Patents

Literature

77results about How to "No hydrogen embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface pretreating method of dry method spray sand type neodymium iron boron permanent magnetic material

ActiveCN101373650AImprove bindingImprove adhesionInductances/transformers/magnets manufactureMagnetic materialsEthylenediamineCopper plating

The invention provides a surface preprocessing method of a dry-process sand-spraying type NbFeB permanent magnet material. The method comprises the following steps: chamfering, polishing, spraying sand, and chemical plating. Under the condition of room temperature, a natural sand blasting material is adopted to apply sand blasting on the surface of the NbFeB permanent magnet material; the pressure of a sand blasting machine is 0.16 to 8MP; the partial pressure of a spray gun is 0.16 to 6MP; and the sand blasting angle is 10 degree to 60 degree. A copper plating bath comprises copper sulfate of 0.03-0.5m / L, sulfite of 0.10-0.3m / L, fluoride of 0.05-0.7m / L and one or more components selected from EDTA, sodium citrate, potassium sodium tartrate and quadrol. The pH of 6.5-8.0 is achieved through adjustment, and the copper plating temperature is 10-65DEG C. The invention improves the binding force of a plating layer and a substrate, changes the roughness of the plating layer and improves the cohesive force of the plating layer.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

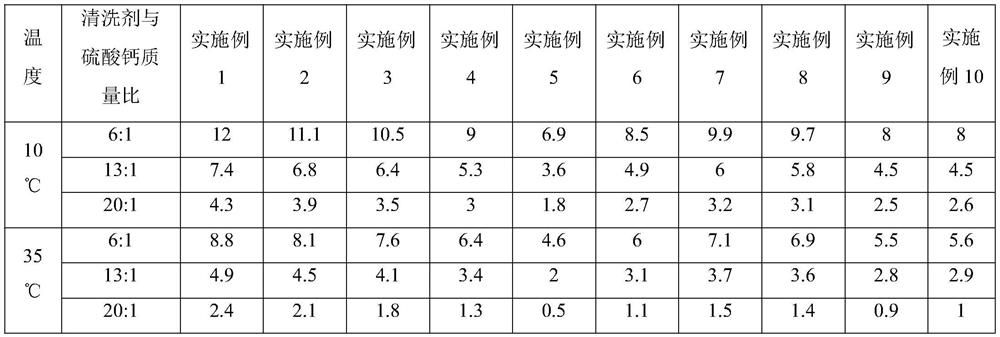

Neutral calcium sulfate scale cleaning agent

InactiveCN101955863AEmission safetyNo hydrogen embrittlementScale removal and water softeningOrganic non-surface-active detergent compositionsCleansing AgentsFatty alcohol

The invention relates to a chemical cleaning agent, in particular to a special chemical cleaning agent for cleaning calcium sulfate (CaSO4) scale. The invention provides a novel cleaning agent and a scheme for cleaning the calcium sulfate scale, in the actual application, the novel cleaning agent can effectively clean the calcium sulfate scale in both working and stopping sates of boilers or industrial circulated cooling water system. The novel cleaning agent is prepared from the following raw material reagents in parts by weight: 10% of HEDP (Hydroxyl Ethidene Diphosphoric Acid), 0.05% of JFC (fatty alcohol-polyoxyethylene ether), 5% of cosolvents and 0.06% of nonionic PAM (polyacrylamide), and the pH value is regulated to 7 by using caustic soda. The reagent is a special cleaning agent for the calcium sulfate scale, mainly comprising a high-polymer organic polymer containing multi-functional groups, such as carboxyl, hydroxyl, amide and the like, and is specially used for cleaning indissolvable calcium sulfate scale, and the pH value of the reagent is 7. The cleaning agent is a neutral solution and has the advantages of thoroughly scale cleanness, no corrosion on metal, enamel and glass, no toxicity to human bodies, safe emission of waste liquid, high efficiency and safety without generating the phenomenon of hydrogen brittleness.

Owner:金保全

Nanometer composite powder zinc impregnation processing method

ActiveCN1730727AMeeting Corrosion Protection NeedsDoes not affect mechanical propertiesHeat inorganic powder coatingCooling downZinc

The invention provides a process for nanometer composite powder zinc impregnation processing method, which comprises metal member pretreatment, powder zinc impregnation processing and metal member post-treatment. The powder zinc impregnation processing comprises formulation of nano composite powder zinc impregnation agent, a zinc impregnation procedure and a cooling down separation process.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +4

Surface treatment method for neodymium iron boron permanent magnetic material by organic aluminum plating

The present invention provides an organic aluminum plating method for a neodymium iron boron permanent magnetic material. The method comprises the following steps: (1) carrying out chamfering and polishing; (2) carrying out degreasing and deoiling; (3) carrying out pickling and derusting; (4) carrying out organic aluminum plating: adopting an aluminum plating solution to carry out aluminum layer plating on the surface of the neodymium iron boron permanent magnetic material under the protection of inert gas, wherein the aluminum plating solution comprises AlCl3, LiAlH4 and tetrahydrofuran; (5) passivating the aluminum plating layer. With the organic aluminum plating method of the present invention, the neodymium iron boron permanent magnetic material can have the excellent corrosion resistance.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Chemical for cleaning boiler

InactiveCN102418103ALow cleaning temperatureShorten the timeCetyldimethylbenzylammonium chlorideAcid washing

The invention relates to a chemical for cleaning a boiler, and belongs to the technical field of the chemical cleaning of equipment. The chemical comprises a corrosion-inhibiting acid-washing agent, a bleaching agent and a passivant, wherein the corrosion-inhibiting acid-washing agent consists of 1,3,5,7-tetraaza-adamantane, ethylenediamine tetracetic acid, hydrochloric acid, phosphoric acid, silicon fluoride, hydrazine hydrate, sodium silicate, cetyl dimethyl benzyl ammonium chloride, ammonium thiocyanate, sodium dodecyl benzene sulfonate and the balance of water; the bleaching agent is citric acid solution; and a passivant consists of ethidene diamine, formaldehyde, diammonium phosphate, hydrogen peroxide, sodium nitrite and the water. The chemical has stable chemical properties, low toxicity, a good sustained-release effect and high scale dissolving capacity, and does not have the damage of sour corrosion to the boiler.

