Sand blasting rust removal device

A technology of sandblasting and derusting, sandblasting equipment, which is applied to the processing equipment of used abrasives, abrasive jet machine tools, abrasives, etc., can solve the problems of high processing cost, harsh production environment, low work efficiency, etc., and achieve stable quality , Low rust removal cost, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

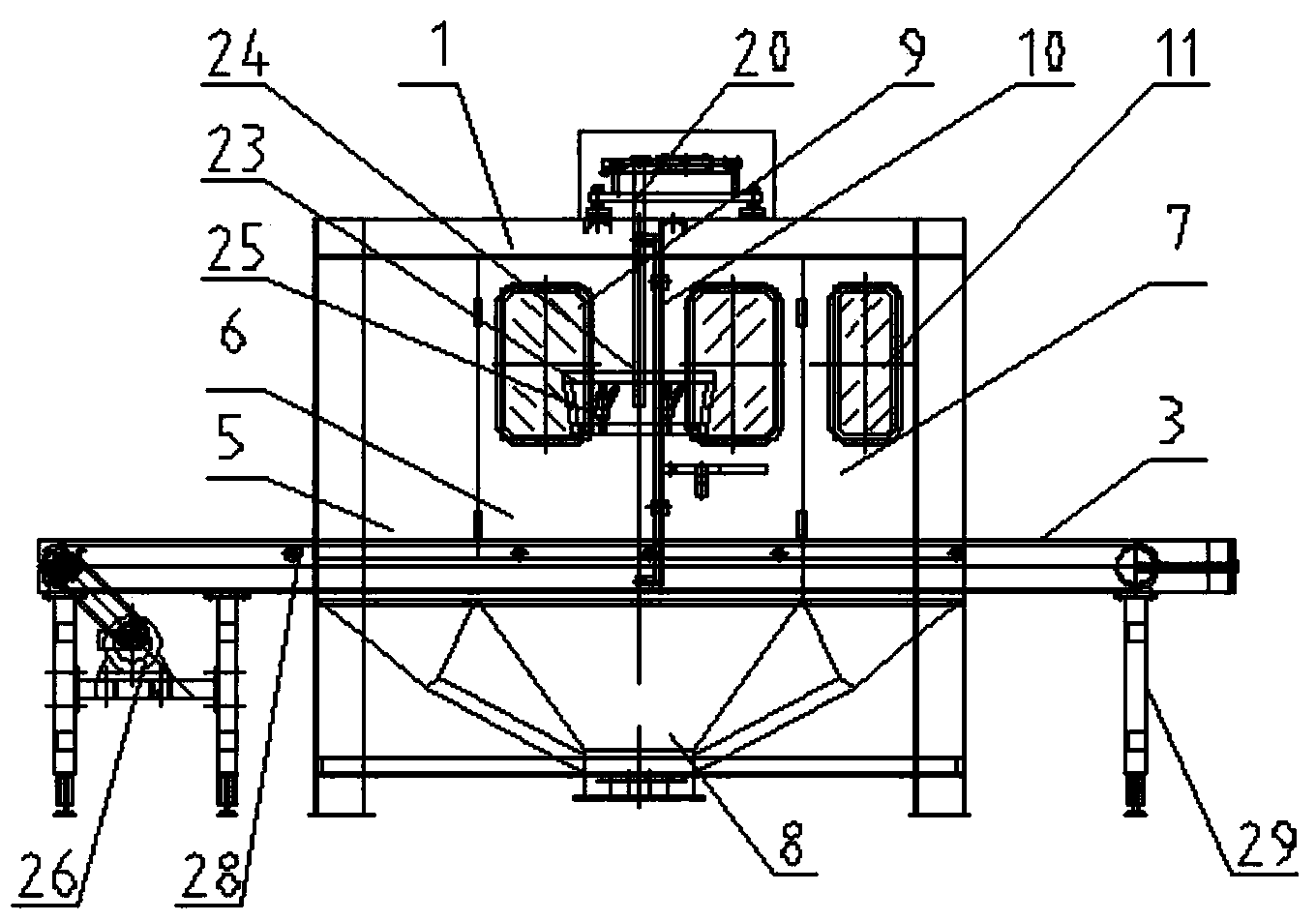

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

