Steel pipe threaded pipe fitting rust removal equipment

A thread and steel pipe technology is applied in the field of rust removal equipment for steel pipe thread and pipe fittings, which can solve the problems of many operators, high labor intensity of rust removal workers, and laborious tooling, and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

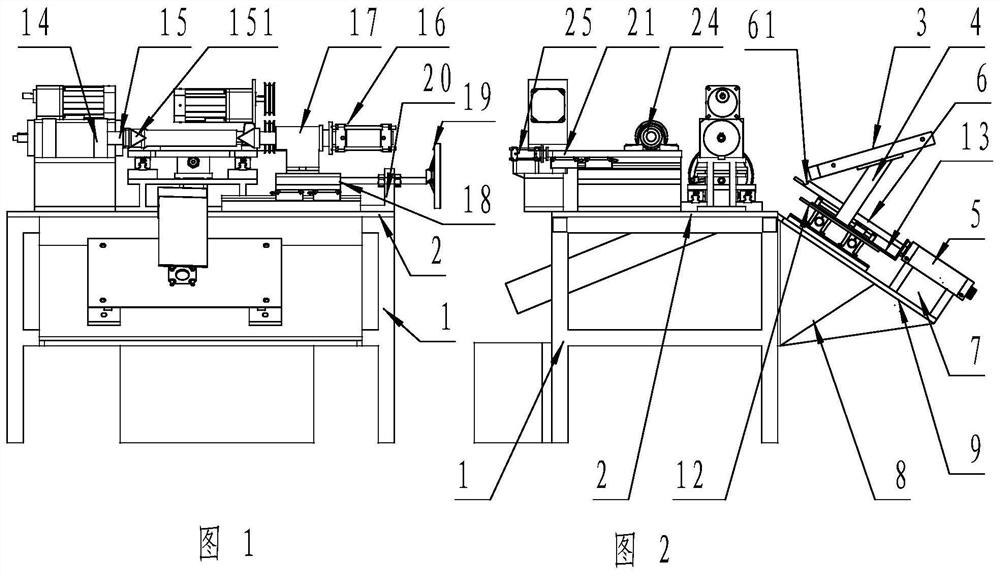

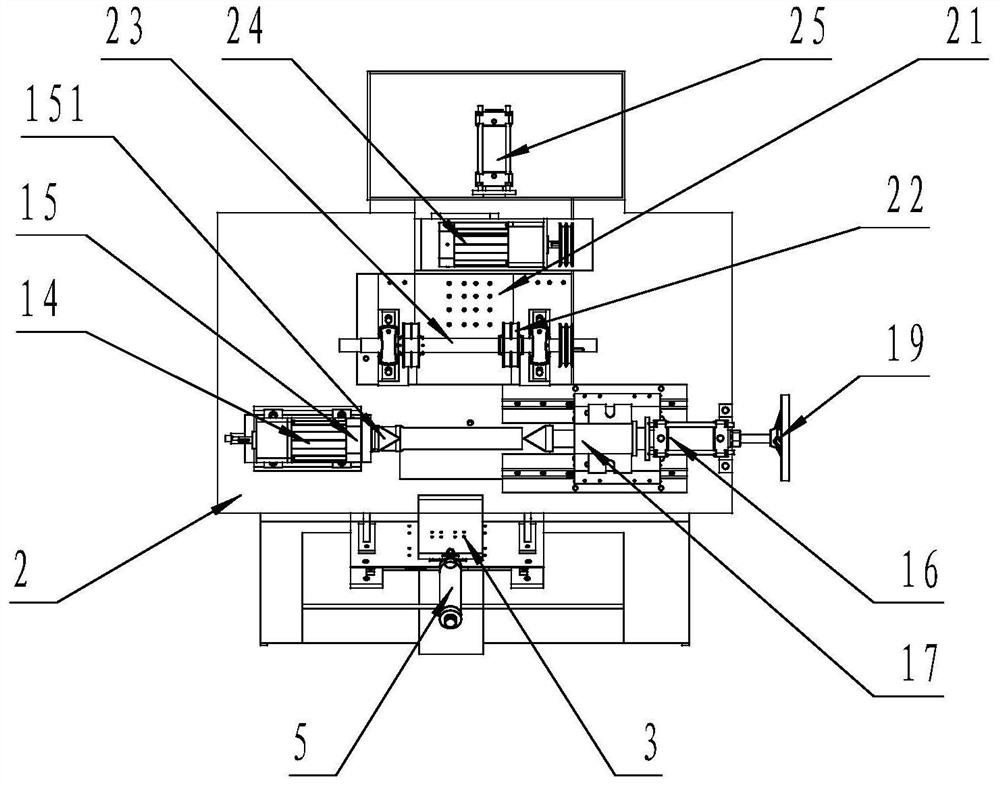

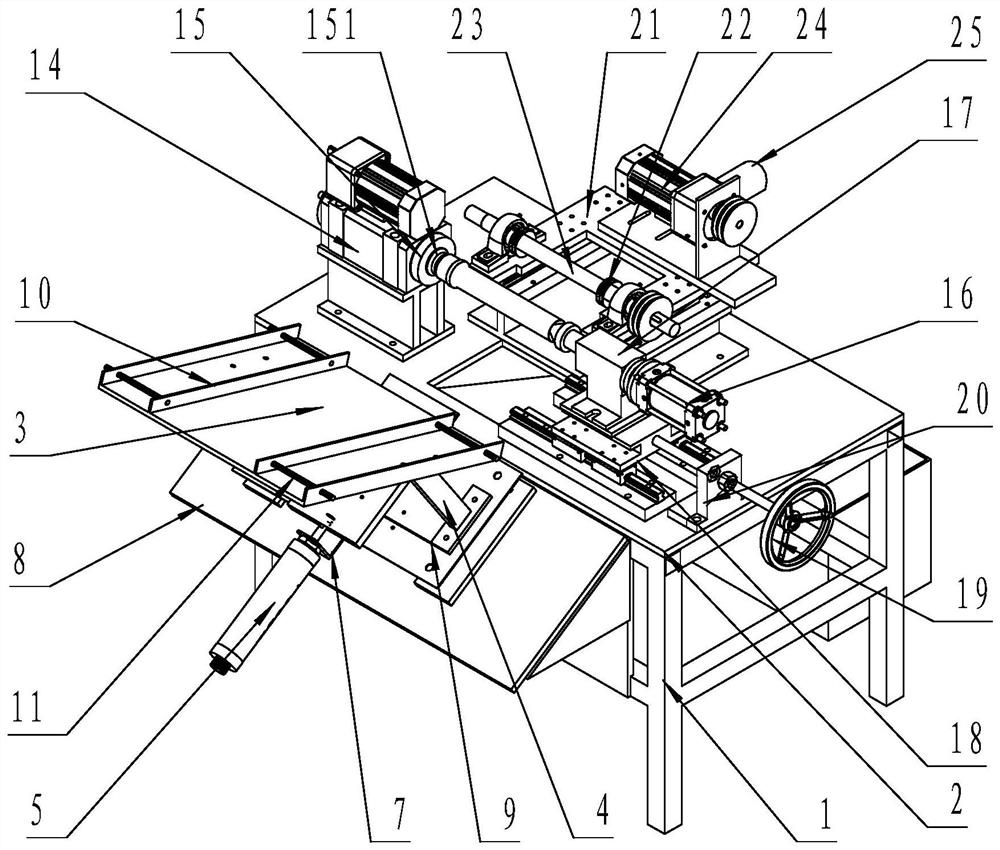

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a steel pipe thread pipe fitting derusting equipment includes a frame 1 and a workbench 2 installed on the frame 1, and is characterized in that it also includes a steel pipe thread pipe fitting feeding device installed on the front frame of the workbench 2 , left and right longitudinally installed on the steel pipe threaded pipe fitting jacking and clamping rotating device on the front side of the top of the workbench 2 (the observer faces the invention, the left side of the observer is the left side of the workbench, and the right side of the observer is the working The right side of the workbench; the side close to the workbench is the front side of the workbench, and the side away from the workbench is the back side of the workbench), the steel pipe thread pipe fitting derusting device installed on the top surface of the workbench 2 rear side; also includes Air pressure and electrical control devices; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com