Owner:CHANGSHA BLUECLEAN TECH

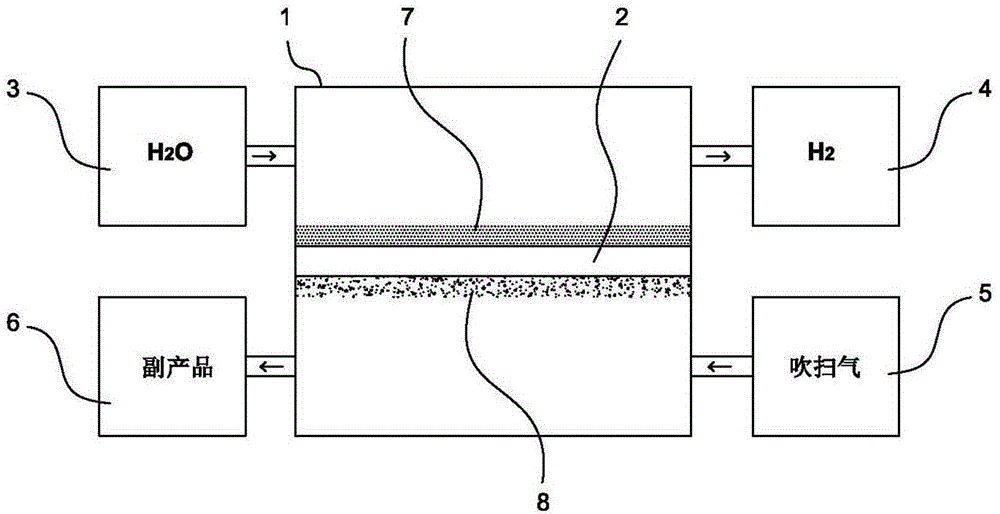

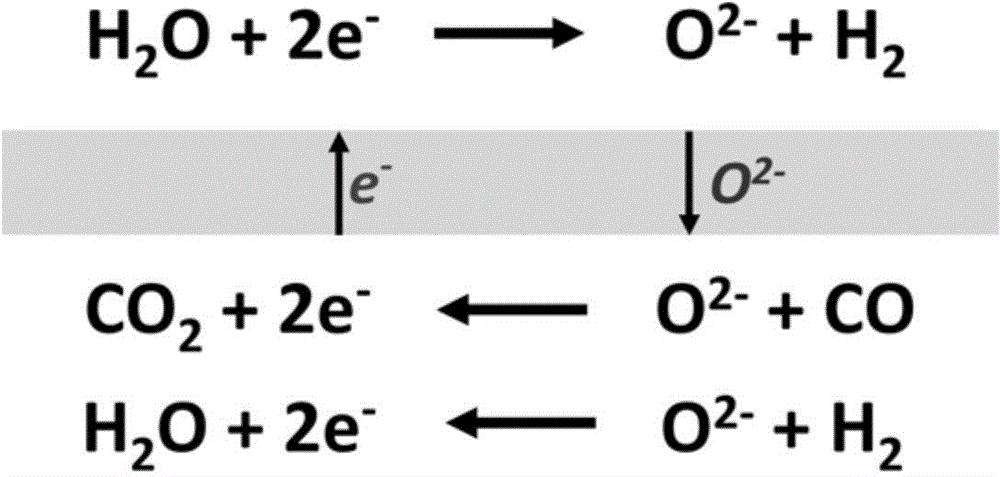

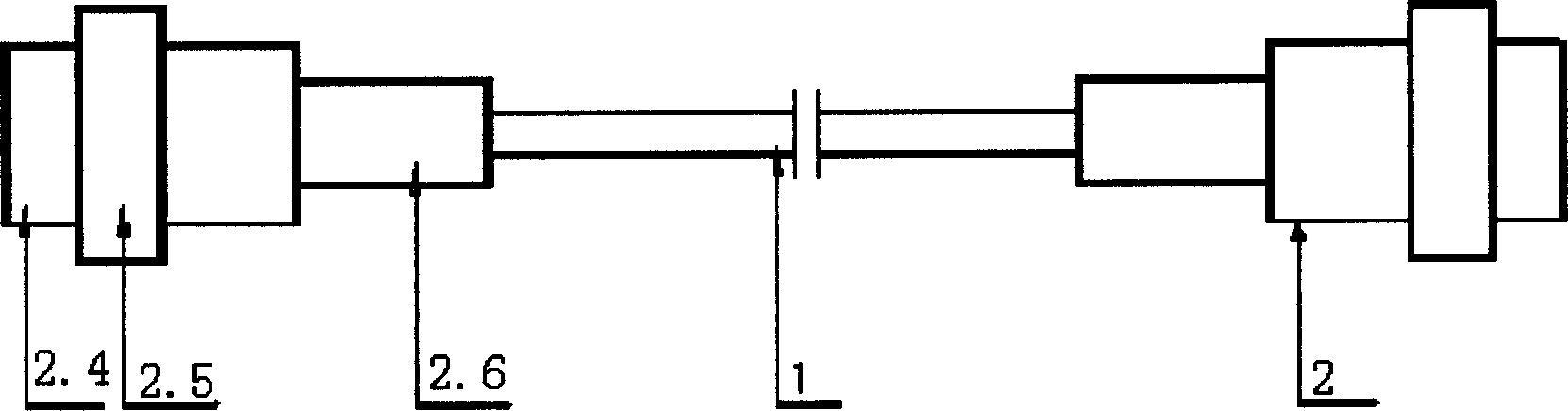

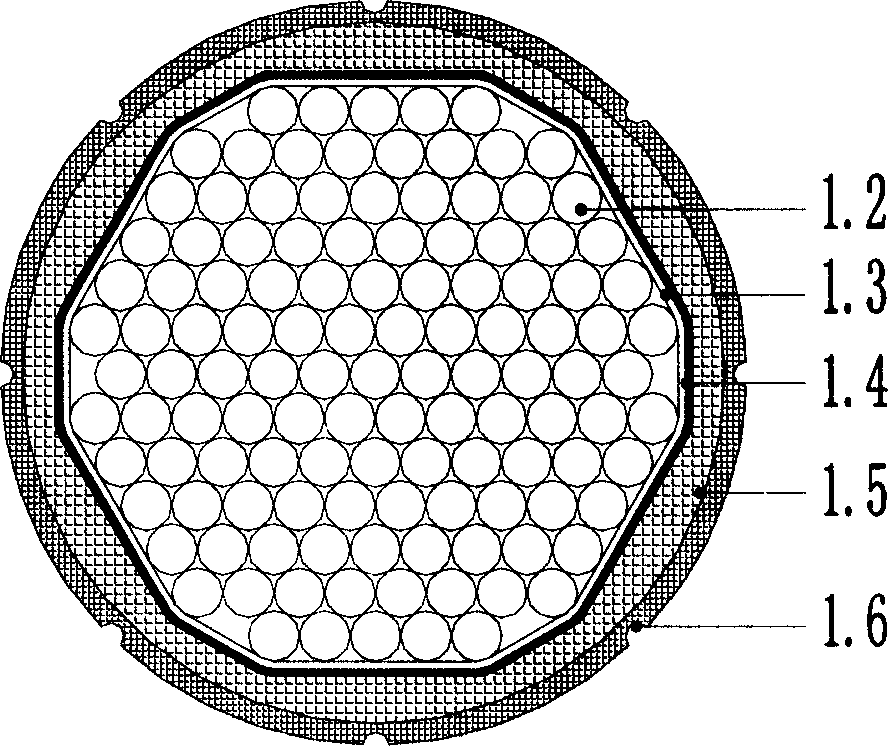

A system for preparing high-purity hydrogen and a method therefor

InactiveCN105692549ANo hydrogen embrittlementImprove stabilityHydrogen productionElectrical conductorWater vapor

A system for preparing high-purity hydrogen and a method therefor are provided. The system comprises a membrane reactor, an oxygen permeable membrane sealed in the membrane reactor, a catalyst moduleI disposed at one side of the oxygen permeable membrane, a catalyst module II disposed at the other side of the oxygen permeable membrane, a gas feeding device I used for feeding raw material gas intoone side of the oxygen permeable membrane, a gas feeding device II used for feeding purge gas to the opposite side of the oxygen permeable membrane, water vapor adopted as the raw material gas and low-purity hydrogen adopted as the purge gas. The method includes separating a raw material that is the low-purity hydrogen in the mixed-conductor oxygen permeable membrane reactor to obtain the high-purity hydrogen. The hydrogen separation rate and purity of the hydrogen prepared by the method are comparable with those of a palladium membrane. A membrane material used in the method is easily prepared and low in cost, and is hoped to replace the expensive palladium membrane to prepare the high-purity hydrogen.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

