Patents

Literature

42results about How to "Reduce rust removal costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

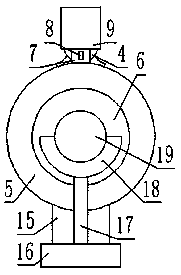

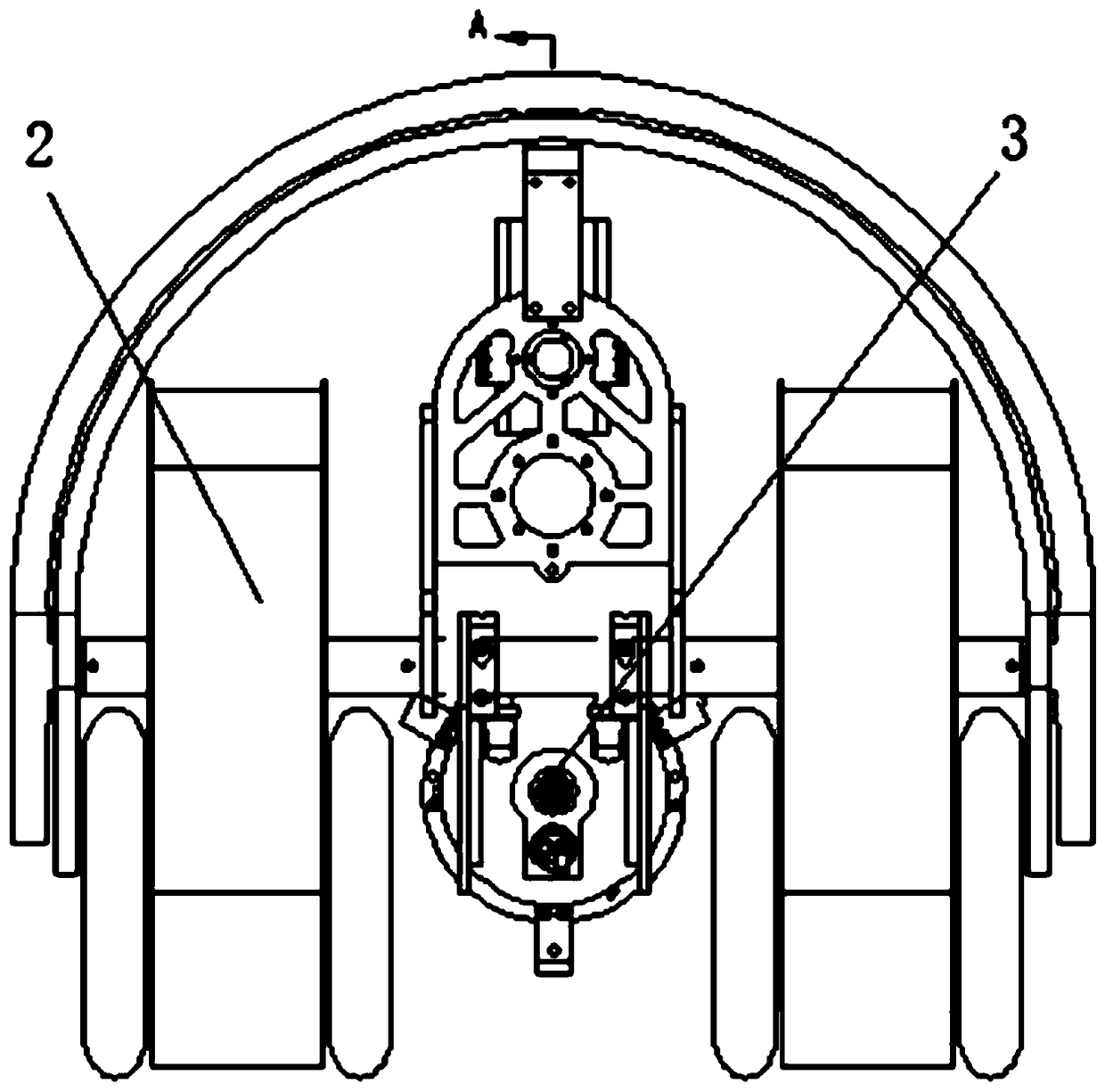

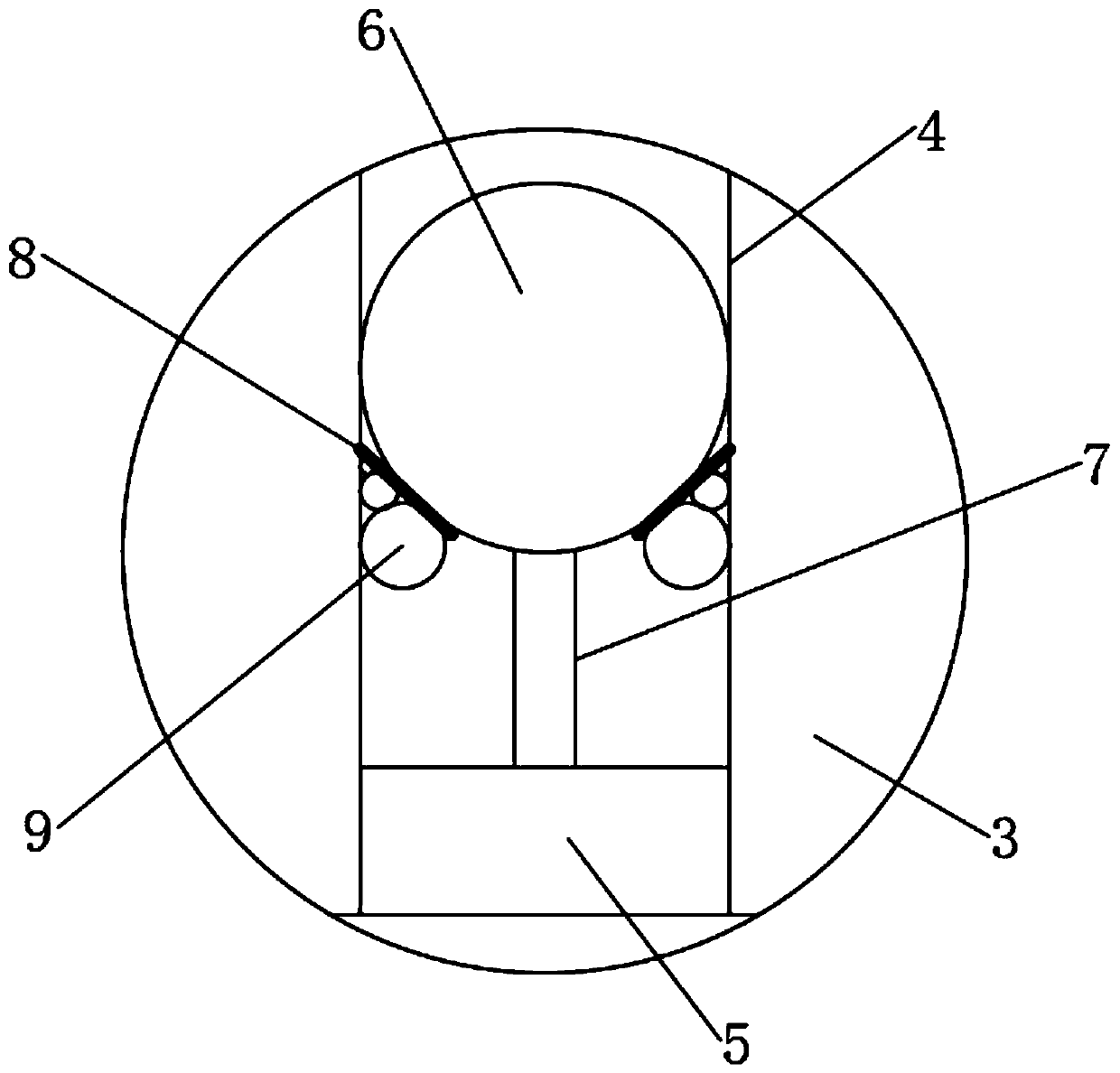

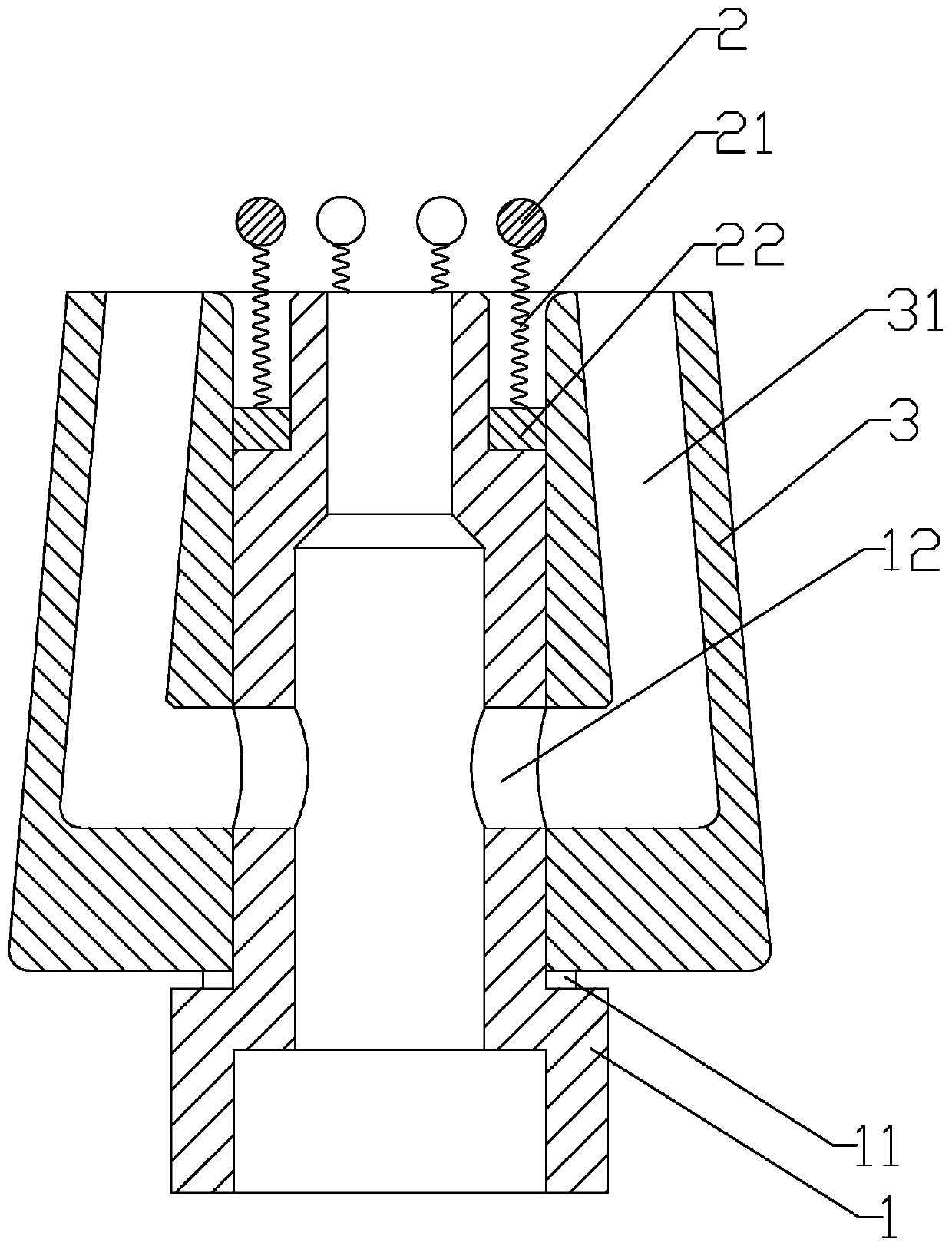

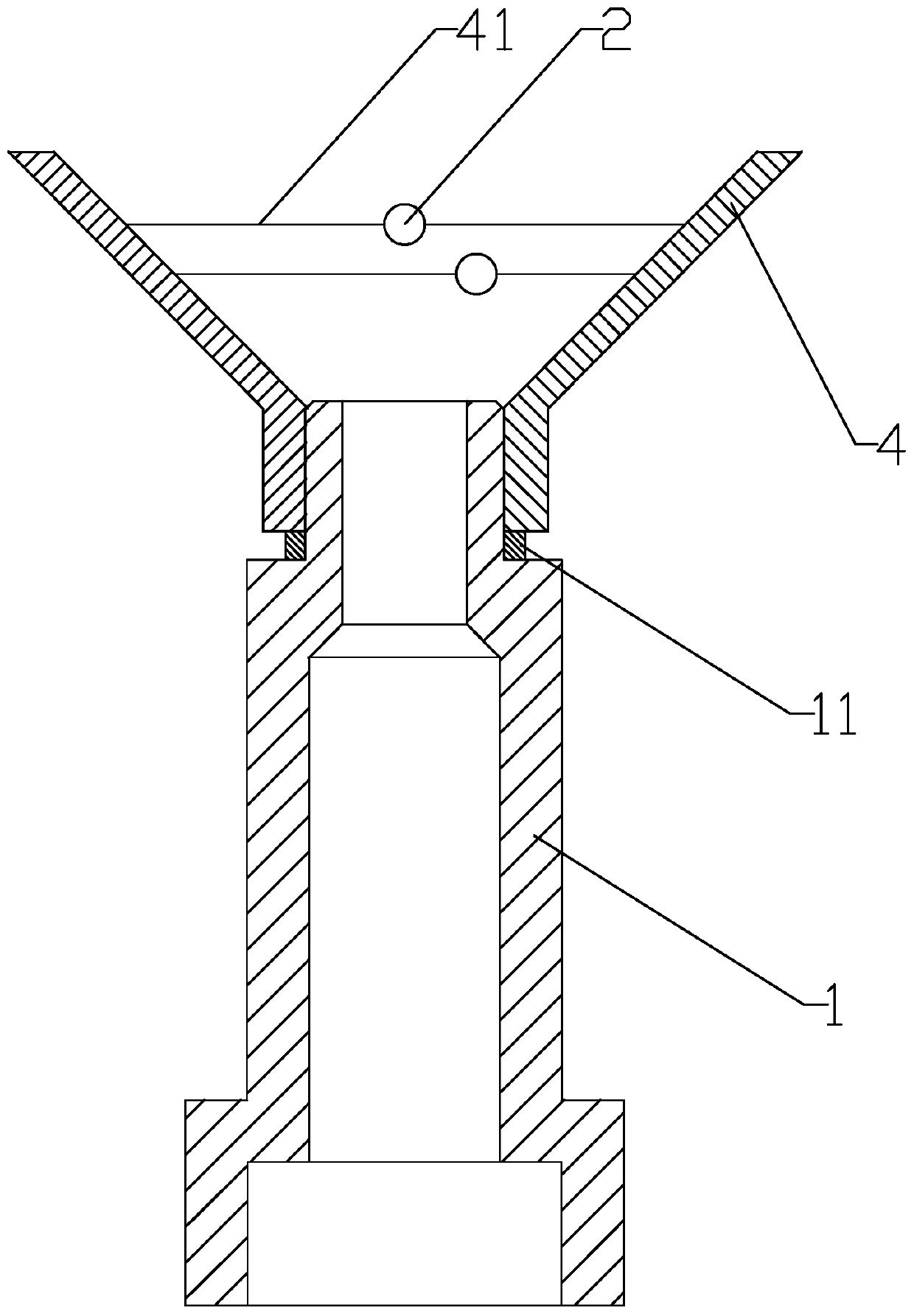

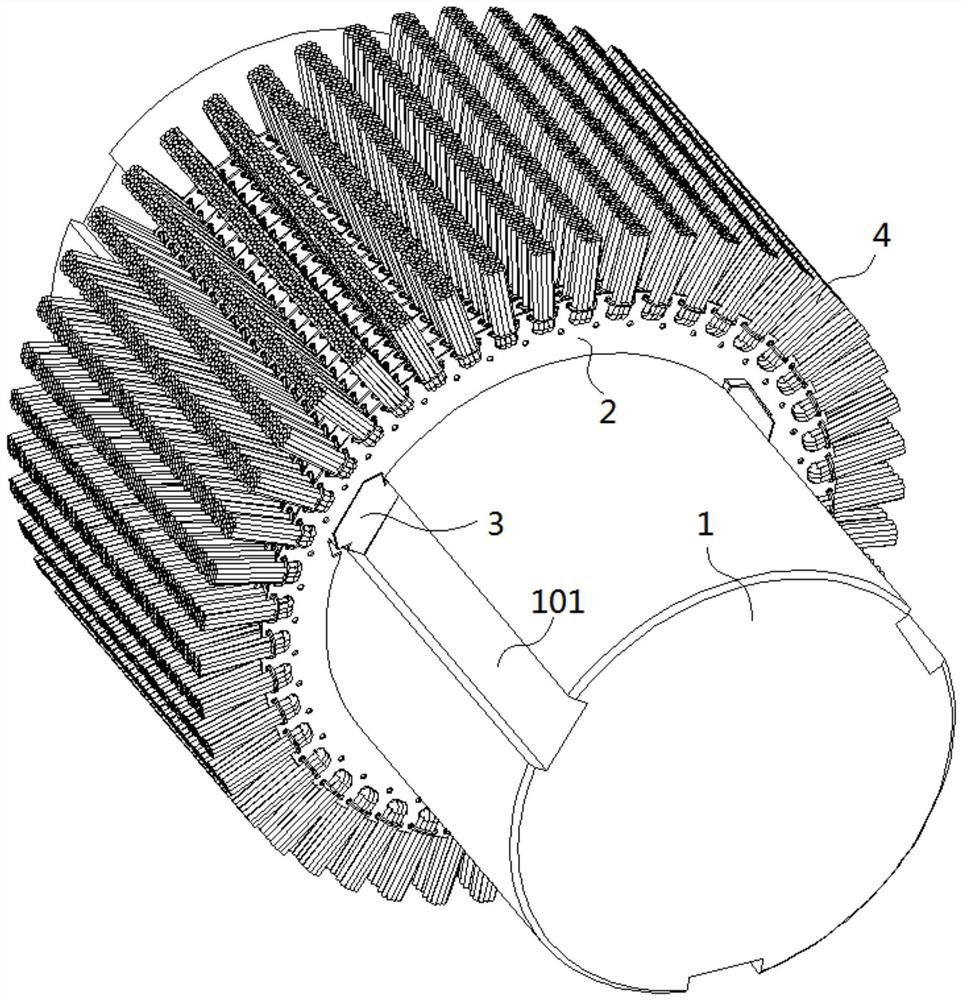

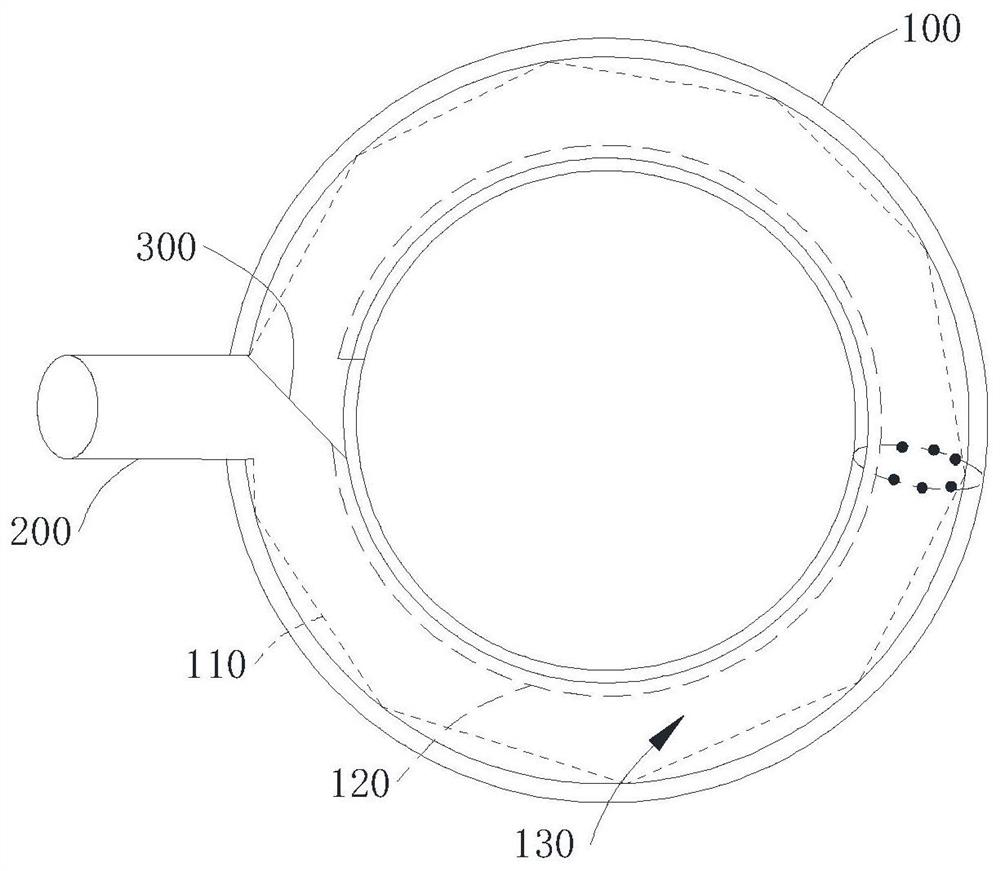

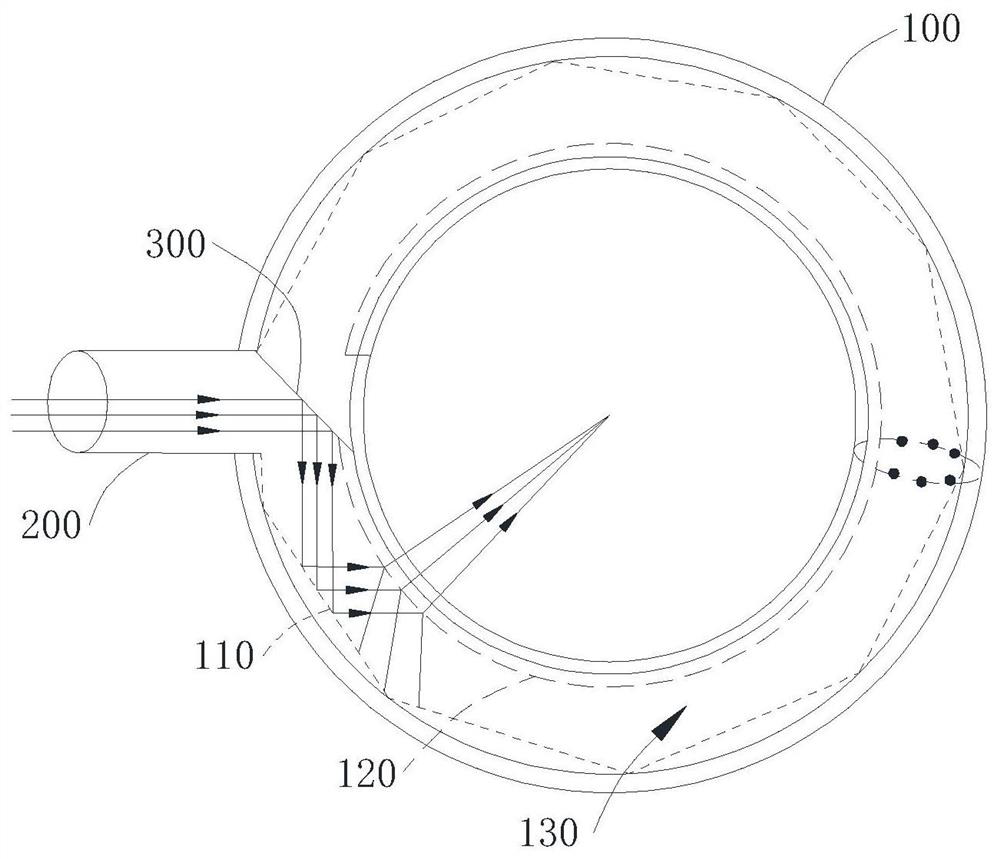

Centring and self-generating fixing device for environment-friendly steel pipe rust removal

ActiveCN110883668AEven contactTo achieve a calming effectGrinding drivesGrinding machinesEngineeringMechanical engineering

