Coil steel surface cleaning equipment for production of elevator guide rail bracket

A technology for surface cleaning and elevator guide rails, which can be applied to cleaning methods using tools, cleaning methods using gas flow, metal processing equipment, etc. It can reduce the labor intensity of workers, improve the rust removal effect, and improve the finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

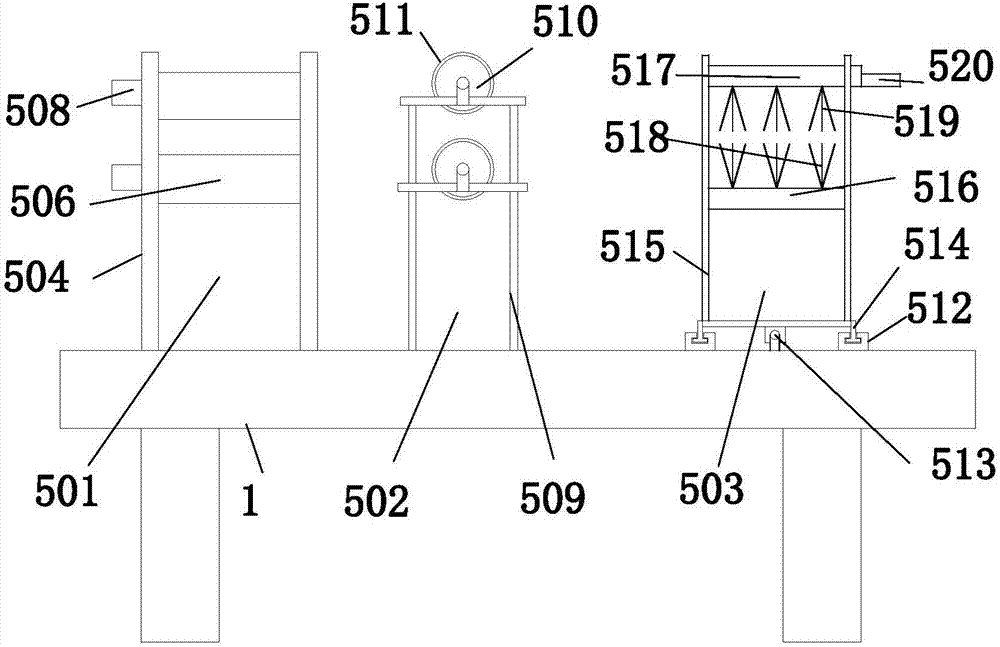

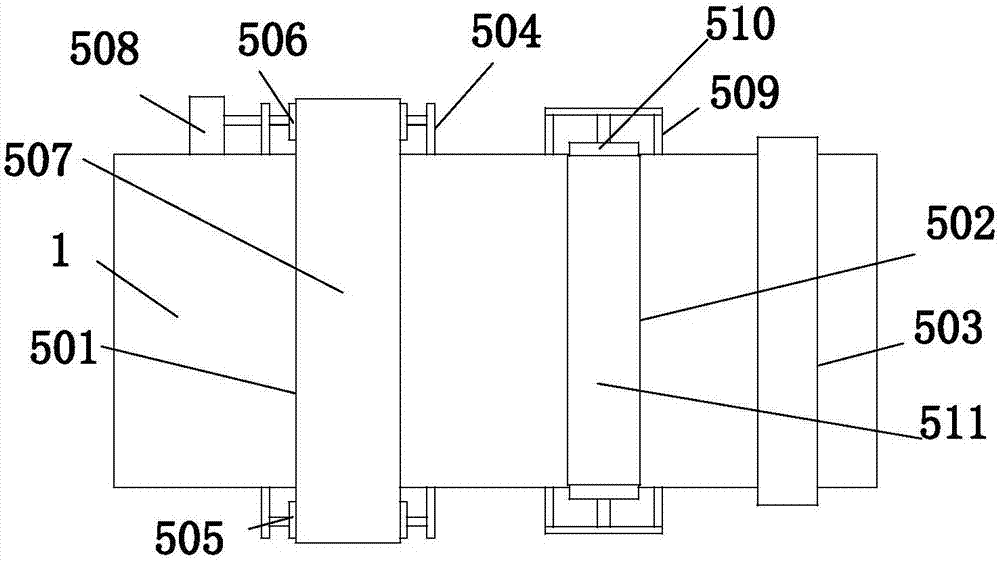

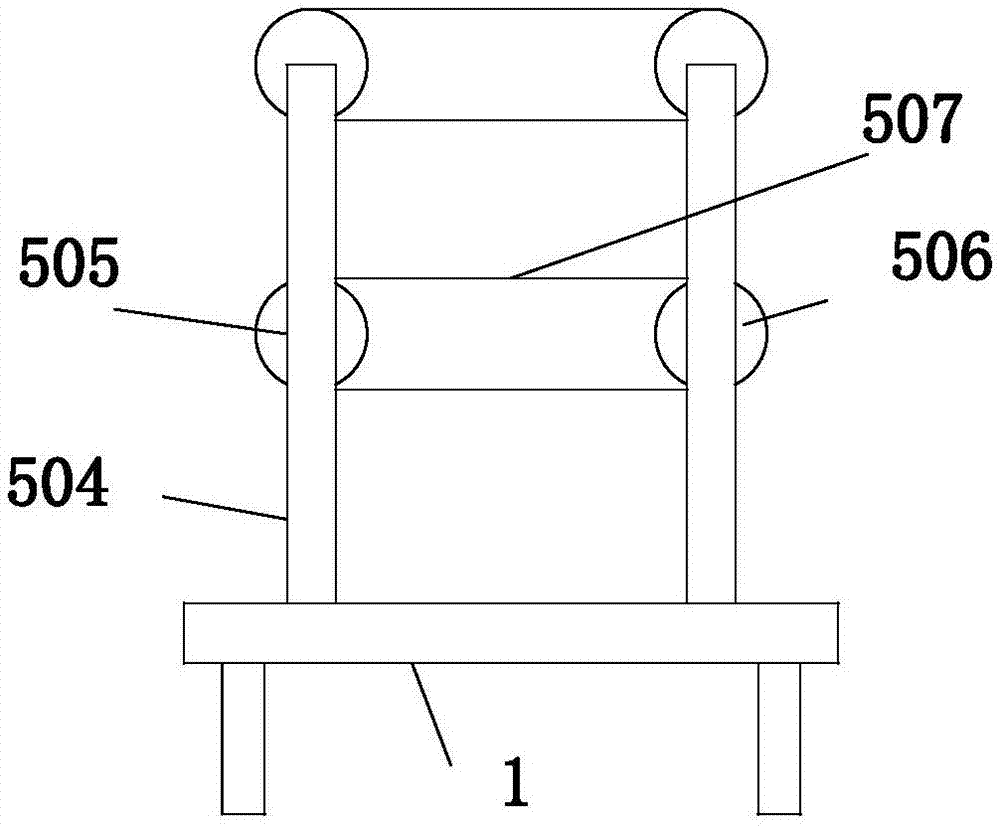

[0016] Example. A coiled steel surface cleaning equipment for producing elevator guide rail brackets, which is composed of Figure 1 to Figure 3 As shown, a frame 1 is included, and the frame 1 is successively provided with a longitudinal cleaning mechanism 501, a horizontal cleaning mechanism 502 and a surface cleaning mechanism 503; 504, two longitudinal sanding devices arranged up and down between two adjacent longitudinal supports 504, the longitudinal sanding devices include driven rollers 505 and driving rollers 506 respectively arranged on the two longitudinal supports 504 An abrasive belt 507 is provided between the driving roller shaft 506 and the driven roller shaft 505 , and the driving roller shaft 506 is connected with a rotating motor 508 .

[0017] The frosting directions of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com