Patents

Literature

41results about How to "Expand the clamping range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

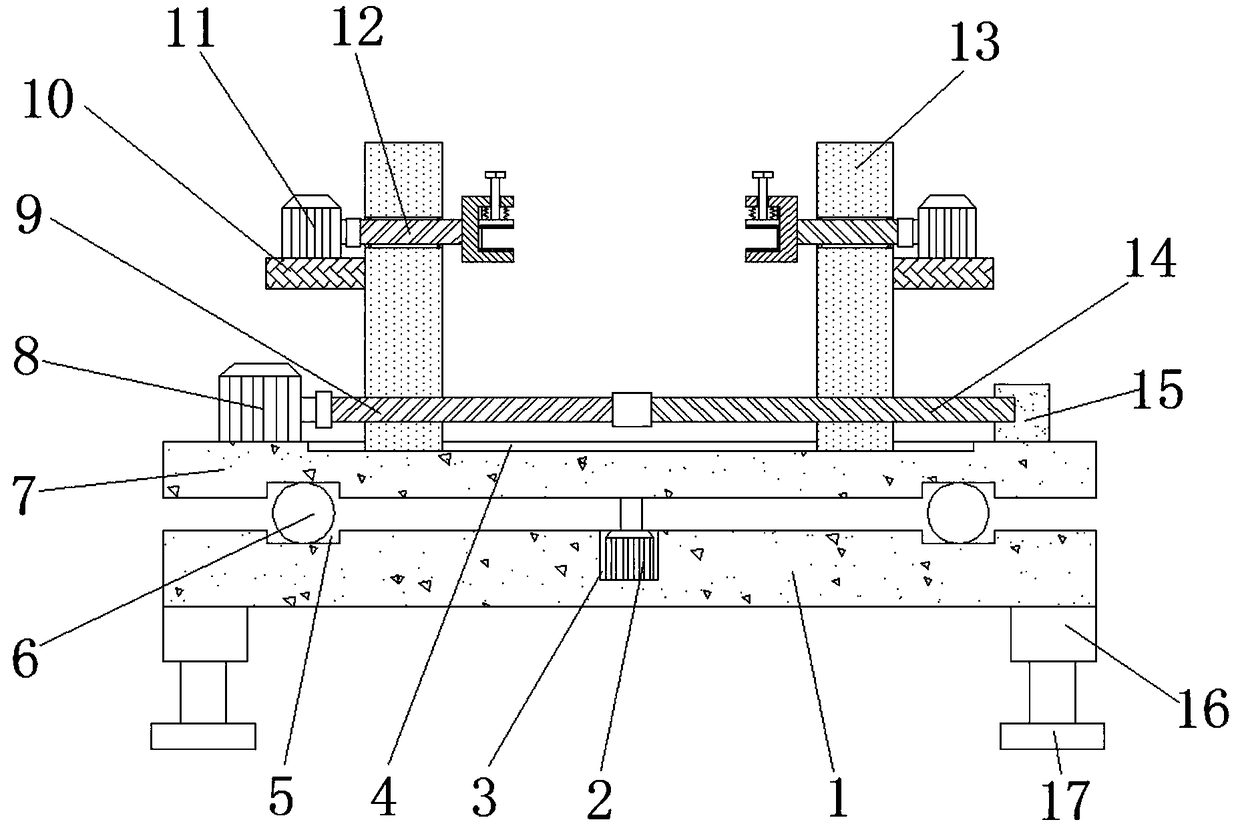

