A round pipe side wall derusting device

A technology of circular tubes and rotating shafts, which is applied in the direction of grinding drive devices, manufacturing tools, and parts of grinding machine tools. It can solve the problems of reduced grinding efficiency, high labor intensity, long grinding time, etc., and achieves improved grinding efficiency. Improve the scope of application and reduce the cost of rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

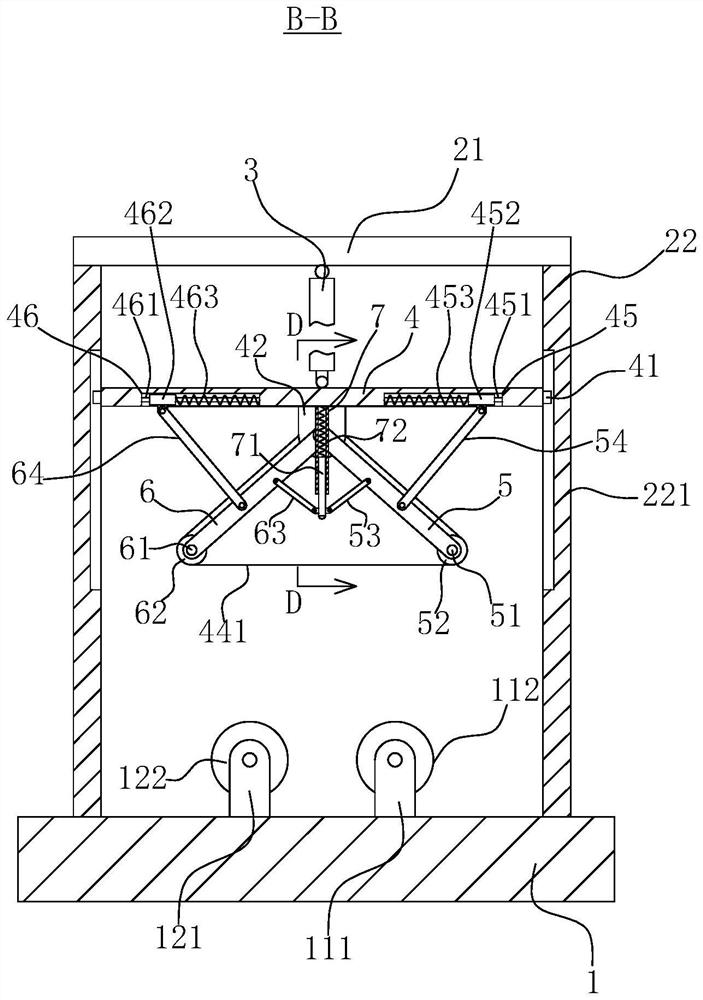

[0060] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

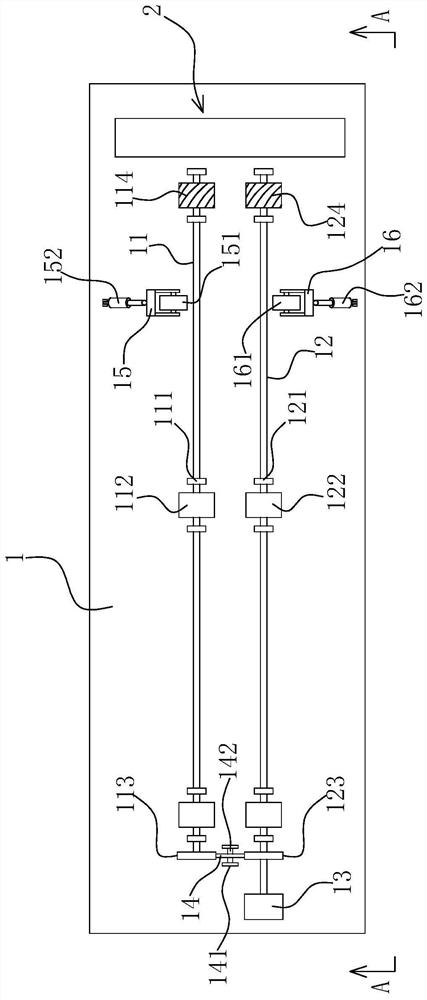

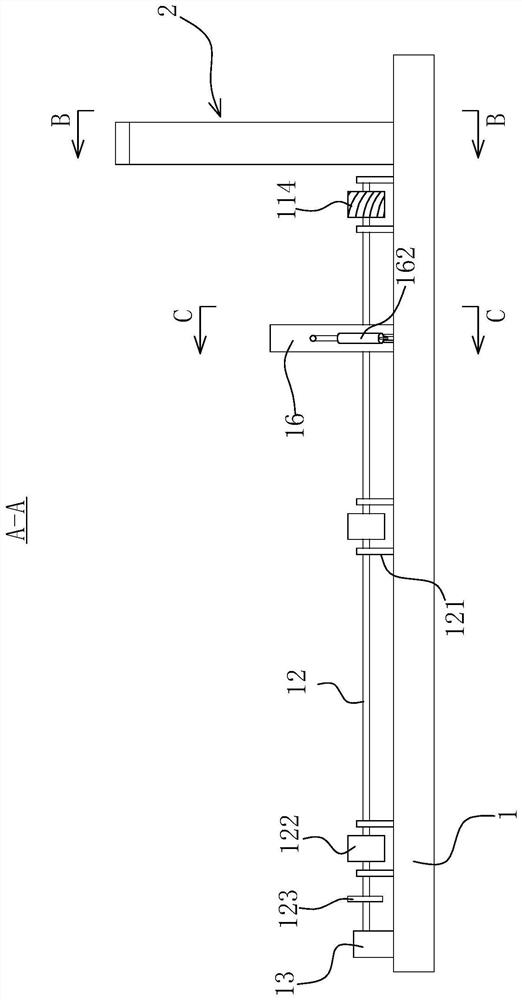

[0061] Such as Figures 1 to 6 As shown, a round pipe side wall derusting device includes a bottom plate 1, a first rotating shaft 11, a second rotating shaft 12, a driving mechanism, an auxiliary mechanism, a door frame 2, a push plate 4 and a grinding mechanism.

[0062] The bottom plate 1 is rectangular.

[0063] The first rotating shaft 11 is arranged above the bottom plate 1 through several first supporting plates 111, and the second rotating shaft 12 is arranged above the bottom plate 1 through several second supporting plates 121. The first rotating shaft 11 Parallel and aligned with the second rotating shaft 12, several first rollers 112 are sequentially fixed on the first rotating shaft 11 along the length direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com