Steel bar rust removal treatment device based on construction site

A processing device and steel bar technology, applied in the direction of spraying device, liquid spraying device, grinding drive device, etc., can solve the problems of low efficiency of rust removal, slow rust removal efficiency of steel bar derusting machine, inconvenient replacement of wire rollers, etc. Achieve the effect of improving the efficiency of rust removal, improving the effect of rust removal, and fast grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

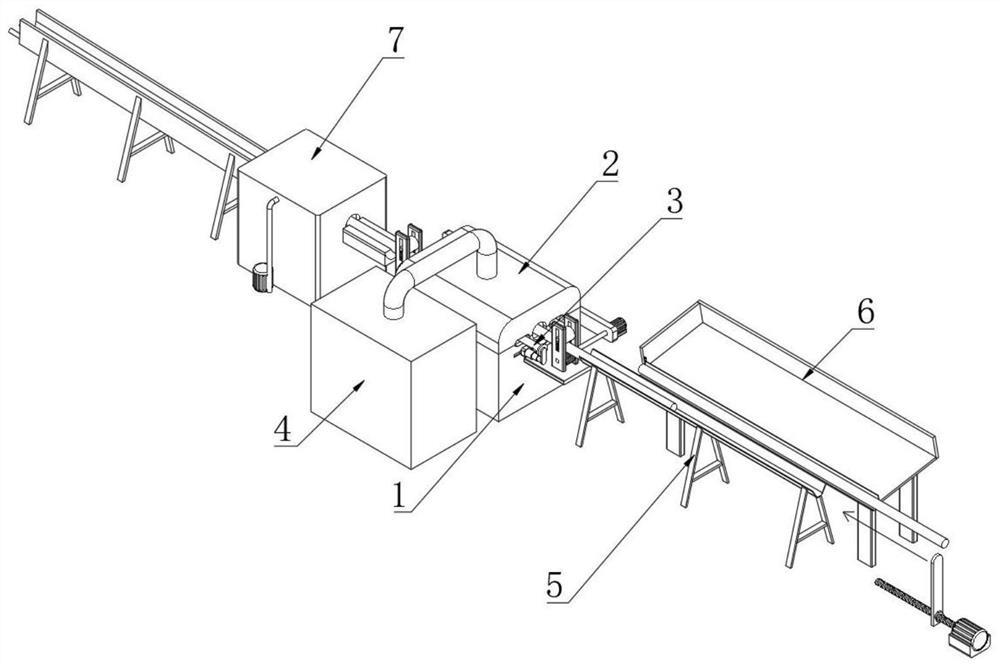

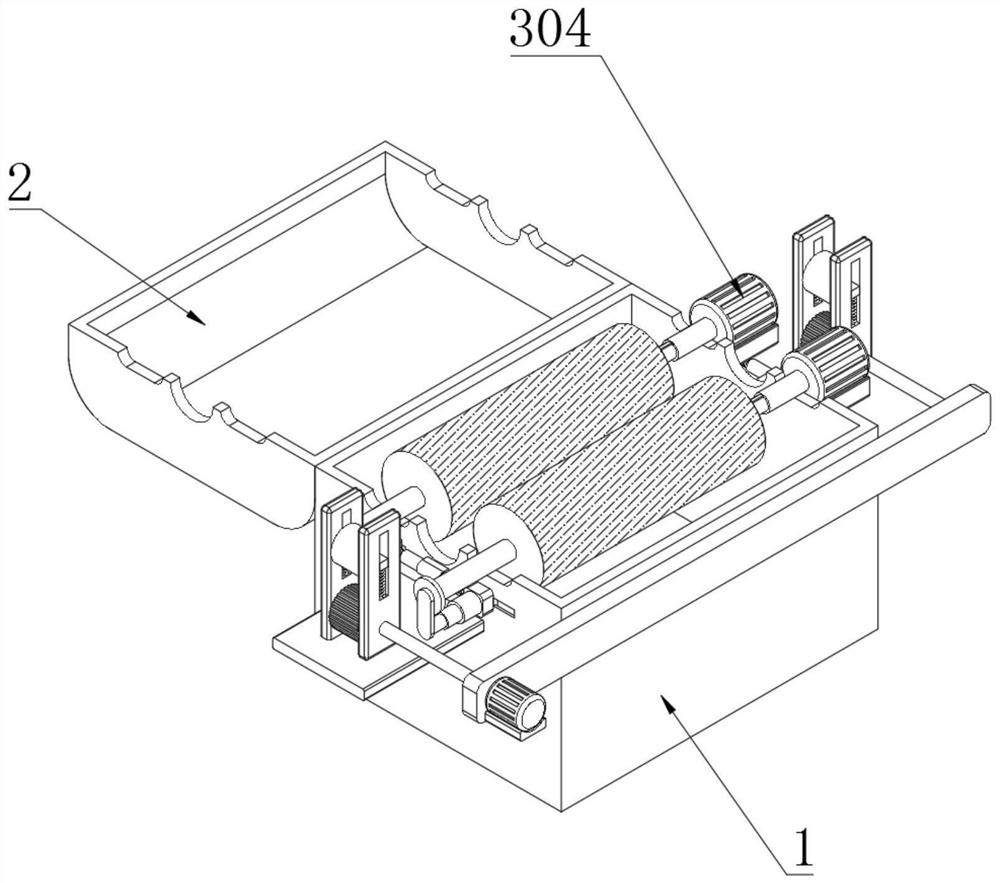

[0057] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a steel bar derusting treatment device based on a construction site, including a grinding box 1, a box cover 2 is hinged on one side of the top end of the grinding box 1, and a steel bar support frame 5 is placed at one end of the polishing box 1;