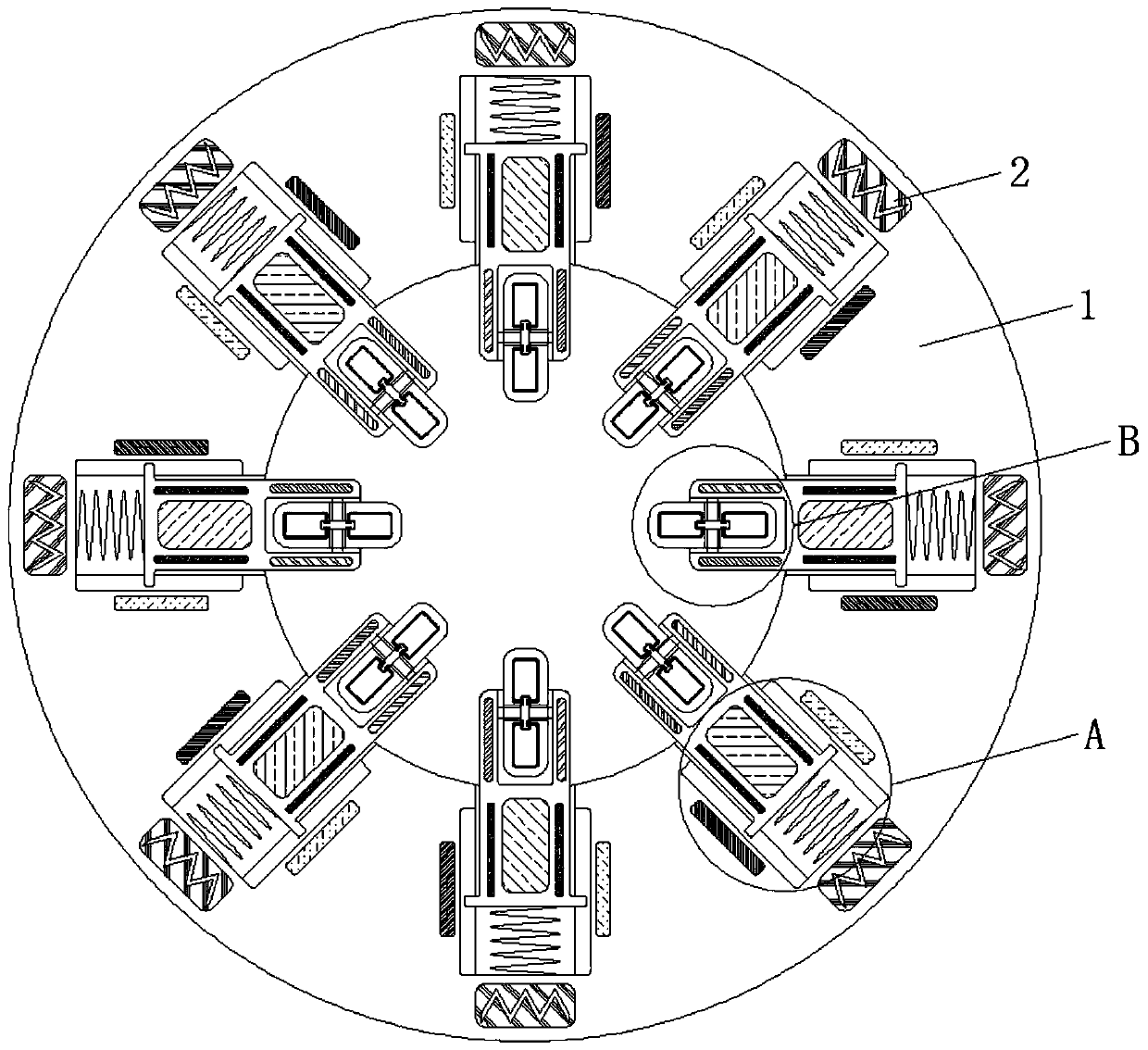

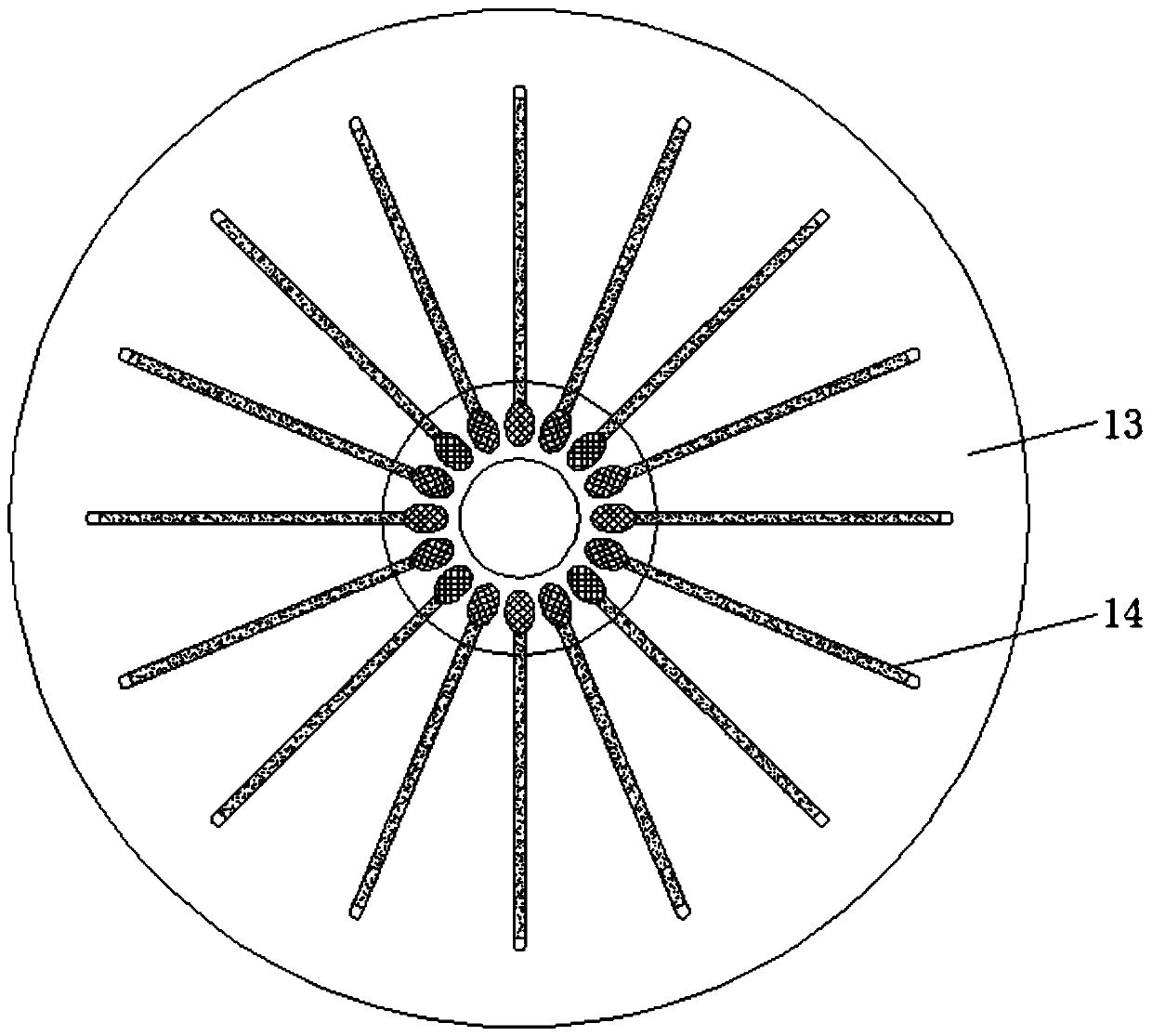

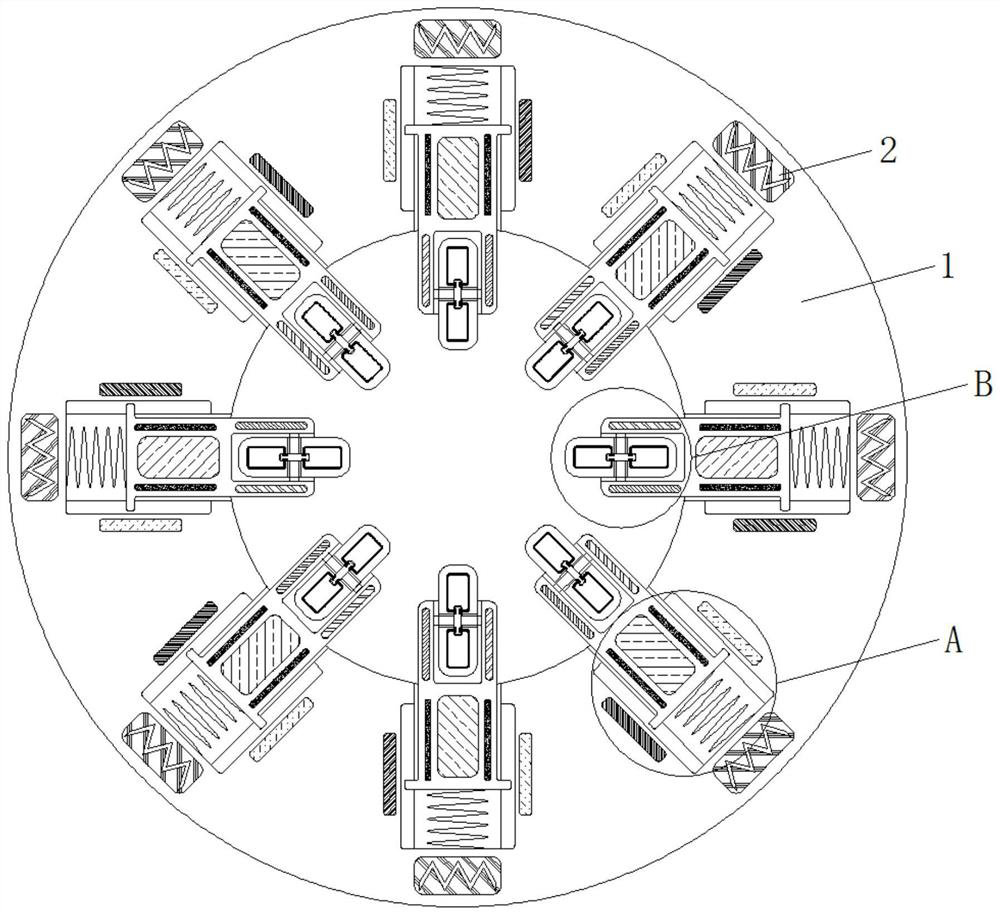

The invention provides a centring and self-generating fixing device for environment-friendly steel pipe rust removal relates to the technical field of environmental protection. The device comprises afixing pipe, an inner wall of the fixing pipe is fixedly connected with uniformly distributed electromagnetic devices 1, and the inner wall of the fixing pipe is provided with uniformly distributed movable grooves. According to the fixing device, the electromagnetic devices 2 and electromagnetic devices 2 are matched for use, since all the electromagnetic devices 1 have the same magnetism, the electromagnetic devices 2 have the same magnetism and the magnetism of inner sides of the electromagnetic devices 1 is the same as that of the outer sides of the electromagnetic devices 2, the electromagnetic devices 1 and the electromagnetic devices 2 repel each other, meanwhile, movable blocks can move towards the inner sides by the same length under the repulsive action of the electromagnetic devices 1 and the electromagnetic devices 2 such that rolling wheels are clamped and located in the center of the fixing pipe, the centering effect is achieved, the rust removal work is effectively guaranteed, an outer side of a steel pipe makes uniform contact with the rust removal device, and the rust removal quality is improved.

Owner:山东东正钢构有限公司

Metal rod derusting device

InactiveCN108555746AQuick clean upPrevent rustLiquid surface applicatorsCleaning using toolsBristleFuel tank

The invention discloses a metal rod derusting device. The device comprises a sleeve A, a rubber layer is attached to the inner wall of the sleeve A, a handle is fixed to the top surface of the sleeveA, a motor is fixed to the top surface of the sleeve A, an annular shell is fixed to one side surface of the sleeve A, multiple through holes are evenly formed in the inner annular surface of the annular shell, a sponge layer is attached to the inner annular surface of the annular shell, an oil inlet pipe is fixed to the top surface of the annular shell in a through mode, a valve is arranged on the middle part of the oil inlet pipe, an oil box is fixed to the top surface of the oil inlet pipe, the oil box is communicated with the oil inlet pipe, an annular groove is formed in the other side surface of the sleeve A, and the cross section of the annular groove is T-shaped. According to the device, the oil box and bristles are designed, rust on a metal rod can be fast cleaned off, moreover, through the sponge layer, rust protection treatment is conducted on the derusted metal rod in time, rusting is avoided, loss is reduced, an arranged semi-annular supporting frame can support the metalrod during derusting, use is simple and convenient, time and energy are saved, the derusting cost is reduced, the efficiency is high, and the device is practical and reliable.

Owner:苏州景欣净化彩板有限公司

Brightening rust removing agent

The present invention relates to a substance which removes rustiness on the surface of steel and iron, in particular to brightening rust remover, which solves the problem that the steel and the iron have gloomy surfaces after the rust removing in the prior art. The brightening rust remover is composed of materials in the following weight ratio: chlorhydric acid is 30-50 percent, hexamethylene tetramine is 1-5 percent, sodium lauryl sulphate is 2-8 percent, peregal OS-15 is 5-10 percent, and the residual is water. The present invention has the characteristics that rustiness can be removed quickly, the steel and the iron are brighter than the original state after the rustiness is removed, no over corrosion and hydrogen brittleness phenomenon exist, no pollution exists, and the cost is low, etc. Since the difference of the degrees of corrosion, the rustiness removing time is generally within 1-5 minutes.

Owner:山西银河镀锌有限公司

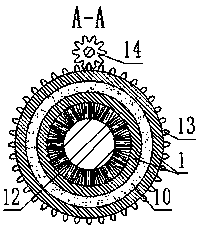

Large-inside-diameter steel pipe inner wall derusting device for machining

InactiveCN107263288AAchieve rust removalReasonable designRevolution surface grinding machinesGrinding drivesGear wheelDrive shaft

The invention discloses a large-inside-diameter steel pipe inner wall derusting device for machining. The device comprises a bottom plate, wherein a first shaft support is vertically and fixedly mounted on the bottom plate and is movably connected with a right end of a driving shaft; a first bevel gear is coaxially and fixedly mounted on the driving shaft; a second bevel gear is coaxially and fixedly mounted on an upper end of a driven shaft and is connected with the first bevel gear in a meshed manner; a rotating wheel is coaxially and fixedly mounted at a lower end of the driven shaft; a second shaft support is vertically and fixedly mounted on the bottom plate; a first connecting rod is horizontally arranged on the second shaft support in a horizontal sliding manner; a limiting roller is coaxially and fixedly mounted on the rotating shaft; a steel pipe for derusting is placed on the limiting roller; a derusting roller is fixedly mounted on the first connecting rod; steel wire brushes are uniformly arranged on a surface of the derusting roller; guiding wheels are fixedly mounted on the rotating roller in a sleeving manner and are pressed against an outer surface of the derusting roller. According to the device disclosed by the invention, axial and annular derusting effects on the inner wall of the steel pipe can be realized at the same time, so that the derusting effect on the inner wall of the steel pipe is preferable.

Owner:深圳市海帮国际商务服务有限公司

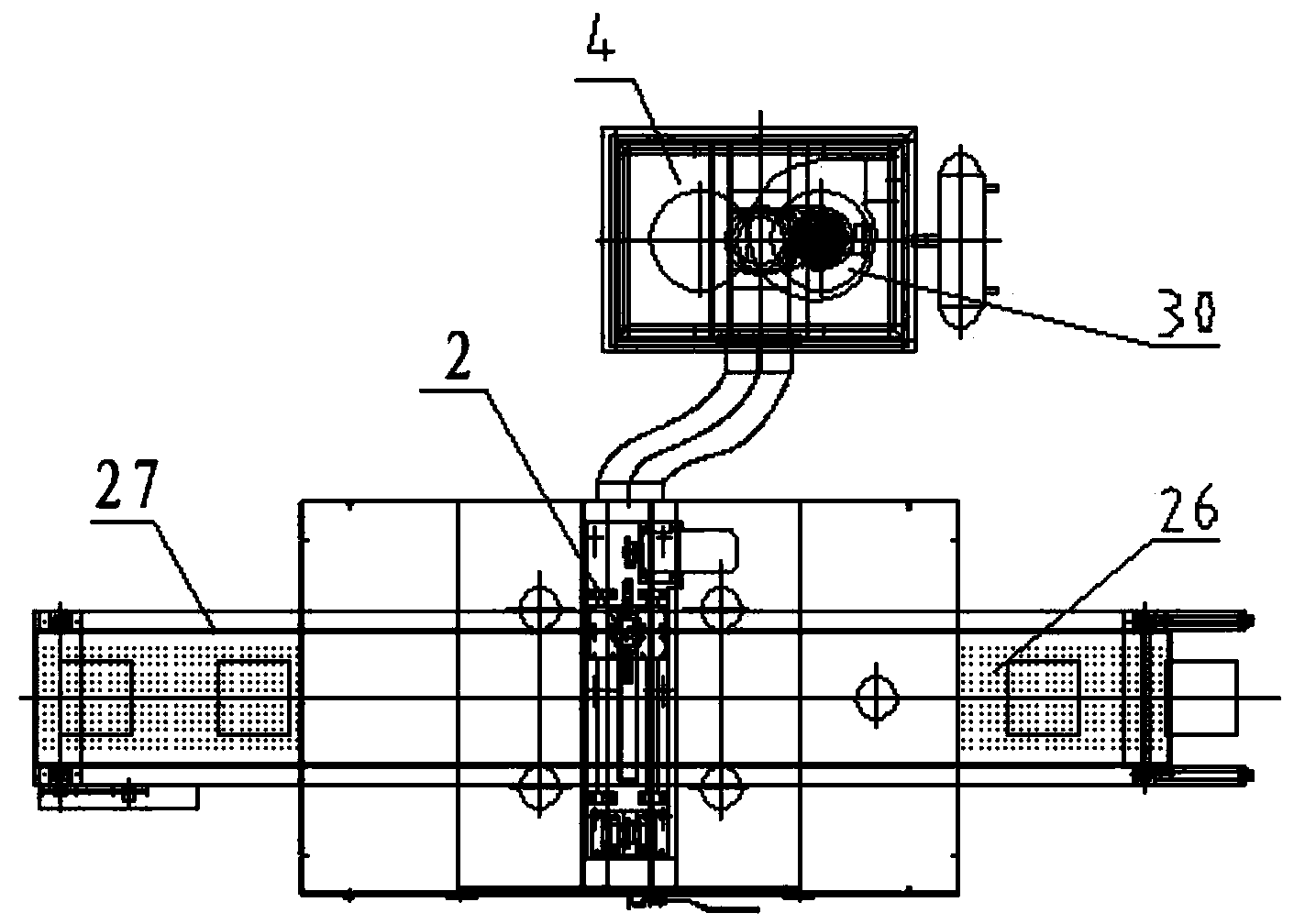

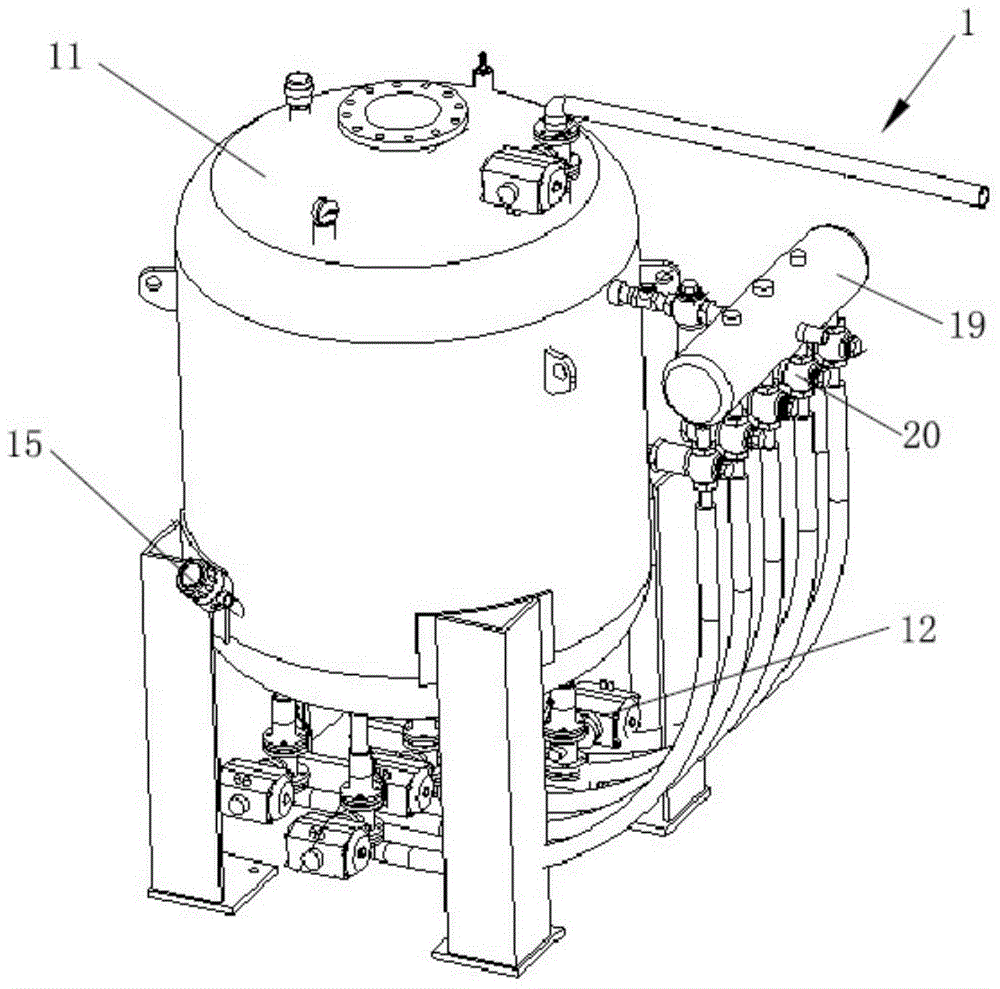

High-pressure water jet flow system for removing rust of ships and working method thereof

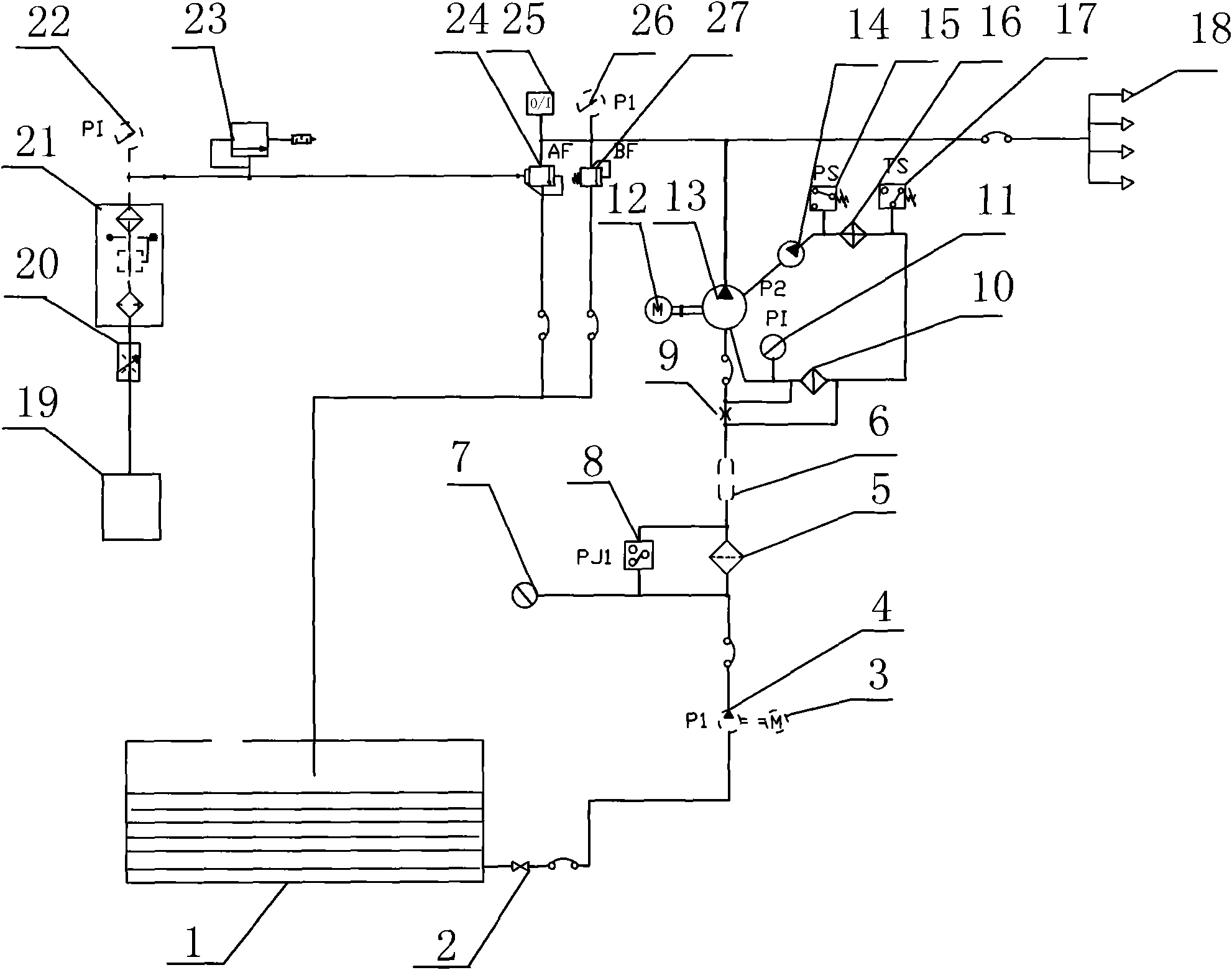

InactiveCN101875045ASolve delivery problemsHigh energy level densityCleaning using liquidsVolumetric Mass DensityHigh pressure water

The invention discloses a high-pressure water jet flow system for removing rust of ships and a working method thereof. The system of the invention comprises a low-pressure water pipeline, a super-high pressure water pipeline, a cooling pipeline and a pneumatic pipeline, wherein the super-high pressure water pipeline comprises a lubricating oil cooler of a super-high pressure pump, a cooling pressure gauge, an super-high pressure motor and the super-high pressure pump; one end of the lubricating oil cooler of the super-high pressure pump is also connected with the super-high pressure pump through the cooling pressure gauge; the other end is connected the super-high pressure pump sequentially through a cooling temperature relay, a cooling filter, a lubricating oil cooling pump and a cooling pressure relay; and a rust removing nozzle is installed at the output end of the super-high pressure pump. The method comprises the steps of sucking stable water flow to be converted into super-high pressure water and jetting the super-high pressure water out through the rust removing nozzle. In the invention, because the high pressure water with the pressure up to 250 MPa, which is generated by the super-high pressure pump, is directly used to be passed through a spray nozzle and the high-speed water flow with extreme high level density is jetted out, the rust removing effect is good and delivering abrasive materials is not needed.

