Treatment device for realizing continuous derusting work of steel rail for rail inner side cleaning

A treatment device and track technology, applied in the field of track cleaning, can solve the problems of poor derusting effect and lack of continuous working ability of rail derusting, so as to avoid collision and improve the quality of derusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

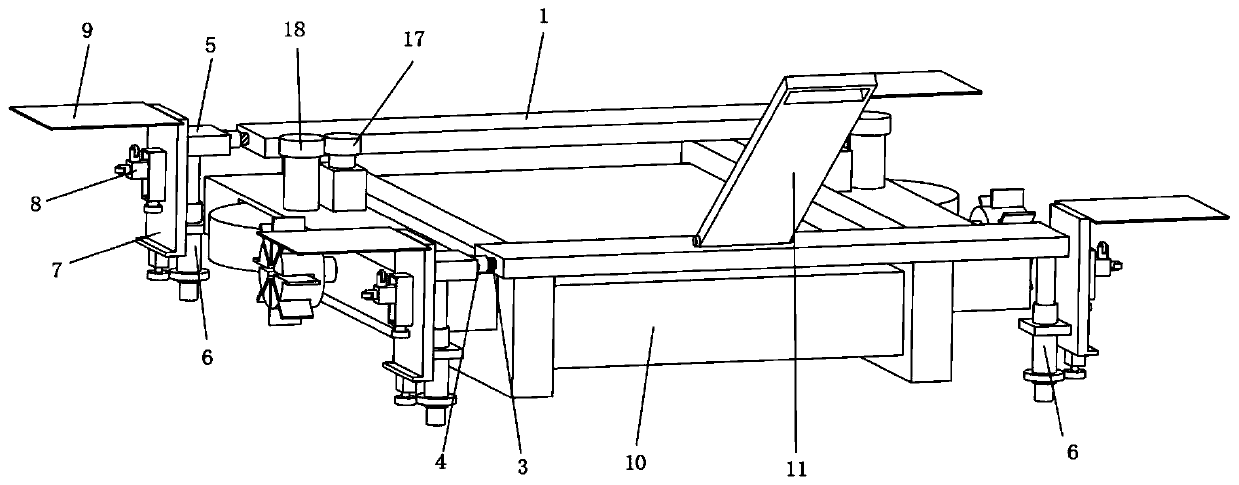

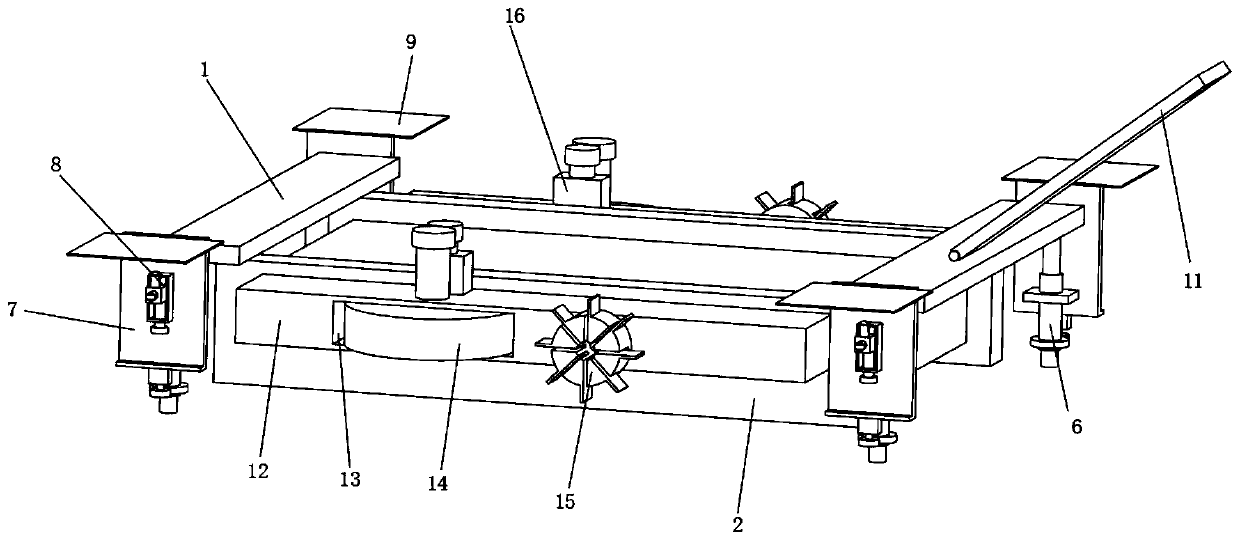

[0040] Such as Figure 1-4 As shown, the present invention provides a technical solution: a processing device for realizing the continuous derusting work of rails for track internal measurement and cleaning, including a supporting top plate 1 and a side mounting plate 2, and two supporting top plates 1 are respectively fixed on two On the front and rear sides of the top of the side mounting plate 2, the left side of the support top plate 1 is fixedly connected with a support screw 3, and the outside of the left side of the support screw 3 is sleeved and threadedly connected with an adjusting thread sleeve rod 4, and the adjustment thread sleeve rod 4 The left side is rotationally connected with an adjustment mounting plate 5, and the left side of the adjustment mounting plate 5 and the right side of the supporting top plate 1 are fixedly connected with a lifting adjustment mechanism 6, and the output end of the lifting adjustment mechanism 6 is fixedly connected with a walking ...

