Power transmission line inspection device

A power transmission line and electric power technology, which is applied in the field of power transmission line inspection devices, can solve the problems of affecting the acquisition accuracy of a camera mechanism, adversely affecting the quality of inspection, and traveling no longer reliably, so as to improve the quality of rust removal, improve stability, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

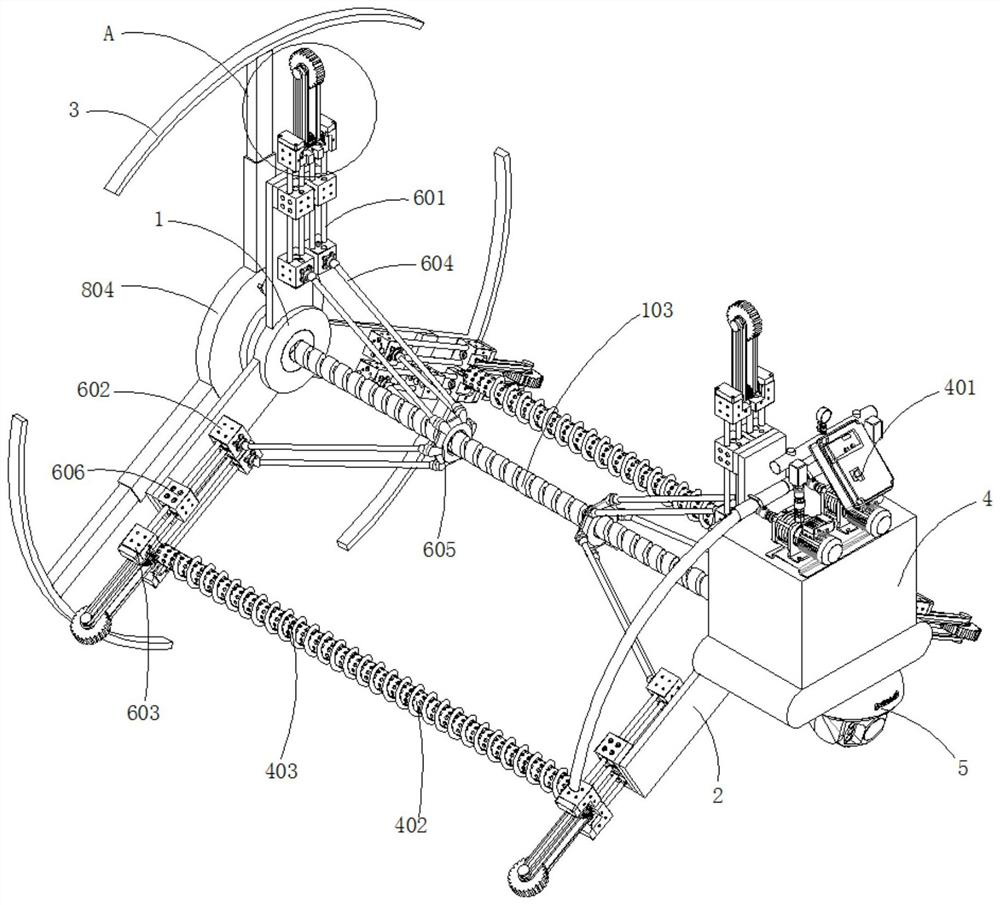

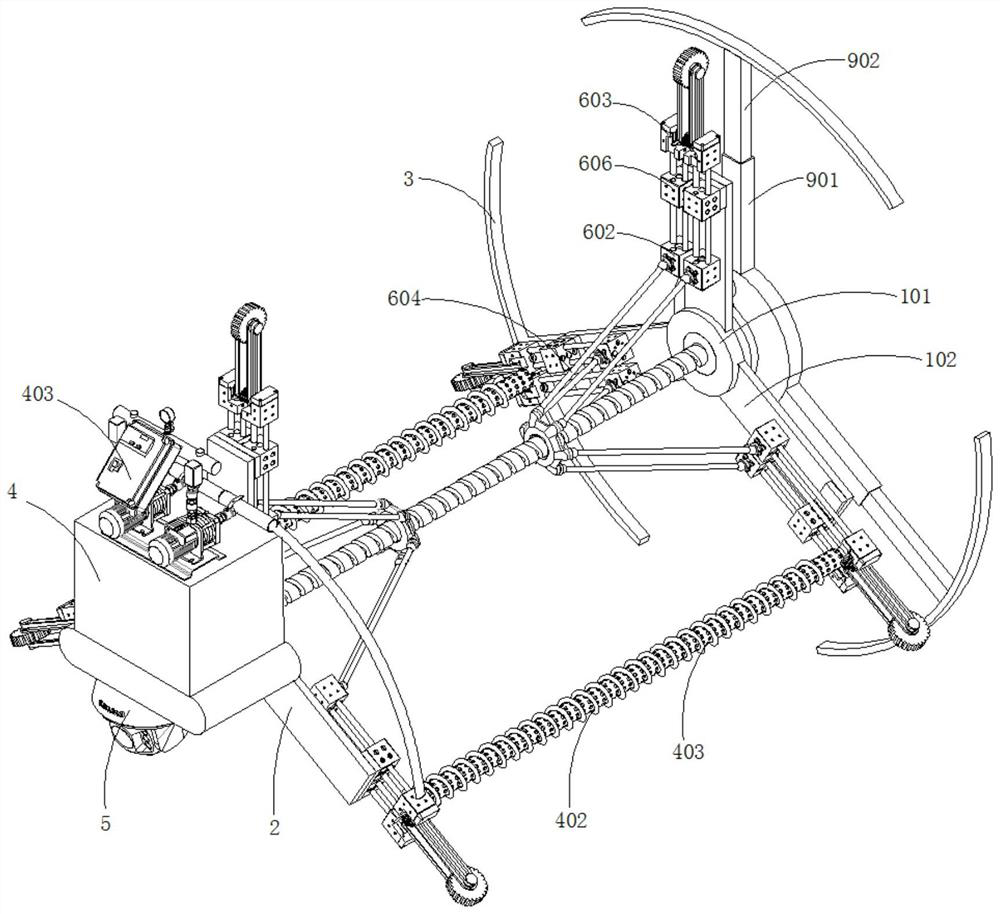

[0040] refer to Figure 1-6 , a power transmission line inspection device, including a controller, a first substrate 1 and a second substrate 2, the first substrate 1 and the second substrate 2 are composed of a central board 101 and a connecting board 102, and the