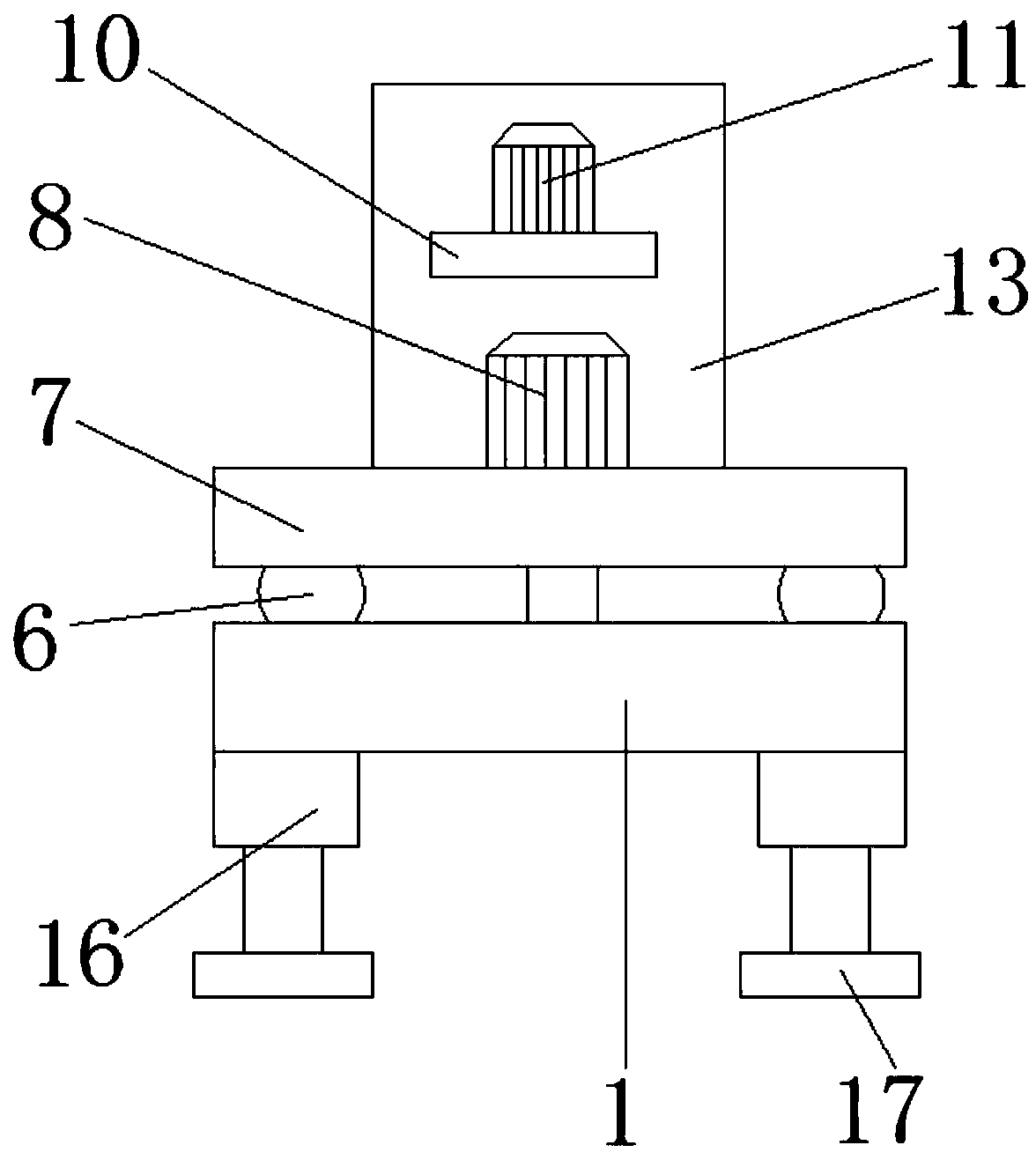

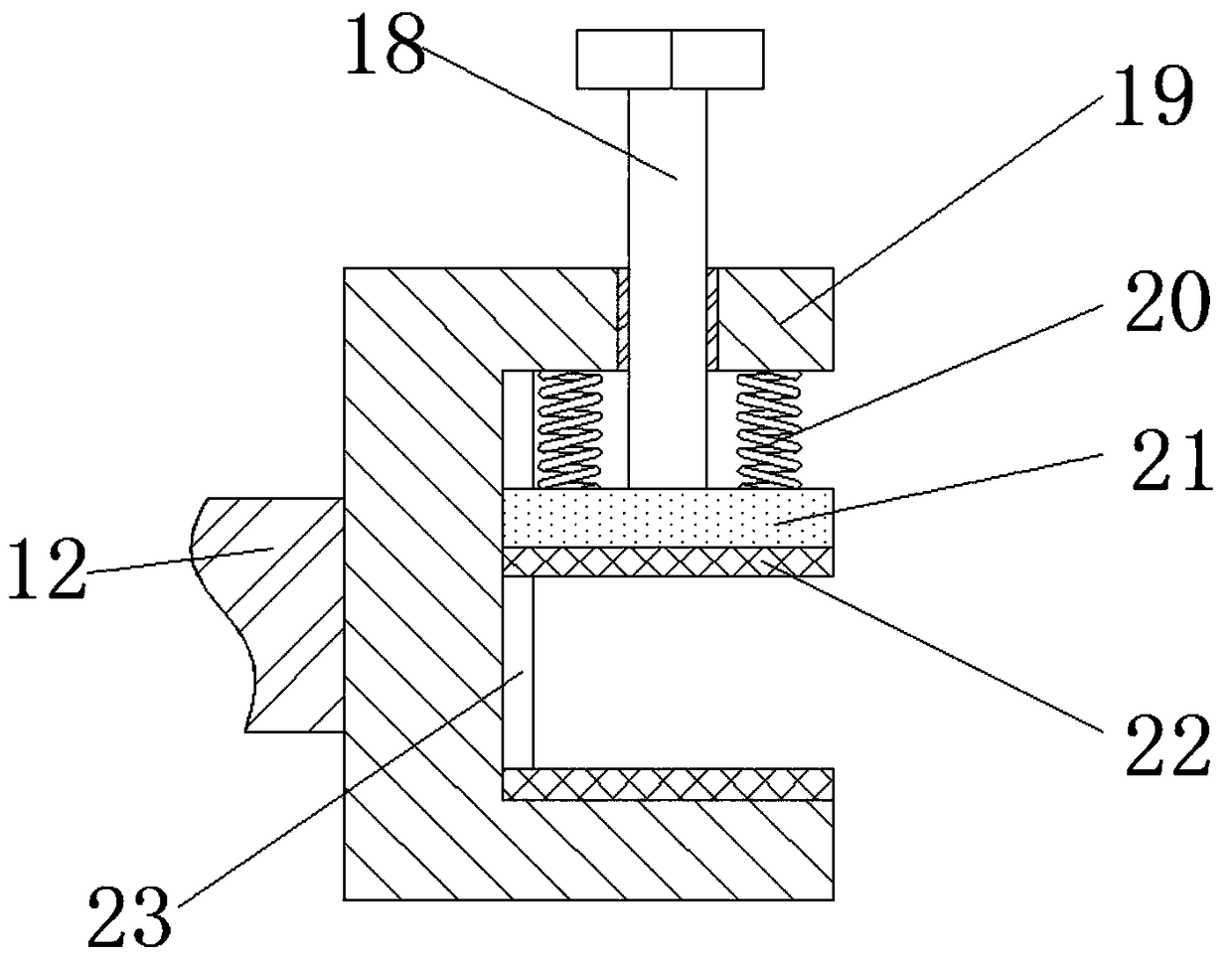

