoid collisionImprove rust removal qualityRailway track constructionManufacturing engineeringSlide plate

The invention discloses a treatment device for realizing continuous derusting work of a steel rail for rail inner side cleaning. The device comprises a supporting top plate and side mounting plates, the left side of the adjusting threaded sleeve rod is rotationally connected with an adjusting mounting plate, lifting adjusting mechanisms are fixedly connected to the left side of the adjusting mounting plate and the right side of the supporting top plate, the output end of the lifting adjusting mechanism is fixedly connected with a walking side plate, a walking supporting mechanism is fixedly connected to the middle of the outer side of the walking side plate, a steel rail top sliding plate is fixedly connected to the left side close to the upper portion of the walking side plate, a derusting through groove is formed in the position, close to the back face, in the side mounting box, a derusting grinding wheel is rotationally connected into the derusting through groove, and a polishing cleaning wheel is rotationally connected to the position, located on the front face of the derusting grinding wheel, of the outer side of the side mounting box. According to the treatment device for realizing continuous derusting work of the steel rail for rail inner side cleaning, which relates to the technical field of rail cleaning, the purposes of achieving continuous derusting work and improving the derusting quality are achieved.

Owner:衡阳远通物流有限公司

Iron rod rust removal device for building

InactiveCN111673598AImprove efficiencyImprove rust removal qualityGrinding drivesGrinding machinesScrapStructural engineering

The invention discloses an iron rod rust removal device for building. The iron rod rust removal device comprises a box, a rotating disc and a fan. A second sliding groove is formed in the middle position of one side in the box, and a first motor is mounted on one side of the top end of the outer portion of the box. The fan is mounted at the middle position of one side in the box, and a second sliding block is fixedly connected to the middle position of one side of the fan. The rotating disc is arranged at the bottom end in the box, and a waste scrap box is arranged on one side of the bottom end in the box. According to the iron rod rust removal device, through the fan mounted at the middle position of one side in the box, a spiral rod can be driven to rotate through forward and reverse rotation of the first motor, a spiral sleeve can drive a supporting rod to move on the spiral rod, and therefore the supporting rod can drive the fan to slide on the second sliding groove through the second sliding block, iron scraps generated at various positions can be blown into the waste scrap box through the fan, unified treatment can be carried out, and the interior of the device can be cleanedconveniently.