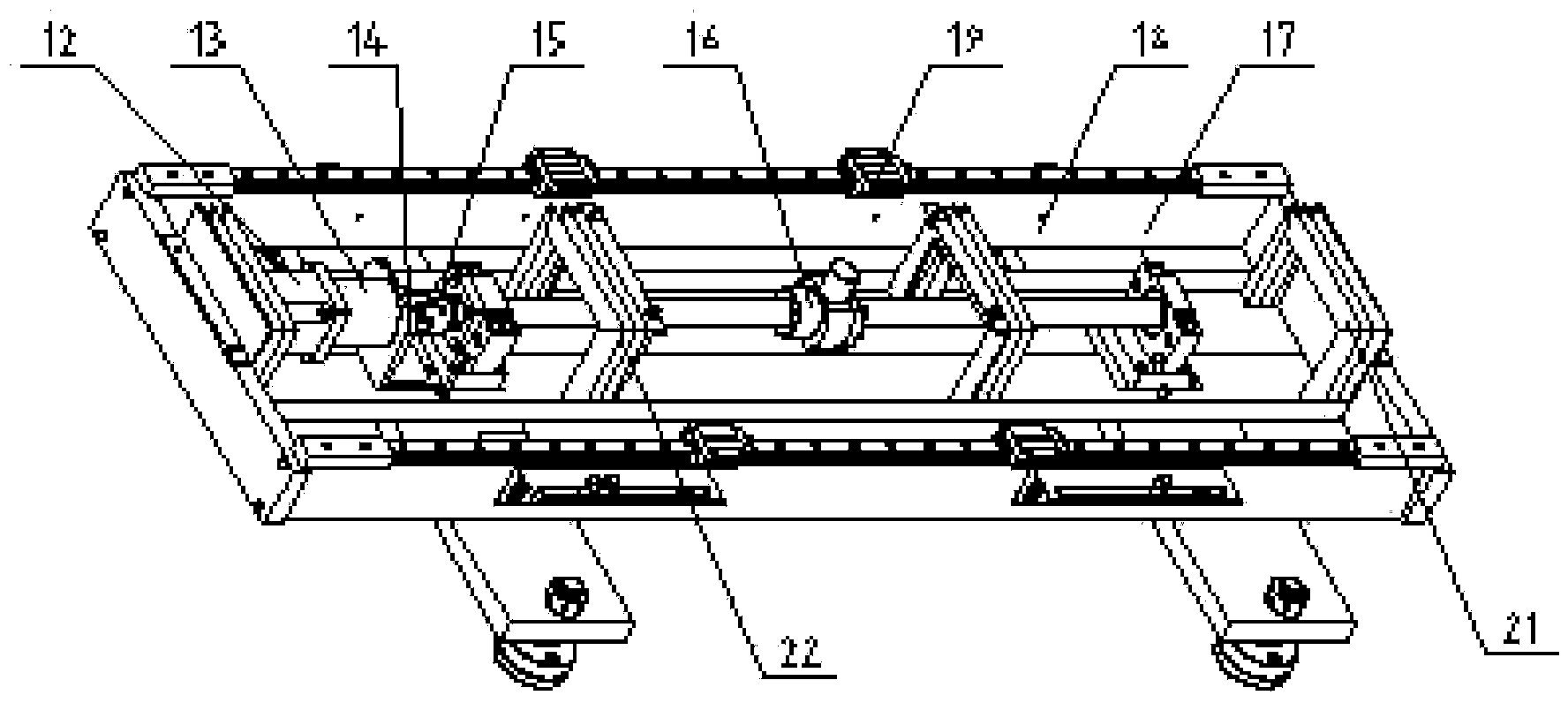

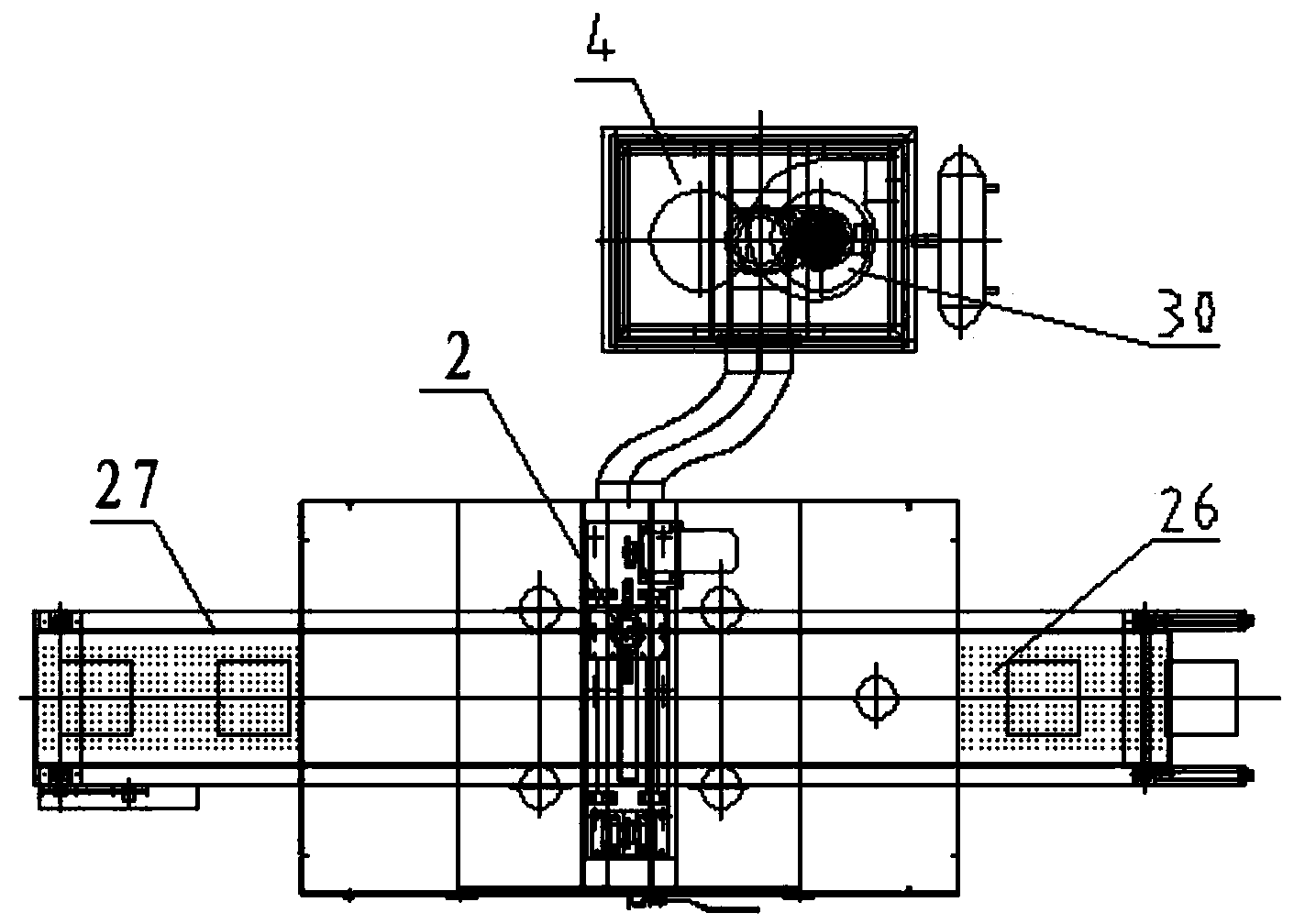

[0038] Such as Figure 1 to Figure 3 As shown, this embodiment provides a sandblasting and derusting device, which includes: a sandblasting cabin 1 connected to an external electric control system, a driving mechanism, a transmission mechanism, a conveying device 3 for transporting workpieces, and a The dust removal device 4 is connected to the driving mechanism and drives the transmission mechanism to rotate to drive the sandblasting device to move in the direction of workpiece transmission.

[0039] Wherein, the driving mechanism includes a servo motor 12 and a reducer 13, the reducer 13 is installed on the frame 17 through the reducer mounting seat 14, two sets of linear guide rail pairs 18 are arranged on the frame 17, and each group of linear guide rail pairs 18 is provided with a There are two groups of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com