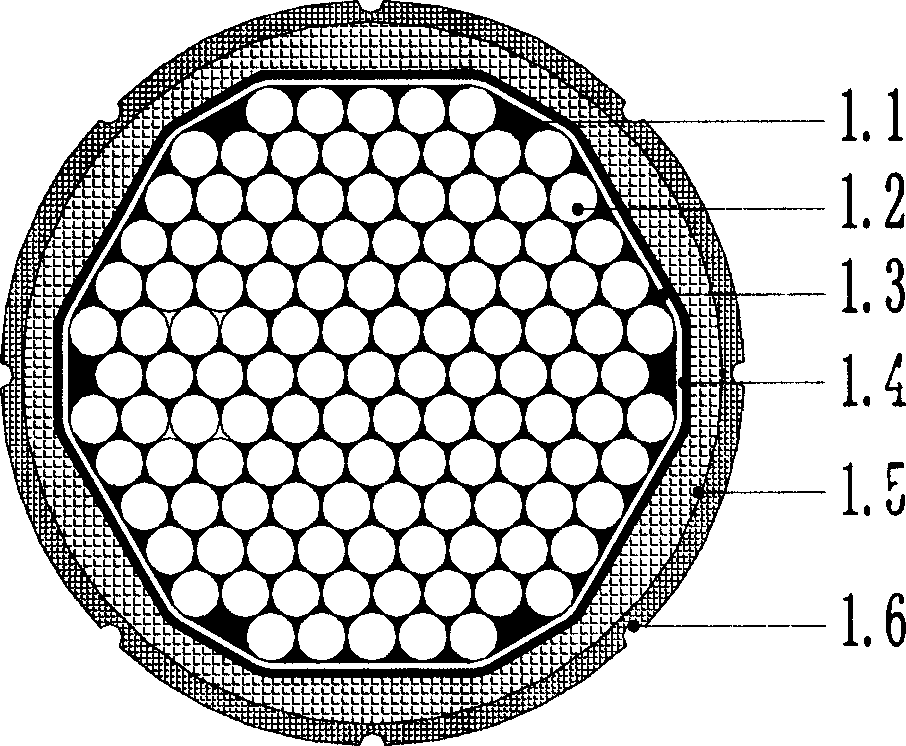

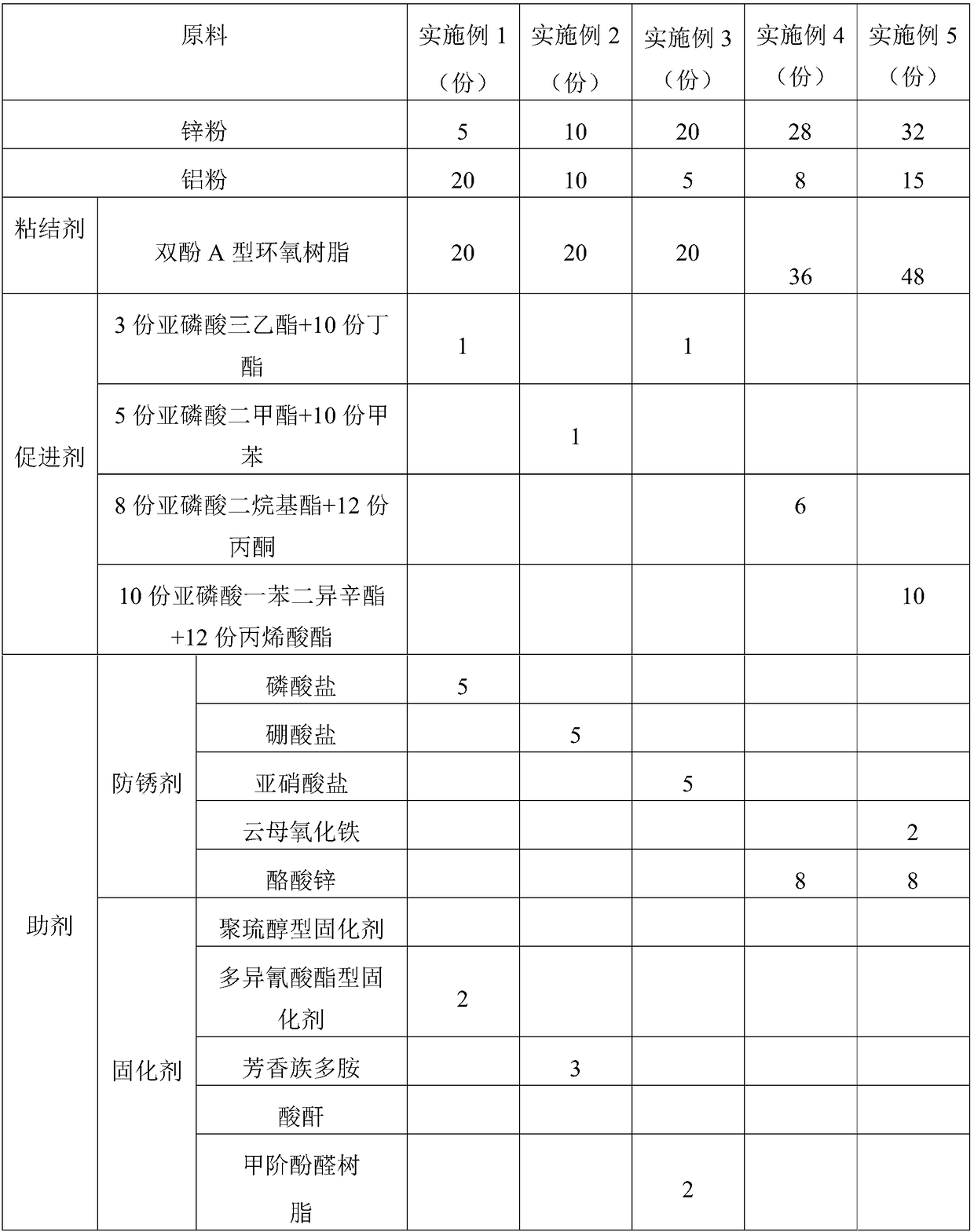

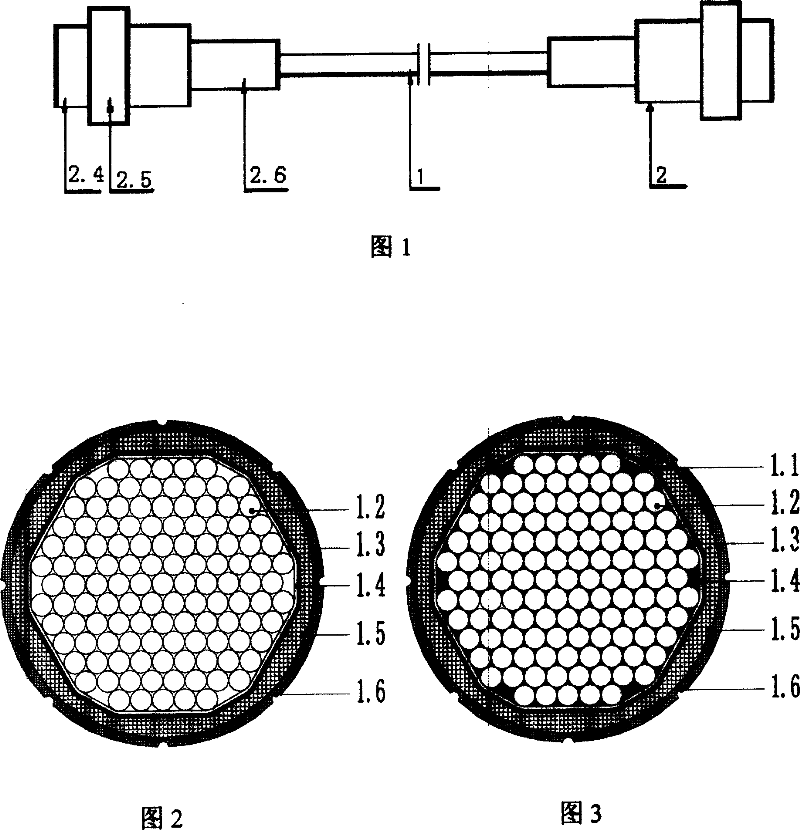

Supehigh strength parallel steel wire durable cables

ActiveCN1644791AImprove fatigue resistanceAvoid Corrosion HazardsBridge structural detailsTextile cablesPolyesterHigh-density polyethylene

An ultrahigh-strength durable pull cable made of parallel steel wires is composed of the cable body consisting of central parallel steel wires, fluorized rubber belt layer winding around said steel wires, fibre reinforced polyester band layer and high-density polyethene jacket, and the archors at both ends of cable body. Its advantages are high anticorrosion power and long service life.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD

Welded joint made of an austenitic steel

InactiveCN1816417ANo hydrogen embrittlementArc welding apparatusPipeline systemsChemical compositionHigh pressure hydrogen