Owner:王春秋

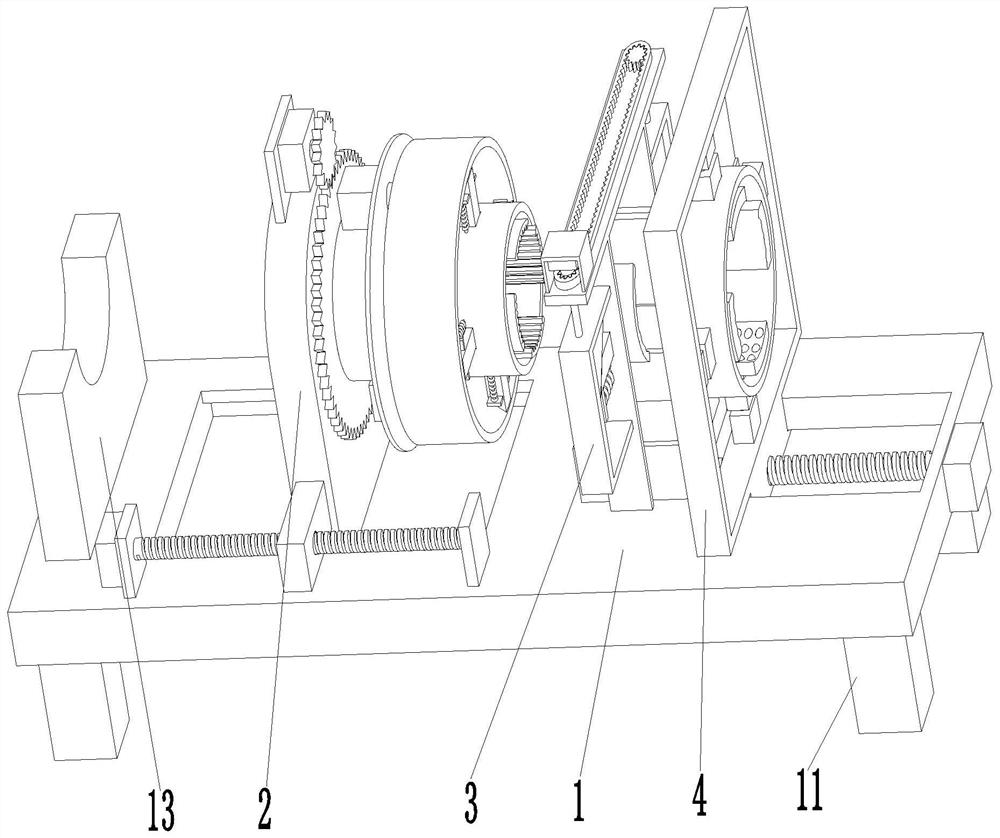

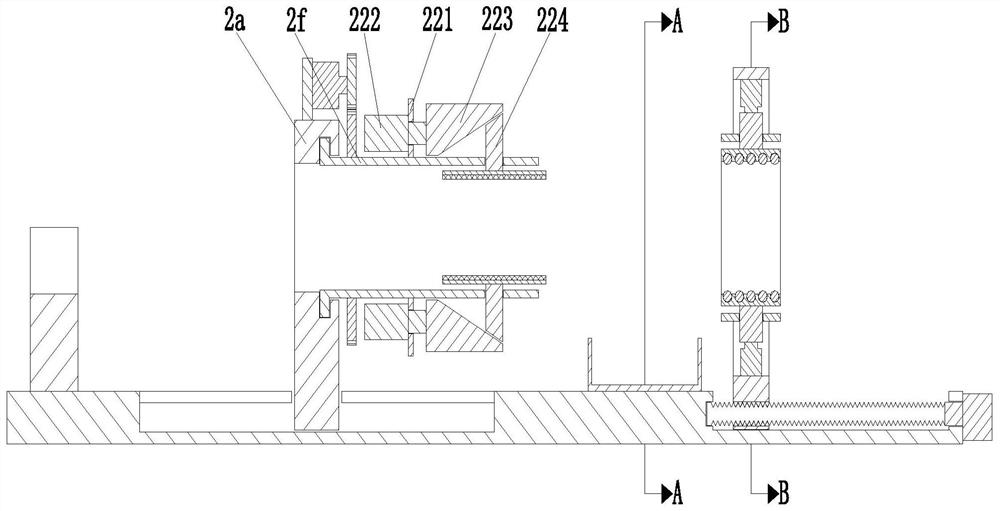

Steel solid waste garbage recycling method

InactiveCN112775153AReduce the effect of recyclingLow efficiencySolid waste disposalGrinding machinesProcess engineeringEnvironmental engineering

The invention relates to a steel solid waste garbage recycling method which mainly comprises the following steps of raw material classification, conveying operation, rust removal operation and other procedures. Adopted steel solid waste rust removal equipment comprises a bottom plate, a feeding device, a rust removal device and a discharging device. The steel solid waste garbage recycling method can solve the following problems existing during existing waste steel rust removal that a, when traditional waste steel rust removal is conducted, rust on the surface of waste steel is generally removed manually through a rust removal tool, due to the fact that the hardness of the rust is large, the phenomenon that the hands of rust removal personnel are scratched frequently occurs, the labor intensity of manual rust removal is large, and the efficiency is low; and b, existing waste steel rust removal equipment cannot perform comprehensive rust removal operation on the waste steel, the phenomenon of iron rust residue often occurs, and the waste steel cannot be slightly corrected, so that the effect of recycling the waste steel is reduced.

