Steel structure shot blasting and rust removing method

A technology of steel structure and cast steel shot, which is applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficacy and small number of projectiles, and achieve the effect of improving efficacy, improving adhesion, and ensuring surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

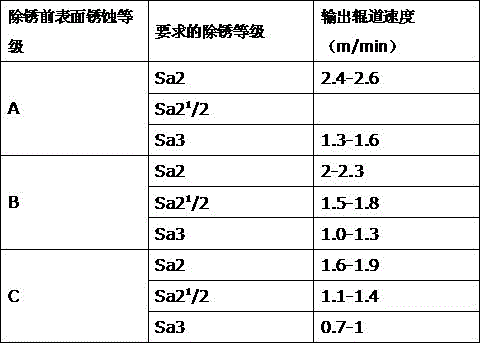

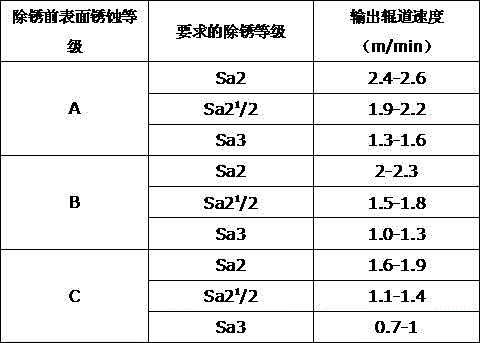

[0015] Steel structure shot blasting derusting is to use the shot blasting machine of the shot blasting machine to throw the dense projectiles thrown from different directions on the surface of the steel to remove the oxide skin, rust layer and dirt on it and obtain a certain surface roughness. Rust removal method. In a typical implementation, the steel structure shot blasting derusting method includes the selection and grading of projectiles, the control of shot blasting time and the adjustment of shot angle.

[0016] 1. Selection and grading of projectiles

[0017] The surface roughness of the steel structure before painting has a great influence on the adhesion of the coating. If the surface roughness is too small, the paint film lacks the necessary anchor points, and the adhesion after complete curing is small, and the coating may be damaged early. Peeling, cracking or delamination, etc. If the surface roughness is too large and the amount of paint film is constant, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com