Owner:NIPPON STEEL CORP

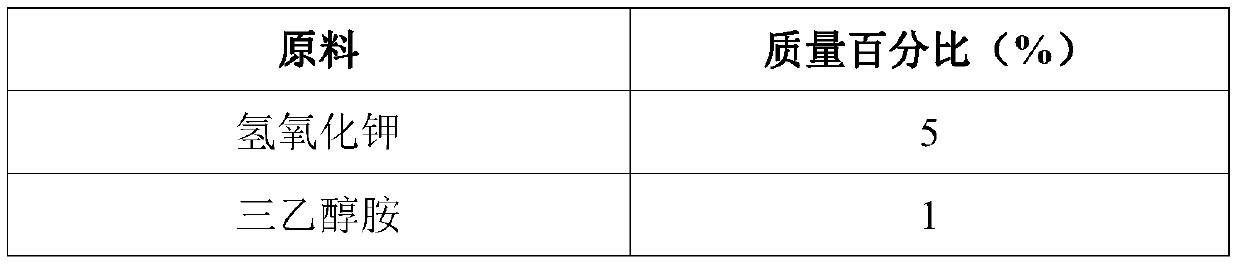

Neutral cleaning agent for mixed water scale and production method thereof

InactiveCN101955862ANot brokenEmission safetyOrganic non-surface-active detergent compositionsTreatment using complexing/solubilising chemicalsHydrogen fluorideCleansing Agents

The invention relates to a chemical cleaning agent, in particular to a neutral cleaning agent special for cleaning the mixed water scale and a production method thereof. The invention provides a novel cleaning agent for treating the mixed water scale and a method thereof. In the actual application, the neutral cleaning agent can be used for effectively cleaning the mixed water scale on a boiler or an industrial cooling circular water system thoroughly during parking or not parking and cannot corrode metal. The neutral cleaning agent comprises the following raw materials in percentage by weight: 5-10 percent of 1-hydoxy ethyidene-1,1-diphosphonic acid, 3-8 percent of citric acid, 0.3-1 percent of nonionic polyacrylamide, 1-2 percent of hydrogen fluoride, 0.5-1 percent of NaOH, 0.05 percent of 6501 degreasing agent and the balance of water. The agent is the cleaning agent special for the mixed water scale, is special for clearing the indissolvable scale in the mixed water scale, has the pH value of the medicament of 7, is a neutral solution, can thoroughly clean the scale without corroding metal, enamel and glass and is nontoxic to human body; and waste liquid can be safely discharged, is high-efficient and safe and avoids the phenomenon of hydrogen embrittlement.

Owner:金宏

Rust remover and preparation method thereof

The invention discloses a rust remover and a preparation method thereof. The rust remover is prepared from the following components in percentage by mass: 60 to 80 percent of organic acid, 19 to 39 percent of inorganic acid and 0.8 to 3 percent of corrosion inhibitor, wherein the organic acid is one or more than two kinds of tartaric acid, citric acid, oxalic acid and trichloroacetic acid; the inorganic acid is one or more than two kinds of sulfamic acid, phosphorous acid and ammonium acid fluoride; and the corrosion inhibitor is benzotrizaole or / and sodium dihydrogen phosphate. According to the rust remover disclosed by the invention, the use of hydrochloric acid or sulfuric acid is completely avoided; no acid mist during rust removal is generated, the corrosion to equipment in a workshop is avoided and the labor environment is improved; meanwhile, the corrosion inhibitor is weaker in acidity, the over corrosion to workpieces is avoided and the condition that the skin of an operator is severely corroded is prevented; in addition, after a certain amount of workpieces are treated, the rust removing efficiency is reduced; and by continuously adding the rust remover disclosed by the invention, the rust removing efficiency can be restored, i.e., a rust removing bath solution disclosed by the invention can be conveniently and repeatedly used.

Owner:ZHONGSHAN HUAGUANG CHEM

Neutral rust remover

The invention relates to a neutral rust remover which is prepared from the following components in percentage by weight: 2 to 4 percent of hydroxy ethyl triphosphate, 2 to 3 percent of tartaric acid, 5 to 7 percent of citric acid, 3 to 5 percent of malic acid, 15 to 20 percent of trisodium phosphate, 0.3 to 0.5 percent of sodium gluconate, 2 percent of fatty alcohol-polyoxyethylene ether and 58.5 to 70.7 percent of deionized water. The neutral rust remover is a neutral rust remover consisting of organic acid, a dispersing agent, a complexing agent, a promoter and a corrosion inhibitor, can only react with metal surface rusts and scales on the surface, does not have any corrosion to various metal workpieces, cannot cause a hydrogen embritttlement phenomenon after being treated, can achieve a protection effect on a steel part within short time, has no volatilization property and pungent smell, does not contain any toxic substances and heavy metals as well as organic pollutants, and is harmless to a human body; the use amount of drugs is reduced, and the working environment of an operator is effectively improved; the neutral rust remover meets the European Union's WEEE & RoHS instruction requirement; stainless steel, PVC and other materials can be made into an accommodating container; and the selection range is wide.

Owner:东莞市精诚环保科技有限公司

Novel composite blackening process

The invention discloses a novel composite blackening process. The novel composite blackening process comprises the steps of short-time nitriding and oxidation blackening. According to the novel process of combining the short-time nitriding and the oxidation blackening, a Fe3N-Fe3O4 two-phase layer can be formed on the surface of a part. The novel composite blackening process has the advantages of corrosion resistance, abrasion resistance, attractive color, durability and wide application.

Owner:上海朋泰机械科技有限公司

Cleaning agent special for galvanizing equipment and using method thereof

The invention discloses a cleaning agent special for galvanizing equipment and a using method thereof. The cleaning agent special for galvanizing equipment comprises the following components in mass ratio: 10% of chromic anhydride, 2% of citric acid, 0.1% of fatty alcohol-polyoxyethylene ether, 0.3% of L-826 corrosion inhibitors and the balance of water, wherein the L-826 corrosion inhibitors are benzotriazole. The using method of the cleaning agent special for galvanizing equipment comprises the following steps of: (1) determining the use level of the basic solution of the cleaning agent special for galvanizing equipment in the invention according to equipment and pipeline conditions; (2) adding the basic solution of the cleaning agent from a suction port of a circulating pump to form circulation; (3) running 4-8 hours according to the scale amount of the equipment and keeping the circulating flow of the cleaning agent by using the circulating pump, wherein the cleaning time is in inverse proportion to the flow speed of the cleaning agent; and (4) then replacing by using clean water to discharge pollution until the turbidity is less than 10 mg / L or water is clean by visual inspection.

Owner:QINGDAO UNIV OF SCI & TECH

Zinc-aluminum-nickel alloy co-penetrated protective layer preparation method

ActiveCN105951037AUniform thicknessDense metallographic structureSolid state diffusion coatingHydrogenRare earth

The invention discloses a zinc-aluminum-nickel alloy co-penetrated protective layer preparation method, which comprises the following steps of weighing co-penetrated agent raw materials: zinc powder, aluminum powder, alumina powder, nickel powder, rare-earth metal oxide powder and catalyst; uniformly mixing the weighed powder, heating the mixture to be 150 to 200 DEG C, insulating for 30 min to 50 min, cooling to be room temperature, and then uniformly mixing with the catalyst to prepare a co-penetrated agent; stacking bridge embedded parts plates with smooth and clean surfaces to form a stack with approximate height and width, paving a layer of co-penetrated agent between each two adjacent bridge embedded part plates, then packaging to form bundles, placing the bundles into a co-penetrated furnace, adding the co-penetrated agent, heating to be 400 to 500 DEG C, and carrying out co-penetrated treatment for 2 h to 3 h under the pressure of 0.10 to 0.20 MPa. According to the zinc-aluminum-nickel alloy co-penetrated protective layer preparation method provided by the invention, the space of the co-penetrated furnace can be efficiently utilized; a zinc-aluminum-nickel alloy co-penetrated protective layer is uniform in thickness and compact in metallographic structure, and has excellent resistance to corrosion on high-temperature salt mist gas; and the phenomenon of hydrogen brittleness does not exist.