Owner:DALIAN MARITIME UNIVERSITY

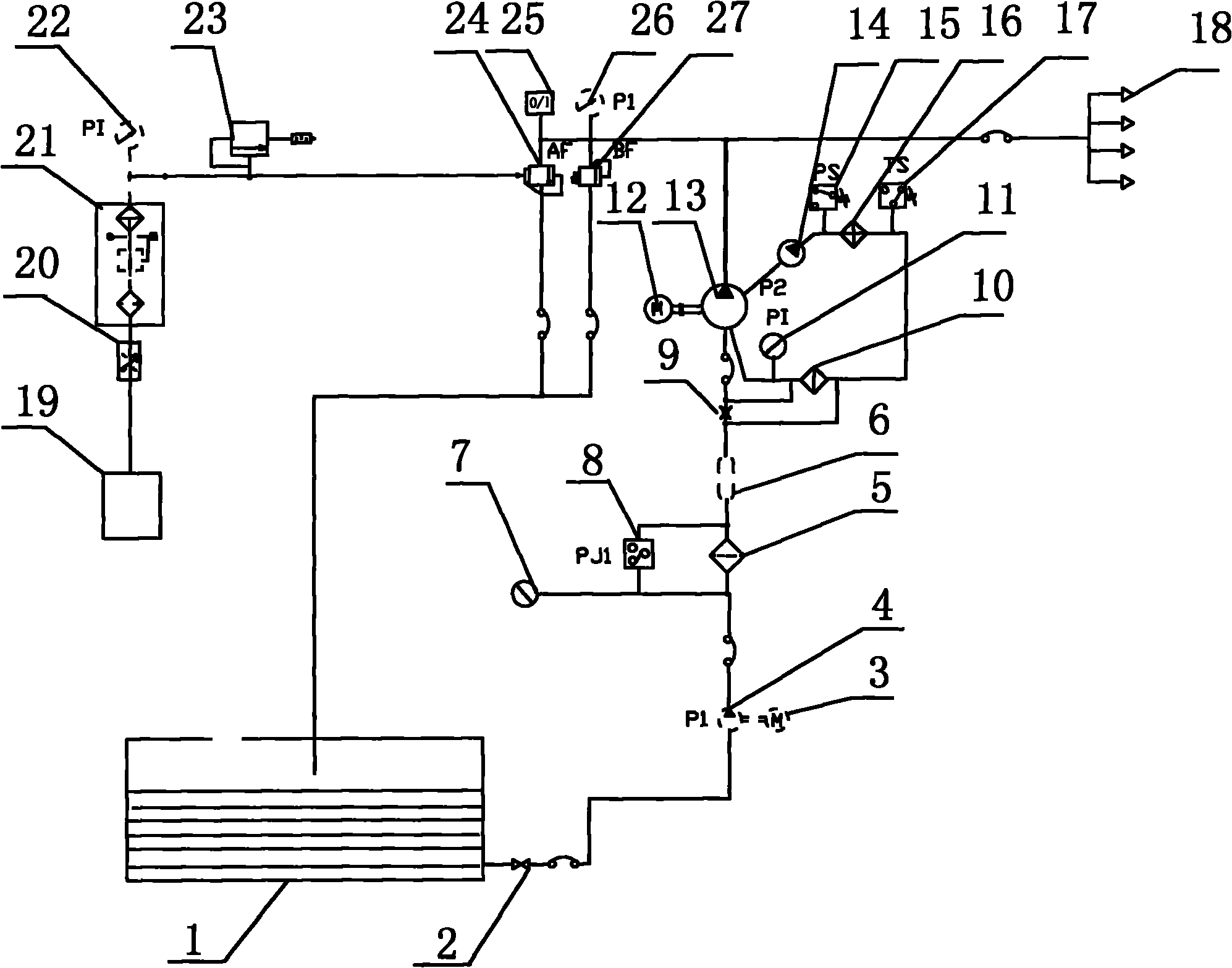

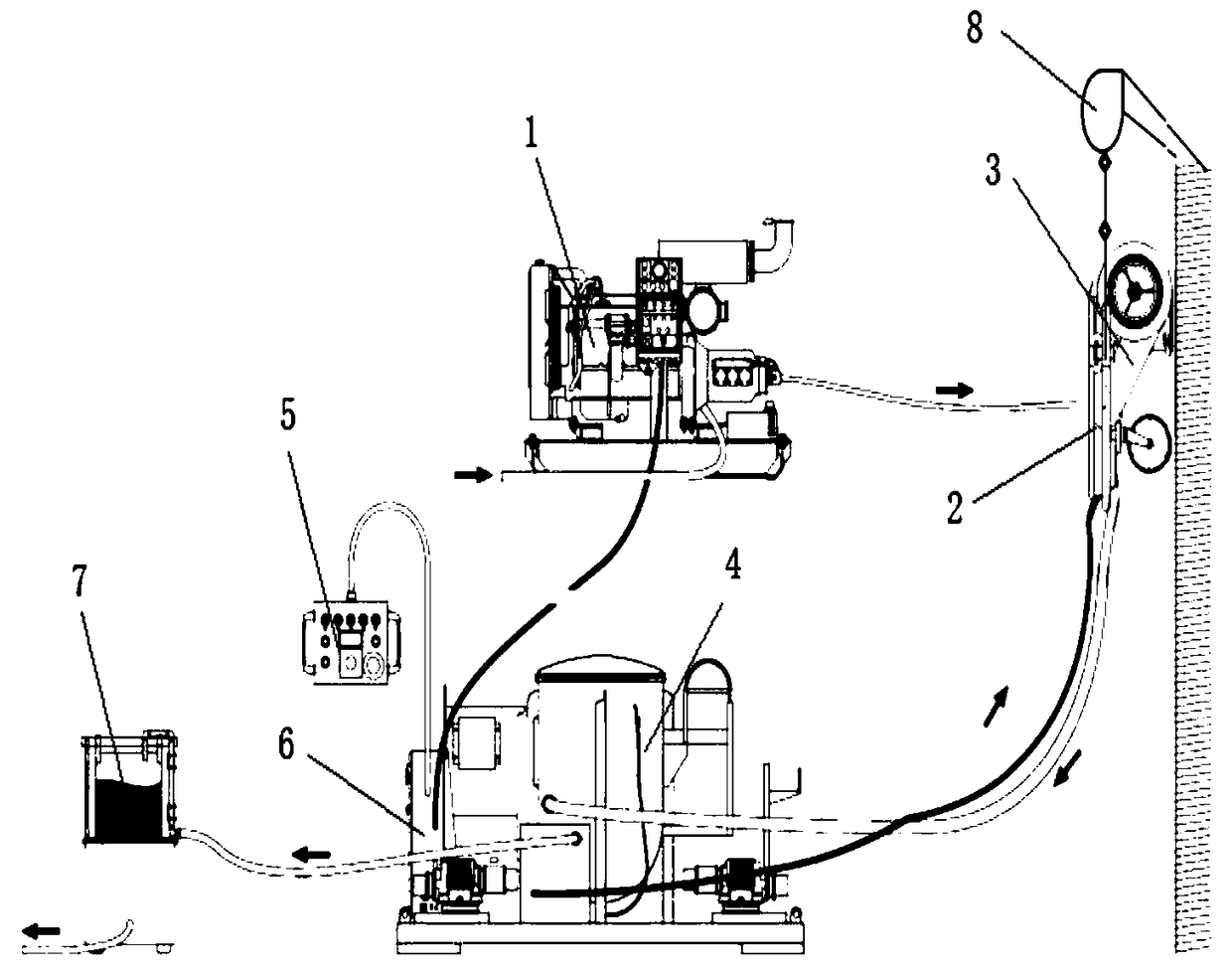

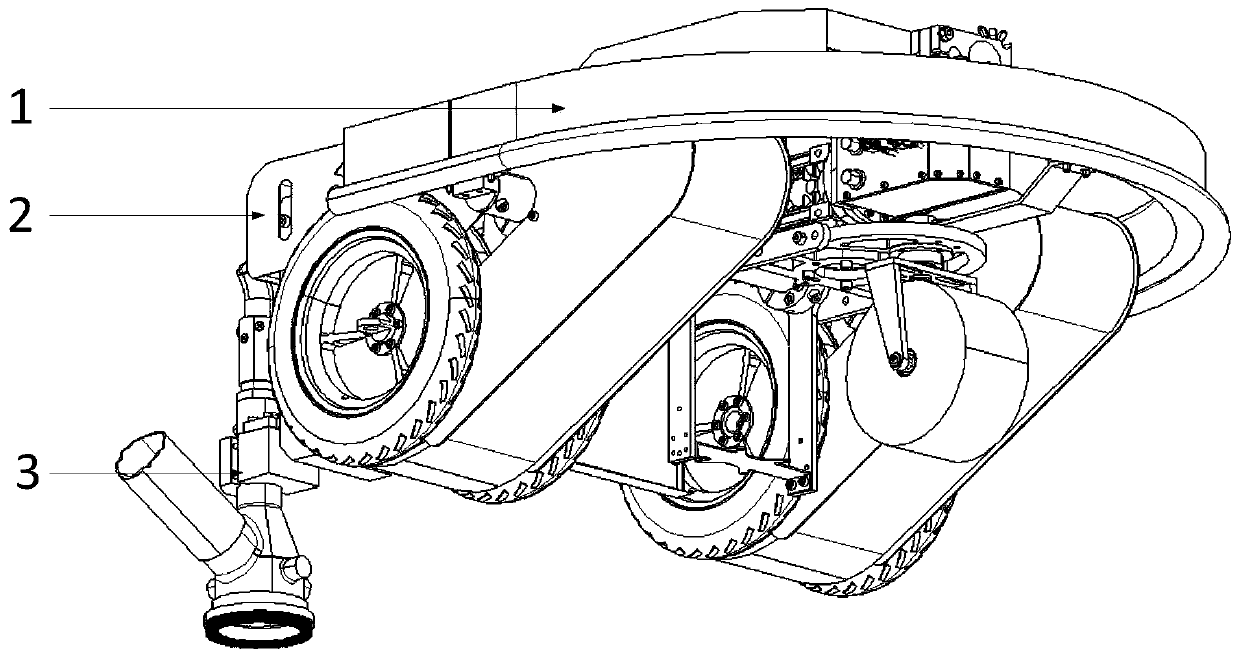

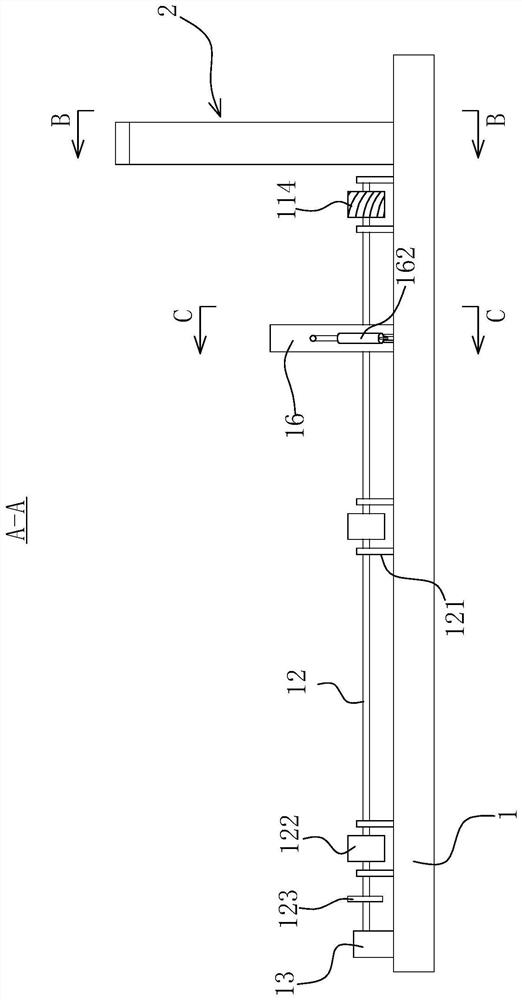

Working system of wall-climbing derusting robot for walls of ships and petrochemical storage tanks

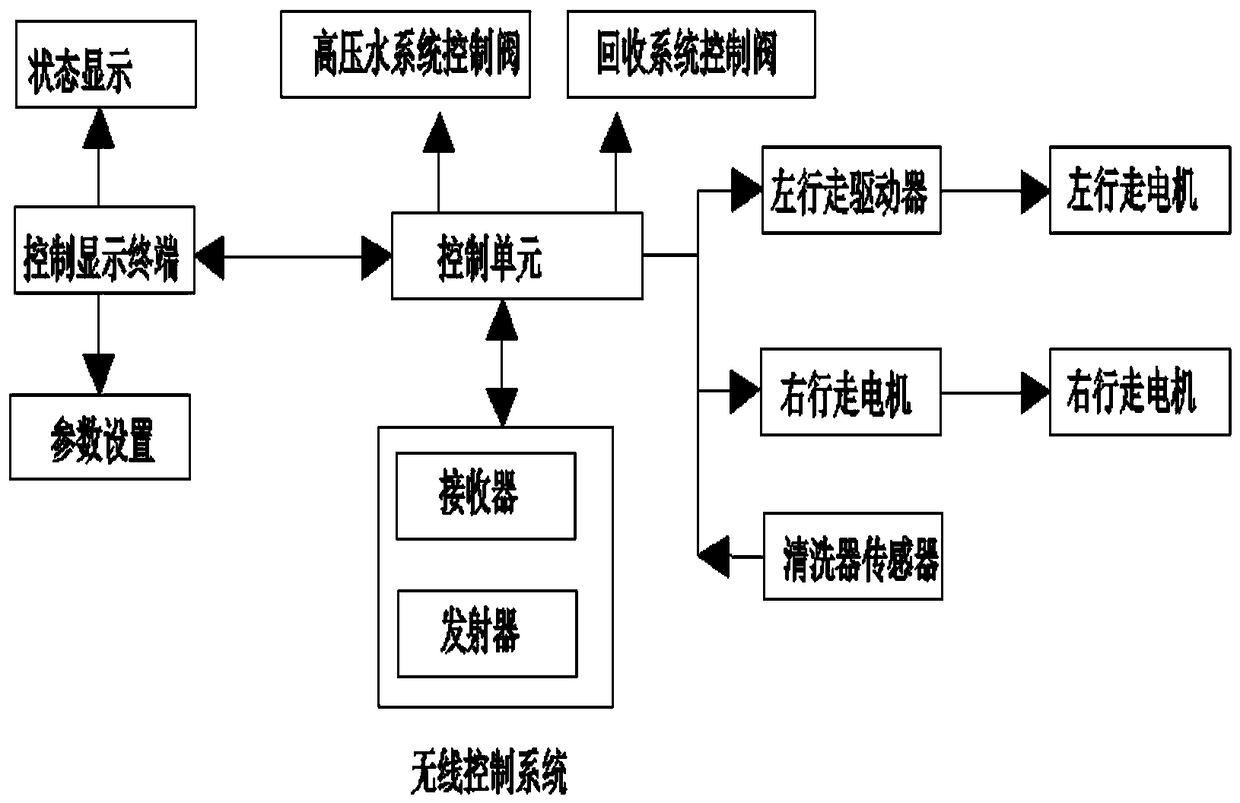

PendingCN108655135AHarm reductionImprove rust removal efficiencyVessel cleaningHollow article cleaningRemote controlWastewater

The invention discloses a working system of a wall-climbing derusting robot for walls of ships and petrochemical storage tanks. The wall-climbing robot is connected with a falling preventer through aflexible protection rope. The falling preventer is connected to the walls of ships and petrochemical storage tanks. The wall-climbing robot is fixedly connected with a vacuum cleaner. By means of theworking system, the problems that as for derusting operation, manpower is adopted and a large number of auxiliary facilities need to be built are solved, the derusting efficiency is improved, harm ofdust to construction personnel is reduced, and the derusting cost is reduced. By adoption of the mode that a recycling device is separated from waste water, pollution to the environment is effectivelyreduced, and the environment protection requirements are met. The wall-climbing robot and a high-pressure water system are controlled in a remote control mode, all control operations can be conductedon a display set terminal, and operation is more convenient. The vacuum cleaner is installed at the belly portion of the wall-climbing robot, is provided with an adaptive device and can adapt to uneven outer surfaces, so that the environmental adaptability of the derusting operation is improved.

