Rust removal device of environment-friendly steel pipe end surface

An environment-friendly, clearing device technology, applied in machine tools suitable for grinding the plane of the workpiece, machine tools designed for grinding the rotating surface of the workpiece, grinding machines, etc., can solve the problems of low grinding efficiency, physical injury of workers, engineering losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is realized through the following technical solutions:

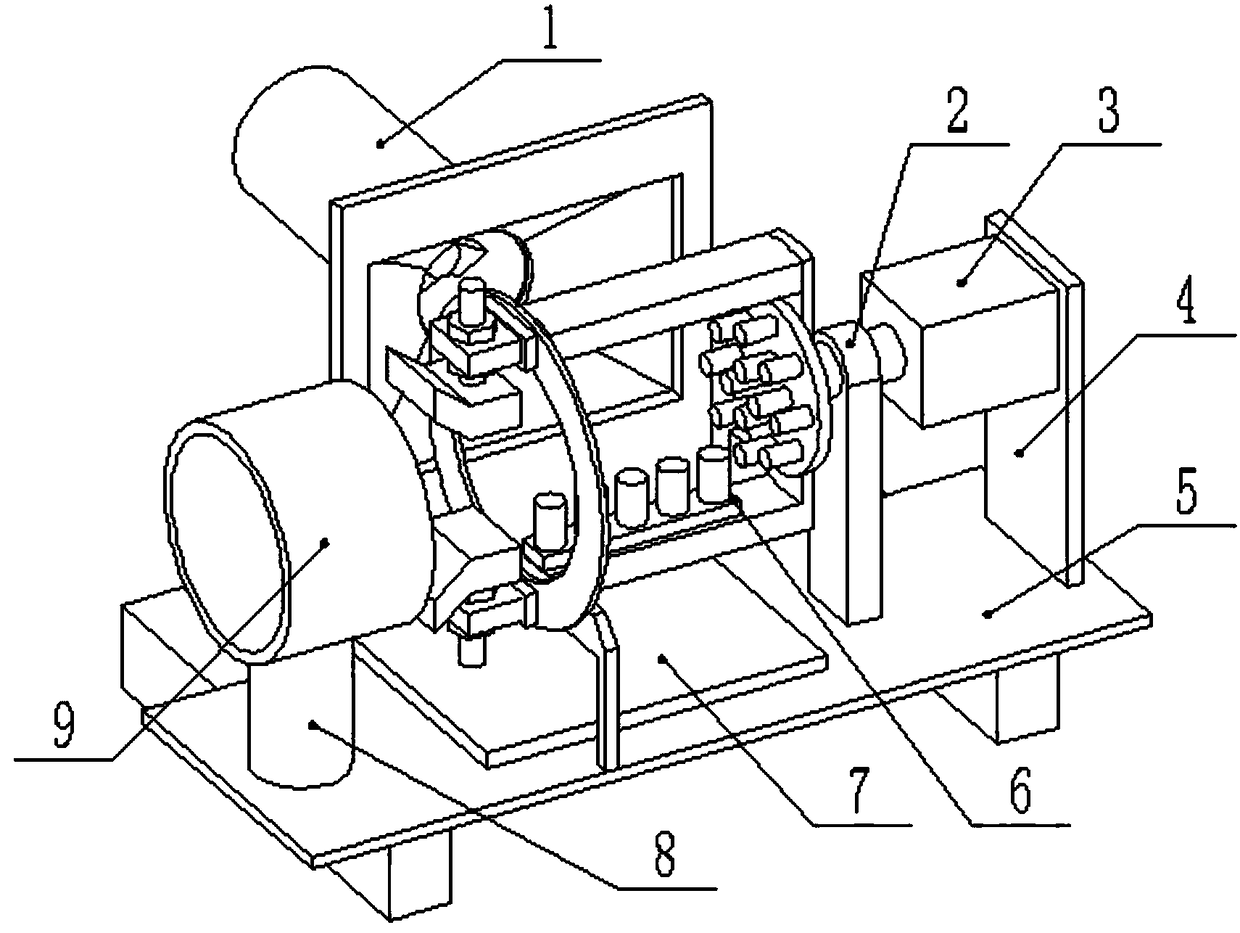