connecting board 102, etc. The distance is distributed on the outer edge of the central plate 101, and the driving screw 103 is connected between the central plates 101;

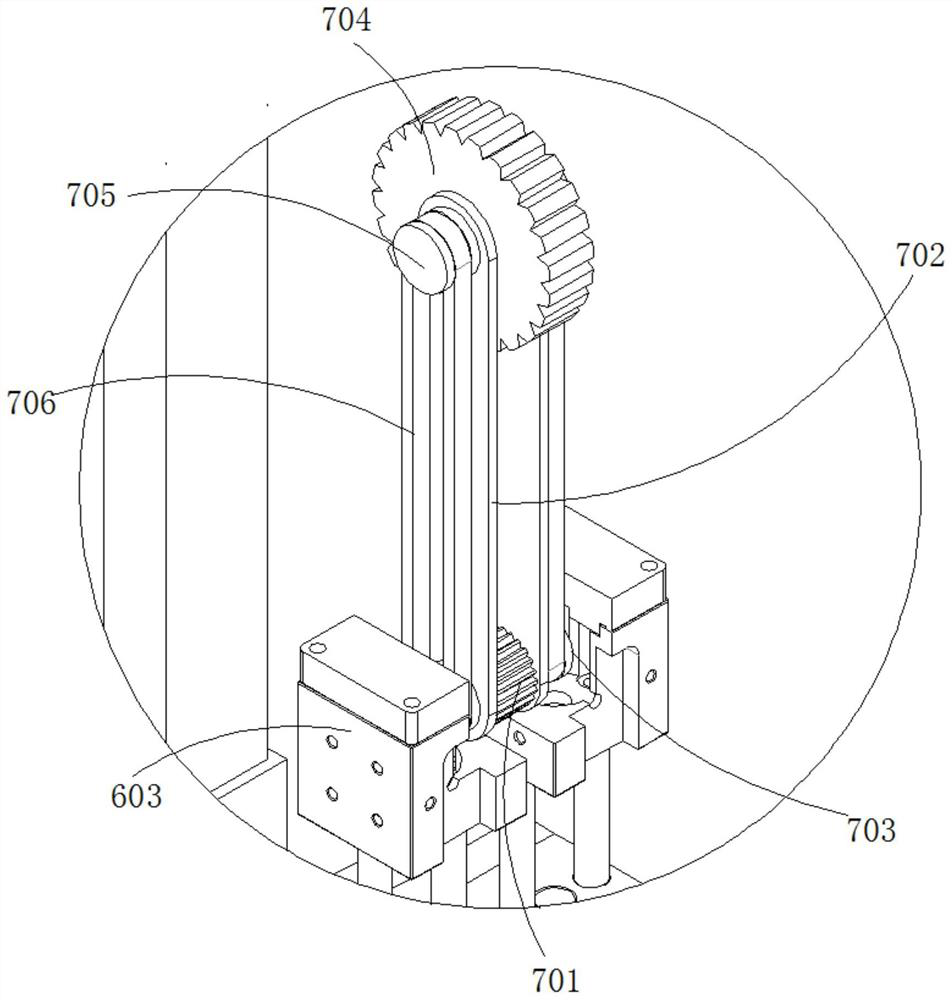

[0041] The end of the connecting plate 102 is fixedly connected with a limit block 606, and the limit block 606 is slidably connected with a telescopic adjustment assembly;

[0042] The adjustment end of the telescopic adjustment assembly is connected with a drive wheel assembly that matches the inner wall of the pipeline;

[0043] The side of the center plate 101 on the first substrate 1 away from the driving screw 103 is connected with a reciprocating mechanism, and the driving end of the reciprocating mechanism is connected with a telescopic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com