Owner:LUOYANG SHENGRUI INTELLIGENT ROBOT

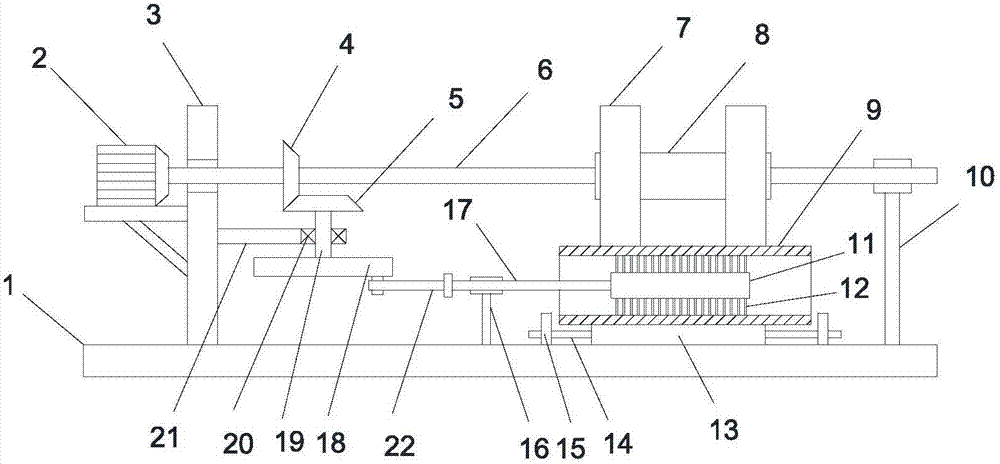

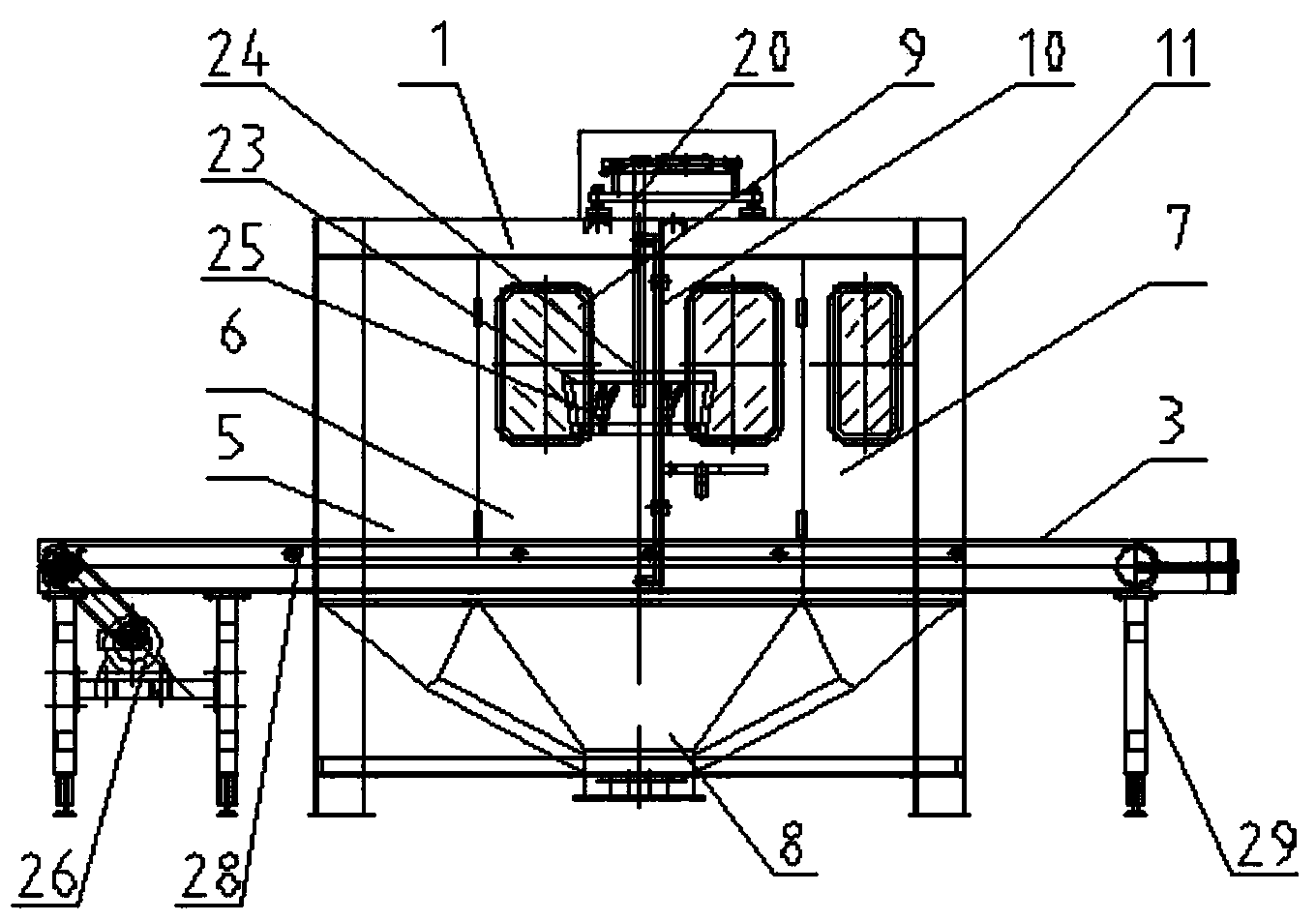

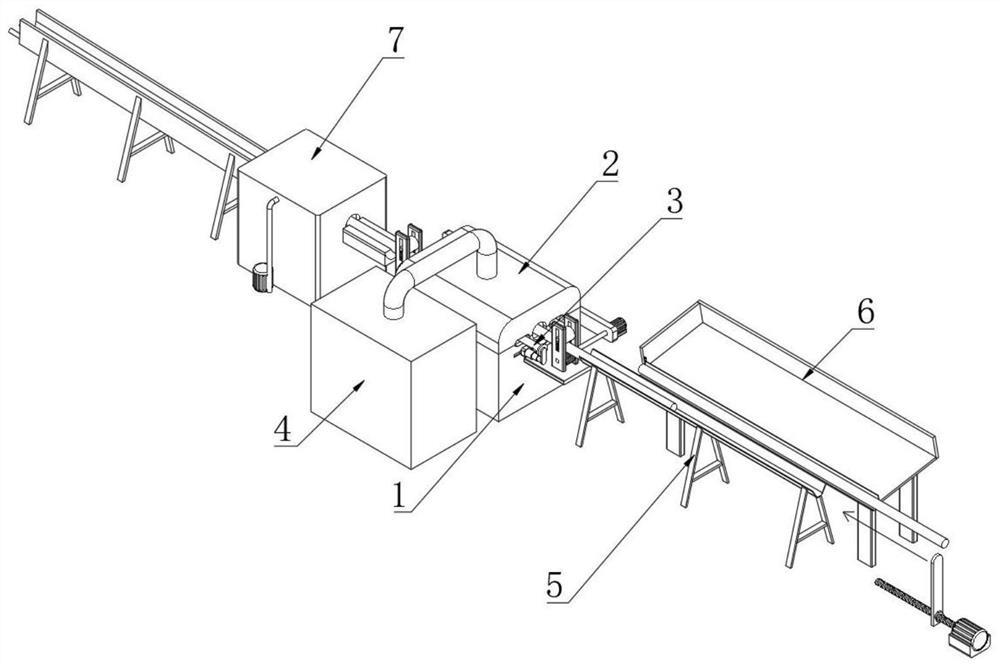

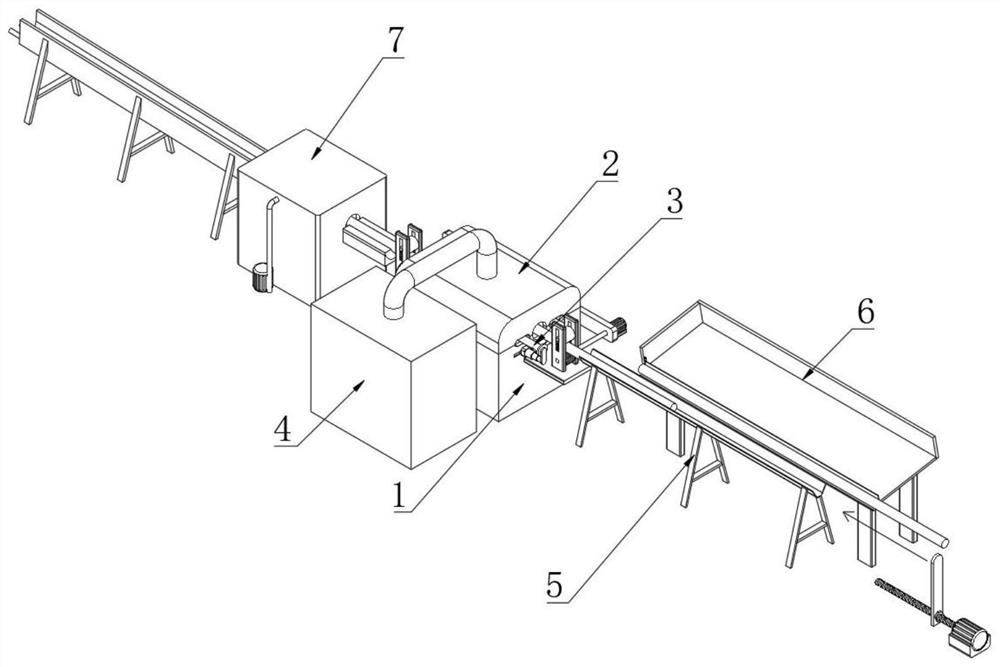

Sand blasting rust removal device

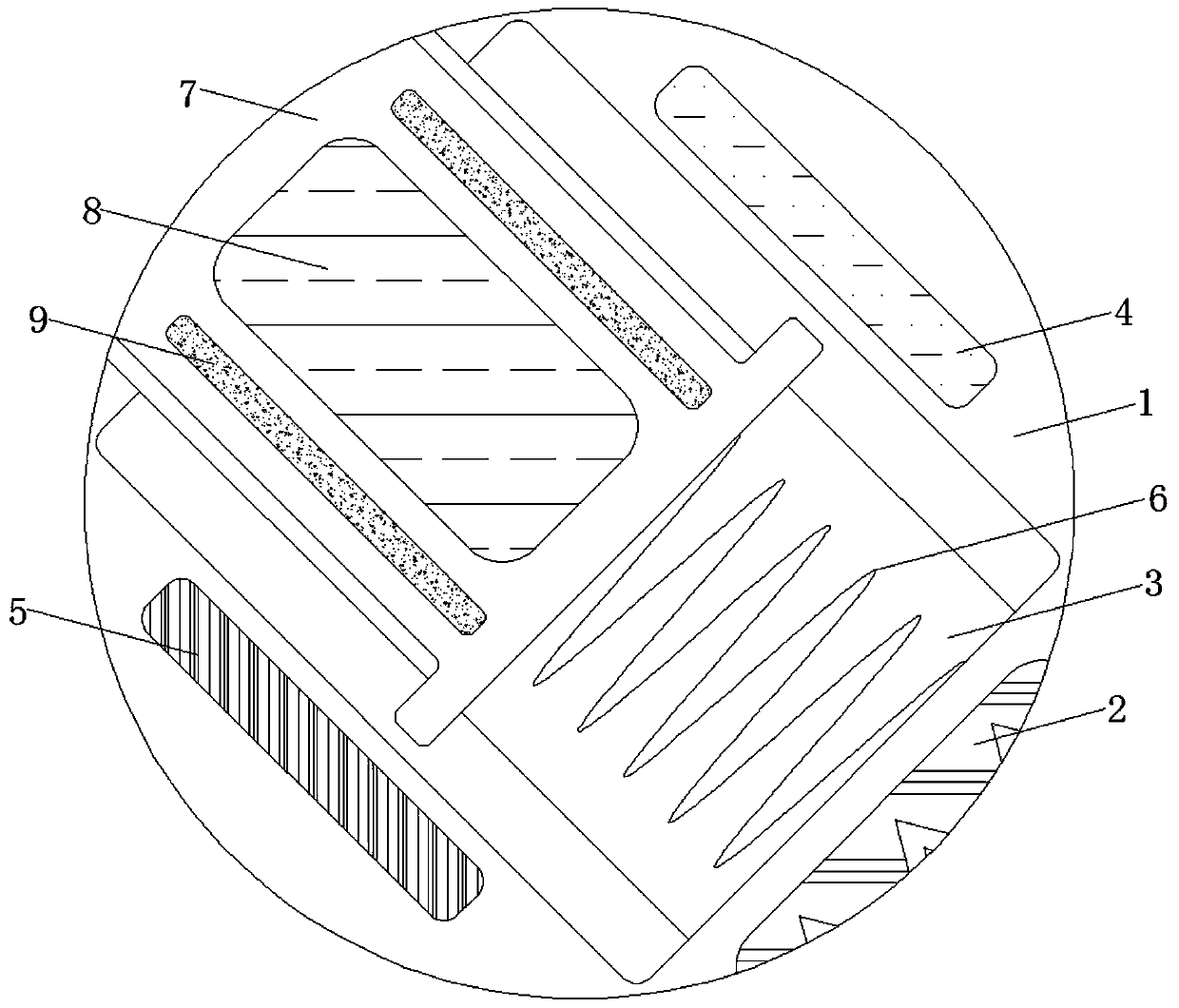

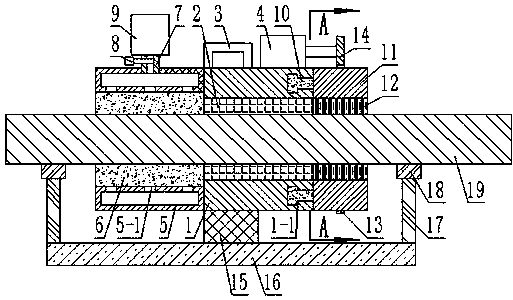

InactiveCN103770011AEfficient removalReduce rust removal costsAbrasive machine appurtenancesAbrasive blasting machinesSand blastingEngineering

The invention relates to the field of sand-blast cleaning technologies and processing, and in particular relates to a sand blasting rust removal device. The sand blasting rust removal device comprises a sand blasting cabin body, a driving mechanism, a transmission mechanism, a conveying device and a dust removal device, wherein the sand blasting cabin body is connected with an external electric control system; the conveying device is used for conveying a workpiece; the dust removal device is used for removing dust; the sand blasting cabin body comprises a sand blasting cabin; a sand blasting device is arranged in the sand blasting cabin; a pellet collecting device is arranged at the bottom of the sand blasting cabin body; the conveying device runs through the sand blasting cabin body; the driving mechanism is connected with the transmission mechanism and drives the transmission mechanism to rotate to drive the sand blasting device to move in the conveying direction of the workpiece; the dust removal device is connected with the sand blasting cabin body through a pipeline. According to the sand blasting rust removal device, the workpiece is driven to move into the sand blasting cabin through the belt conveying device; under the driving action of the driving device, a spraying gun is driven by the transmission of the transmission mechanism to uniformly spray sands to the workpiece, so that rust on the surface of the workpiece is effectively removed, and the sand blasting rust removal device is low in rust removal cost, stable in quality, high in working efficiency, environment-friendly and energy-saving.

Owner:昆山开信精工机械股份有限公司

Production method of anti-corrosion steel

InactiveCN112934639AReduce consumptionImprove performanceAnti-corrosive paintsSpecial surfacesProduction lineProduct inspection

The invention discloses a production method of anti-corrosion steel. The production method of the anti-corrosion steel comprises the following steps: (1) cooling rolled steel on a factory production line; (2) conducting cleaning treatment on surfaces of the steel; (3) coating the steel with anti-corrosion paint, and conducting drying; and (4) conducting finished product inspection on the steel and coatings thereof, and conducting packaging, warehousing and delivery. According to the production method of the anti-corrosion steel, the steel produced on the production line is immediately coated with the anti-corrosion paint, thus each piece of steel is coated with one corresponding anti-corrosion coating before leaving a factory, moreover, it is guaranteed that the coatings have good performance, the steel cannot be rusted due to absence of protection before use, and cannot be rusted due to coating film damage, thus subsequent coating project can be directly carried out, rust removal processes are omitted, and not only can the rust removal cost be reduced to reduce environmental pollution, but also steel consumption can be reduced, so that the service lives of steel structures are prolonged.

Owner:深圳市嘉达节能环保科技有限公司

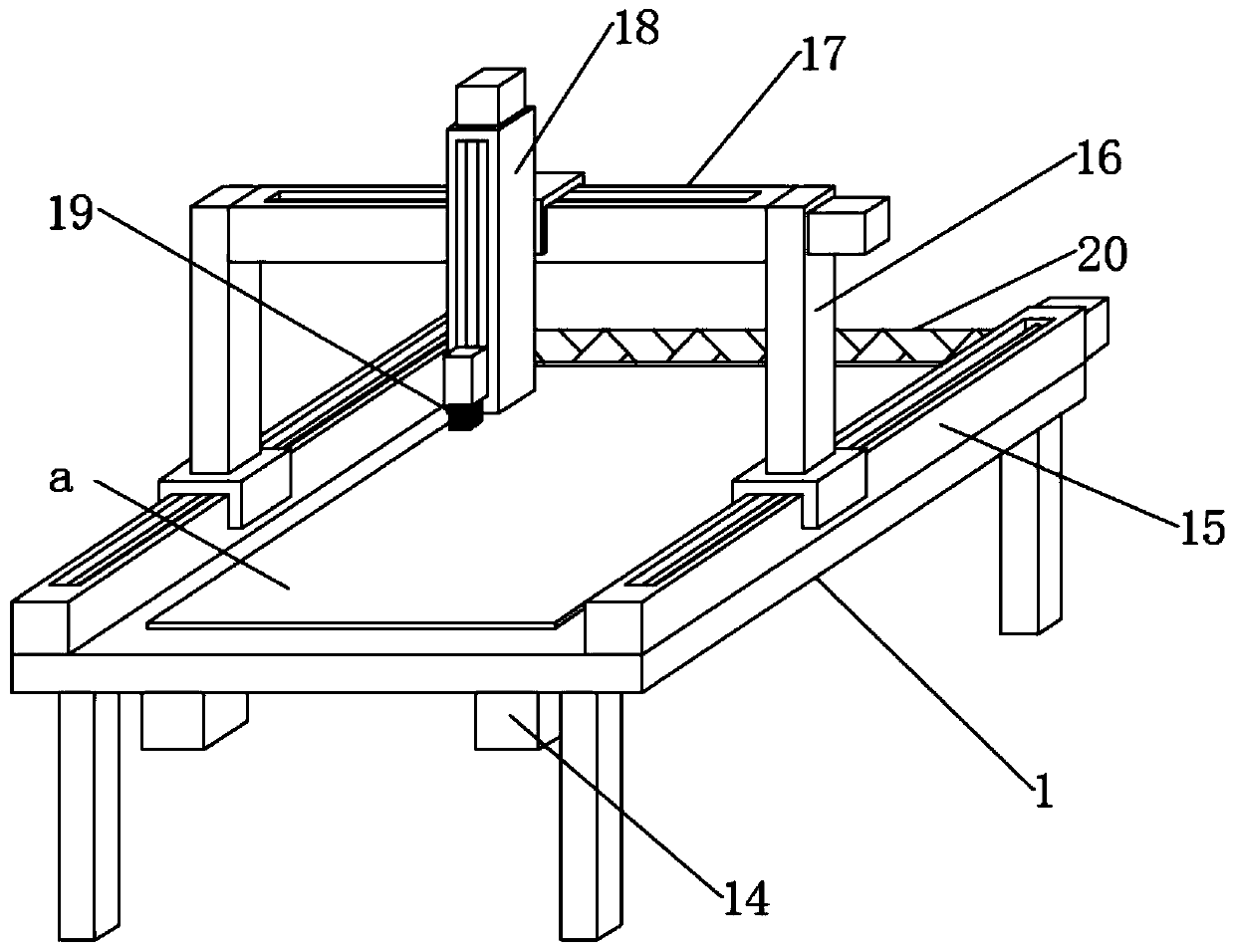

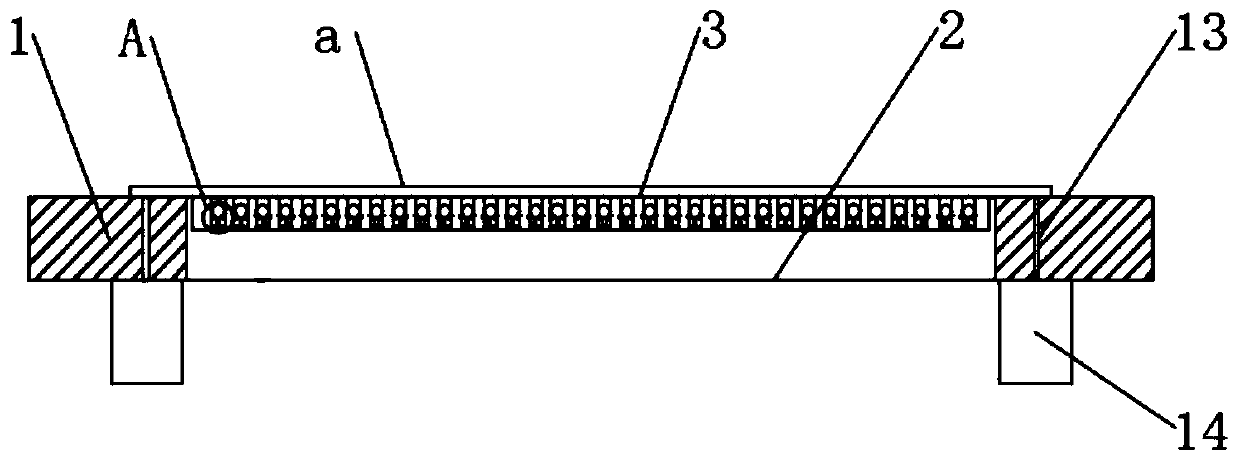

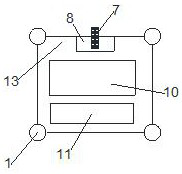

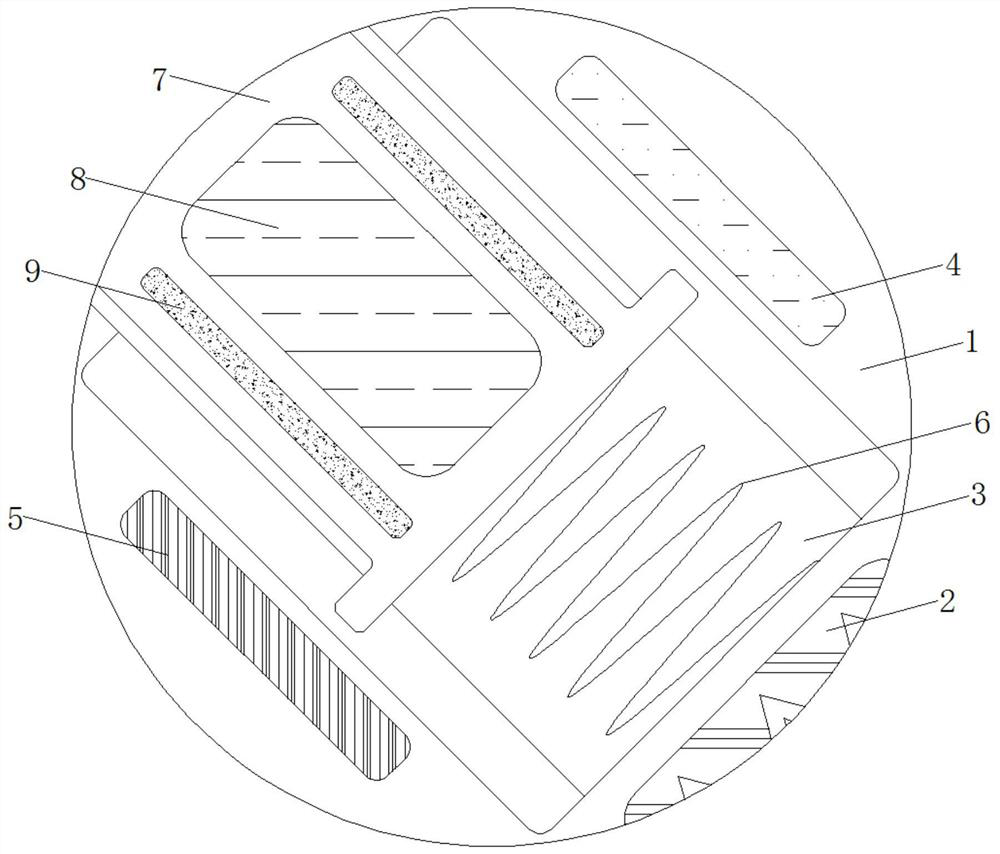

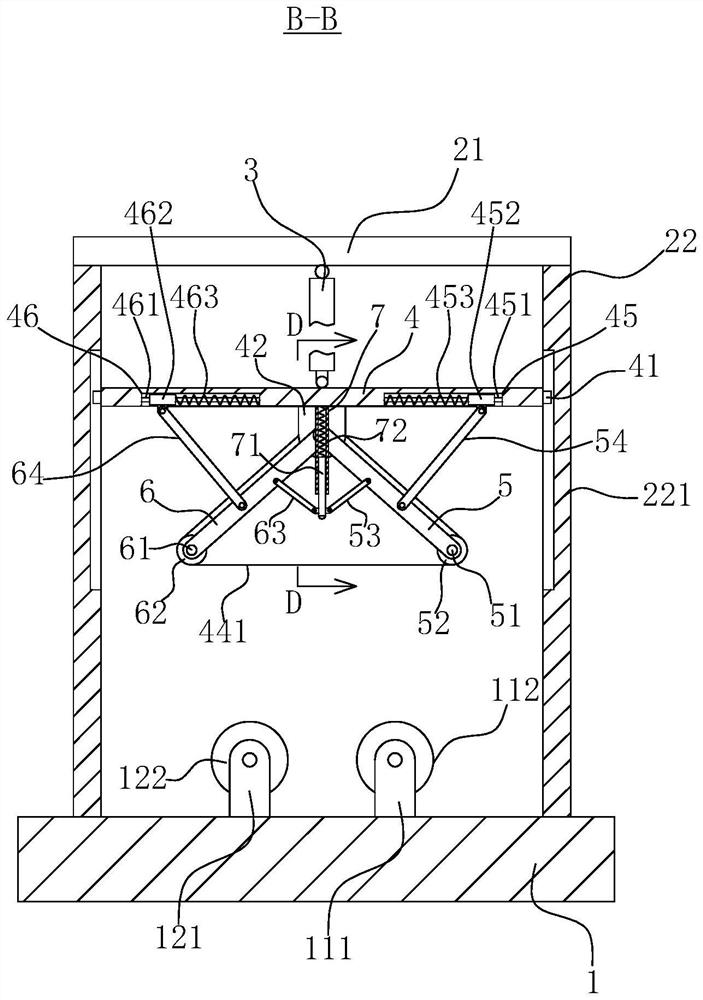

Micro-impact deformation-type plane plate rapid rust removal equipment

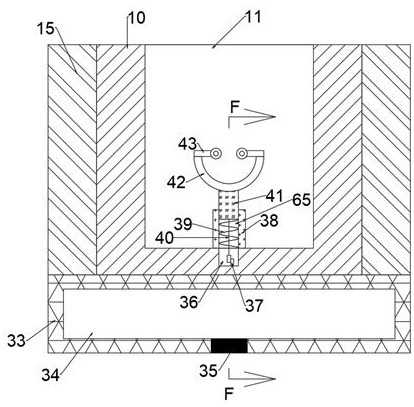

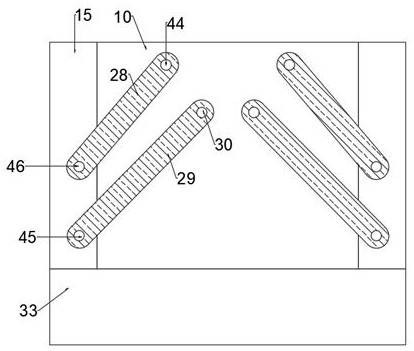

ActiveCN111589798AImprove rebound impact effectIncrease elasticityGrinding machinesPress ramRepulsion forceStructural engineering

The invention discloses micro impact deformation-type plane plate rapid rust removal equipment, and belongs to the technical field of rust removal. The micro impact deformation-type plane plate rapidrust removal equipment, the situation that through the magnetic force generated by an electromagnet under the plate, a multi-seismic magnetic is enforced to make a small local impact on the place under the action of the magnetic repulsion force, on the one hand, the plate vibration brought by the impact force can be utilized to make the corrosion on the plate surface separate from the plate, on the other hand, the local deformation of the plate caused by the impact force can pull the corrosion and cause cracking, separation falling is more facilitated, the deep grinding can be effectively avoided to achieve the self-falling of the corrosion, the equipment is very efficient, the plate is not prone to being worn, even in the stubborn corrosion area, the impact strength of the area can be increased by strengthening a magnetic field, the area is enforced to deform to be obviously different from the adjacent area, thus the dense steel wire brush is conveniently subjected to targeted treatment, finally the deformation area is restored by the method of double rolling hot pressing, and the efficient and high-quality rust removal of the plane plate is completed.