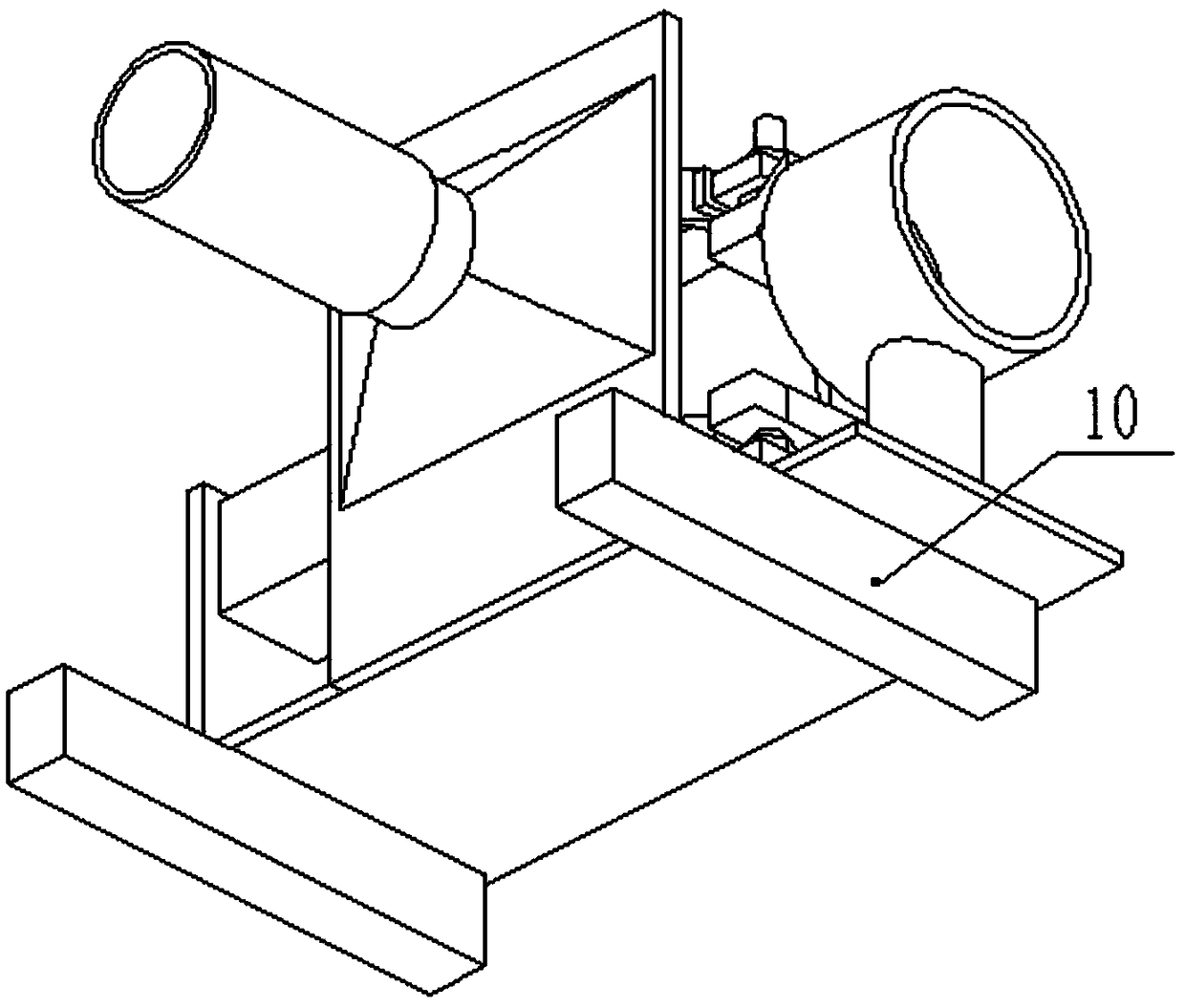

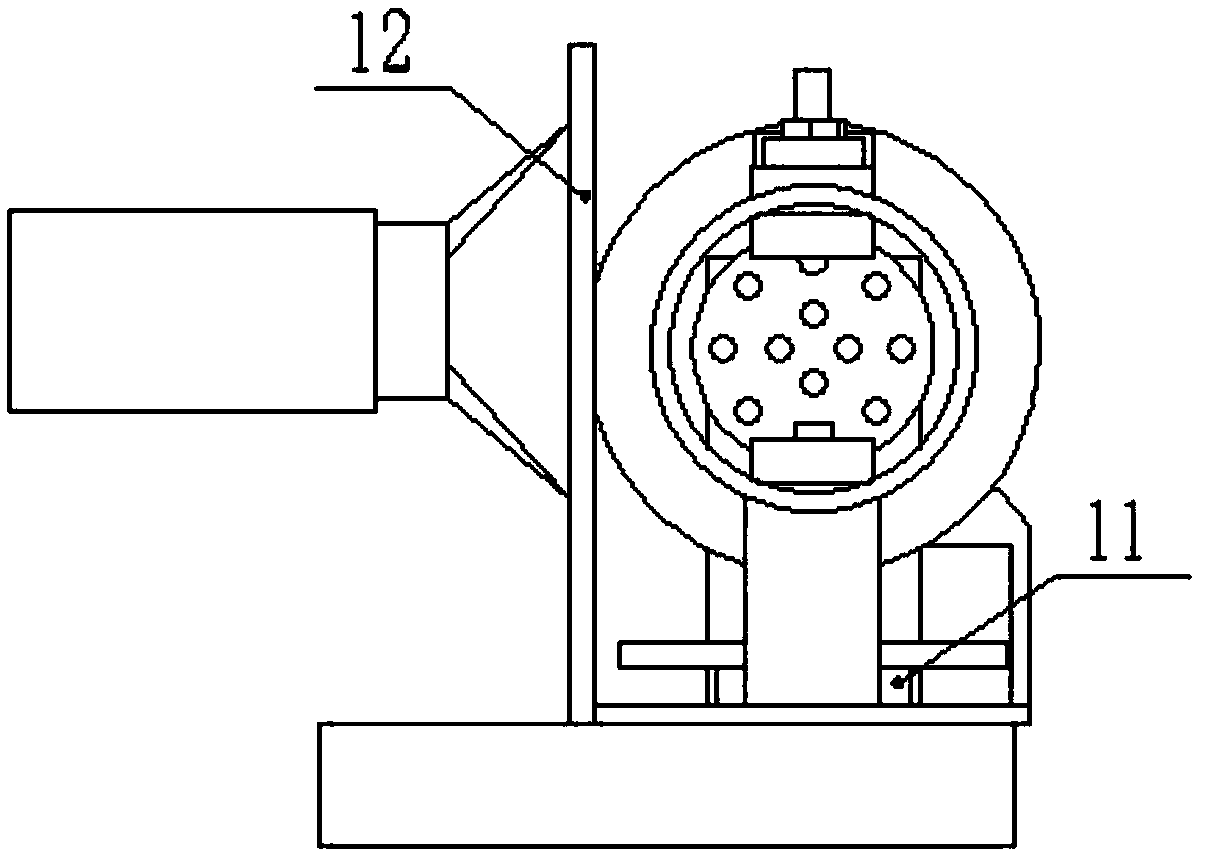

[0019] An environment-friendly rust removal device for the end of a steel pipe, including an exhaust device 1, a spindle support 2, a motor 3, a motor base 4, a workbench 5, a grinding device 6, a magnet 7, a first support 8, and a limit support 9 , legs 10, second bracket 11 and third bracket 12, the exhaust device 1 is fixed behind the third bracket 12, used to absorb the toxic gas generated during the grinding process, and reduce the damage to the worker's body, the main shaft The support 2 is fixed on the top of the workbench 5, it is located between the motor 3 and the grinding device 6, and its top has a circular hole with an inner diameter of 0.5 cm. The motor 3 is fixed on the top of the motor base 4, and its main shaft passes through the main shaft support 2 The round hole on the top is connected with the grinding device 6, which is used to drive the grinding device 6 to rotate so as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com