Owner:FUJIAN HONGGUAN ROADS & BRIDGE ANTI CORROSIVE TECH

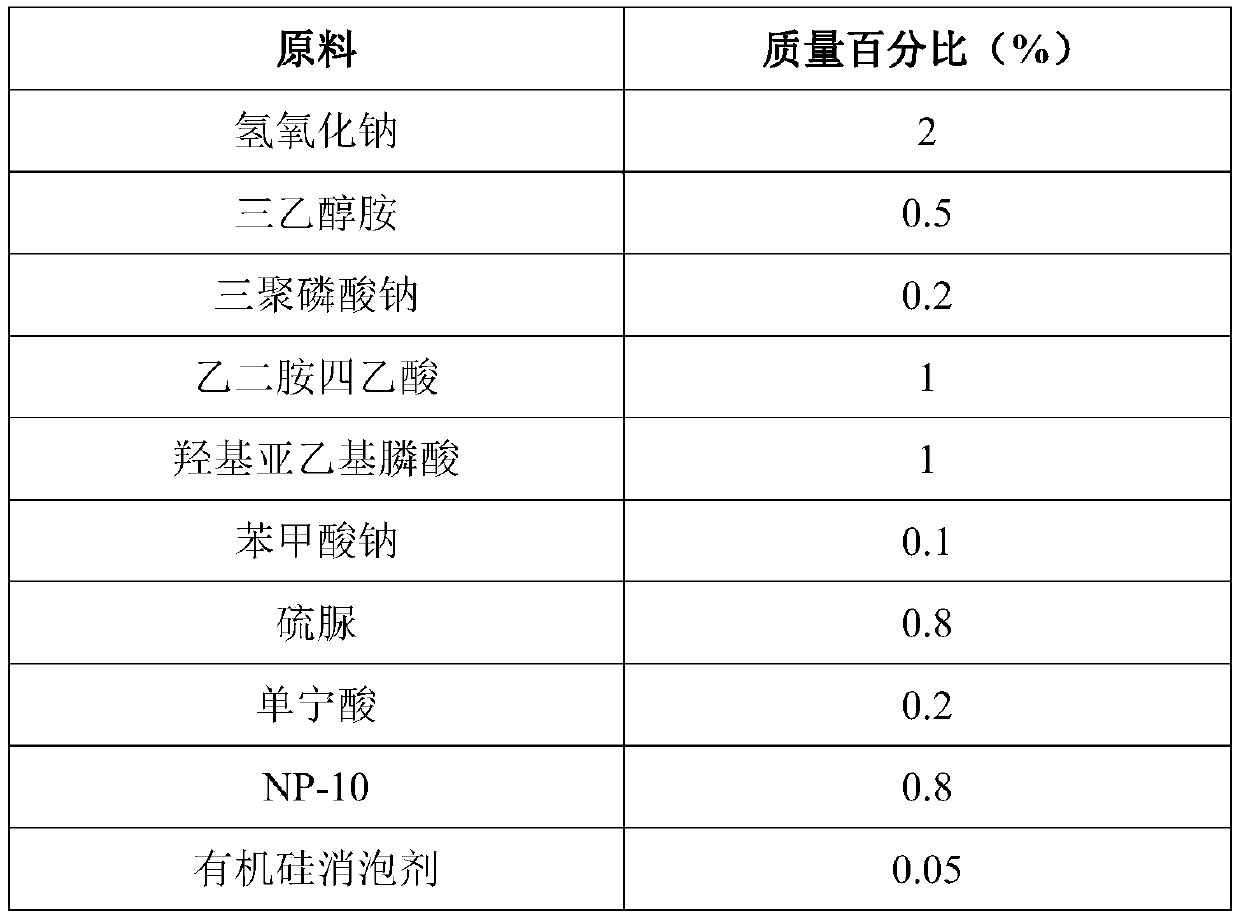

Alkaline steel rust remover and preparation method thereof

The invention discloses an alkaline steel rust remover and a preparation method thereof. The alkaline steel rust remover is prepared from the following components of, in percentage by mass, 0.1%-8% ofan alkali agent, 0.01%-5% of a complexing agent, 0.01%-3% of a corrosion inhibitor, 0.1%-3% of an emulsifier, 0.01%-0.05% of a defoaming agent, 0.02%-1% of a thickening agent and the balance water. The preparation method of the alkaline steel rust remover is very simple, and the components are mixed uniformly in batches; and the rust removal effect of the alkaline steel rust remover is good, steel is not corroded, acid mist is not generated, the hydrogen embrittlement phenomenon does not occur, the production process is simple, and safety and environmental protection are achieved.

Owner:广东中联邦精细化工有限公司

Cleaning agent for calcium sulfate scale

ActiveCN102703233BWash thoroughlyNo hydrogen embrittlementCationic surface-active compoundsScale removal and water softeningButenedioic acidReverse osmosis

The invention provides a cleaning agent for cleaning calcium sulfate scale. The cleaning agent comprises the following components in percentage by weight: 10 to 30 percent of sodium citrate, 0.5 to 5 percent of dodecyl dimethyl benzyl ammonium chloride, 0.5 to 5 percent of sodium di-iso-octyl maleate sulfonate, 5 to 15 percent of absolute ethanol and 45 to 85 percent of reverse osmosis water. The cleaning agent for the calcium sulfate scale is particularly used for removing insoluble calcium sulfate scale, can completely remove the scale, does not corrode metals, is nontoxic to human bodies and is efficient and safe, a medicament is a neutral solution, waste liquid can be safely discharged, and a phenomenon of hydrogen embrittlement can be avoided.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Environment-friendly metal surface degreasing and derusting agent

The invention discloses an environment-friendly metal surface degreasing and derusting agent. The degreasing and derusting agent is composed of 8-12 parts by weight of hydrochloric acid, 5-9 parts byweight of boric acid, 3-5 parts by weight of citric acid, 3-5 parts by weight of tartaric acid, 2-4 parts by weight of a nonionic surfactant, 2-4 parts by weight of an anionic surfactant, 2-5 parts byweight of disodium ethylenediaminetetraacetate, 2-5 parts by weight of sodium alginate, 1-2 parts by weight of thiourea, 1-2 parts by weight of urotropine, 2-3 parts by weight of an organosilicone defoamer, 3-5 parts by weight of benzotriazole, 2-5 parts by weight of polyethylene glycol oleate and 80-120 parts by weight of water. The degreasing and derusting agent can simultaneously remove oil and rust on the metal surface, does not contain phosphoric acid, does not produce phosphorus-containing substances polluting the water source after use, is safe and environment-friendly, does not produce excessive corrosion and hydrogen embrittlement on the metal substrate, does not produce irritating odor, has stable properties, is prepared through simple processes and has a wide application range.

Owner:王衍春

Method for hotly plating zinc and aluminum on surface of steel product

InactiveCN108395806APerformance is easy to controlSimple processAnti-corrosive paintsEpoxy resin coatingsPipe fittingFree cooling

The invention discloses a method for hotly plating zinc and aluminum on the surface of a steel product. The method comprises the following steps: (1) pre-treating: carrying out oil removal and rust removal treatment on the surface of the steel product and wiping and cleaning; (2) immersing: putting a workpiece treated by step (1) into a zinc and aluminum plating solution; after immersing for 5 to10 seconds, draining; (3) baking: transferring the workpiece treated by step (2) into a baking device and baking; (4) naturally cooling to room temperature and packaging to obtain a finished product.The method disclosed by the invention has a simple technology and no emission of VOC (Volatile Organic Compounds); automatic line production can be realized and the performance of a plated layer is controllable in real time; a finished product has stable quality and high yield; parts which are difficultly electroplated with zinc, such as deep holes, slits and pipe fitting inner walls, also can beuniformly coated and plated; the method is especially applicable to surface protection of abnormal-shape members including lamp rods, steel pipes, parts and the like.