Owner:山东绿钢环保科技有限公司

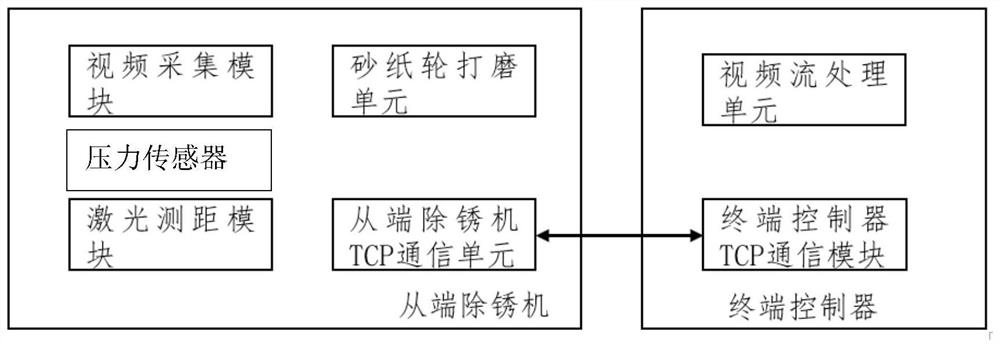

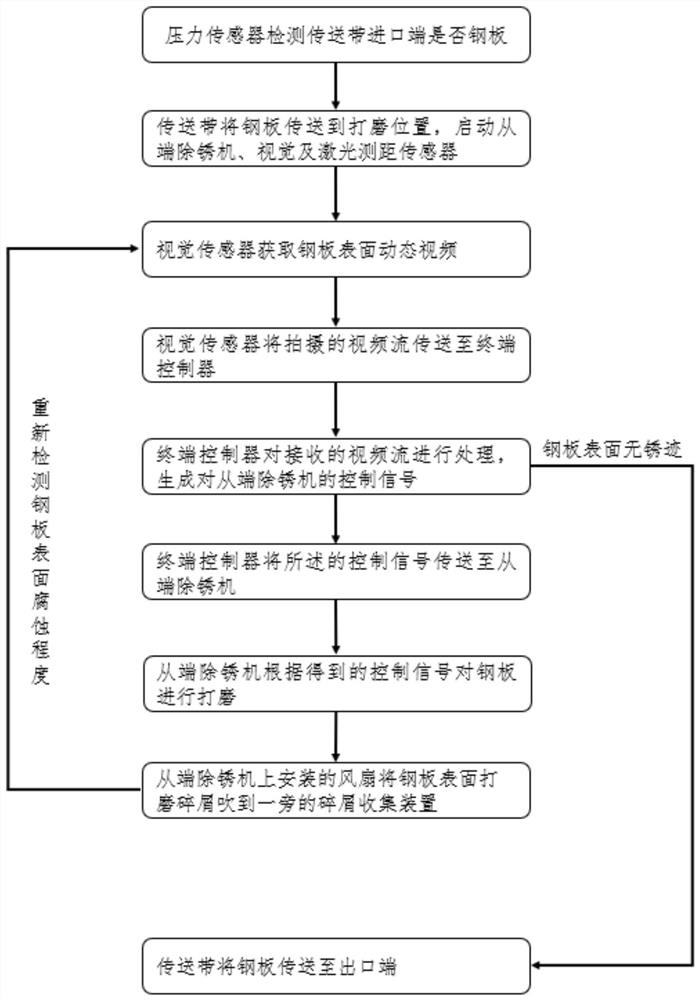

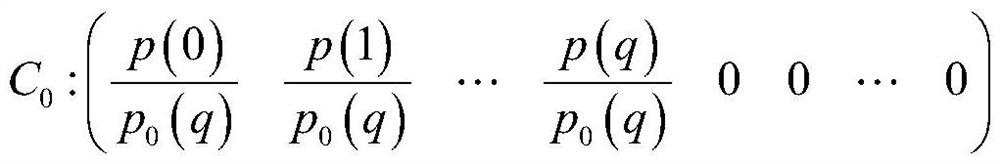

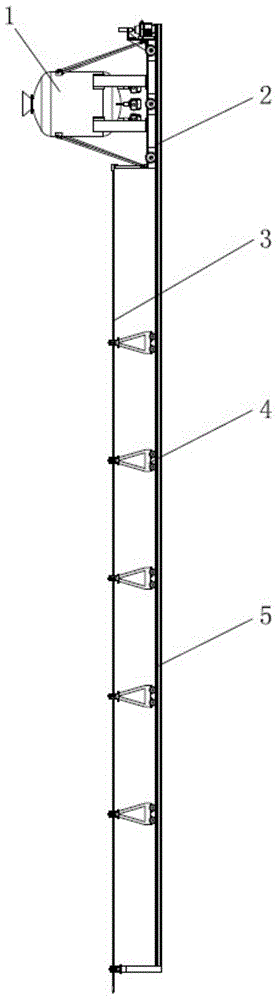

Automatic rust removal device and method for surface of steel plate

PendingCN113858004AFully automaticImprove work efficiencyImage enhancementImage analysisLaser rangingControl signal

The invention discloses an automatic rust removal device and method for the surface of a steel plate. The method comprises the steps that the steel plate is controlled to be conveyed and enter a conveying belt through a pressure sensor, the steel plate is polished and subjected to rust removal through an abrasive paper wheel polishing unit, the displacement of the abrasive paper wheel polishing unit in the polishing and rust removal process is detected in real time through a laser ranging module, and then polishing depth information is obtained; a surface image of the polished and subjected to rust removal is collected through a video collecting module, and the surface image of the steel plate and the polishing depth information are sent to a video stream processing unit through TCP communication; and a terminal controller is used for processing the surface image of the steel plate and the polishing depth information and feeding back and sending a control signal to the abrasive paper wheel polishing unit in real time. According to the automatic rust removal device and method for the surface of the steel plate, full automation of the whole process is achieved, the labor force is greatly saved while the working efficiency is improved, accurate polishing of the depth of the steel plate is achieved, a fault diagnosis mechanism and feedback are achieved, the good rust removal effect is achieved, and the rust removal cost of the surface of the steel plate is reduced.

Owner:ZHEJIANG UNIV

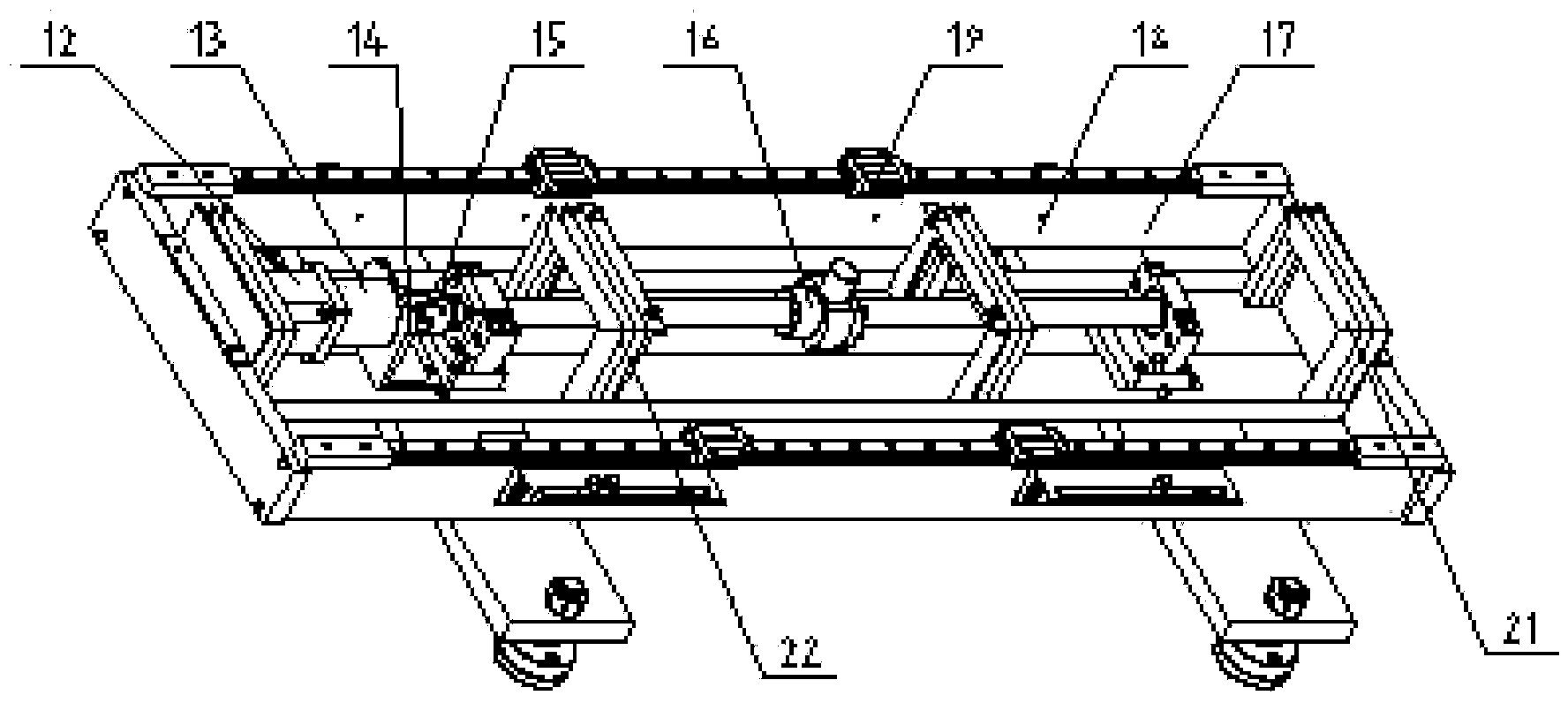

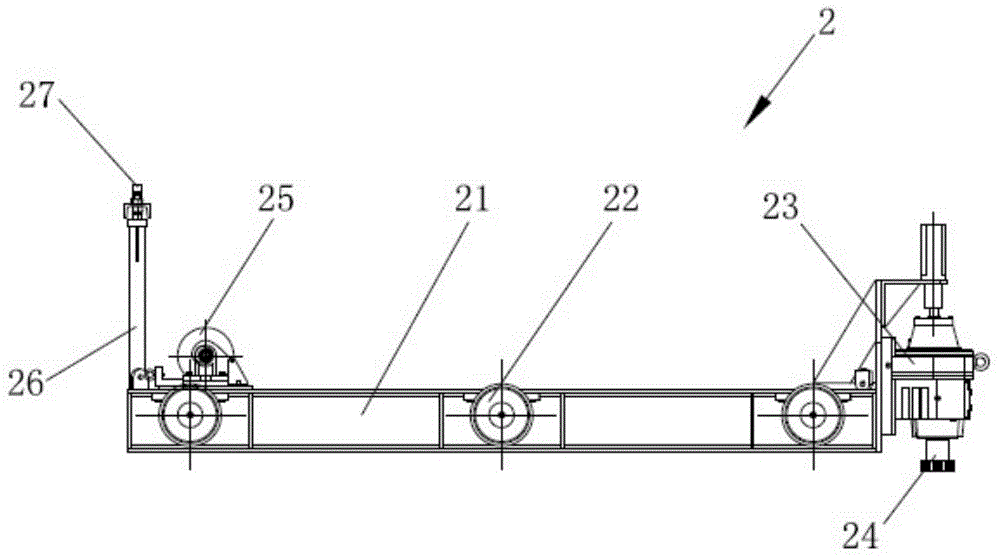

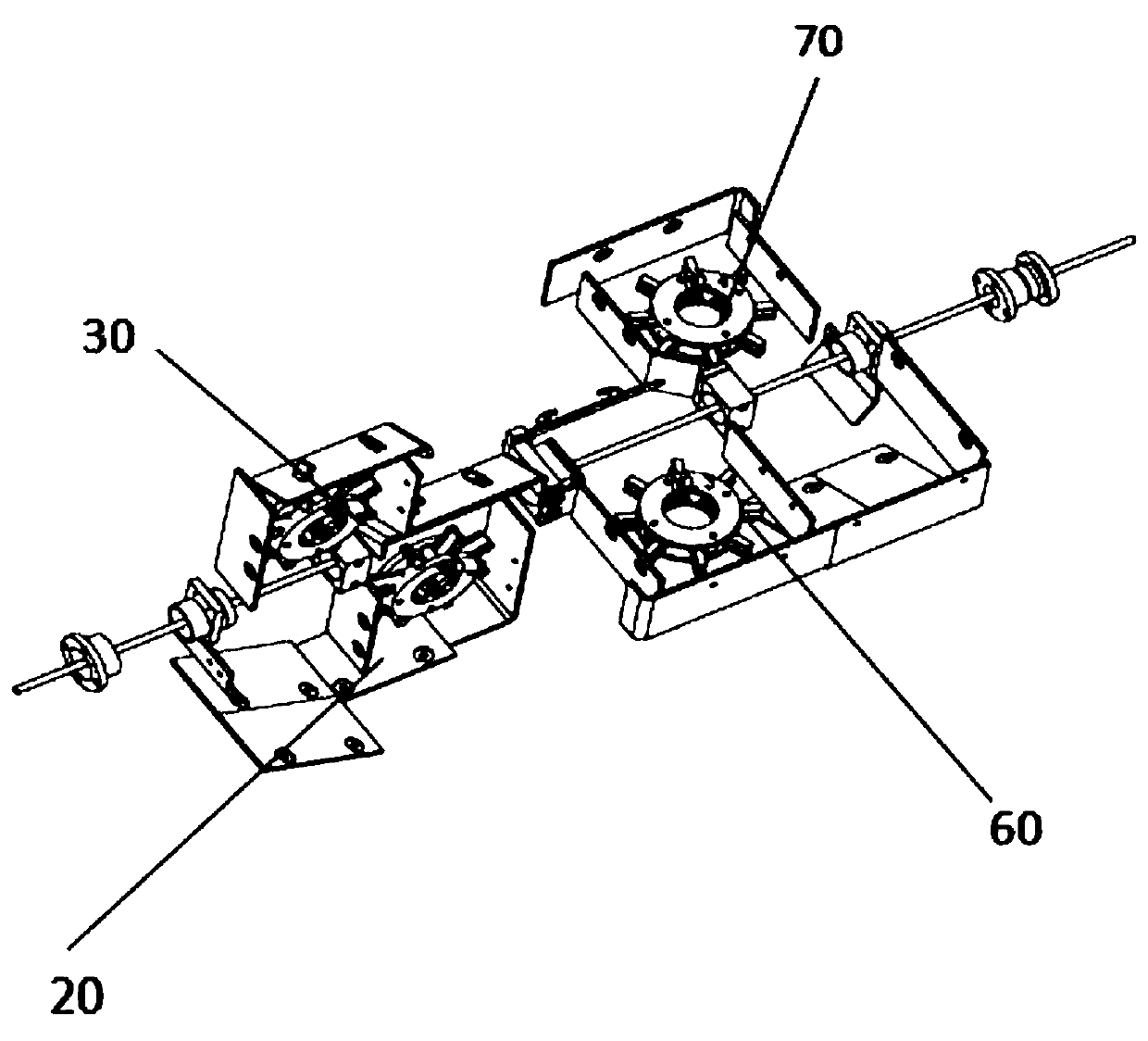

Sand blasting device for processing inner wall surface of pipeline

InactiveCN104552024AEfficient removalReduce rust removal costsAbrasive blasting machinesSand blastingEngineering

The invention discloses a sand blasting device for processing the inner wall surface of a pipeline. The device is characterized in that one end of a travelling trolley is equipped with a driving assembly which provides a driving force to the travelling trolley, and while the other end of the travelling trolley is equipped with a plurality of blasting gun racks for fixing a blasting gun assembly; the blasting gun assembly comprises a blasting gun rod which is erected on a plurality of blasting gun supporting mechanisms, and a blasting gun head which is connected with one end of the blasting gun rod; an inner wall sand blaster is arranged at the end part of the blasting gun head; track wheel sets are arranged at the bottom parts of the spraying gun supporting mechanisms and matched with a track system arranged in the pipeline. According to the device, the travelling trolley drives a blasting gun erected on the blasting gun supporting mechanisms on the track system, materials in a sand blasting tank are uniformly blasted on the inner wall of the pipeline through the inner wall sand blaster arranged on the blasting gun head, and therefore, the rust on the surface can be effectively removed. The device is low in dust removal cost, stable in quality, environmentally friendly, and energy saving.

Owner:昆山开信精工机械股份有限公司

High-pressure descaling spray head

ActiveCN110682215AReduce rust removal costsAvoid dust pollutionBlast gunsEnvironmentally friendlyEngineering

The invention relates to a high-pressure descaling spray head which comprises a spray head body. At least one impacting piece is arranged at a water outlet of the spray head body and is connected withthe spray head body through an elastic piece, and the impacting piece is arranged in the range of jet of high-pressure liquid. The impacting piece does a reciprocating motion parallel to the axial direction of the spray head body with the action of the high-pressure liquid and the elastic piece. The high-pressure descaling spray head solves the problems in the prior art that a descaling site is difficult to clean, the environment is polluted seriously, the inner wall of the spray head is easy to wear, and the service life is long. The high-pressure descaling spray head has the following beneficial effects that recycling abrasives and cleaning the site are not needed, the descaling cost is saved, the descaling effect is ensured while the spray head is more environmentally friendly, the service life is prolonged, the water outlet area is expanded, and water mist is prevented from being reversely sprayed so as to not harm a user or affect the vision of the user.

Owner:ZHEJIANG OCEAN UNIV

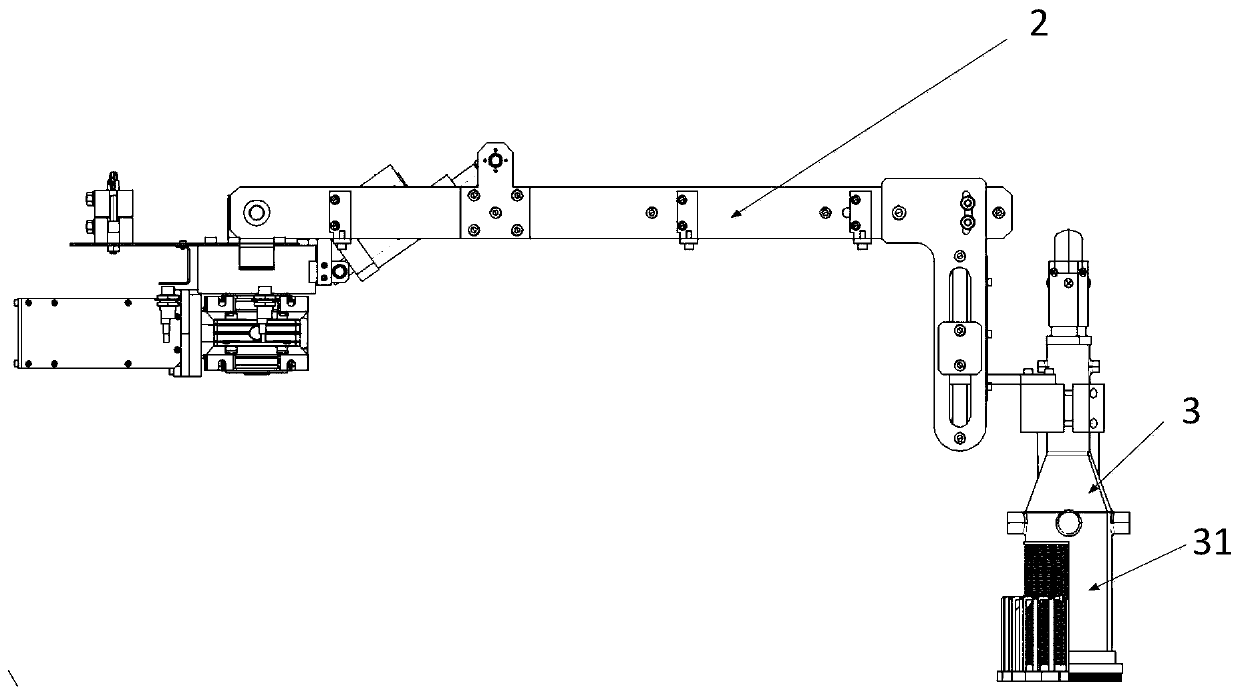

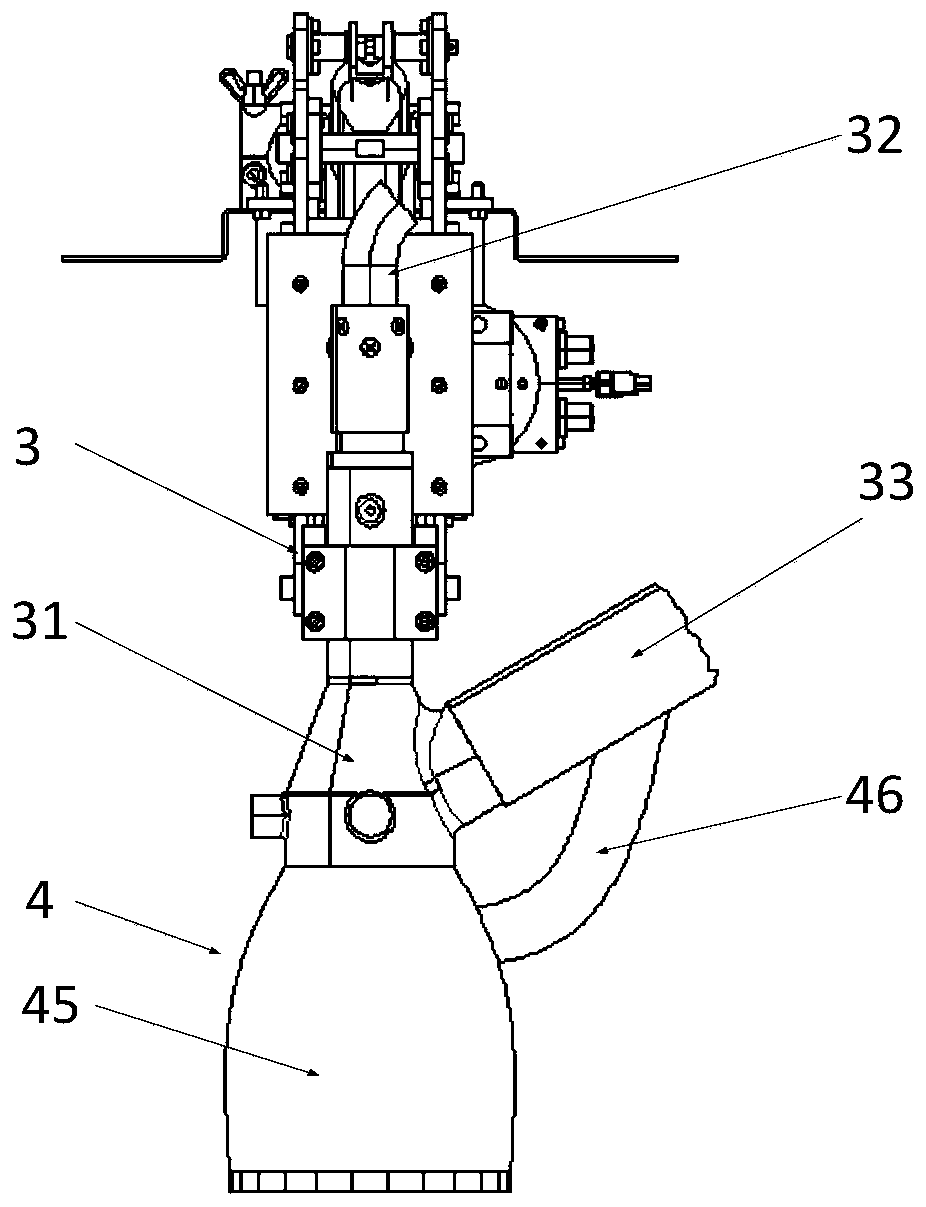

Magnetic attraction specialized robot working system and implementing method thereof

PendingCN111531471AImprove environmental adaptabilityImprove rust removal efficiencyProgramme-controlled manipulatorBlast gunsSand blastingControl engineering

Owner:KUNSHAN WELD MECHANICAL EQUIP

Dimethyl ether fuel lubricant for explosion-proof motor

InactiveCN104694223AIncrease brightnessReduce rust removal costsLiquid carbonaceous fuelsLubricant compositionUnsaturated fatty acidOleic Acid Triglyceride

The present invention discloses a dimethyl ether fuel lubricant for explosion-proof motor. The lubricant is characterized by consisting of the compositions in the following contents: 60-90% unsaturated fatty acids, 2-5% thickening agent, 5-20% polyethers and 5-20% polyetheramines. The polyunsaturated fatty acids are one or mixtures of oleic acid, linoleic acid and ricinoleic acid.

