Welded joint made of an austenitic steel

一种焊接接头、奥氏体的技术,应用在焊接/焊接/切割物品、焊接介质、焊接设备等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

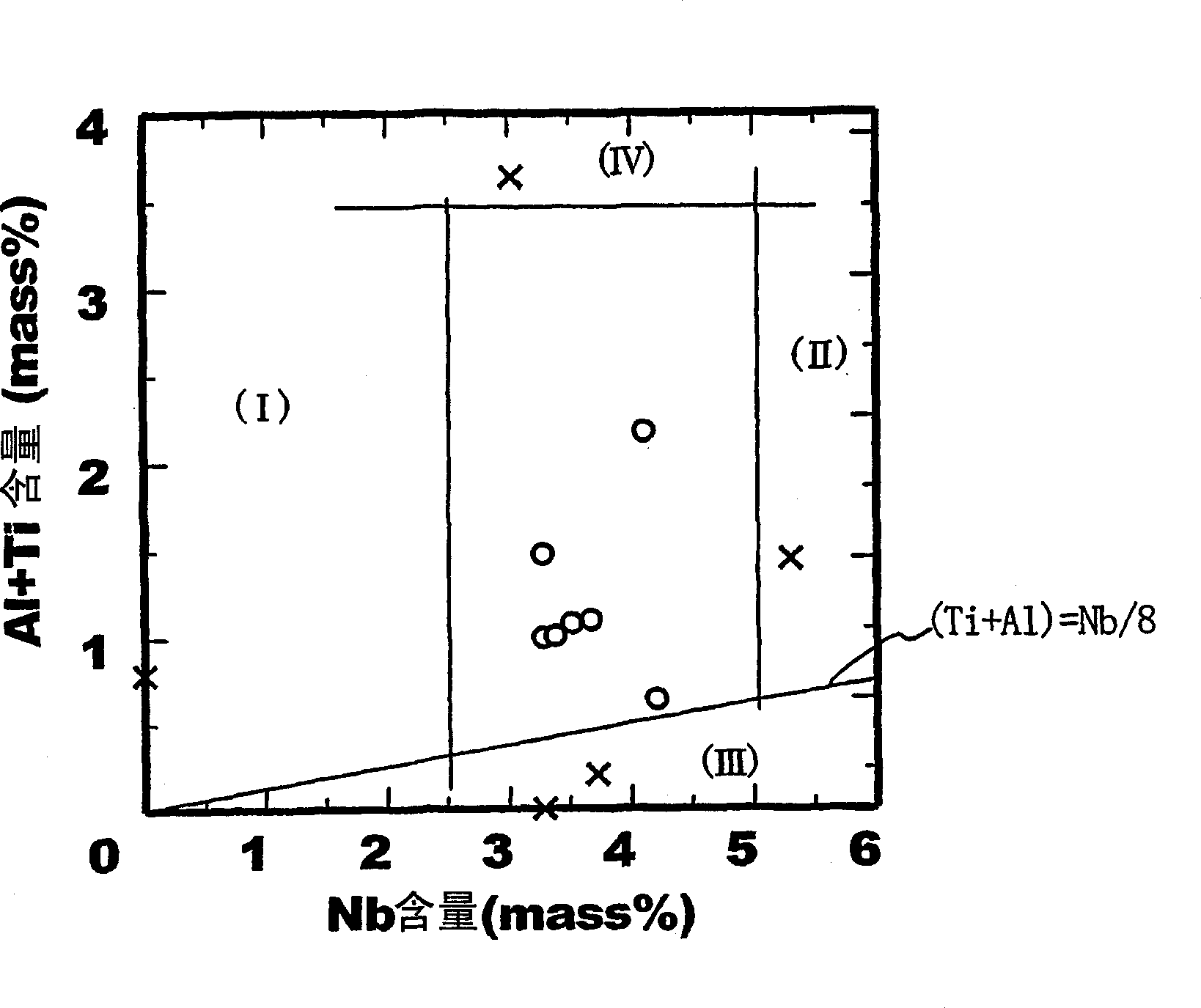

[0091] The base metals coded M1~M4 with the chemical composition shown in Table 1 were dissolved in a 50kg vacuum high-frequency furnace, then formed into a 25mm thick plate by forging, and kept at 1000°C for 1 hour for water cooling and heat treatment to form a welding base material. test material.

[0092] In addition, the alloys W1-W5 and Y1-Y5 with the same chemical composition shown in Table 1 were dissolved in a 50kg vacuum high-frequency furnace and then processed into wire rods with an outer diameter of 2mm as welding materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com