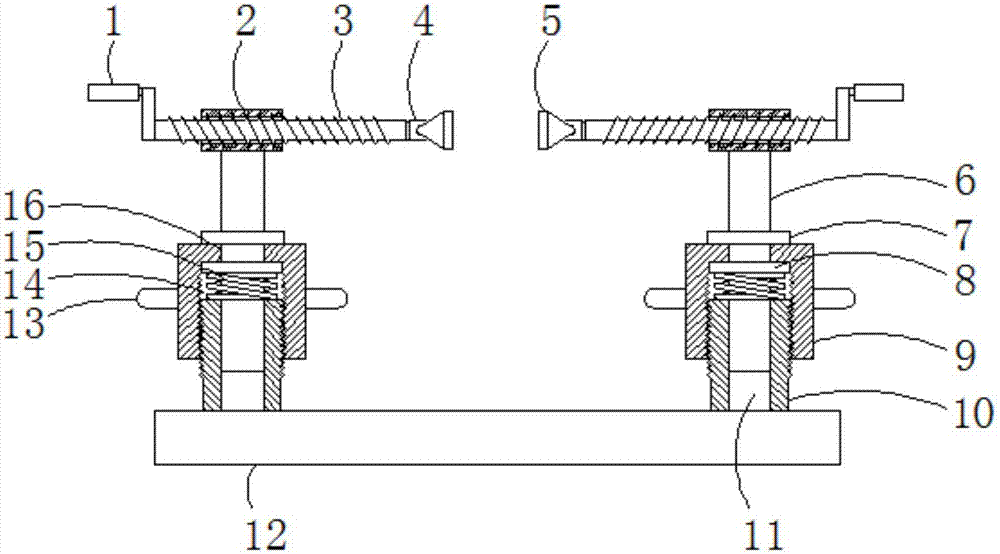

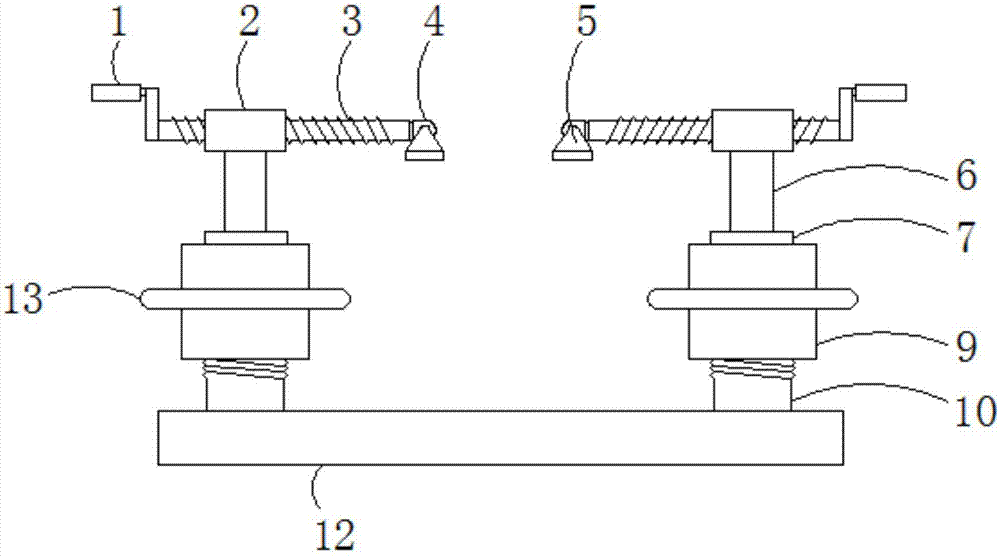

