Carriage trucks water under high pressure jet stream rust cleaning production line and technique

A high-pressure water jet and production line technology, which is used in manufacturing tools, explosion generating devices, metal processing equipment, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

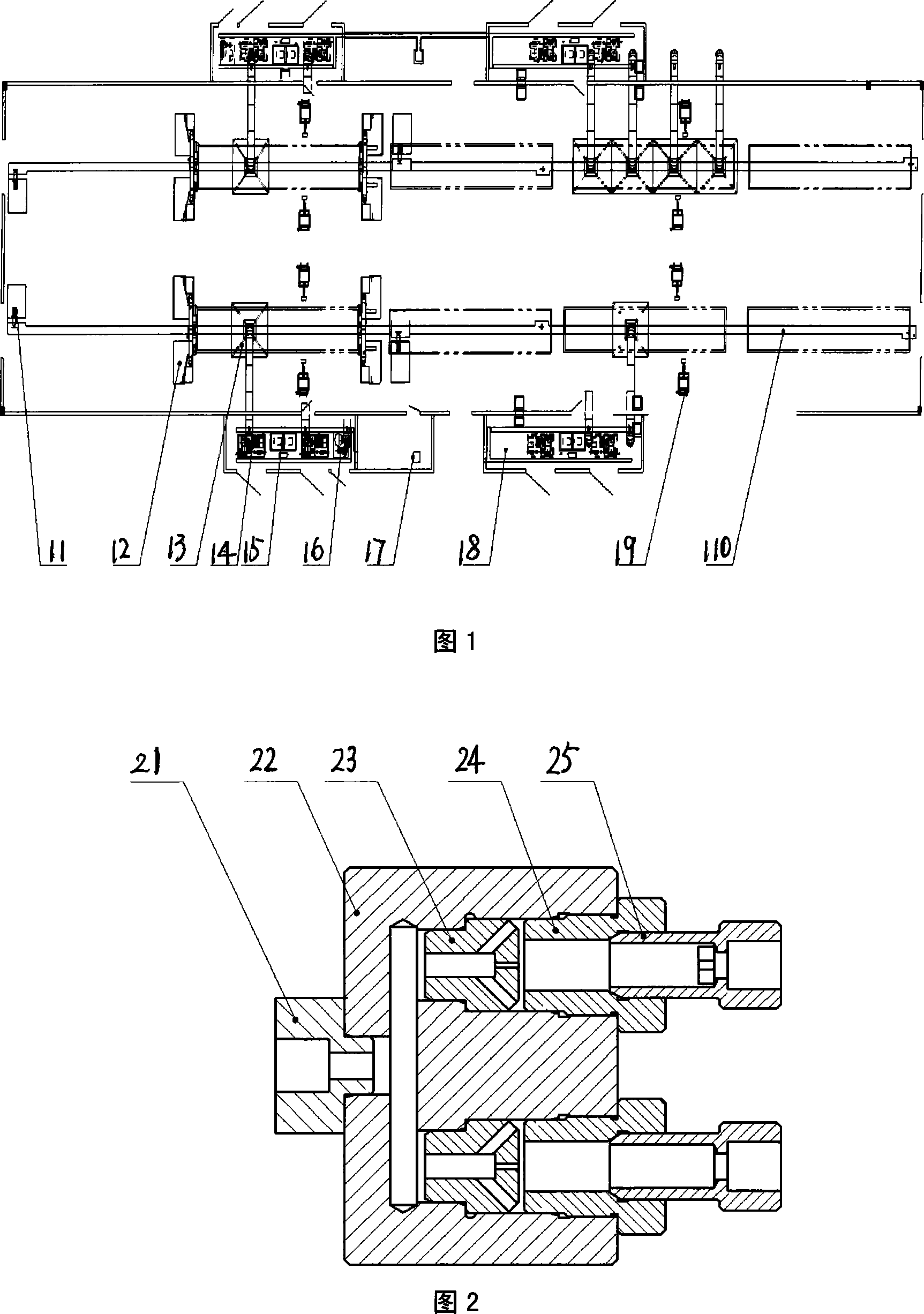

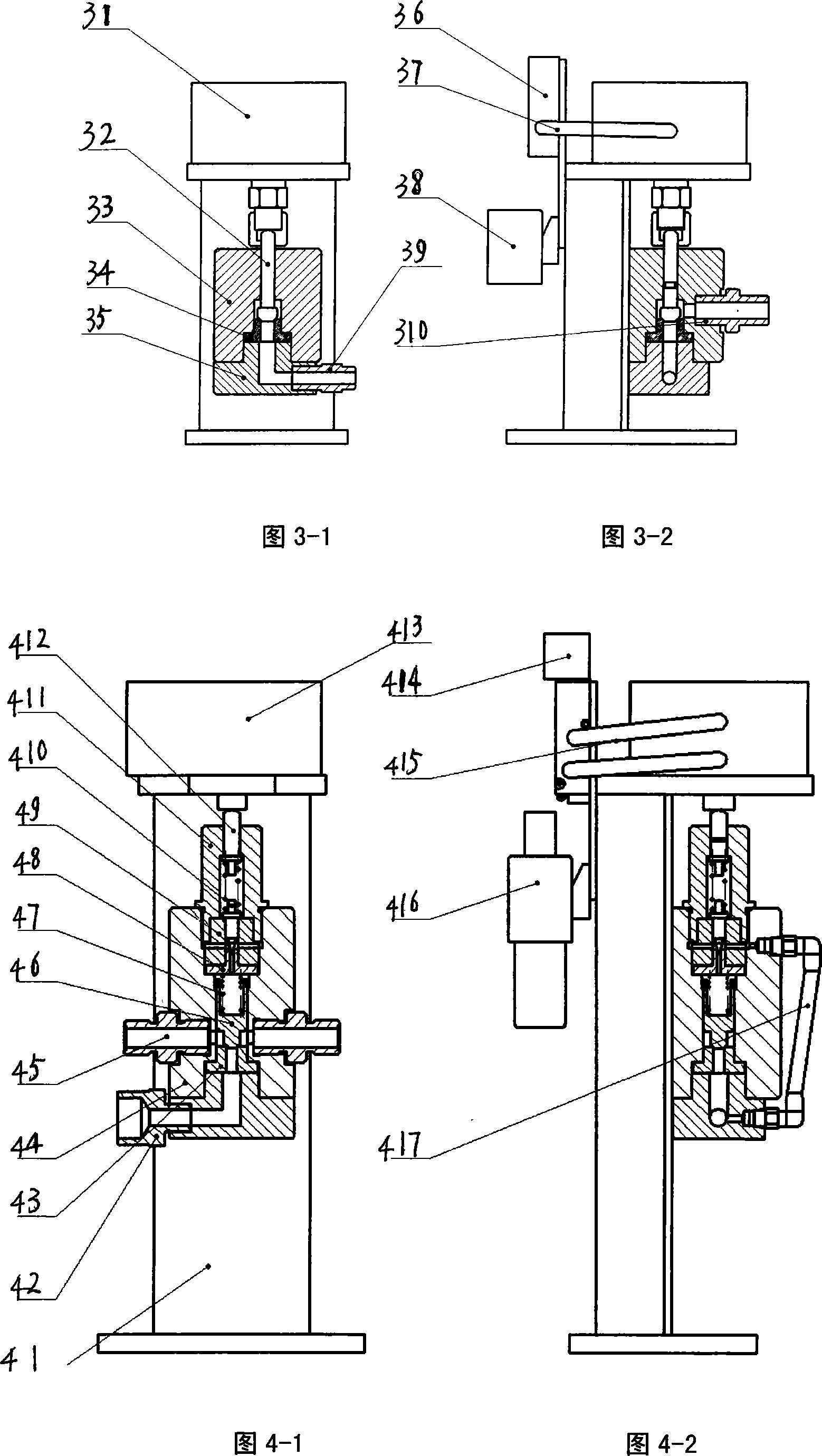

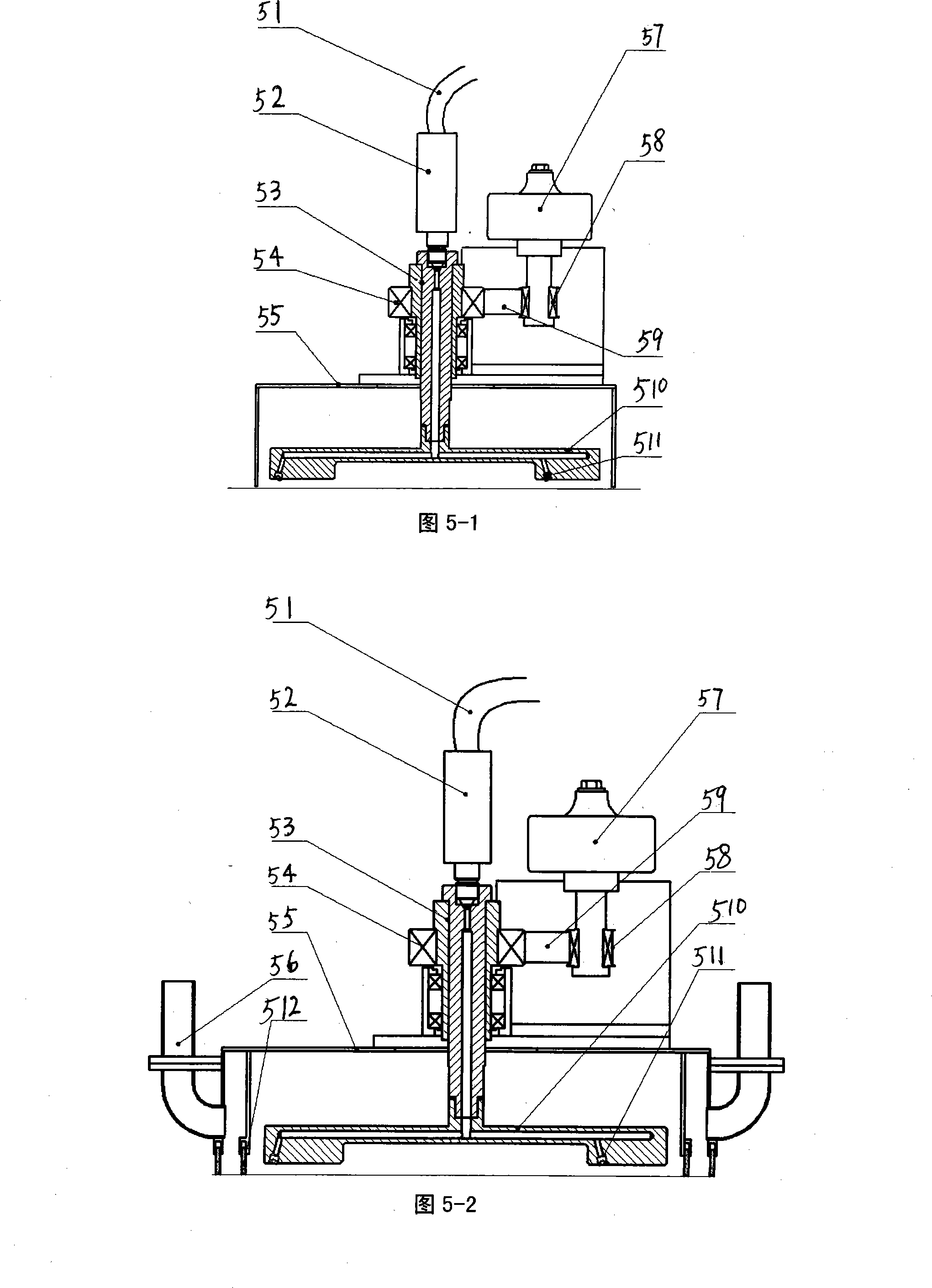

[0025] 1. High-pressure water jet derusting production line for trucks:

[0026] Including ultra-high pressure pump unit and its power and control system, water pool, ultra-high pressure pump unit includes motor, reducer, frequency converter and ultra-high pressure pump, frequency converter is used to control the motor speed, and then control the ultra-high pressure pump, ultra-high pressure pump The front centrifugal pump and precision filter are installed before the import; the ultra-high pressure pump is connected with high-pressure water jet cleaning equipment through ultra-high pressure hose and control valve. Install without / with a cover, the cover is installed on the outside of the spray rod of the rotary nozzle, and the edge of the cover is fixed with an elastic ring. The casing is connected to the vacuum recovery system. The vacuum recovery system consists of a vacuum pump unit, a vacuum tank, valves and pipelines, and a control system. The vacuum pump and sewage pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com