Annular joint device for facilitating rust removal by laser cleaning machine

A joint device and cleaning agent technology, which is applied in the field of laser cleaning, can solve difficult problems such as processing, and achieve the effects of improving utilization, saving labor resources, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

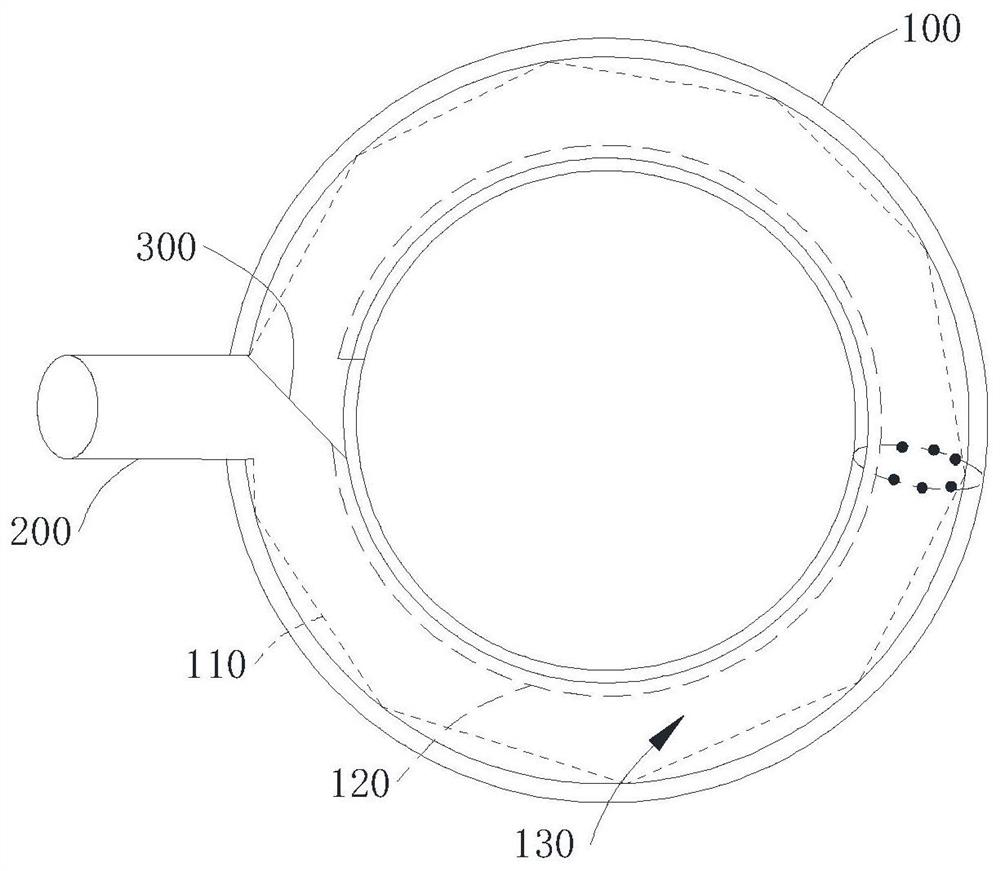

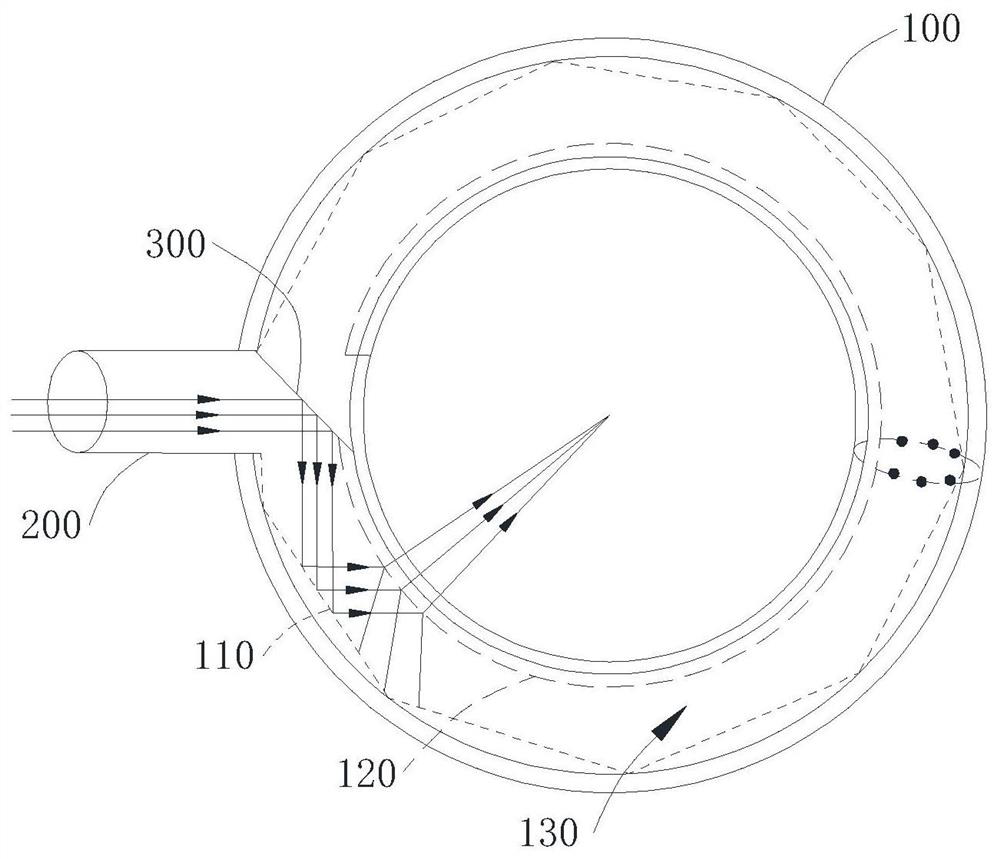

[0032] Please refer to figure 1 with figure 2 , a ring joint device for laser cleaning agent derusting, comprising an outer layer mirror 110, an inner layer mirror 120, a first cylindrical laser input tube 200 and a first total reflection mirror 300 at the beginning, and the outer layer mirror 110 is composed of several total reflection mirrors Formed in a circular arrangement, the inner mirror 120 is formed by a number of half-reflecting mirrors arranged in a ring, the inner mirror 120 is arranged in the area enclosed by the outer mirror 110, and the outer mirror 110 and the inner mirror 120 form a ring reflection Area 130, the outer layer mirror 110 is provided with an opening along the ring direction, the first cylindrical laser input tube 200 communicates with the reflection area at the opening, the first cylindrical laser input tube 200 is configured to deliver the line beam laser, the first initial section The total reflection mirror 300 is disposed in the annular refl...