Embodiment 2

[0044] Such as Figure 5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a processing device for realizing the continuous derusting work of rails for track internal measurement cleaning. The lifting adjustment mechanism 6 includes a transmission threaded rod 61, and a transmission threaded rod 61 The top of the top is fixedly connected with the support top plate 1, the outside of the transmission threaded rod 61 is sheathed and threaded with a transmission sleeve rod 62, the outside of the transmission sleeve rod 62 is connected with an auxiliary support plate 63, and the outer side of the auxiliary support plate 63 is connected to the walking side plate 7 fixed connection

[0045] Drive sleeve bar 62 is fixedly connected with driven gear 64 near the outer side below, and the bottom of walking side plate 7 is fixedly connected with the 3rd driving motor 65, and the output shaft of the 3rd driving motor 65 is fixedly connected with d...

Embodiment 3

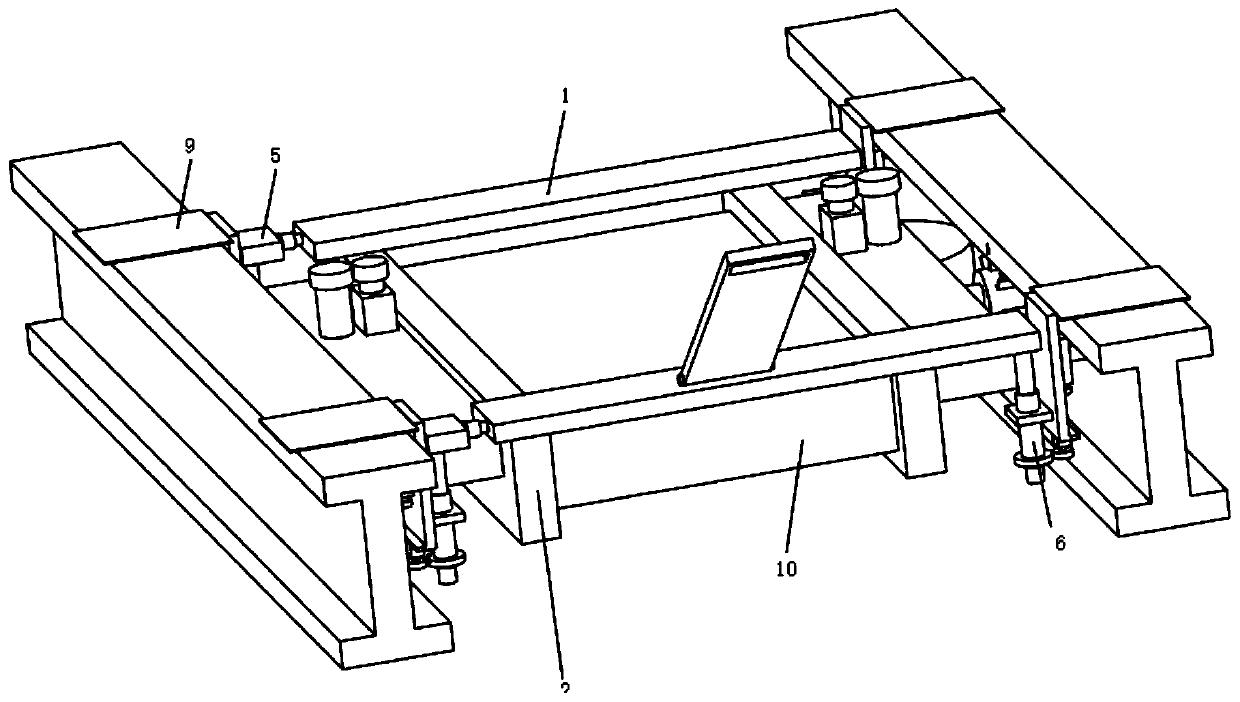

[0047] Such as Figure 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a processing device for realizing the continuous derusting work of rails for internal measurement and cleaning of rails. The inner side of the track 81 is fixedly connected with the walking side plate 7, and the position inside the limit track 81 is slidably connected with an adjustment slider 82, and the vertical position inside the limit track 81 is penetrated and rotated and connected with an adjustment bolt 83. The adjustment bolt 83 One end located inside the limiting track 81 is threadedly connected with the adjusting slider 82 .

[0048] The top running wheel 84 is fixedly connected to the top end of the adjusting slider 82 outside the limiting track 81 , and the side limiting wheel 85 is fixedly connected to the side of the adjusting slider 82 outside the limiting track 81 . The device can move smoothly along the top of the inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com