Owner:中山市普利斯顿化工科技有限公司

Supehigh strength parallel steel wire durable cables

ActiveCN100354471CDoes not affect tolerance fitNo hydrogen embrittlementBridge structural detailsTextile cablesPolyesterHigh density

An ultrahigh-strength durable pull cable made of parallel steel wires is composed of the cable body consisting of central parallel steel wires, fluorized rubber belt layer winding around said steel wires, fibre reinforced polyester band layer and high-density polyethene jacket, and the archors at both ends of cable body. Its advantages are high anticorrosion power and long service life.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD

Multi-component alloy co-permeation surface treatment process for container workpiece

InactiveCN109750252AUniform penetrationNo pollution in the processSolid state diffusion coatingCoating systemAlloy

The invention discloses a multi-component alloy co-permeation surface treatment process for a container workpiece. The process specifically comprises the steps of uniformly mixing a multi-osmotic agent such as zinc powder, nickel powder and aluminum powder; pre-treating the workpiece with degreasing and derusting; heating the multi-osmotic agent and the pre-treated workpiece to 400 DEG C in a closed container and kept at a temperature of 250-400 DEG C for 1-6 h; after the workpiece is discharged and cooled for 1-6 h, separating the workpiece from the multi-osmotic agent to remove the surface of the workpiece; and post-treating the workpiece by polishing, passivation, phosphating, coating, etc., specifically, color of the outer surface coating of the multi-component co-permeation alloy layer can be arbitrarily selected. The multi-component alloy co-permeation surface treatment process for the container workpiece has good corrosion resistance, wear resistance, scratch resistance, thermalstability and adhesion, uniform permeation layer, no hydrogen embrittlement phenomenon, compatibility with other coating systems, low cost, no waste discharge, no pollution to the environment, and the like.