Owner:林超

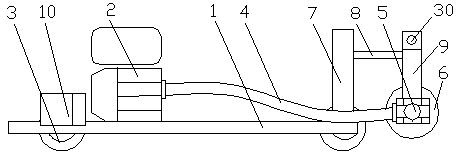

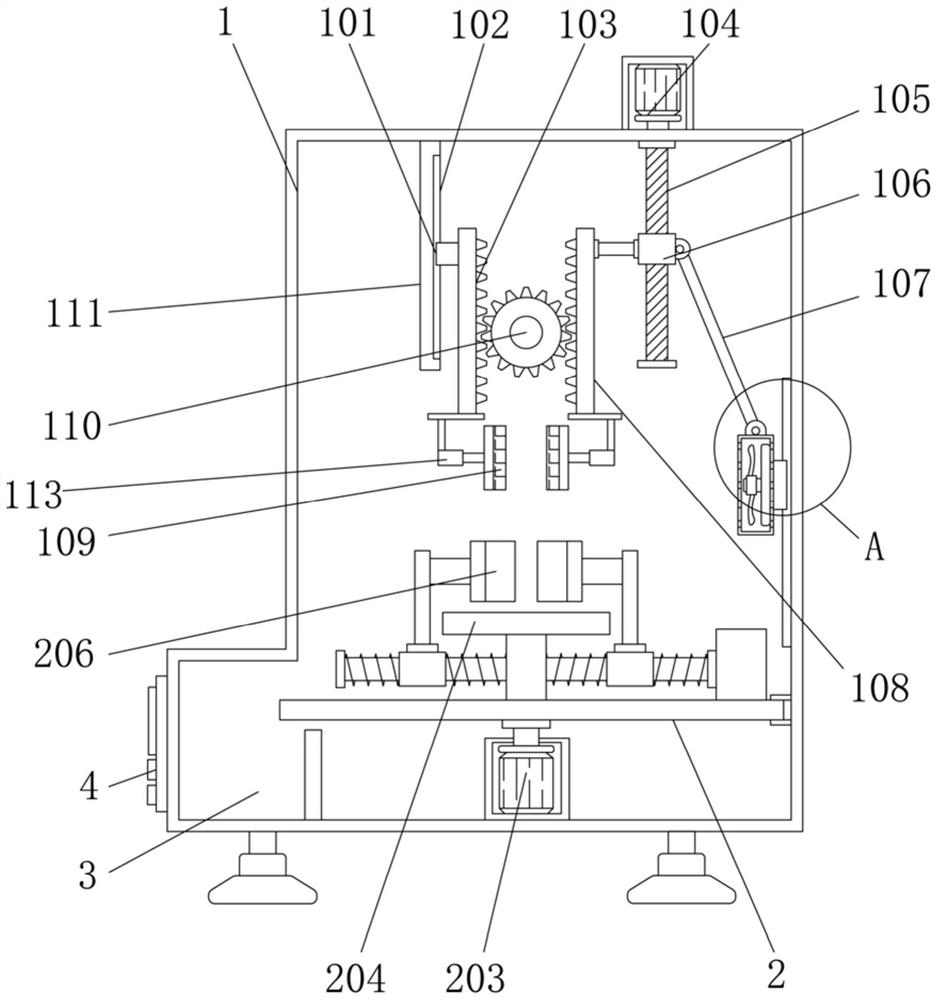

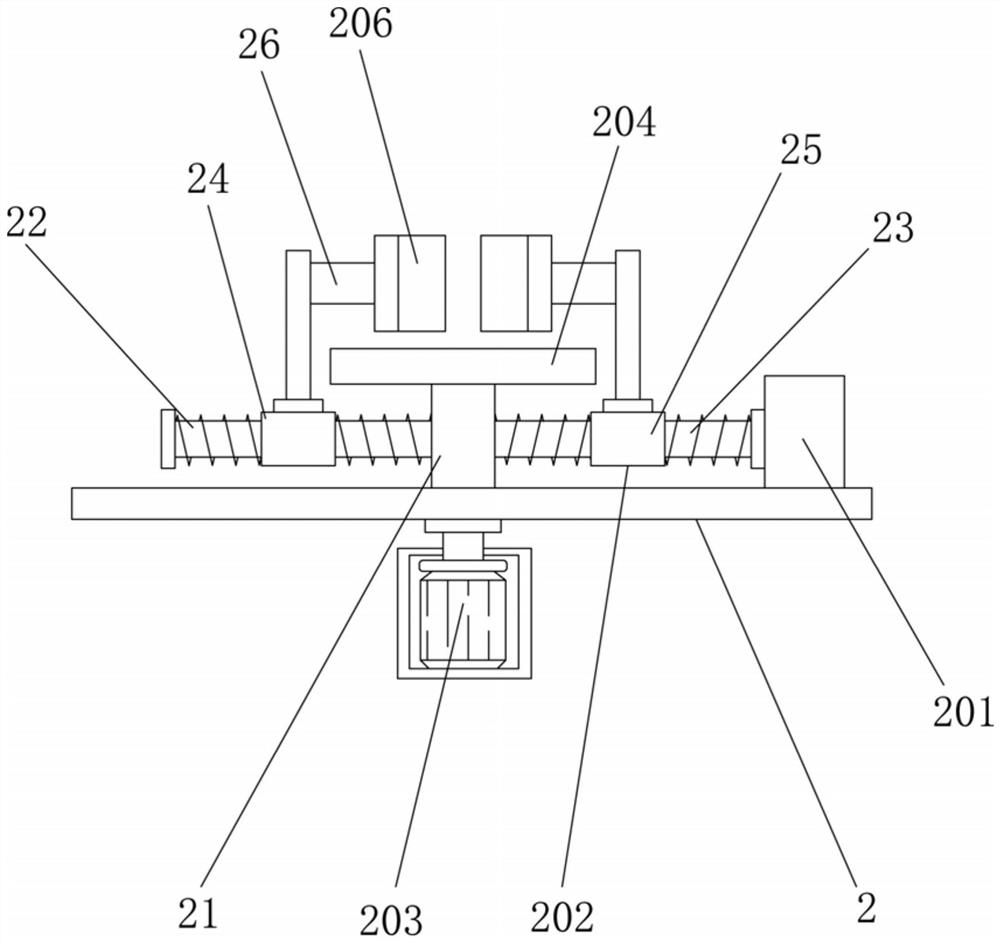

Portable steel bar rust removal equipment

ActiveCN112959196AExtended service lifeImprove rust removal qualityGrinding carriagesGrinding drivesRebarAgricultural engineering