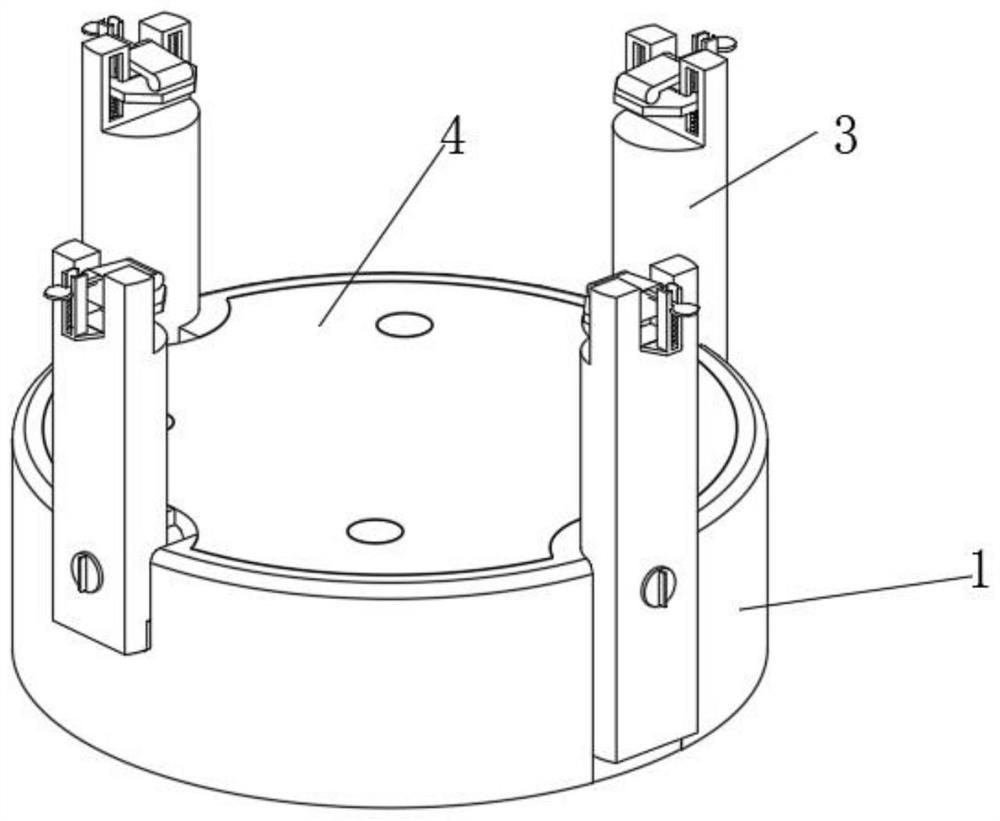

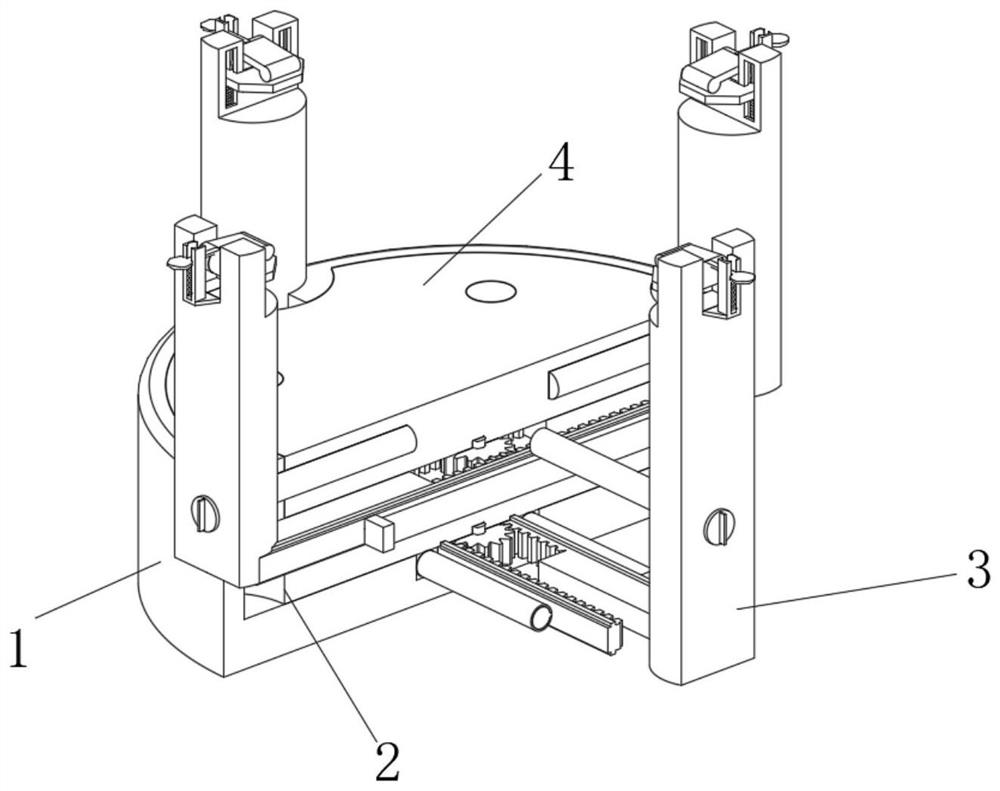