Owner:青岛艾斯寨车辆零部件有限公司

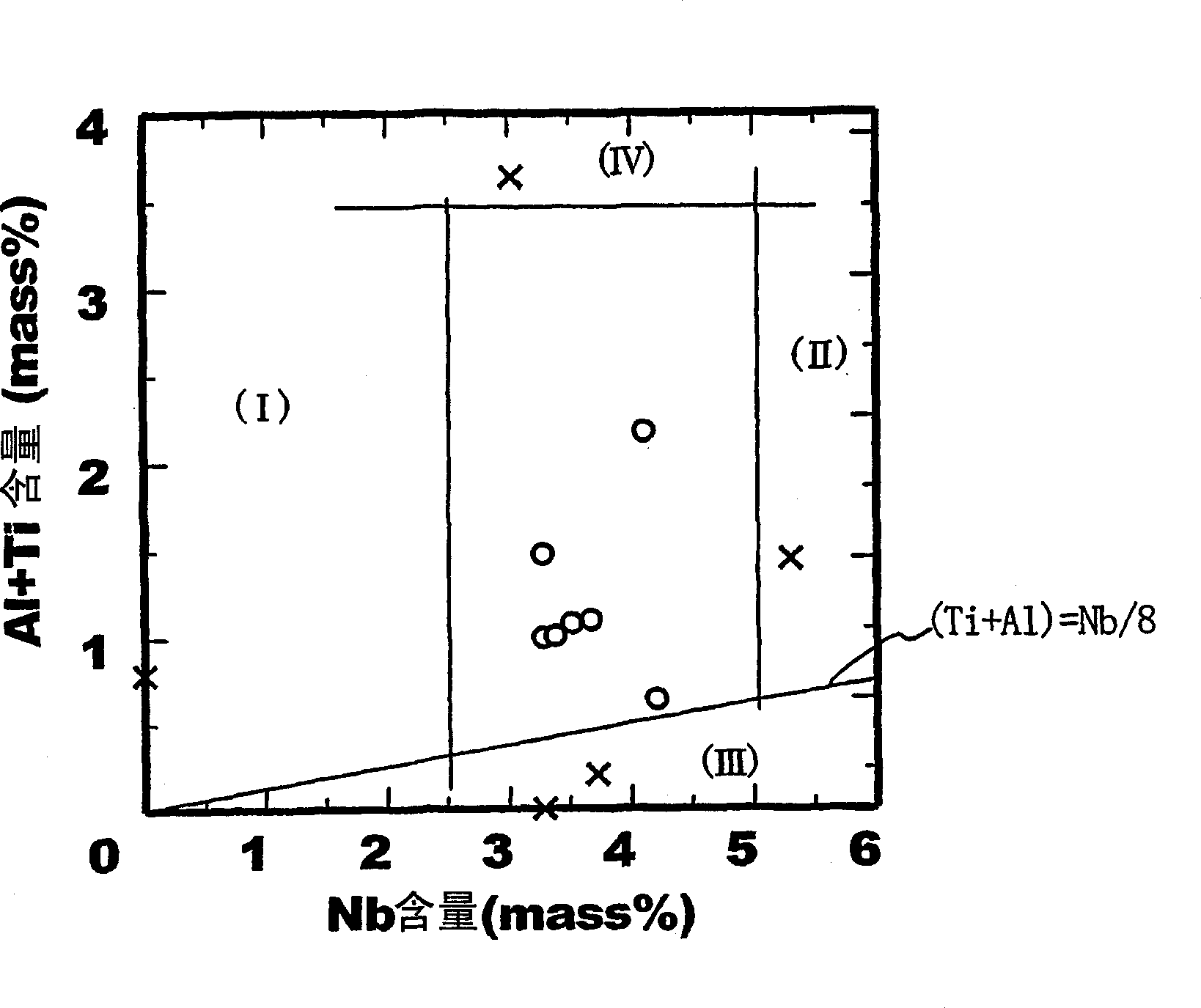

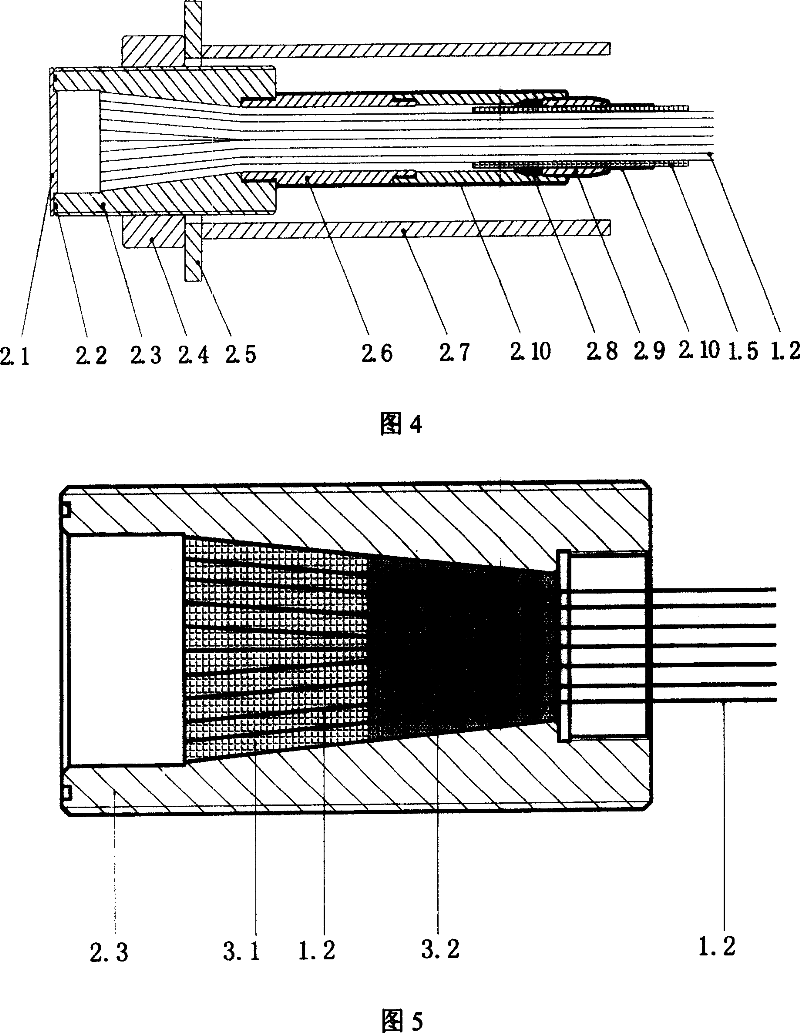

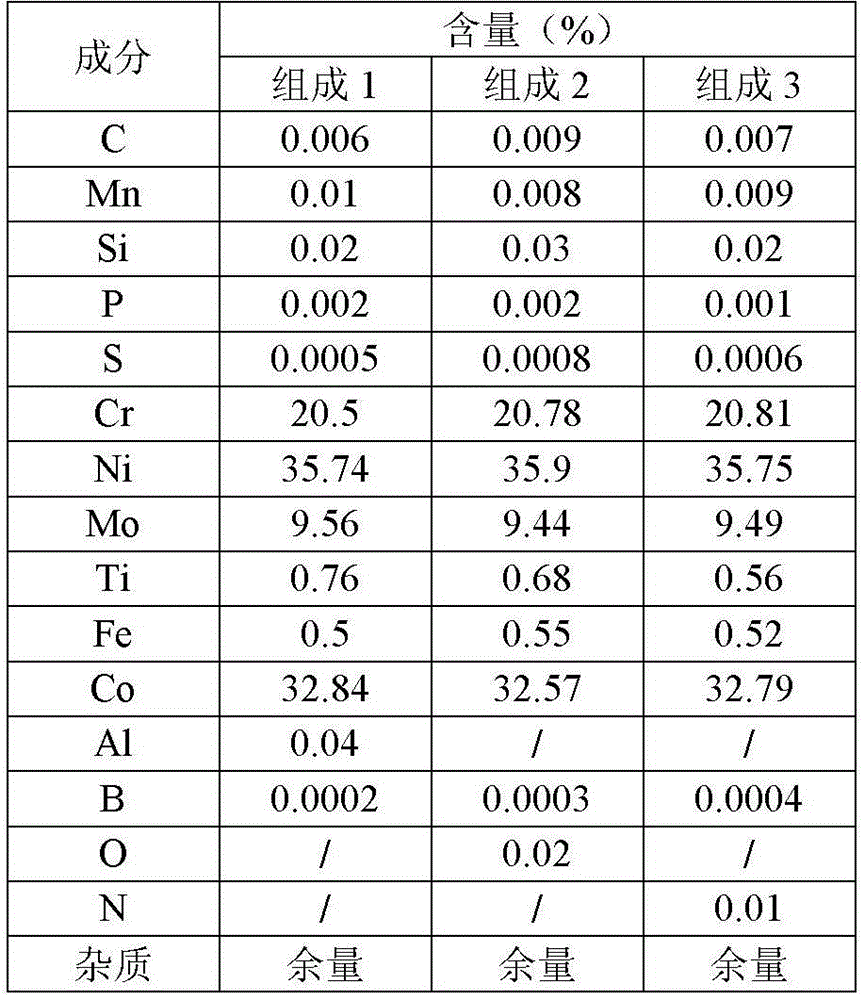

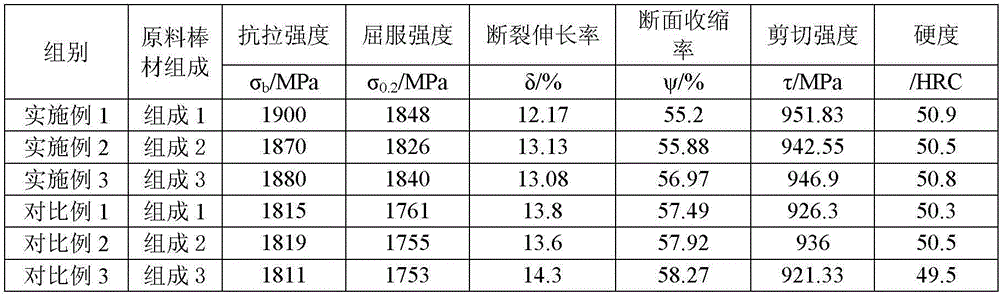

Ultra-high-strength fastening connecting piece and manufacturing method thereof

The invention provides an ultra-high-strength fastening connecting piece. Nickel-cobalt-based alloy is adopted by the connecting piece to be used as a base body, and chemical compositions of the connecting piece comprise C smaller than or equal to 0.025 percent, Mn smaller than or equal to 0.15 percent, Si smaller than or equal to 0.15 percent, P smaller than or equal to 0.015 percent, S smaller than or equal to 0.01 percent, Cr ranging from 19.0 percent to 21.0 percent, Ni ranging from 33.0 percent to 37.0 percent, Mo ranging from 9.0 percent to 10.5 percent, Fe smaller than or equal to 1.0 percent, Ti smaller than or equal to 1.0 percent, B smaller than or equal to 0.05 percent, Al smaller than or equal to 2.0 percent, Zr smaller than or equal to 2.0 percent, O smaller than or equal to 0.05 percent, N smaller than or equal to 0.05 percent, and the balance Co and unavoidable impurities. The created fastening connecting piece can meet the requirement for the tensile strength exceeding 1800 MPa and even can meet the higher tensile strength, and meanwhile the connecting piece has the excellent comprehensive performance.

Owner:AEROSPACE PRECISION PROD INC LTD

Method for mechanically plating zinc on surface of steel piece

InactiveCN108048825AImprove oxidation resistanceImprove corrosion resistanceLiquid/solution decomposition chemical coatingZincWear resistance

The invention discloses a method for mechanically plating zinc on a surface of a steel piece. The method comprises the following operation steps that 1, the surface of the prepared steel piece is cleaned, then the steel piece is added into a mechanical zinc plating roller and is added with an activating solution, and a rotating cylinder is started to process the mixture for 5-7 minutes; and 2, a zinc plating solution is continuously added into the mechanical zinc plating roller, and the rotating cylinder is starting to process the mixture for 25-30 minutes to obtain a finished product. The method for mechanically plating zinc on the surface of the steel piece has the advantages of being is stable in process and can realize continuous large-scale production; the prepared steel piece has excellent oxidation resistance and corrosion resistance, the adhesive force of a film layer of the steel piece is relatively high, the surface film layer is uniformly distributed, and excellent wear resistance of the the film layer is achieved; the obtained piece has no hydrogen embrittlement phenomenon; and therefore the quality of the steel piece is greatly improved.

Owner:刘珍

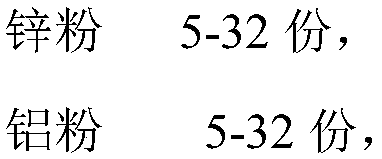

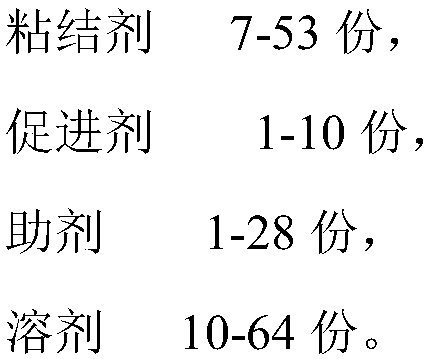

Anticorrosion coating, isolating switch spring part using the same and preparation method thereof

ActiveCN104140749AImprove anti-corrosion performanceExcellent surface bump resistance and scratch resistanceSynthetic resin layered productsPretreated surfacesPolyesterSurface layer

The invention discloses an anticorrosion coating, an isolating switch spring part using the same and a preparation method thereof. The anticorrosion coating is composed of a bottom layer and a surface layer. The bottom layer is a Dacromet layer formed by a Dacromet paint, and the surface layer is a baking varnish layer formed by polyester amino baking varnish. The surface of the isolating switch spring part using the coating is coated with an anticorrosion coating composed of a bottom layer and a surface layer. The bottom layer is a Dacromet layer formed by a Dacromet paint, and the surface layer is a baking varnish layer formed by polyester amino baking varnish. The anticorrosion coating provided by the invention has the advantages of excellent surface bump and scratch resistance and surface rusting resistance, long anticorrosion time, and low maintenance cost. The isolating switch spring part using the coating provided by the invention is coated with the anticorrosion coating involved in the invention on the surface, has excellent surface corrosion resistance, shock resistance, heat resistance and surface stability, the working life of the spring part is prolonged, and the maintenance cost of the isolating switch is reduced.