Owner:WUXI XIAN EXPLOSION PROOF MOTOR

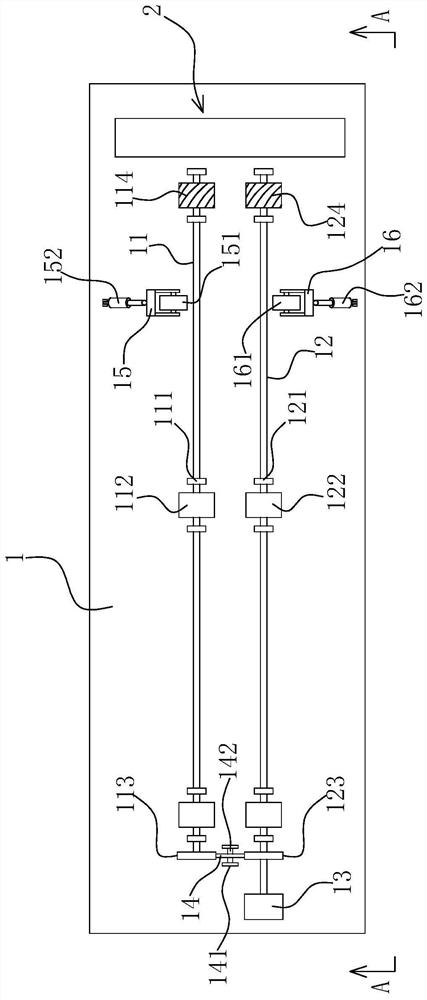

Ship body surface derusting repairing equipment without enabling ship to go ashore

InactiveCN111993289AAvoid pollutionHigh degree of automationWaterborne vesselsAbrasive blasting machinesSewageMechanical engineering

The invention discloses ship body surface derusting repairing equipment without enabling a ship to go ashore. The ship body surface derusting repairing equipment comprises a main body box; a cleaningcavity with an upward opening is formed in the main body box; first electric sliding rails with forward openings are symmetrically arranged on the inner wall of the rear side of the cleaning cavity about the cleaning cavity; and a first sliding chute cavity and a second sliding chute cavity with inward openings are formed in the inner walls of the left and right sides of the cleaning cavity. The ship body surface derusting repairing equipment is mounted at a harbor, when the ship stops at the harbor, the ship is driven to a designated area, and the ship body surface derusting repairing equipment is automatically started to lift up the ship, drains seawater in the ship, and additionally arranges and lengthens protective plates around the ship, so that sewage is prevented from entering seawater to avoid pollution to the water body during the derusting process by sandblast, so that the ship body surface derusting repairing equipment is high in degree of automation, is free of geographicallimitation, can timely derust the ship, improves the derusting efficiency and reduces the derusting cost.

Owner:YONGKANG WEIWEI INTELLIGENT TECH CO LTD

Brightening rust remover for explosion-proof motor

InactiveCN104694943ADoes not produce clothingNo hydrogen embrittlementHexamethylenetetramineRust remover

The invention discloses a brightening rust remover for an explosion-proof motor. The brightening rust remover comprises the following substances in percentage by weight: 30%-50% of hydrochloric acid, 1%-5% of hexamethylenetetramine, 2%-8% of sodium dodecyl sulfate, 5%-10% of peregal 0S-15, 1%-2% of a stabilizer and the balance of water.

Owner:WUXI XIAN EXPLOSION PROOF MOTOR

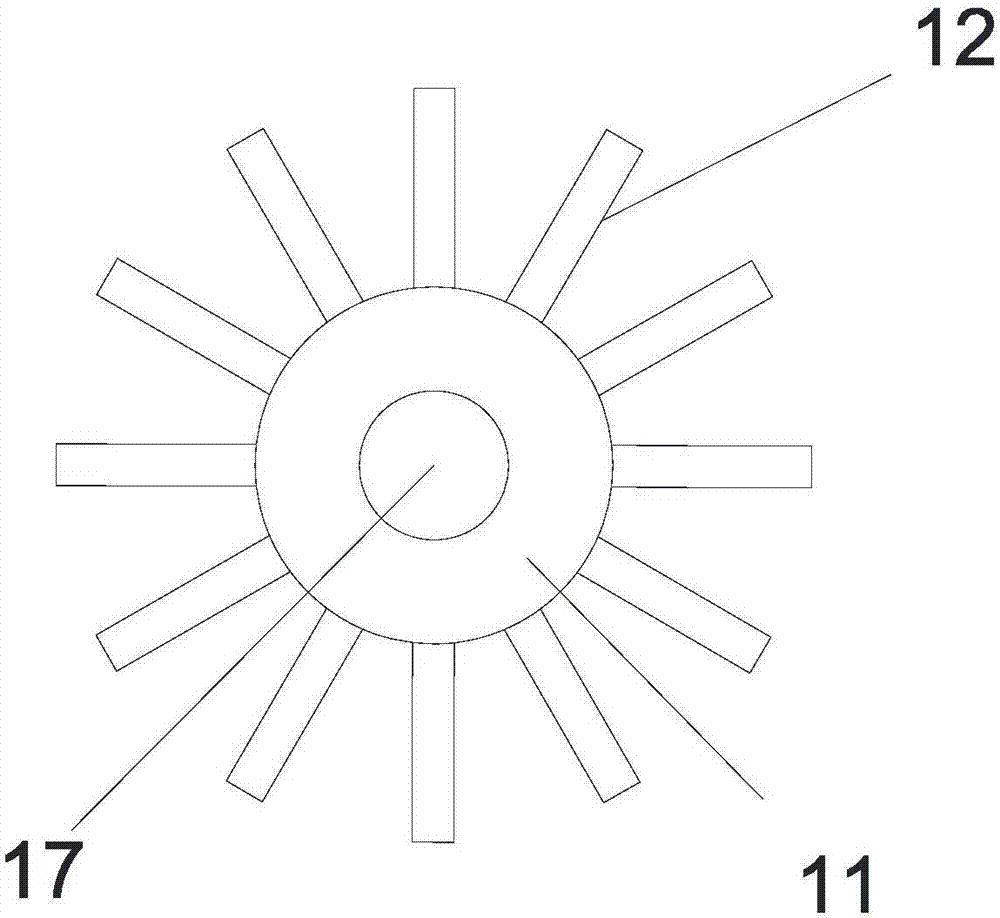

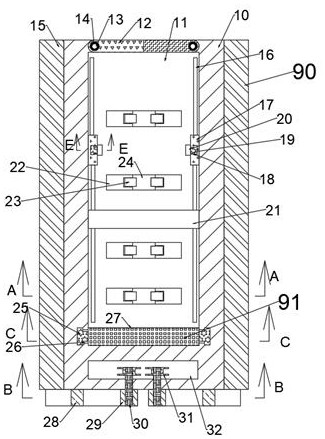

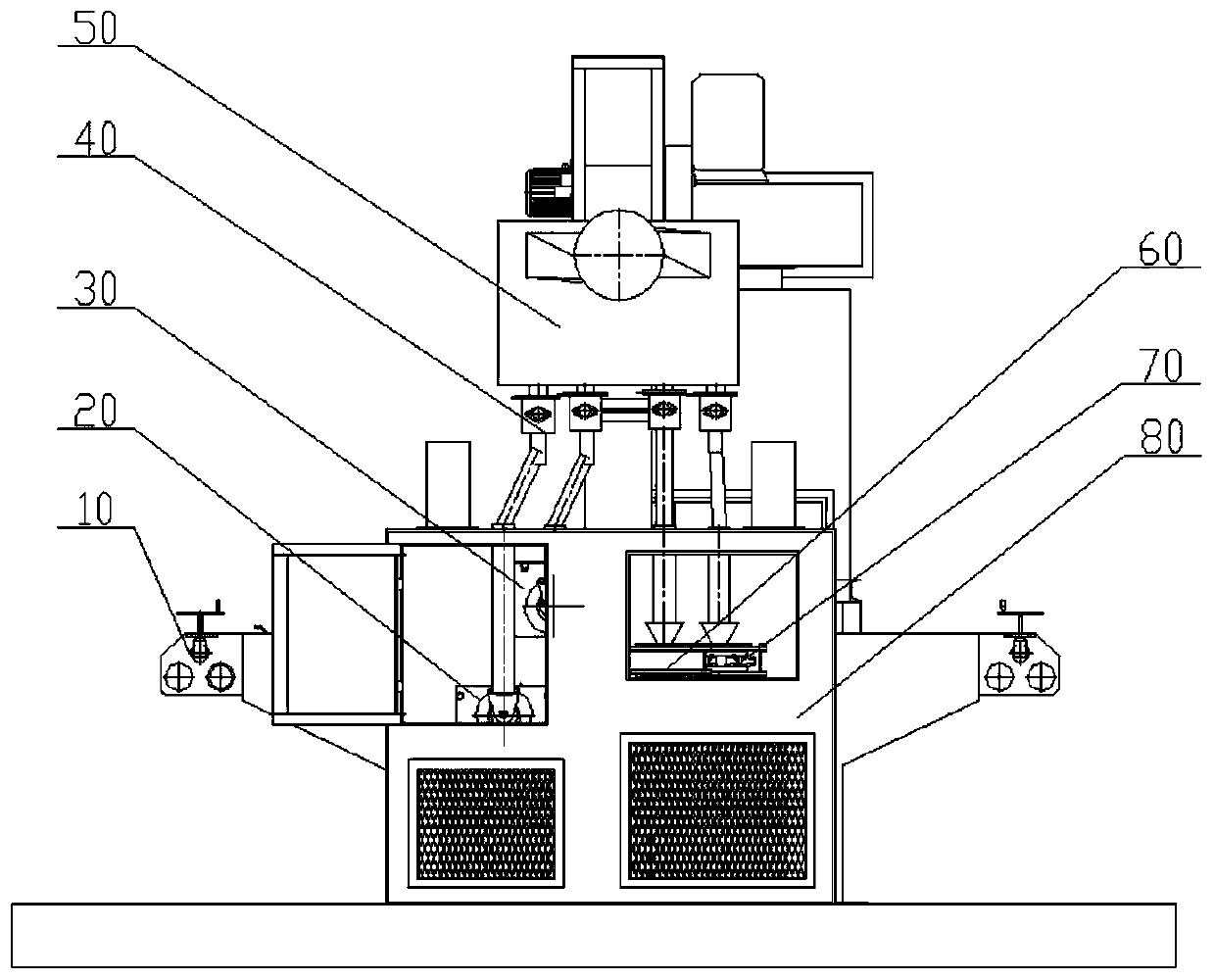

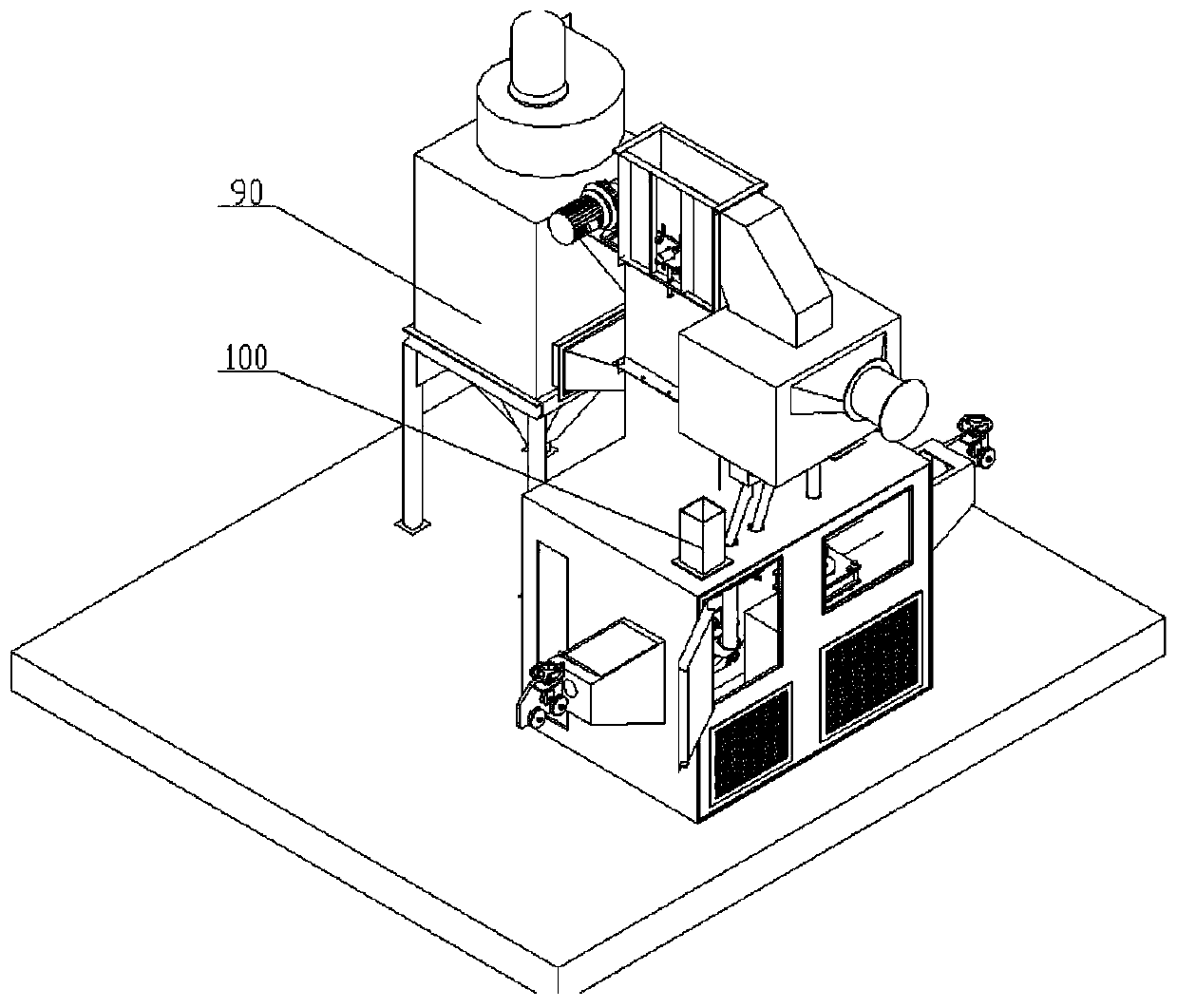

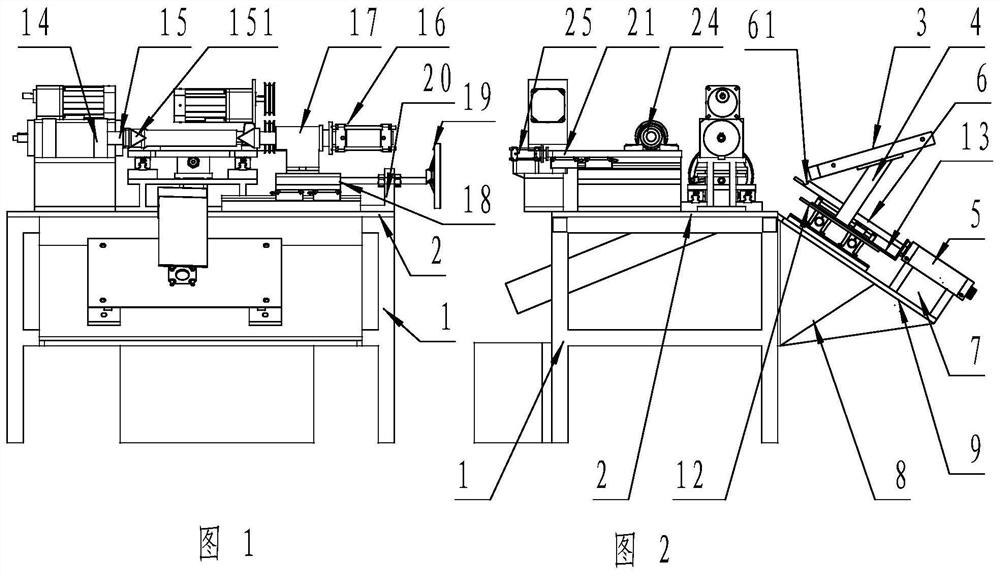

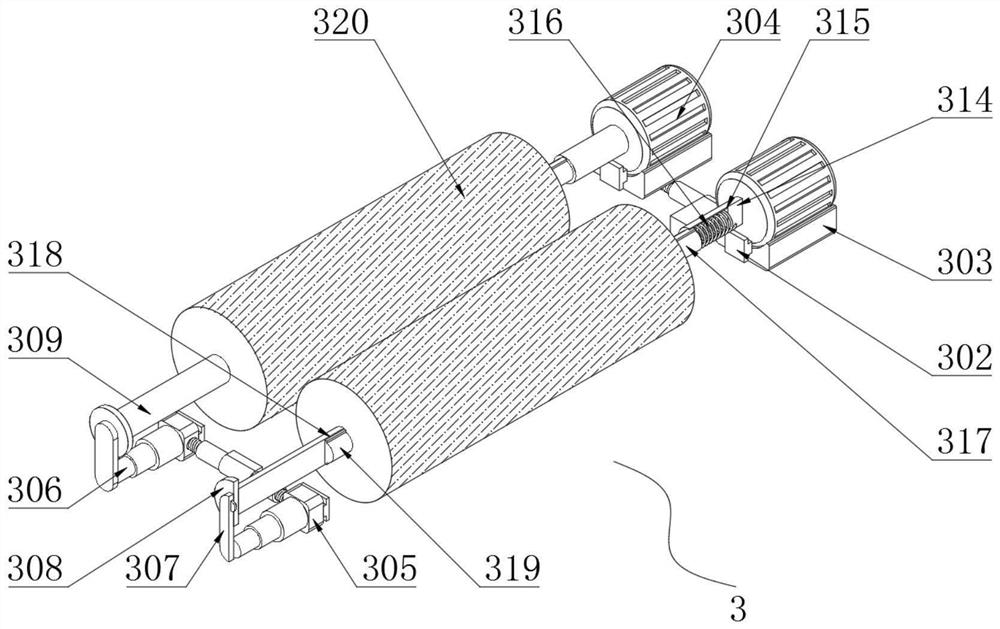

Miniaturized intelligent welding material shot blasting rust removal equipment

InactiveCN111230751AImprove cleaning efficiencyReduce rust removal costsAbrasive blasting machinesWire rodDust control

The invention discloses miniaturized intelligent welding material shot blasting rust removing equipment. The equipment comprises a shell stripping and straightening mechanism, a cleaning chamber, a shot blasting device assembly, a shot circulating purification system and a dust removing system, wherein a shot blasting device is a built-in shot blasting device; and the cleaning chamber is divided into an inner cleaning chamber and an outer cleaning chamber and is divided into four shot blasting chambers, and a wire guiding system automatically feeds wires. The intellectualization can measure speed intelligently, adjust the shot blasting amount automatically and carry out threading automatically, so that the purposes of low power and low consumption are achieved; and according to the miniaturized intelligent welding material shot blasting rust removing equipment, the problems of semi-automation, high cost, low efficiency and poor effect of various rust removing equipment, and pollution caused by acid pickling in the prior art are solved, then the wire cleaning cost is reduced, and the wire cleaning efficiency, speed and automation degree are improved.

Owner:中国机械总院集团江苏分院有限公司

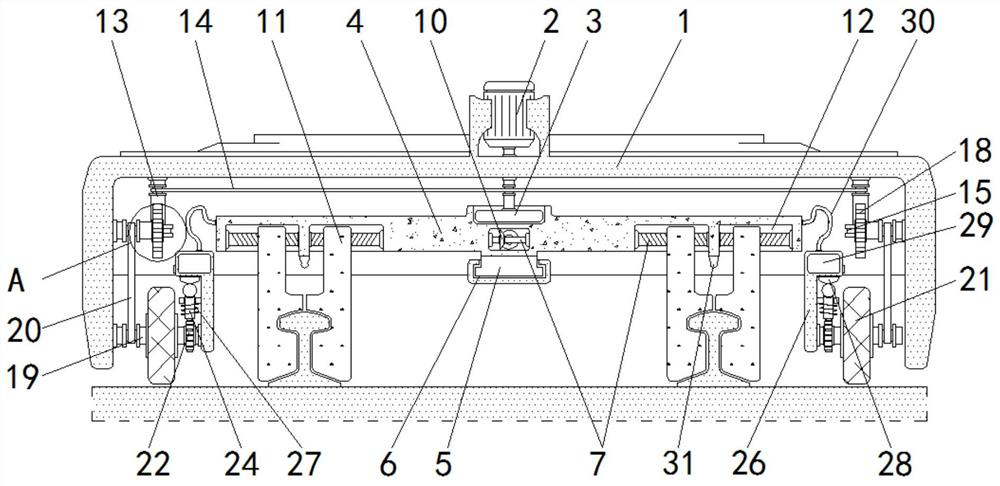

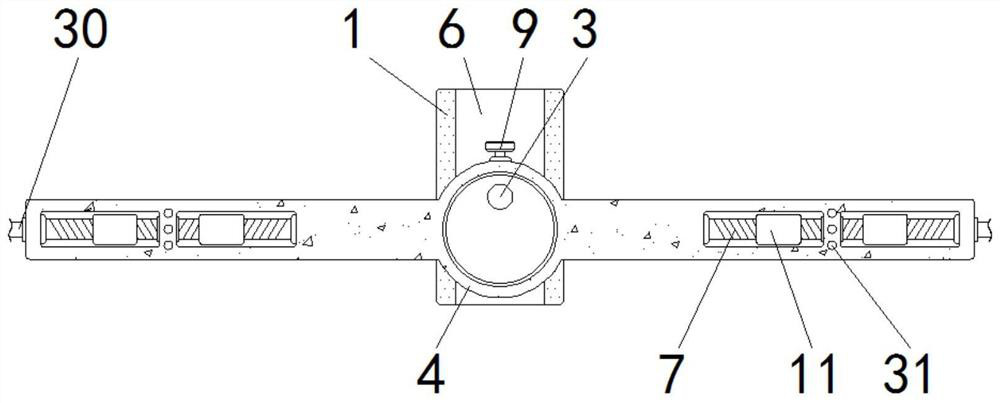

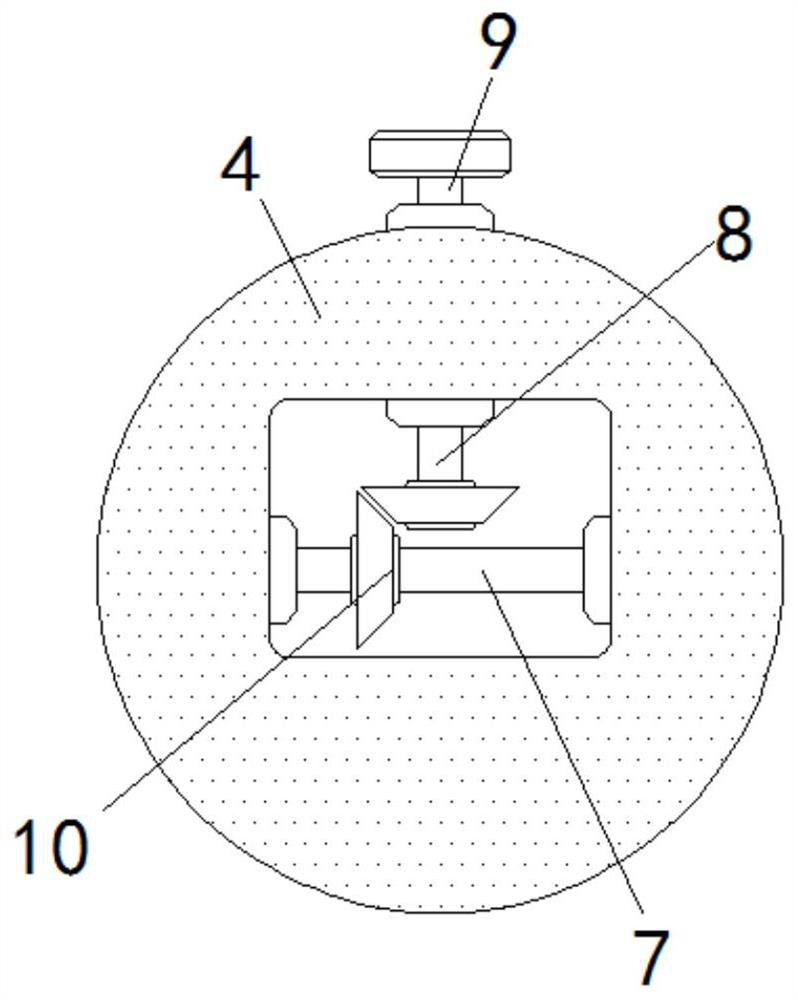

Multidirectional movable rust removal device for railway track maintenance

InactiveCN113737586AImprove rust removal effectReduce rust removal costsRailway track constructionElectric machineryMining engineering

The invention discloses a multidirectional movable rust removal device for railway track maintenance. The movable rust removal device comprises a machine body, a motor, a working plate, a rust removal polishing piece and a spray head, wherein the motor is fixedly installed in the middle of an upper end of the machine body, the working plate is arranged on the outer side of a rotating disc in a sleeving mode, and a guide block is located in a guide groove; a rotating rod and a bevel gear roller are in shaft connection with the interior of the working plate, the middle of the rotating rod is sleeved with a bevel gear ring and a rust removal polishing piece, a rotating ring is fixed to a lower end of a vertical rod, one end of a driving strip is located in a groove, and a disc roller bearing is installed on the inner wall of the side of the machine body; and a second transmission belt is mounted between the disc roller and a rotating shaft. According to the movable rust removal device capable of being carried out in multiple directions and used for railway track maintenance, all-directional grinding and rust removal can be conveniently carried out on a railway track, a rust remover can be quantitatively sprayed, the rust removal effect is improved, meanwhile, waste can be avoided, and the rust removal cost can be reduced.

