High-pressure descaling spray head

A nozzle and high-pressure technology, applied in the direction of spray guns, explosion generating devices, abrasives, etc., can solve the problems of difficulty in cleaning the rust removal site, easy wear of the inner wall of the nozzle, and difficulty in recycling sandblasting, etc., to achieve enhanced and guaranteed rust removal effects , to prevent the effect of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

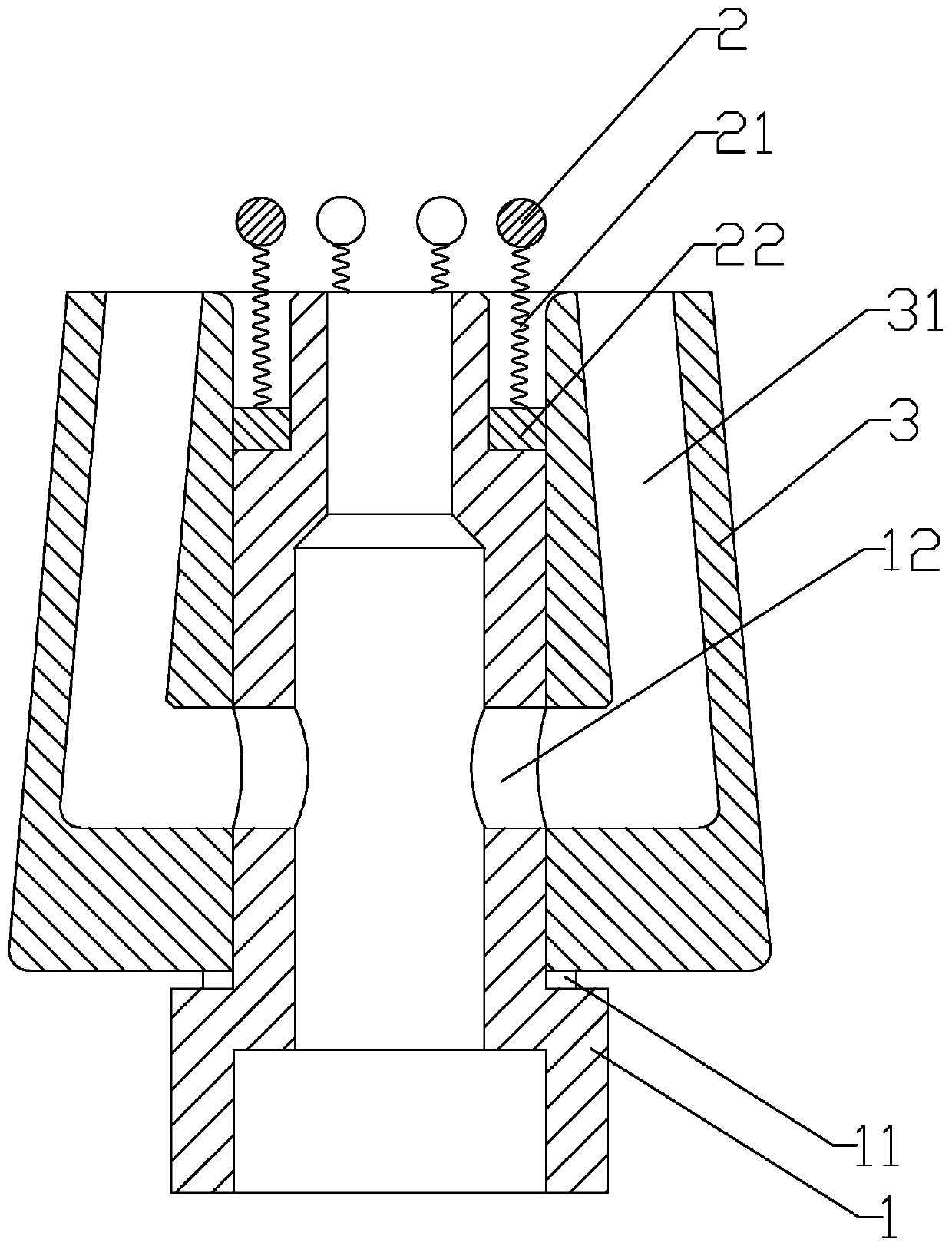

[0036] Such as figure 1 In the shown embodiment 1, a high-pressure derusting nozzle includes a nozzle body 1 , an impact member 2 and an outer nozzle 3 . The outer wall of the nozzle body 1 is provided with a through hole 12, the outer nozzle body 1 is provided with an outer nozzle 3, the nozzle body 1 and the outer nozzle 3 are threaded, and the cavity 31 inside the outer nozzle 3 communicates with the inner cavity of the nozzle body 1 through the through hole 12, The cavity 31 of the outer spray head 3 is annular and has a conical cross section. The outer end of the nozzle body close to the water outlet, the fixed ring 22 is set between the nozzle body and the outer nozzle, the fixed ring 22 is fixed with evenly distributed tension springs 21, one end of the tension spring 21 is connected with the fixed ring, and the other end is fixed with a shock Part 2, the impact part is made of steel balls, the tension spring is set parallel to the central axis of the nozzle body, and ...

