Magnetic attraction specialized robot working system and implementing method thereof

A working system and robot technology, applied in chemical instruments and methods, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as the failure of normal operation of the convex surface of ships, and achieve easy loading, unloading and transportation, increasing environmental adaptability, and convenience. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Magnetic special robot working system, including rust removal robot 1, remote control, electric control cabinet and sandblasting device;

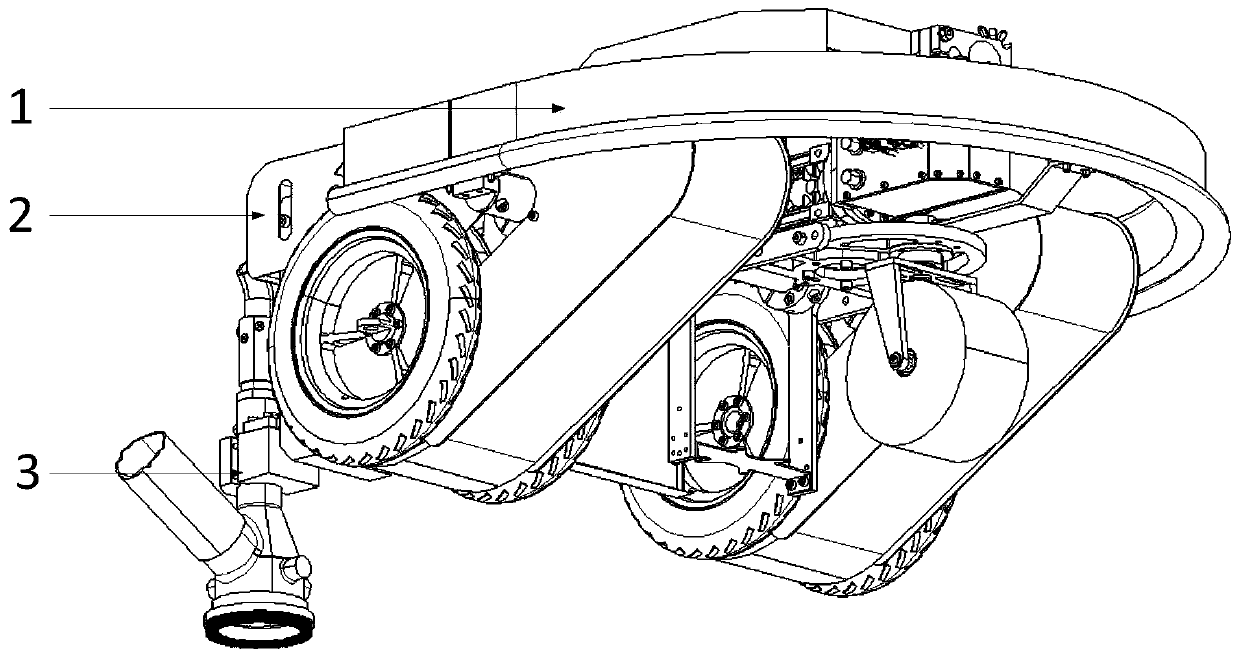

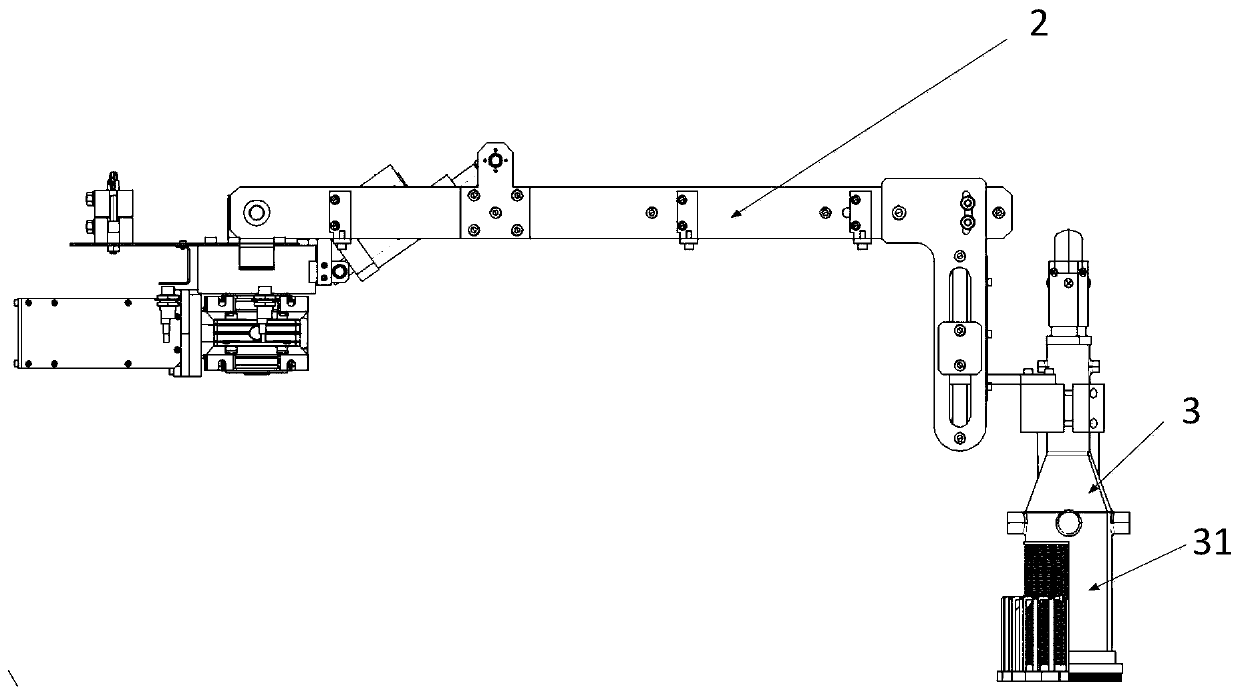

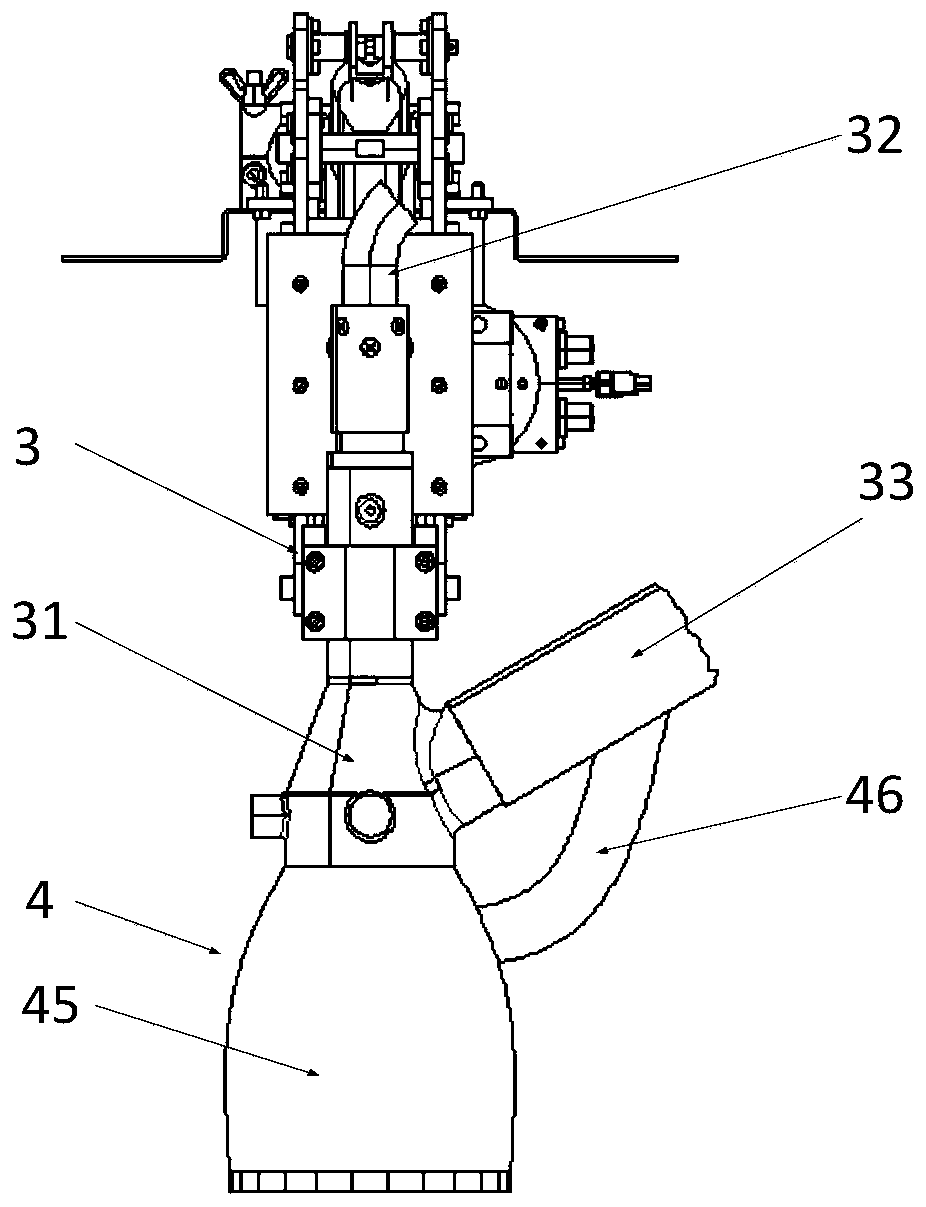

[0024] Such as Figure 1-3 As shown, the derusting robot 1 includes a driving module, a magnetic adsorption module, a mechanical arm module 2, a derusting module 3, a control box module and a body; the driving module includes a driving wheel and a driven wheel, and the two driving wheels are fixed on the front of the body. Power is provided by a servo motor and a reducer, and the servo motor is connected to the control box module through wires; the driven wheel is a universal wheel set in the center of the rear of the body; the magnetic adsorption module includes permanent magnets set on the driving wheel and the driven wheel respectively to ensure The body is adsorbed on the outer surface of the ship; the mechanical arm module 2 is mainly composed of a turntable, a swing rod and an electric push rod. The swing rod is installed on th...

Embodiment 2

[0029] On the basis of Embodiment 1, a permanent magnet or an electromagnet for adsorbing the surface of the ship is provided at the bottom of the cover 44, and the electromagnet is connected to the control box module through a wire; the adsorption and sealing effect of the sealing cover 4 can be increased.

Embodiment 3

[0031] On the basis of Embodiment 1, a cleaning brush is provided at the bottom of the cover rod 44, and a vibrator is arranged on the cover rod 44, and the vibrator is connected to the control box module through wires. Because there are many attachments on the surface of the hull, the working conditions of the derusting robot 1 are greatly affected, which is unfavorable for the derusting operation of the derusting robot 1. The cleaning brush is driven by the vibrator, so that it can clean up the attachments on the hull and certain rust on the surface during walking, so as to create better working conditions for the spray gun 31 .

[0032] Such as Figure 5 As shown, the implementation method of the magnetic suction special robot working system includes the following steps:

[0033] S1. Check whether the rust removal robot 1, the remote control, the electric control cabinet and the sandblasting device are in good condition;

[0034] S2. Adjust the tightness between the derus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com