Owner:深圳市寇彬科技有限公司

Steel bar rust removal treatment device based on construction site

ActiveCN111843778AScientific and reasonable structureEasy to useGrinding carriagesGrinding drivesElectric machineryEngineering

The invention discloses a steel bar rust removal treatment device based on a construction site. The steel bar rust removal treatment device comprises a grinding box, wherein moving grooves are formedin two ends of two sides of the grinding box; a moving block is connected to the inside of each moving groove in a sliding manner; a grinding motor is mounted at the top end of a motor base; screws are movably mounted at one end of a driving block and one end of a mounting block; every two adjacent screws are connected through a threaded cylinder; the outer side of each threaded cylinder is fixedly connected with a fixed sleeve in a sleeving manner; and one end of each fixed sleeve is mounted at one end of the grinding box through a screw. Compared with the prior art, the steel bar rust removal treatment device has the beneficial effects that a worker can conveniently move a steel wire roller and can directly move the steel wire roller from the outside of the grinding box, the problem thatthe worker needs to open a box cover to move the steel wire roller in the prior art is solved, meanwhile, the steel wire roller can be directly moved without closing a machine in the grinding process, the steel bar rust removal treatment device can adapt to steel bars with different specifications in the grinding process, different steel bars are ground, and the grinding efficiency is improved.

Owner:安徽恒星建设工程有限公司

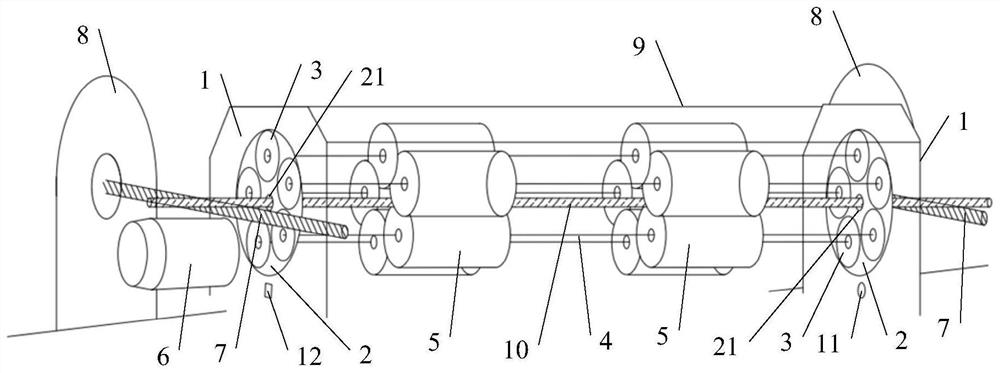

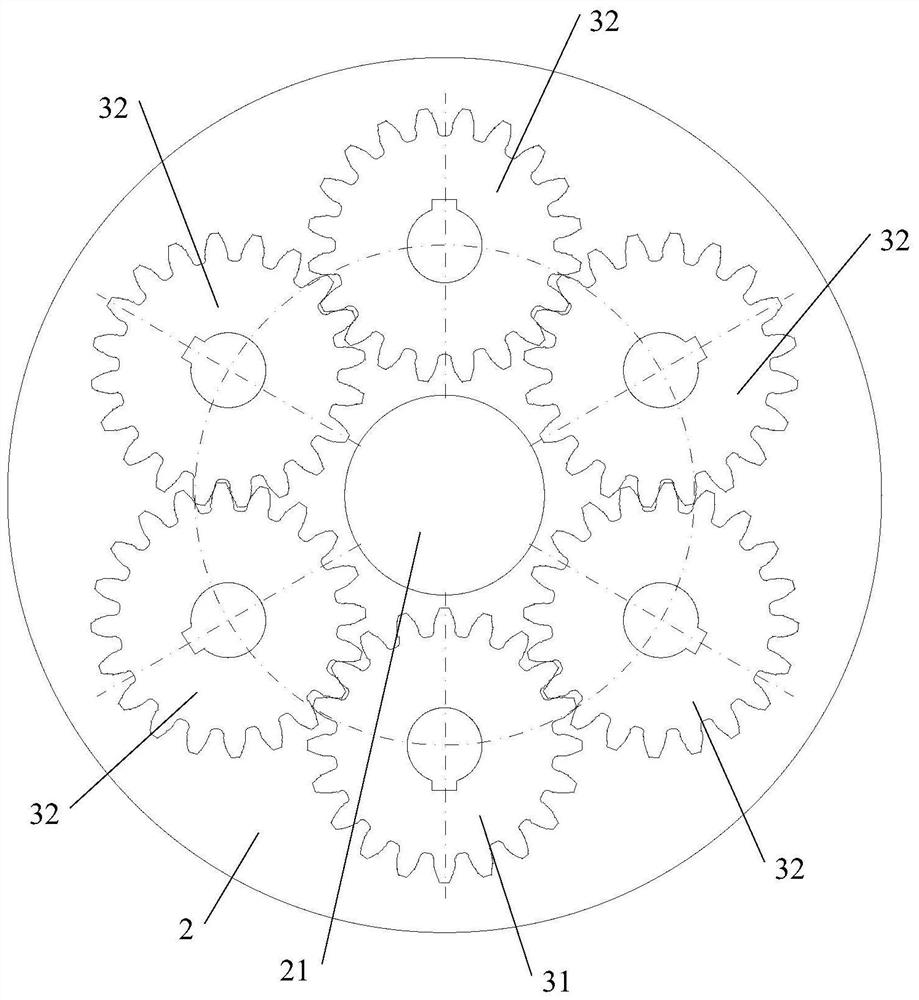

Steel pipe rust removal device

PendingCN113664687ARust removal saves time and effortSimple structureGrinding machinesGrinding feedersGear wheelElectric machinery

The invention relates to a steel pipe rust removal device. The steel pipe rust removal device comprises two supporting frames arranged in a spaced mode, the two supporting frames are each correspondingly provided with a gear frame, and the two gear frames are each correspondingly provided with a circular through hole and a group of transmission gear assembly; each group of transmission gear assembly comprises a driving gear and a plurality of driven gears, the driving gear and the driven gears are sequentially in meshing transmission, and the driving gear and the driven gears are circumferentially arranged around the center of the corresponding circular through hole; a plurality of rotating shafts are arranged between the two groups of transmission gear assemblies, the two ends of each rotating shaft are fixedly connected between the two corresponding driving gears or the two corresponding driven gears, and each rotating shaft is provided with a plurality of rust removal steel brushes; and the driving gears are driven by a driving motor. The steel pipe rust removal device is high in rust removal efficiency, good in rust removal effect, easy to operate, capable of saving time and labor, low in rust removal cost and capable of guaranteeing health and safety of operators.

Owner:CHINA MCC 2 GRP CO LTD

Iron wall surface rust removal device

PendingCN112318247AReduce rust removal costsImprove efficiencyGrinding drivesPlane surface grinding machinesElectric machineryDrive motor

The invention discloses an iron wall surface rust removal device which comprises a mounting plate. Wall surface walking mechanisms are arranged at the four corners of the mounting plate correspondingly, each wall surface walking mechanism comprises a sleeve, an annular electromagnet is arranged at the opening end of each sleeve, a supporting column body penetrates through the center of each annular electromagnet, and a spring is arranged between each supporting column body and the corresponding sleeve; balls are arranged at the ends, away from the sleeves, of the supporting columns, a drivingmechanism is arranged at one side of the mounting plate, the driving mechanism comprises a driving motor module and a driving wheel, the driving wheel and the balls make contact with the wall surface,and a plurality of sets of grinding mechanisms are arranged on the mounting plate towards the wall surface; and each grinding mechanism comprises an eccentric wheel vibration module installed on themounting plate, and each eccentric wheel vibration module is connected with a vibration friction plate towards the wall surface. According to the scheme, compared with traditional manual wall rust removal, the cost is lower, the efficiency is higher, and high mechanization and automation are achieved.

Owner:唐华喜

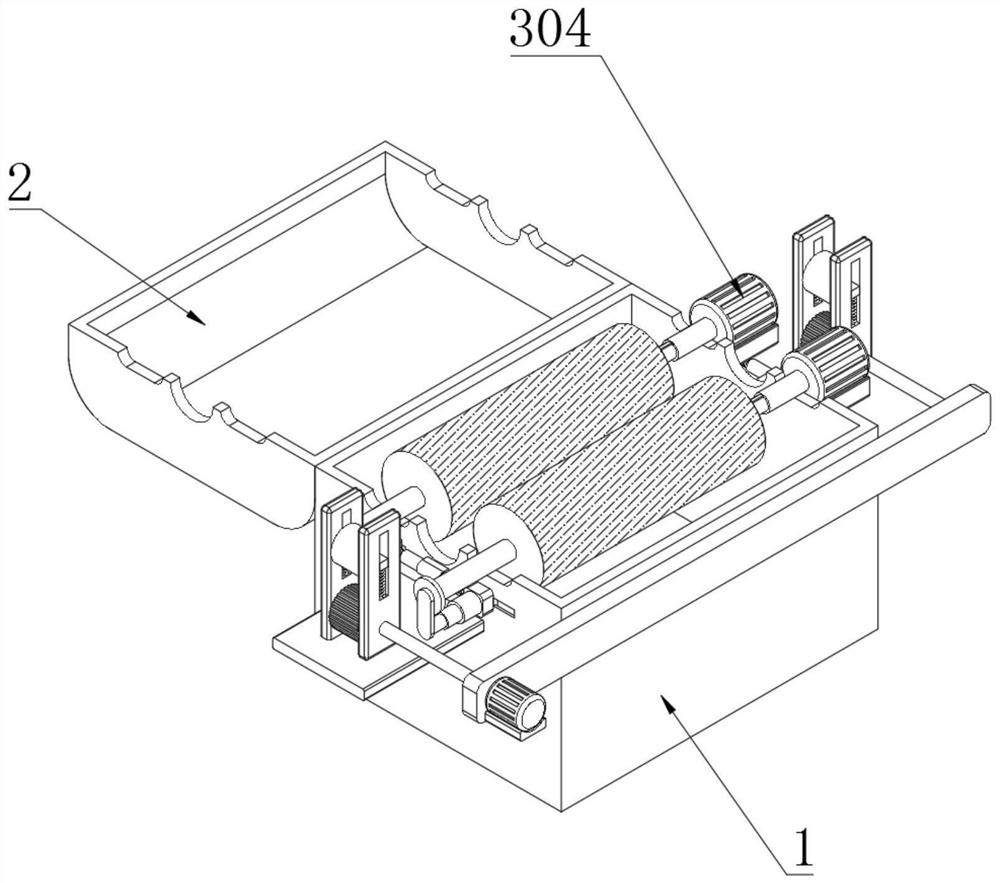

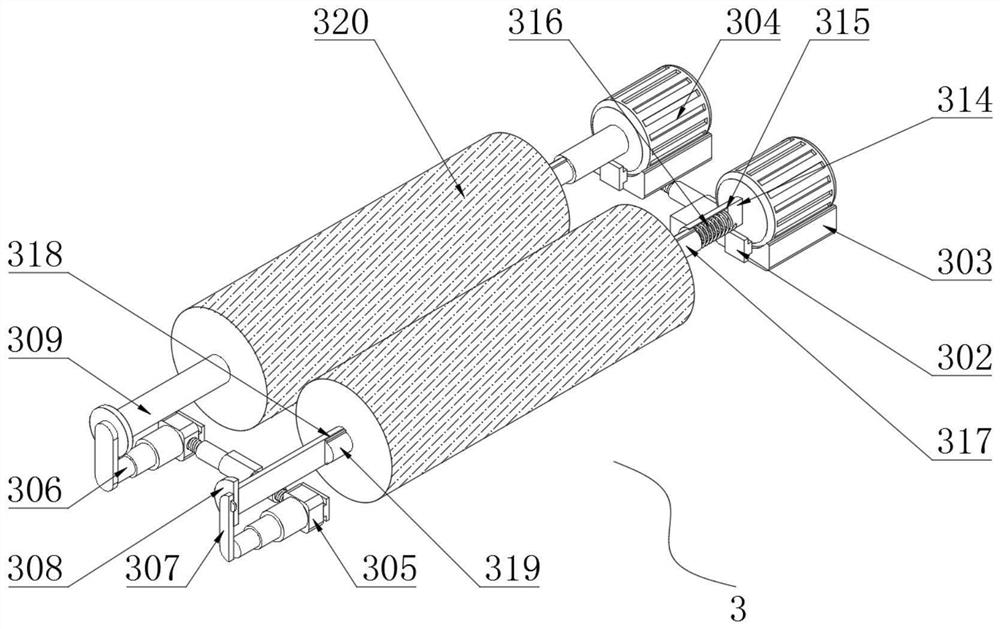

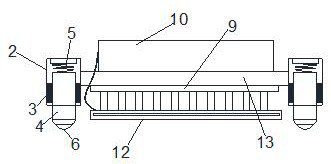

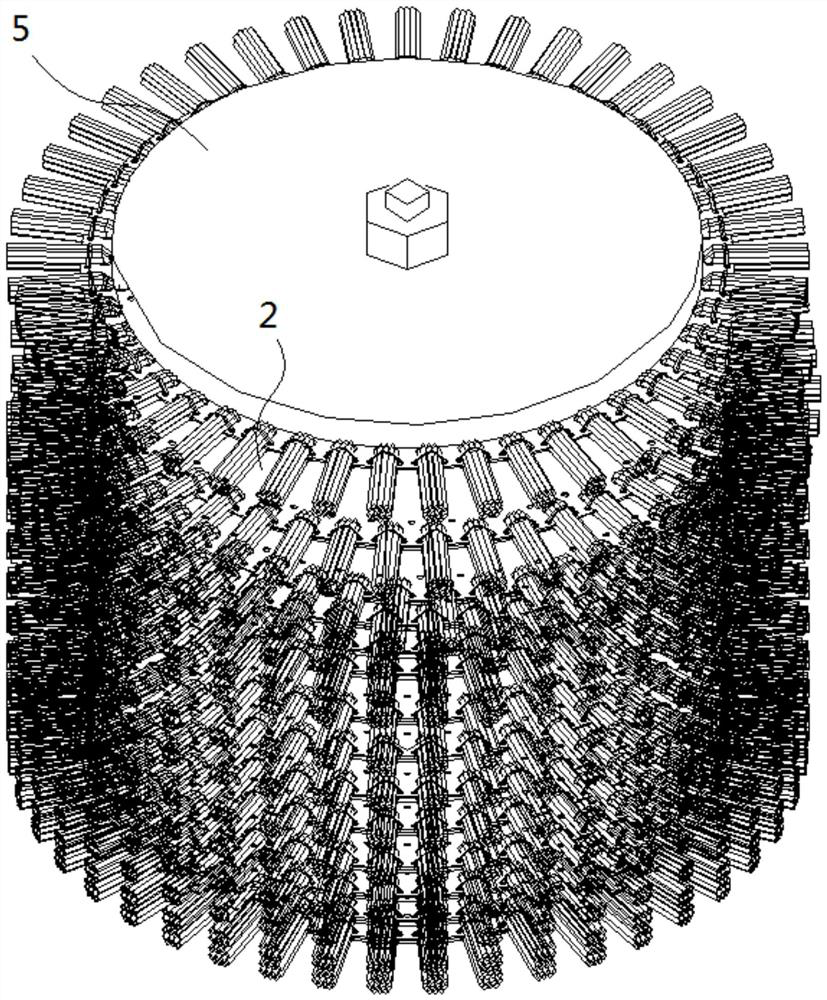

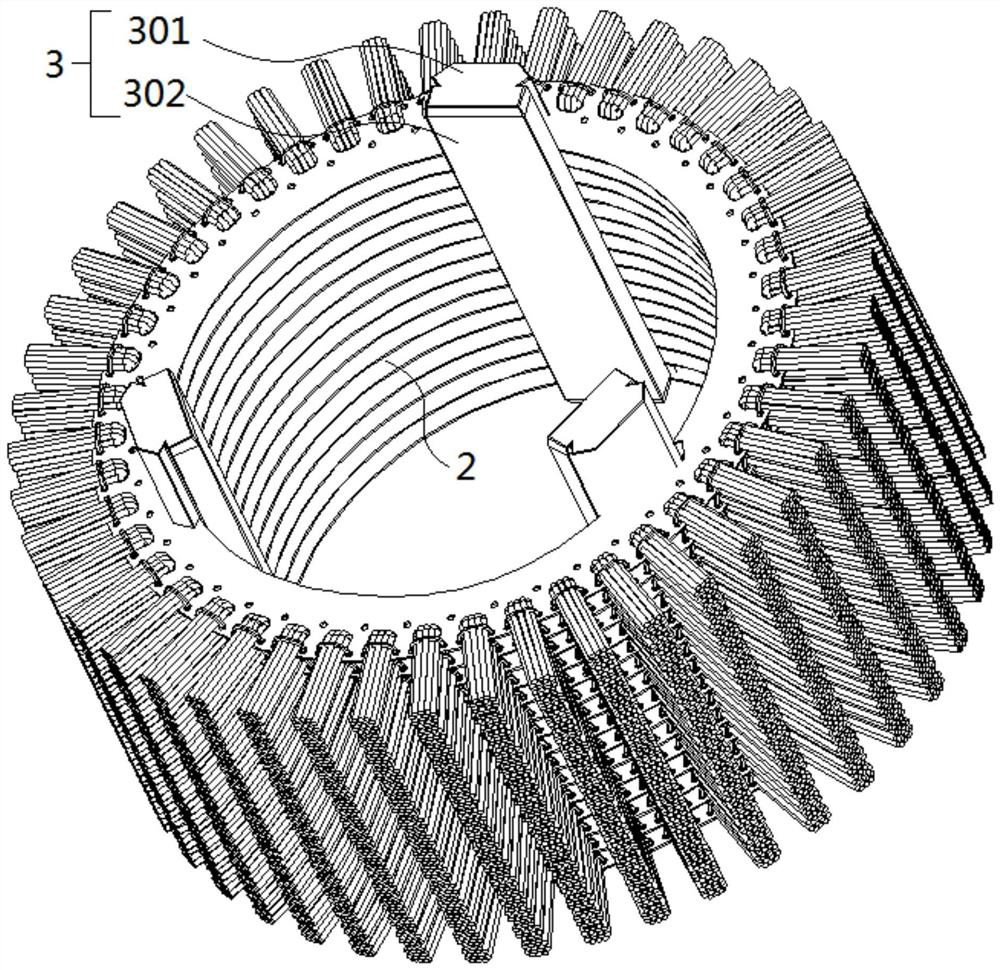

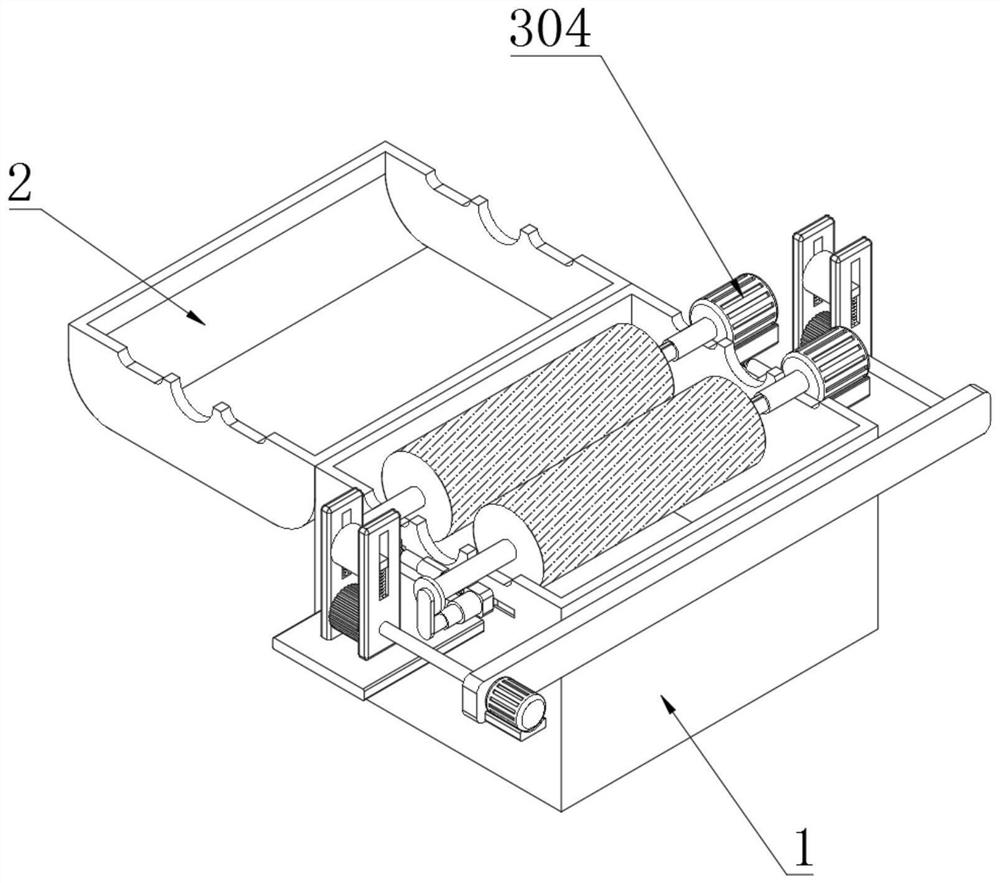

Brush roller and metal plate surface rust removal treatment device

ActiveCN114055313AReduce replacement costsReduce rust removal costsGrinding machine componentsGrinding machinesMetallurgyEngineering

The invention discloses a brush roller and a metal plate surface rust removal treatment device. The brush roller comprises a roller core, and the outer wall of the roller core is wrapped with a scouring pad; a fixing groove is formed in the side wall of the roller core, and the fixing groove penetrates through the top end face of one side of the roller core; a rotating part is rotatably arranged in the fixing groove, and the rotating part can be switched between a locking position and an unlocking position; at the locking position, the rotating part rotates to be attached to the bottom of the fixing groove, and one end of the scouring pad is clamped between the rotating part and the bottom of the fixing groove; at the unlocking position, the rotating part rotates to be separated from the bottom of the fixing groove, and the scouring pad is separated from the rotating part and the fixing groove. The metal plate surface rust removal treatment device comprises the brush roller, after the scouring pad is abraded, the rotating part rotates to be separated from the groove bottom of the fixing groove, the scouring pad can be separated from the rotating part and the fixing groove, the scouring pad can be replaced only by rotating the rotating part, and convenience and rapidness are achieved.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

