Neutral environment-friendly cleaning agent as well as preparation method and application thereof

A neutral and environmentally friendly technology, applied in the preparation of detergent mixture compositions, surface active detergent compositions, detergent compounding agents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

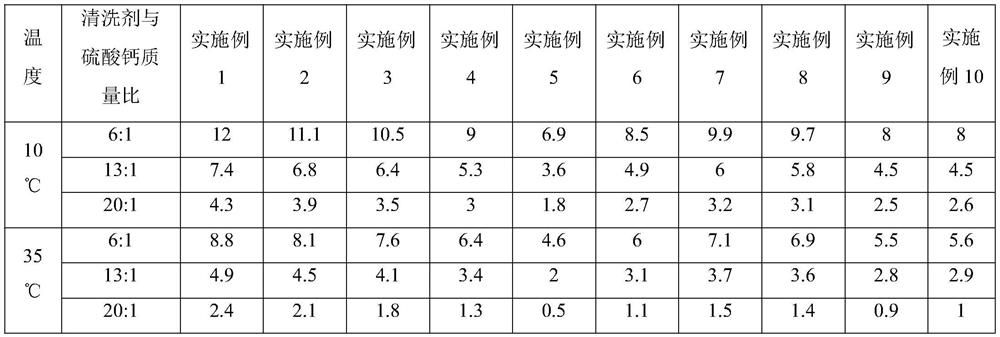

Examples

Embodiment 1

[0031] A neutral environment-friendly cleaning agent

[0032] In terms of mass percentage, the cleaning agent is composed of 10% descaling agent, 0.5% penetrating agent, 5% cosolvent, 0.5% stripping agent, 1% pH regulator and the balance of desalinated water;

[0033] The descaling agent is selected from nitrilotriacetic acid, sodium nitrilotriacetate, and glycolic acid mixed in any proportion;

[0034] The penetrating agent is selected from fatty alcohol polyoxyethylene ether;

[0035] Cosolvent is selected from dehydrated alcohol;

[0036] The stripping agent is selected from polyquaternium salts;

[0037] The pH regulator is selected from sodium hydroxide.

[0038] A preparation method of a neutral environment-friendly cleaning agent, comprising:

[0039] Add 80% desalinated water to the descaling agent, stir and dissolve, adjust to neutral with a pH regulator, and obtain the first mixture for later use;

[0040] The penetrant and the co-solvent are mixed and stirred e...

Embodiment 2

[0044] A neutral environment-friendly cleaning agent

[0045] In terms of mass percentage, the cleaning agent is composed of 15% descaling agent, 1% penetrating agent, 6% cosolvent, 1% stripping agent, 2% pH regulator and the balance of desalinated water;

[0046] The descaling agent is selected from sodium glycolate, and potassium glycolate is mixed in any proportion;

[0047] The penetrating agent is selected from dioctyl sulfosuccinate sodium salt;

[0048] Cosolvent is selected from isopropanol;

[0049] The stripping agent is selected from dodecylguanidine acetate;

[0050] The pH regulator is selected from sodium hydroxide.

[0051] A preparation method of a neutral environment-friendly cleaning agent, comprising:

[0052] Add 80% desalinated water to the descaling agent, stir and dissolve, adjust to neutral with a pH regulator, and obtain the first mixture for later use;

[0053] The penetrant and the co-solvent are mixed and stirred evenly to obtain the second mix...

Embodiment 3

[0057] A neutral environment-friendly cleaning agent

[0058] In terms of mass percentage, the cleaning agent is composed of 20% descaling agent, 1.5% penetrating agent, 7% cosolvent, 1.5% stripping agent, 3% pH regulator and the balance of desalinated water;

[0059] The descaling agent is selected from nitrilotriacetic acid, sodium glycolate, and potassium glycolate mixed in any proportion;

[0060] The penetrating agent is selected from dioctyl sulfosuccinate sodium salt;

[0061] Cosolvent is selected from dehydrated alcohol;

[0062] The stripping agent is selected from dodecylguanidine acetate;

[0063] Potassium hydroxide is selected as the pH regulator.

[0064] A preparation method of a neutral environment-friendly cleaning agent, comprising:

[0065] Add 80% desalinated water to the descaling agent, stir and dissolve, adjust to neutral with a pH regulator, and obtain the first mixture for later use;

[0066] The penetrant and the co-solvent are mixed and stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com