The invention discloses portable steel bar rust removal equipment, and relates to the field of building equipment. The portable steel bar rust removal equipment is characterized in that the portable steel bar rust removal equipment comprises a rack, handles are symmetrically arranged on the rack, the lower end of the rack is rotationally connected with rust removal frames which are symmetrically arranged, rust removal mechanisms for removing rust on steel bars through rotating friction are arranged at the two ends of each rust removal frame, and a moving mechanism for driving the rack and the steel bars to move relatively is arranged in the rack. The portable steel bar rust removal equipment has the technical effects that the moving mechanism can drive the rust removal frames to move on the steel bars along with the rack, a user does not need to drive the rack to move to remove rust on the whole steel bars, and the labor intensity is reduced.

Owner:安徽华兴管业有限责任公司

Device for rapidly removing dust on surface of steel plate for construction machinery

InactiveCN109202668AThorough rust removalAchieve positioningGrinding carriagesGrinding machinesSheet steelArchitectural engineering

The invention relates to the field of construction machinery, in particular to a device for rapidly removing dust on the surface of a steel plate for construction machinery, and the device comprises awork table, a dust collection box, a support screen plate, a support plate, a top plate and a polishing plate. The two sides of the bottom of the work table are fixed installed at supporting legs. Areinforcing plate is fixedly connected to the inner sides of two groups of support legs, and a dust collecting box is disposed at the top of the reinforcing plate. Magnets are disposed at the left andright ends of the interior of the dust collecting box, and the inside of the work table is provided with the support screen plate. A guide rail is arranged at the upper part of the inner side of thework table, and the upper part of the inner side of the work table is connected with a sliding block through the guide rail. A fastening bolt is installed at the middle side of the top of the slidingblock in a passing-through manner, and the bottom of the fastening bolt is fixedly connected with a pressing disc. Two sides of the top of the work table are fixedly connected with support plates, andthe inner sides of the support plates are provided with dust collecting plates. In the invention, the overall device has the advantages of simple structure, convenient operation, diversified functions and certain promotion value.

Owner:甘肃西部云盟网络科技有限公司

Surface rust removal device for corrosion-resistant square steel

InactiveCN113427378AReduce the impactUniform derustingGrinding drivesGrinding machinesStructural engineeringMechanical engineering

The invention discloses a surface rust removal device for corrosion-resistant square steel. The device comprises a rack, a rack upper cover, a square steel input roller set, a square steel output roller set, a radial derusting device, a transverse derusting device and a plurality of conveying rollers, wherein the rack upper cover is arranged at the upper end of the rack, one side of the rack upper cover is hinged to the rack, the rack upper cover can be turned over, a square steel input port and a square steel output port which can be matched with square steel are formed in two ends of the rack upper cover respectively, a square steel input roller set capable of being matched with the square steel input port is arranged at the position, close to the square steel input port, of the upper end of the rack, and a square steel output roller set capable of being matched with the square steel output port is arranged at the position, close to the square steel output port, of the upper end of the rack. The upper end of the rack is provided with the radial rust removal device and the transverse rust removal device, so that the upper, lower, left and right surfaces of square steel can be uniformly derusted, the rust removal quality is improved, and the rust removal efficiency is improved; the dust in the rust removal process is reduced by arranging the rack upper cover, and the influence on the environment is reduced.

Owner:ZHEJIANG YALEI STEEL COLD DRAWING

Metal sheet conveying and derusting mechanism

InactiveCN107243814AReasonable structural designEfficient rust removalGrinding carriagesGrinding machinesEngineeringMechanical equipment

The invention discloses a metal sheet conveying and derusting mechanism, which belongs to the field of material processing mechanical equipment. The invention comprises a guide plate support, an upper translation plate, an upper derusting plate, a lower translation plate, a lower derusting plate, a pressing plate mechanism and a translation driving mechanism, and a plurality of guide plate rollers are uniformly rotated and connected in sequence along the horizontal direction on the guide plate support, and the upper derusting The plate is horizontally set on the lower side of the upper translation plate, the platen mechanism is horizontally set on both sides of the upper translation plate, the lower derusting plate is horizontally set on the upper side of the lower translation plate, the translation drive mechanism is vertically set on the side of the guide plate bracket, the upper translation gear and the upper An upper push pedal rod is arranged between the translation baffles, and a lower push pedal rod is arranged between the lower translation gear and the lower translation baffles. The invention has a reasonable structural design, can derust the upper and lower sides of the metal plate synchronously and efficiently during the conveying process of the metal plate, improves the efficiency and quality of derusting the metal plate, and meets the needs of production and use.

Owner:桐乡市川泰纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com