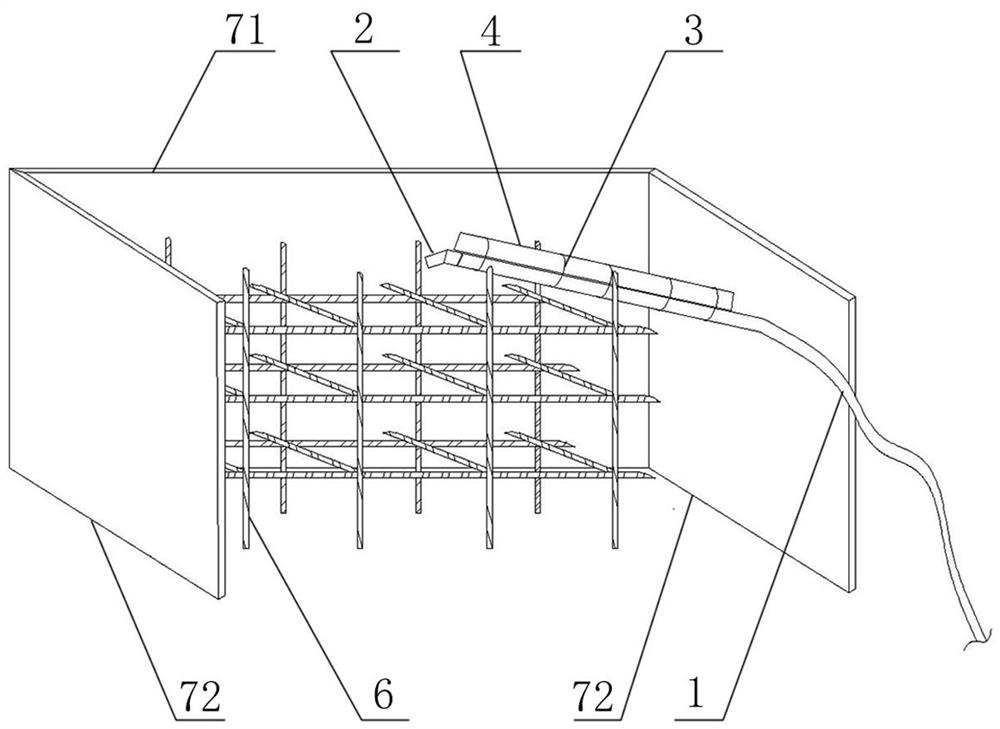

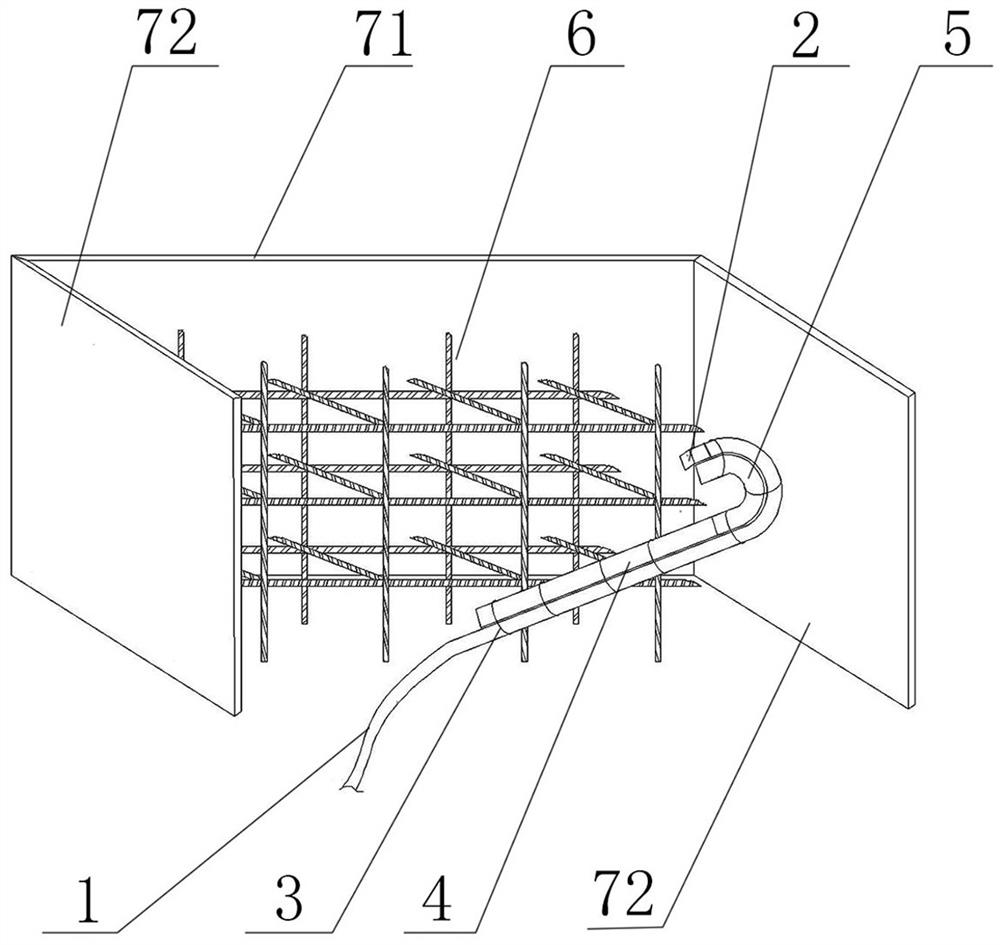

Rust removal construction method for reserved steel bars in buildings

ActiveCN109571272BFast rust removalImprove bindingAbrasive machine appurtenancesAbrasive blasting machinesSand blastingArchitectural engineering

The invention provides a construction method for derusting steel bars reserved for buildings. The specific steps are: a. preparing dry sand material; A sand delivery pipe is connected to the sand outlet of the sandblasting machine, and a spray gun is connected to the outlet end of the sand delivery pipe; c, close the air compressor and the sandblasting machine, add sand to the sandblasting machine, and add step a Prepared sand material; d, making the operating straight rod and the rod head cooperating with the operating straight rod; e, after adding the sand material, carry out the derusting operation on the front side of each steel bar of the reserved steel cage; f, Carry out derusting operations on the back and both sides of each steel bar of the reserved steel cage; g. After the derusting work is completed, clean the sand particles at the reserved steel cage. The cost of the derusting device used in the present invention is relatively low, and can effectively ensure the quality of the project, and has remarkable effects in saving economic costs and shortening the construction period.

Owner:HEBEI CONSTR GRP

A fixing device for rust removal of environmentally friendly steel pipes that can be centered and self-generated

ActiveCN110883668BEven contactTo achieve a calming effectGrinding drivesGrinding machinesEngineeringPipe

Owner:山东东正钢构有限公司

Anti-rust agent for anti-explosion motors

The invention discloses an anti-rust agent for anti-explosion motors. The anti-rust agent is characterized in that a solution is prepared from xylitol, glycerol and aluminium chloride in a mass ratio of 3:5:2, and the pH value of the solution is regulated to 7.8 by using stabilizers (propanesulfonic acid and sodium hydroxide).

Owner:WUXI XIAN EXPLOSION PROOF MOTOR

A round pipe side wall derusting device

ActiveCN112571233BEasy to operateIncrease contact areaGrinding drivesBelt grinding machinesStructural engineeringMechanical engineering

The invention provides a round pipe side wall derusting device, which belongs to the technical field of round pipe derusting. The present invention includes a base plate, a first rotating shaft and a second rotating shaft, a driving mechanism, a door-shaped frame, a push plate, and a grinding mechanism. The second supporting plate is rotatably arranged above the bottom plate, several first rollers are fixed on the first rotating shaft along the length direction in sequence, and several second rollers are fixed on the second rotating shaft along the length direction sequentially, and the driving mechanism can drive the first roller at the same time The first rotating shaft and the second rotating shaft rotate in the same direction. The door-shaped frame is set on the right side of the bottom plate. The door-shaped frame includes a top plate and two side plates arranged on both sides of the top plate. The push plate is movably set between the two side plates through a telescopic structure. In between, the telescopic structure can drive the push plate to slide up and down horizontally, and the grinding mechanism can grind the side walls of round pipes of different sizes. The invention can adapt to round pipes of different sizes and improves the grinding efficiency.

Owner:ZHEJIANG OCEAN UNIV

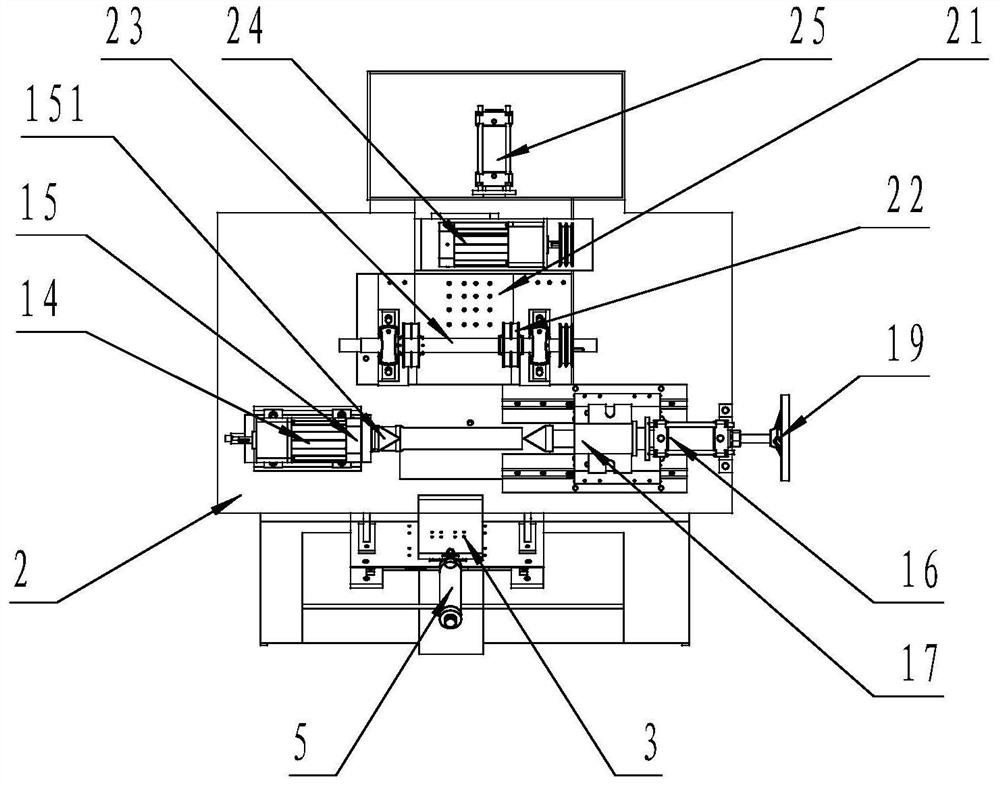

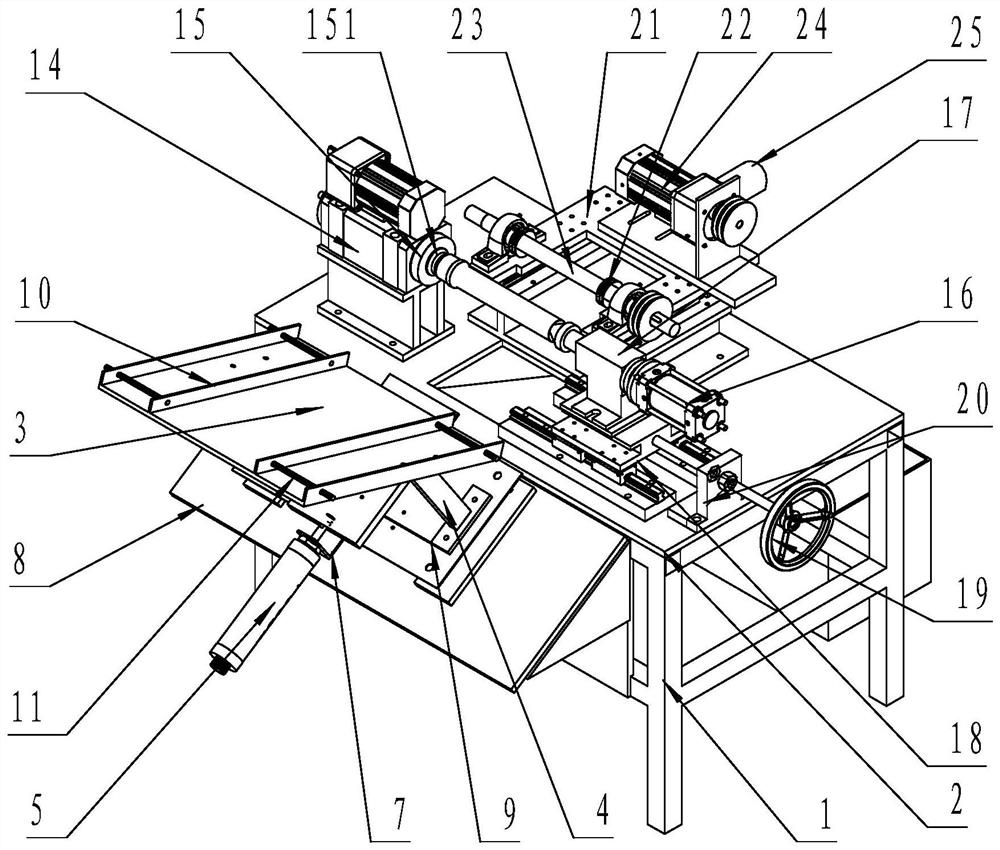

Steel pipe threaded pipe fitting rust removal equipment

PendingCN112108979ARust removal achievedRealize automatic feeding processGrinding carriagesGrinding drivesPipe fittingThreaded pipe

The invention discloses steel pipe threaded pipe fitting rust removal equipment. The steel pipe threaded pipe fitting rust removal equipment comprises a machine frame and a workbench installed on themachine frame, and further comprises a steel pipe threaded pipe fitting feeding device installed on the part, on the front side of the workbench, of the machine frame, a steel pipe threaded pipe fitting jacking, clamping and rotating device longitudinally installed on the front side of the top face of the workbench in the left-right direction, and a steel pipe threaded pipe fitting rust removal device mounted on the top surface of the rear side of the workbench. An air pressure and electric appliance control device is further included; and the steel pipe threaded pipe fitting rust removal equipment further comprises a steel pipe threaded pipe fitting rolling feeding groove bottom transverse width adjusting device, and a large sliding base pushes a positioning device. By means of the steelpipe threaded pipe fitting rust removal equipment, automatic feeding and automatic rust removal of steel pipe threaded pipe fitting rust removal are achieved, the labor intensity of rust removal workers and the rust removal cost of the steel pipe threaded pipe fitting are reduced, and the rust removal efficiency of the steel pipe threaded pipe fitting is improved; and the steel pipe threaded pipefitting rust removal equipment is also suitable for rust removal of steel pipe threaded pipe fittings with different specifications and sizes.

Owner:济南迈科管道科技有限公司

A kind of steel bar derusting treatment device based on the construction site

ActiveCN111843778BEasy to moveSolve mobileGrinding carriagesGrinding drivesArchitectural engineeringElectric machinery

The invention discloses a steel bar derusting treatment device based on a construction site, which includes a grinding box, two ends of the grinding box are provided with moving grooves, a moving block is slidably connected to the inside of the moving groove, and a grinding motor is installed on the top of the motor base to drive One end of both the block and the installation block is movably installed with a screw rod, and the two adjacent screw rods are connected through a threaded cylinder. Compared with the technology, the beneficial effect of the present invention is convenient for the staff to move the steel wire roll, and the staff can directly move the steel wire roll from the outside of the grinding box, which solves the problem in the prior art that the staff needs to open the box cover to move the steel wire roll, and at the same time During the grinding process, the steel wire roller can be moved directly without shutting down the machine. It can adapt to different specifications of steel bars during the grinding process, and can grind different steel bars to improve the grinding efficiency.

Owner:安徽恒星建设工程有限公司

Lubricant composition for explosion-proof motor

InactiveCN104694239ADoes not produce clothingNo hydrogen embrittlementLubricant compositionBoridePotassium

The invention discloses a lubricant composition for an explosion-proof motor, and is characterized in that the composition contains: on a weight basis, 20-60 parts of a lower polyol, 0.001-2 parts of glycerophosphate, 0.001-3 parts of boride, 0.02-0.1 parts of a stabilizer, and 25-80 parts of water, wherein the glycerophosphate is at least one of ammonium glycerophosphate, sodium glycerophosphate, potassium glycerophosphate, calcium glycerophosphate and magnesium glycerophosphate; the boride is at least one of ammonium pentaborate, borax, boric acid and stannous fluoborate; and the lower polyol is at least one of ethylene glycol, propylene glycol, glycerin, butanediol and pentanediol.

Owner:WUXI XIAN EXPLOSION PROOF MOTOR

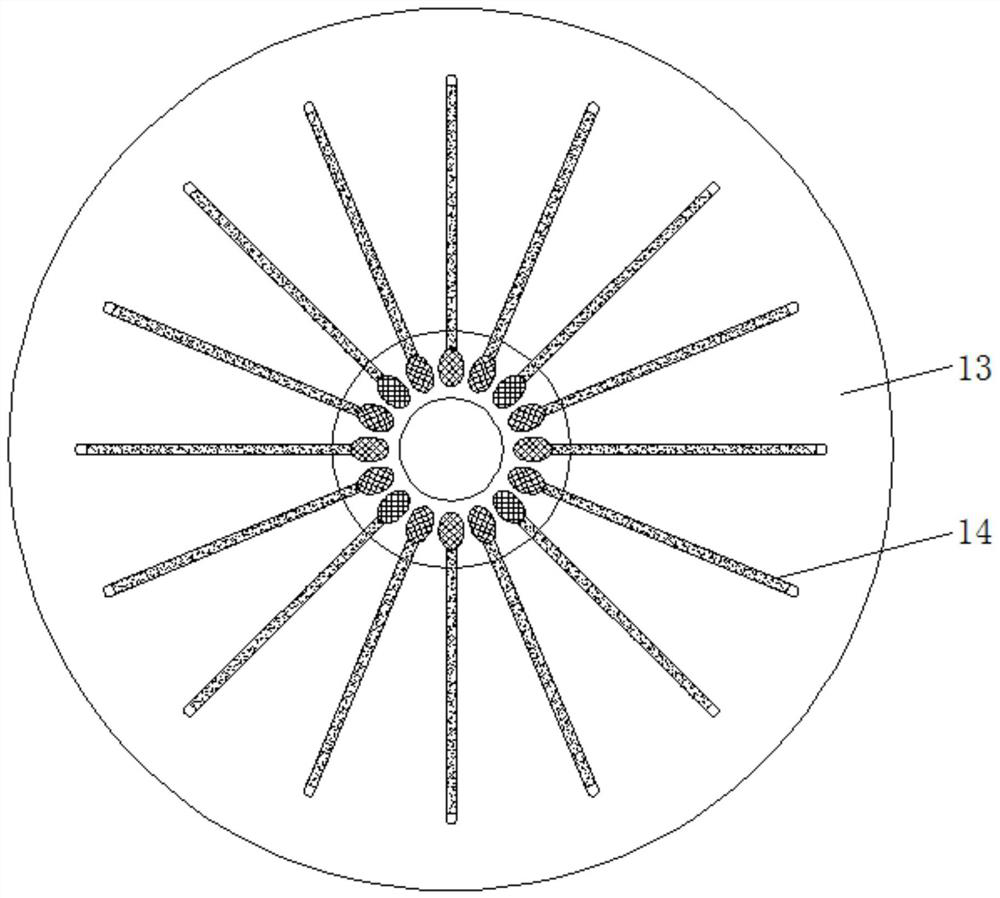

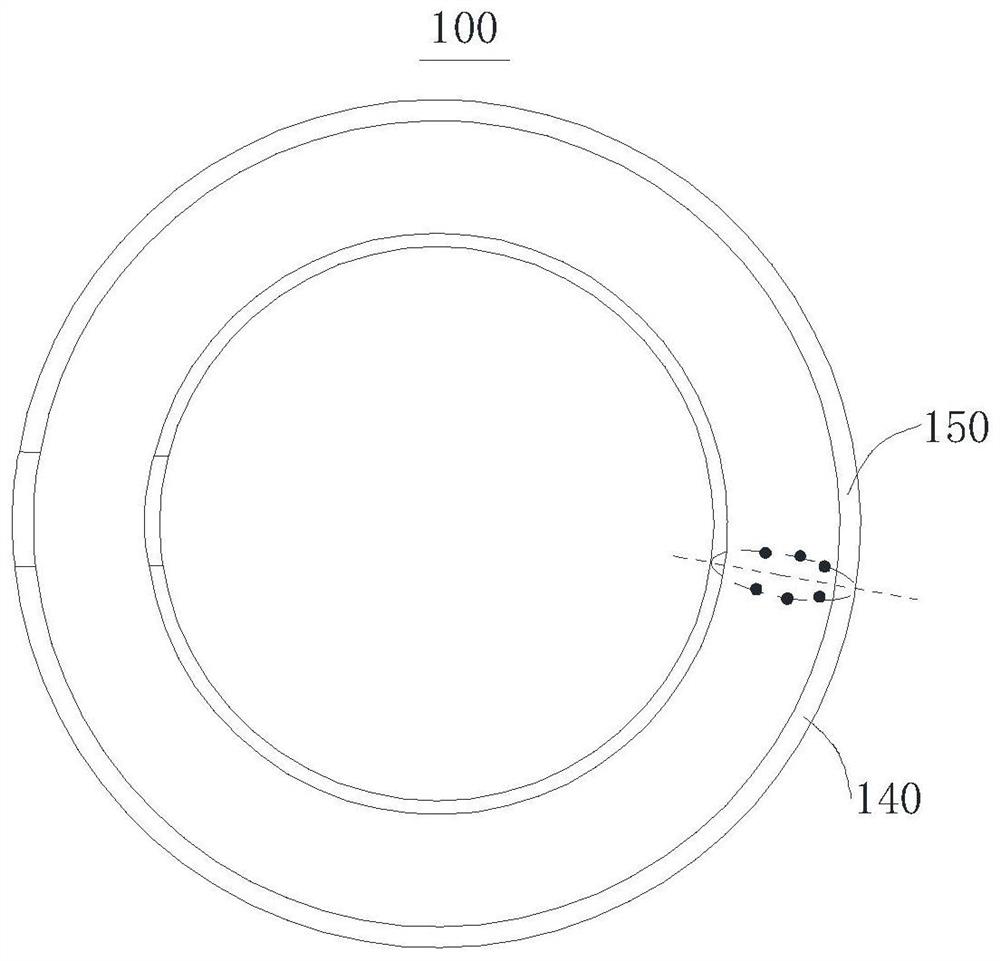

Annular joint device for facilitating rust removal by laser cleaning machine

ActiveCN111906094AIncrease profitImprove work efficiencyCleaning processes and apparatusEngineeringMechanical engineering

Disclosed is an annular joint device for facilitating rust removal by a laser cleaning machine. The annular joint device comprises an outer-layer mirror, an inner-layer mirror, a first cylindrical laser input pipe and a first initial-section total reflection mirror, wherein the outer-layer mirror is formed through annular distribution of a plurality of total reflection mirrors, the inner-layer mirror is formed by through annular distribution of a plurality of half reflection mirrors, and the inner-layer mirror is arranged in an area defined by the outer-layer mirror. The outer-layer mirror andthe inner-layer mirror define an annular reflection area, the outer-layer mirror is provided with an opening in the circumferential direction, the first cylindrical laser input pipe communicates withthe reflection area at the opening, and is configured to convey wire harness laser, the first initial-section total reflection mirror is arranged in the annular reflection area, and the reflection surface of the first initial-section total reflection mirror is obliquely arranged at the opening and is arranged in the direction of the central line of the annular reflection area. The annular joint device can convert input wire harness laser into ring-shaped laser, is suitable for surface purification treatment of cylinders and irregular workpieces, is convenient to implement, and can save energy, and improve the cleaning efficiency, thereby achieving quick treatment and reducing energy consumption.

Owner:中国南方电网有限责任公司超高压输电公司柳州局

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com