Automatic feeding device for lift guide rail bracket production

A technology of automatic feeding and elevator guide rails, applied in metal extrusion cleaning equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of affecting the turning speed, steel plate damage, high labor intensity, etc., and achieve convenient transportation. and installation, fast delivery and installation, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

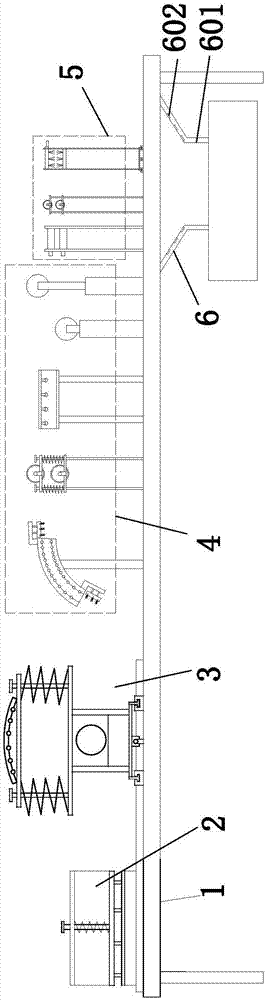

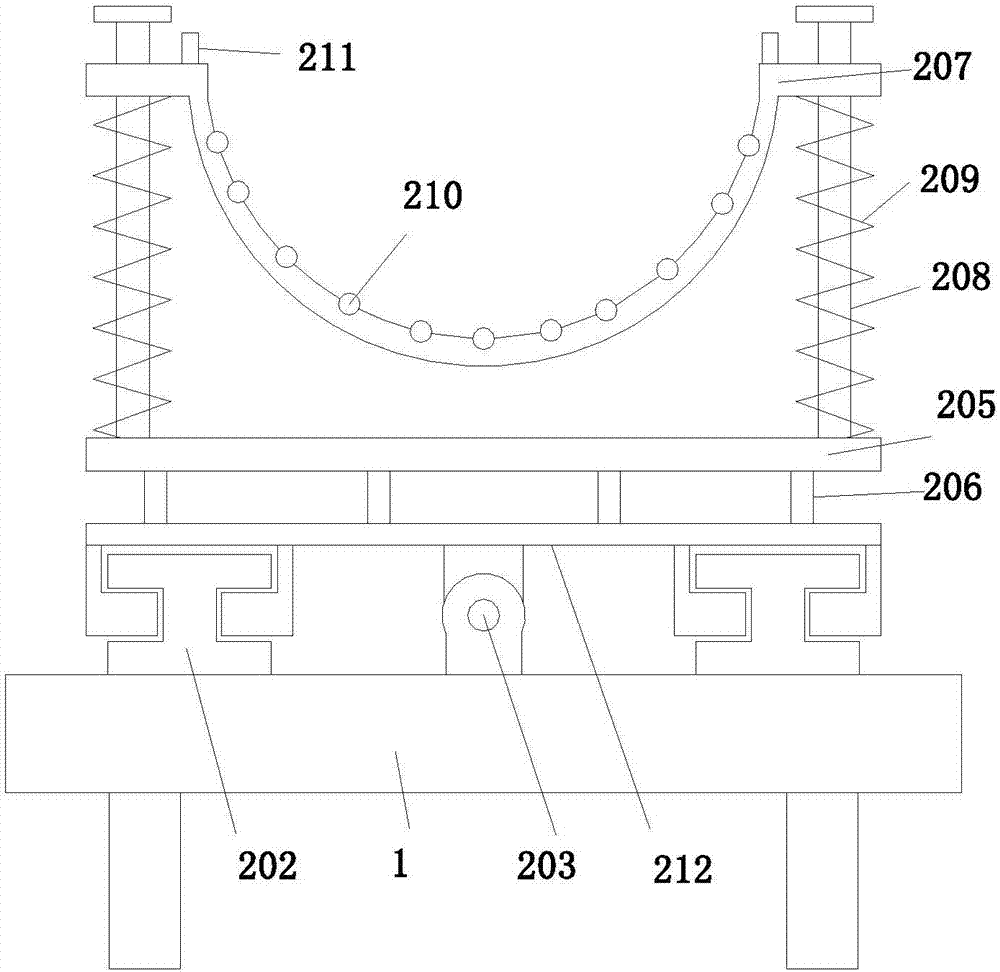

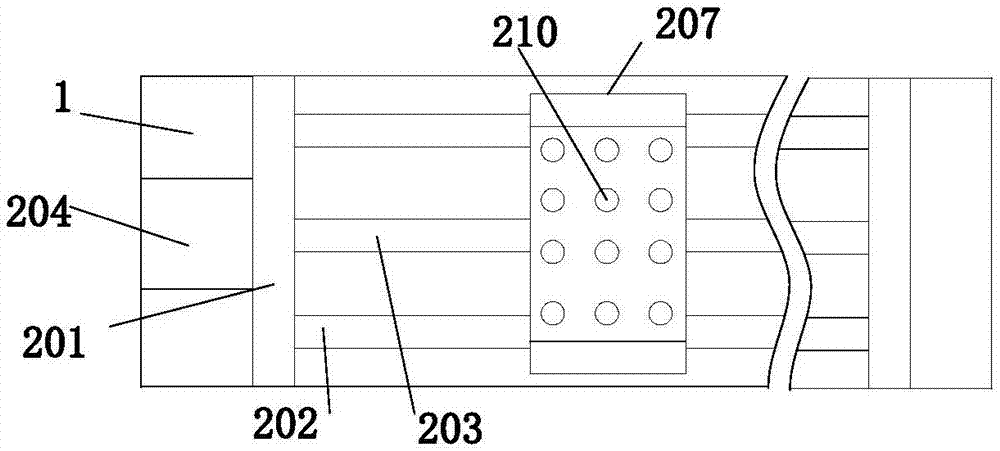

[0035] Example. An automatic feeding device for producing elevator guide rail brackets, which is composed of Figure 1 to Figure 14 , comprising a frame 1, the frame 1 is successively provided with a coil conveying device 2, a coil turning device 3, a straightening device 4 and a coil surface cleaning device 5, and a waste recovery device 6 is arranged below the coil surface cleaning device 5 The waste recycling device 6 includes a tapered recovery bucket 601 fixed on the frame 1 and positioned below the steel coil surface cleaning device 5, and the inner surface of the tapered recovery bucket 601 is evenly provided with a plurality of electromagnets 602; The coil conveying device 2 is connected with a controller 7, and the controller 7 is connected with the coil turning device 3, the coil surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com