Embodiment 2

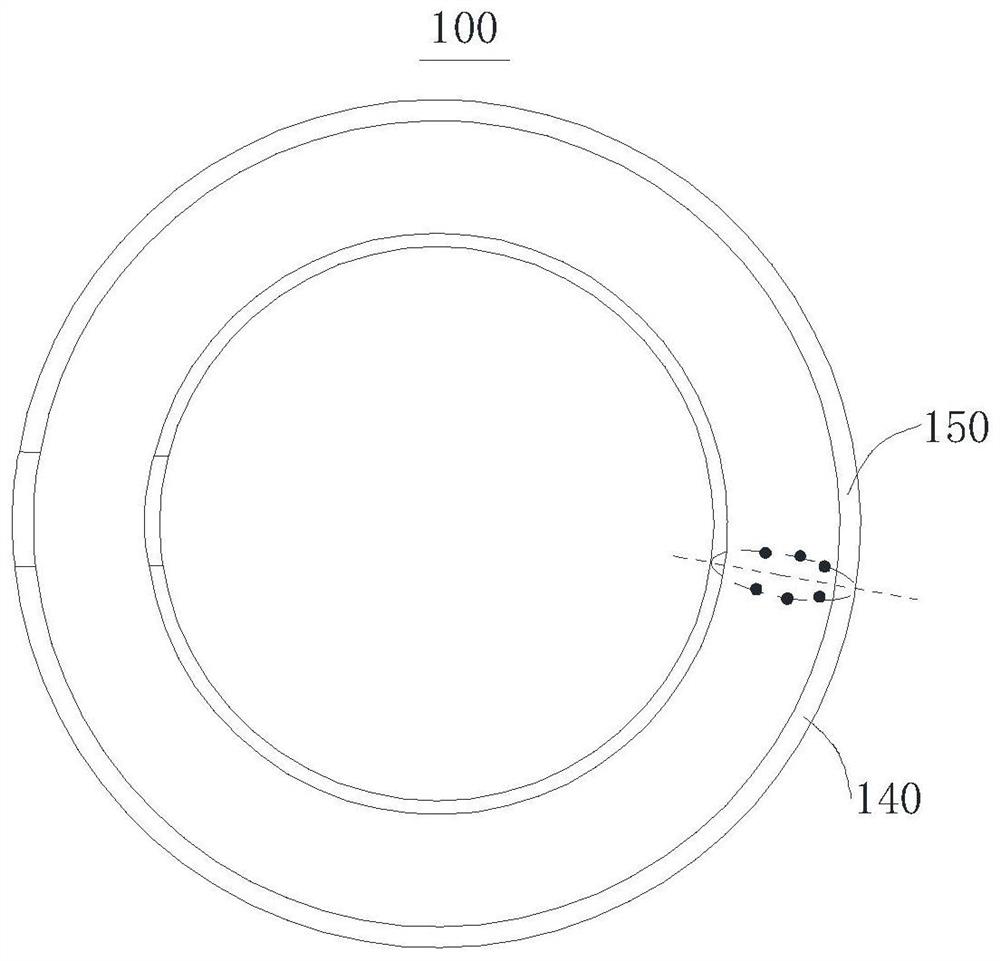

[0046] Please refer to Figure 4 , Figure 4 For this embodiment of the present invention, a laser cleaning agent derusting ring joint device is provided.

[0047] This embodiment provides a laser cleaning agent derusting annular joint device, which is roughly the same as the laser cleaning agent derusting annular joint device of the first embodiment, the difference between the two is that the second cylindrical laser input tube 400 of this embodiment With the second total reflection mirror 500 at the beginning.

[0048] Please refer to Figure 4 , the laser cleaning agent derusting annular joint device is also provided with a second cylindrical laser input tube 400, and the second cylindrical laser input tube 400 is equipped with a second initial total reflection mirror 500, and the second cylindrical laser input tube 400 is connected to the second cylindrical laser input tube 400. A cylindrical laser input tube 200 is arranged side by side and all communicates with the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com