Embodiment 2

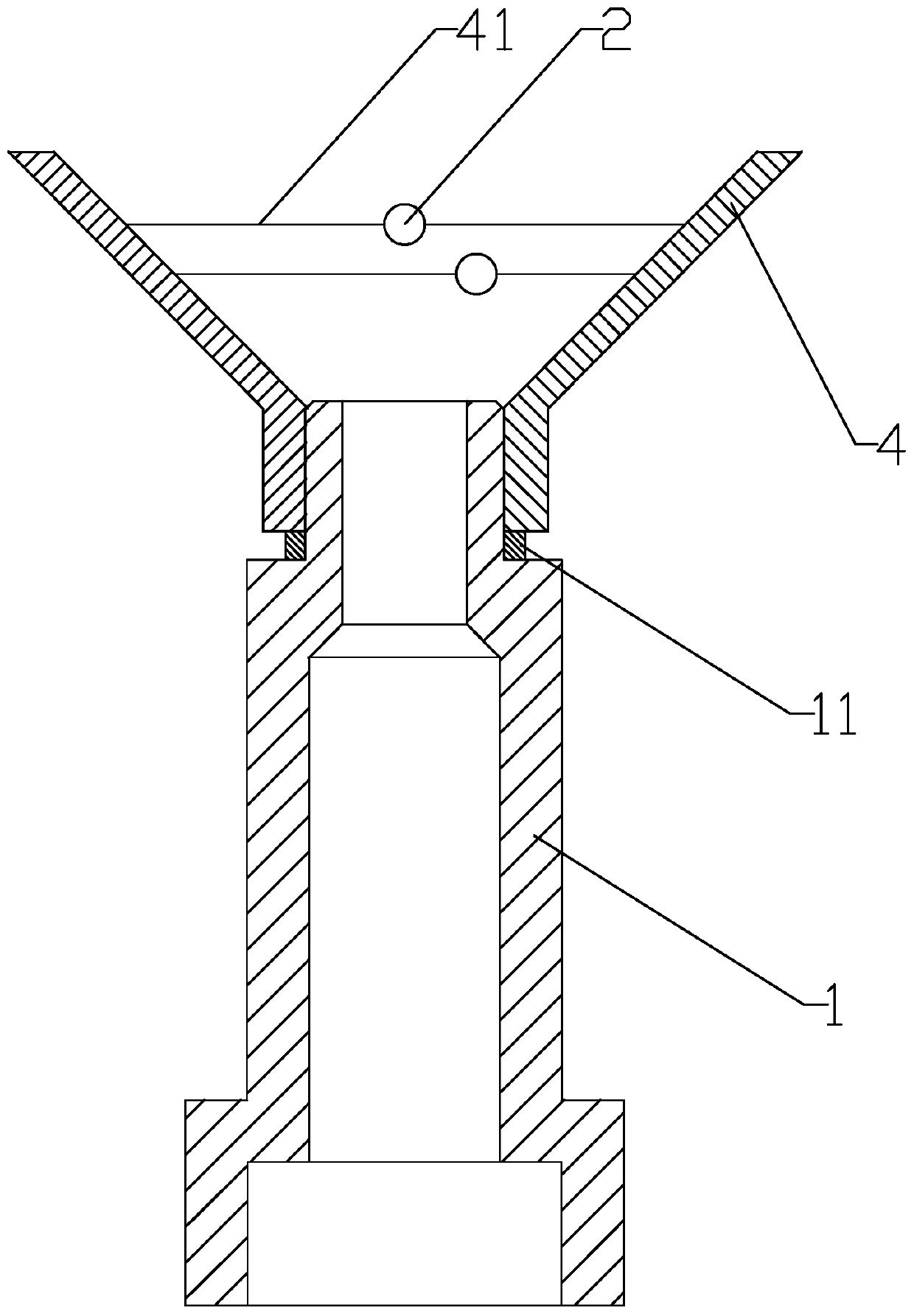

[0039] Such as figure 2 In the shown embodiment 2, a high-pressure derusting nozzle includes a nozzle body 1 , an impact member 2 and a diffuser cover 4 . The outer cover of the front end of the nozzle body 1 is provided with a horn-shaped diffusion cover 4 , one end of the diffusion cover 4 is threadedly connected with the sneeze body 1 , and a number of elastic ropes 41 parallel to each other are connected to the open end of the other end, and the elastic ropes 41 are parallel to the radial direction of the diffusion cover 4 The two ends of the elastic rope 41 are connected to the inner wall of the diffuser cover 4, and the middle part of the elastic rope 41 is connected with the impact piece 2. The impact piece is a steel ball, and the steel balls on different elastic ropes are arranged alternately.

[0040]When the nozzle is working, the high-pressure derusting liquid flows out of the nozzle body 1, diffuses and sprays outwards through the diffusion cover 4, and at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com