Owner:STATE GRID CORP OF CHINA +2

Manufacturing method of powder sherardizing-aluminum multi-element alloy anticorrosive coating of stay cable threaded anchorage device

ActiveCN114318215AHigh bonding strengthUniform thicknessSolid state diffusion coatingHeating furnaceMachining

The invention relates to a manufacturing method of a powder sherardizing-aluminum multi-element alloy anticorrosive coating for a threaded anchorage device of a stay cable, and belongs to the related technical field of anchorage devices. The method comprises the following steps: 1, performing heat treatment; 2, finish machining and flaw detection are conducted on the anchor device subjected to heat treatment; step 4, preparing a hot-dip galvanizing aluminum alloy material, and uniformly mixing the hot-dip galvanizing aluminum alloy material at normal temperature to form a permeating agent; 5, the anchorage device is loaded into the infiltration tank, and the infiltration tank is filled with the infiltration agent; 6, the rotary heating furnace is filled with quartz sand, the infiltration tank is buried in the quartz sand, the infiltration tank is arranged in the center of the rotary heating furnace, and the furnace is covered and sealed; seventhly, the co-permeation temperature is set, and the anchorage device is subjected to heating co-permeation treatment; 8, cooling treatment; and 9, sealing treatment is conducted on the surface of the anchorage device subjected to hot infiltration. The zinc-aluminum multi-element alloy infiltrated layer is formed on the surface of the anchorage device, the thickness of the infiltrated layer is uniform, the surface layer is free of burrs, and the method is particularly suitable for corrosion prevention of the stay cable threaded anchorage device with the tolerance fit requirement.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD +4

Neutral environment-friendly cleaning agent as well as preparation method and application thereof

PendingCN114045188AThorough responseAvoid harmInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSulfateEnvironmental engineering

The invention discloses a neutral environment-friendly cleaning agent as well as a preparation method and application thereof. The cleaning agent comprises the following components in percentage by mass: 10-30% of a descaling agent, 0.5-3% of a penetrant, 5-10% of a cosolvent, 0.5-5% of a stripping agent and 1-5% of a pH regulator, with the balance being demineralized water. According to the neutral environment-friendly cleaning agent provided by the invention, calcium sulfate and composite scales thereof can completely react at one time in a short time at normal temperature, a removal rate is 98% or above, and time and labor are saved; the pH value is neutral, so metal equipment is not corroded, and the phenomenon of hydrogen embrittlement is avoided; the agent is free of toxicity and harm to human bodies; the agent does not contain phosphorus, can be completely biodegraded, and does not influence the environment when being directly discharged; and parking or non-stopping cleaning can be carried out according to actual requirements.

Owner:YINGKOU KELIN MEMBRANE TECH ENG SERVICE

Electroplating metal fastener and its electroplating process and hydrogen embrittlement detection method

The invention discloses a plating metal fastener, which comprises the following steps: plating copper, nickel and zinc; sleeving metal fastener in the elastic pad; rotating metal fastener in the ferric board hole with two thirds force as standard torque until fastening tightly; placing tested screw in the refrigerator at -5 deg. c for 24h; fetching to restore to normal temperature; dropping ferric board vertically from one meter height; judging whether the end breaks; satisfying the standard if not breaking.

Owner:杨东佐

Multicomponent alloy infiltration anticorrosion method

InactiveCN108930013AHigh tensile strengthHigh yield strengthMolten spray coatingSolid state diffusion coatingCapacitanceWear resistance

The invention belongs to the technical field of metal surface anticorrosion, and more specifically relates to a zincizing enclosing anticorrosion method. The zincizing enclosing anticorrosion method is simple in technology, excellent in corrosion resistance and wear resistance, and high in toughness, tensile strength, and yield strength, and is friendly to the environment. The zincizing enclosinganticorrosion method comprises following steps: surface treatment shot blasting, high temperature heating, double zinc aluminum wire capacitance spraying onto steel surface, secondary heating penetration, and forming of surface zinc aluminium ferroalloy layers. The best collision resistance and corrosion resistance are achieved, and zincizing waste heat is adopted for another time of spraying of sealing layer alloy powder. The zincizing enclosing anticorrosion method is widely adopted in the field of steel structure member anticorrosion processing.

Owner:山西军昊实业有限公司

An environmental-friendly type steel decontamination rust remover and a preparing method thereof

The invention discloses an environment-friendly decontamination and derusting agent for steel and a preparation method thereof, which is prepared from the following raw materials in parts by weight: 68-88 parts of deionized water, 10-14 parts of sodium tripolyphosphate, and 15 parts of pentaerythritol fatty acid ester ‑18 parts, 13‑16 parts of dodecenyl succinic acid, 5‑8 parts of konjac gum, 10‑14 parts of sodium alginate, 2‑6 parts of polyacrylamide, 2‑6 parts of potassium oxalate, dialkyl di Zinc thiophosphate 4‑10 parts, benzotriazole 5‑11 parts, ethylene glycol 22‑25 parts. The environment-friendly decontamination and derusting agent for steel prepared by the invention is non-toxic, environmentally friendly and energy-saving, and has little pollution to the environment; the derusting efficiency is high, and it can quickly remove oil stains, rust, oxide films, etc. on the metal surface; There is basically no over-corrosion and hydrogen embrittlement.

Owner:WUXI EPIC TECH

Aluminum alloy scale chemical cleaning agent and preparation method thereof

The invention discloses an aluminum alloy scale chemical cleaning agent and a preparation method thereof. The aluminum alloy scale chemical cleaning agent comprises, by weight, 20-40 parts of concentrated hydrochloric acid with the mass fraction of 37%, 0.5-5 parts of lauric acid methyl ester sulfonate, 5-14 parts of methenamine, 1-3 parts of thiourea, 2-6 parts of benzotriazole, 5-15 parts of absolute ethyl alcohol and 70-90 parts of water. The components are mixed, heated and stirred to prepare the aluminum alloy scale chemical cleaning agent. The dissolving capacity for aluminum alloy scales reaches 81.6-113.5 g / Kg, the scale dissolving effect is good, the scales are cleaned up thoroughly, efficiently and safely, the hydrogen embrittlement phenomenon is not generated, the scales can be directly drained, and the environment is not polluted.

Owner:SUZHOU BEC BIOLOGICAL TECH

Foamed rust remover with brightening function

The invention discloses a foamed rust remover with a brightening function. The foamed rust remover consists of the following raw materials in parts by weight: 40-50 parts of phosphoric acid, 12-15 parts of tartaric acid, 5-10 parts of sodium hydrogen carbonate, 5-8 parts of calcium phosphate, 5-10 parts of glycerol, 3-5 parts of aminosulfonic acid, 6-8 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 3-5 parts of cocamidopropyl betaine, 5-6 parts of cobalt chloride hexahydrate, 5-10 parts of tannic acid, 6-8 parts of stearic acid and 5-8 parts of phenylethylamine. The foamed rust remover with the brightening function, disclosed by the invention, is reasonable in component and formula and good in utilization effect, can be used for rapidly removing rust without peculiar smell or irritative gas escape, cannot cause corrosion or hydrogen embrittlement phenomenon to metals, can be used for keeping the surface gloss of a metal matrix, and ensures that the metal surface is more bright.

Owner:梁胜光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com