Production method of anti-corrosion steel

A technology of steel and anti-corrosion coatings, applied in anti-corrosion coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as environmental pollution, damage to steel structures, incomplete rust removal, etc., to reduce environmental pollution and prolong service life The effect of life and cost reduction of derusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] S1, in the iron and steel manufacturing plant, cooling the produced section steel to 70°C;

[0044] S2, using a laser processing device to remove scale, oil and dust on the surface of the steel;

[0045] S3, using automatic spraying method to apply two-component zinc-rich anti-corrosion coating (90% metal zinc content in the dry film) using the residual temperature of the steel for self-curing, and it will be dry after 6 minutes;

[0046] S4, conduct coating film performance test, the results are shown in Table 1, after that, the surface of the steel can be protected and stored.

[0047] The two-component zinc-rich anti-corrosion coating includes: component A includes 8-10 parts of epoxy resin, 10-15 parts of solvent, 60-70 parts of zinc powder, 0.5-1.0 parts of anti-settling agent, and 0-1 parts of coupling agent. Parts; B component includes 8-10 parts of epoxy curing agent, 6-10 parts of solvent.

Embodiment 2

[0049] S1, in the iron and steel manufacturing plant, the produced steel pipe is cooled to 80°C;

[0050] S2, using a laser processing device to remove scale, oil and dust on the surface of the steel;

[0051]S3, adopt dip coating method to apply one-component high-zinc anti-corrosion coating (metal zinc content in the dry film is 93%), the steel pipe passes through the anti-corrosion coating tank to make the inner and outer walls covered with coating, and passes through the annular flexible scraper to make the anti-corrosion coating The inner and outer wall paint is evenly applied, and the excess paint is recycled to avoid the sagging phenomenon in the later stage. After construction, the residual temperature of the steel is used for self-curing, and it will be dry after 8 minutes;

[0052] S4, conduct coating film performance test, the results are shown in Table 1, after that, the surface of the steel can be protected and stored.

[0053] The one-component high-zinc anticor...

Embodiment 3

[0055] S1, in the iron and steel manufacturing plant, the produced steel rail is cooled to 65°C;

[0056] S2, using a laser processing device to remove scale, oil and dust on the surface of the steel;

[0057] S3, using automatic spraying method to apply single-component high-zinc anti-corrosion coating (metal zinc content in the dry film is 92%). After 5 minutes, it will be dry to the touch;

[0058] S4, conduct coating film performance test, the results are shown in Table 1, after that, the surface of the steel can be protected and stored.

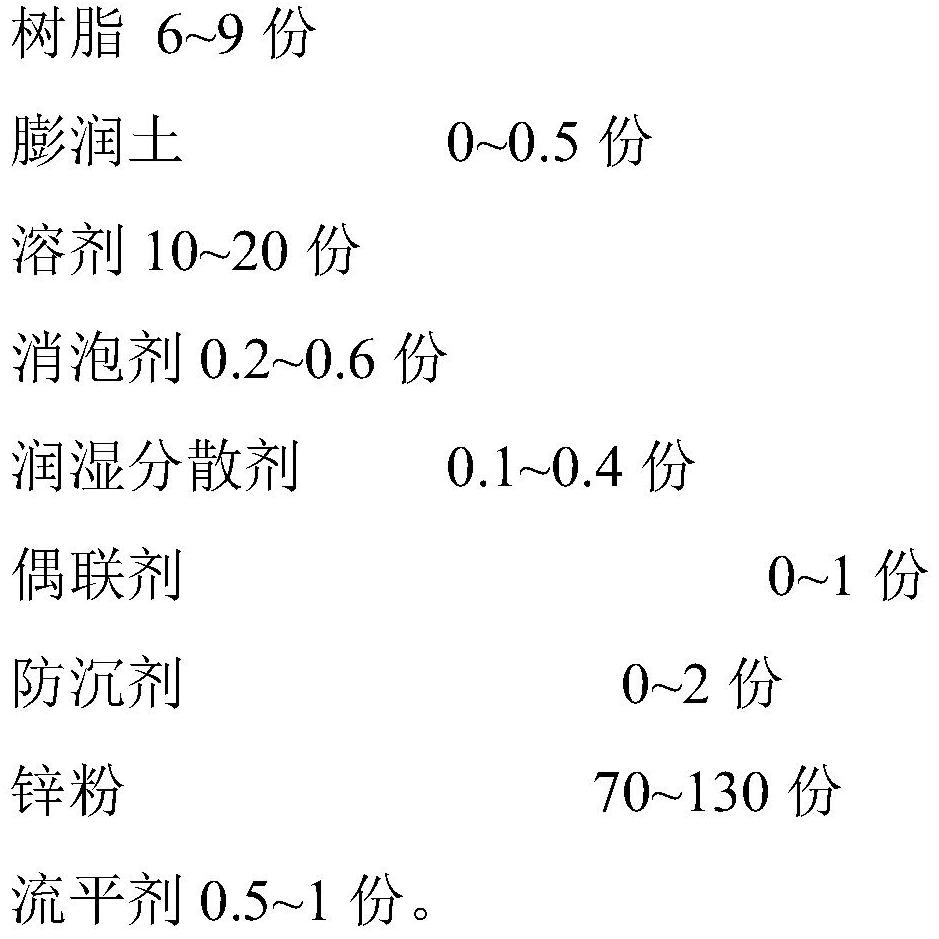

[0059] The one-component high-zinc anticorrosion coating includes: 6-9 parts of modified epoxy resin, 0-0.5 parts of bentonite, 10-20 parts of solvent, 0-1 part of coupling agent, 1-2 parts of anti-settling agent, zinc Powder 70~130 parts.

[0060] Table 1

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com