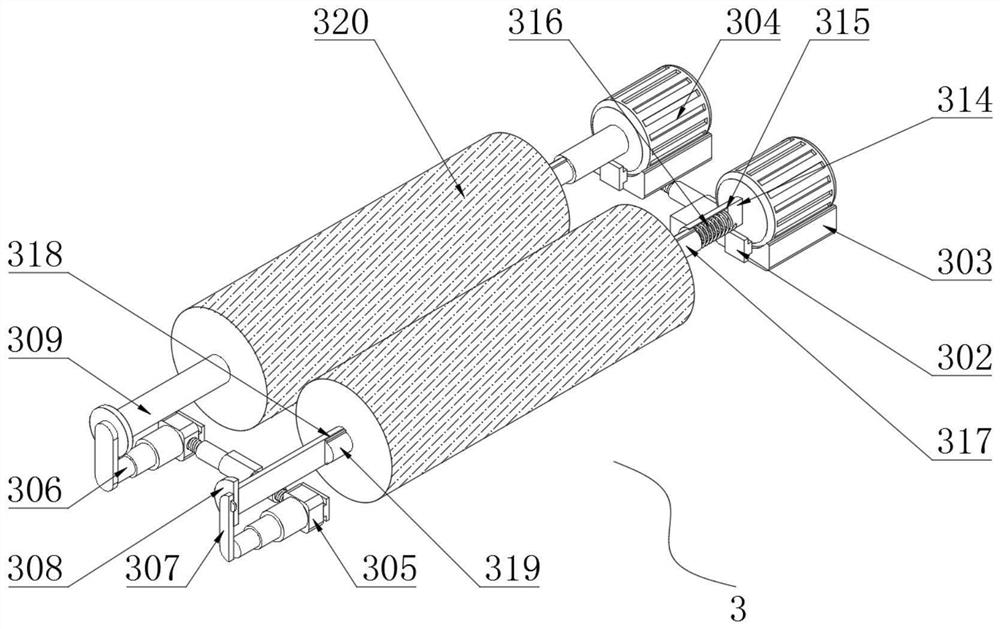

[0058] A high-efficiency grinding and disassembly assembly 3 is installed inside the grinding box 1, and the high-efficiency grinding and disassembly assembly 3 includes a moving slot 301, a moving block 302, a motor seat 303, a grinding motor 304, a mounting block 305, an electric telescopic rod 306, a connecting plate 307, and a fixed plate 308 , installation shaft 309, driving block 310, screw rod 311, threaded cylinder 312, fixed sleeve 313, rotating shaft 314, driving groove 315, tension spring 316, insertion column 317, installation groove 318, installation column 319, wire roller 320 and sliding hole 321;

[0059] Both ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com