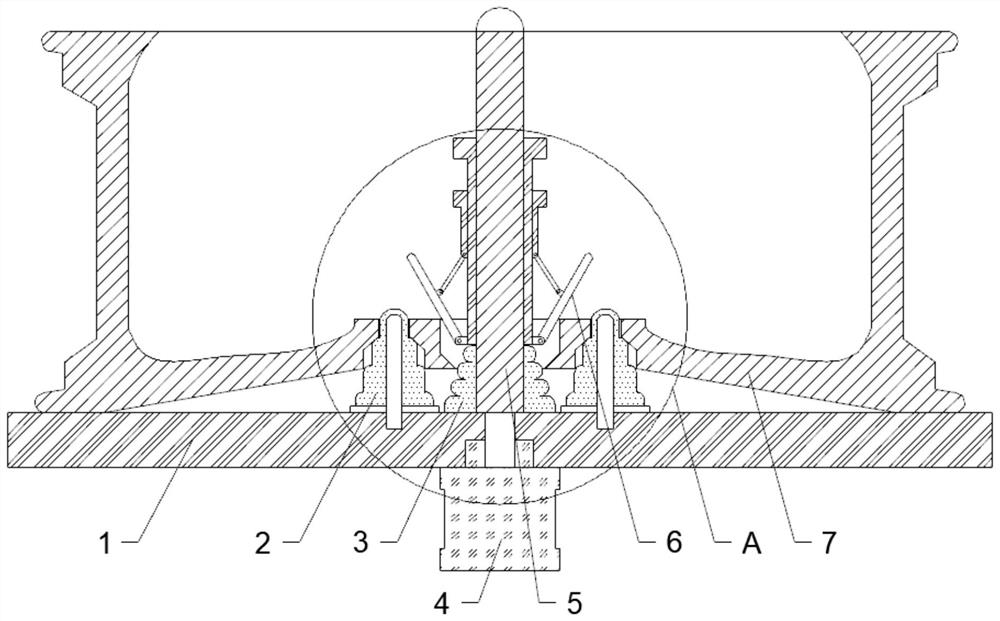

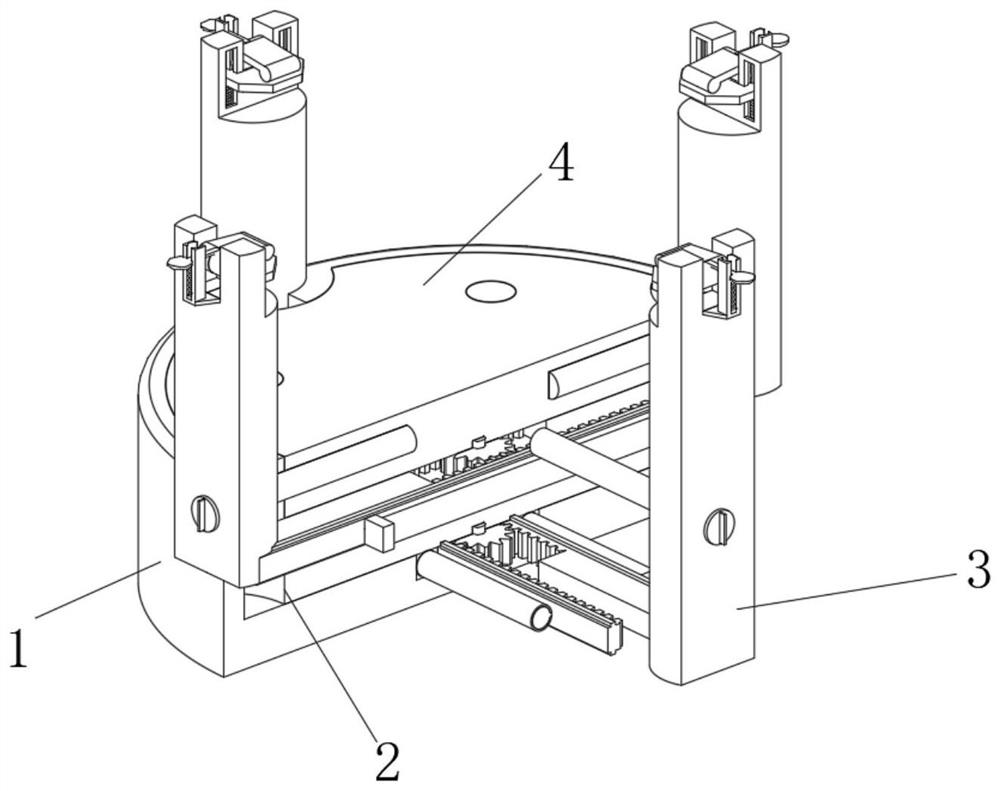

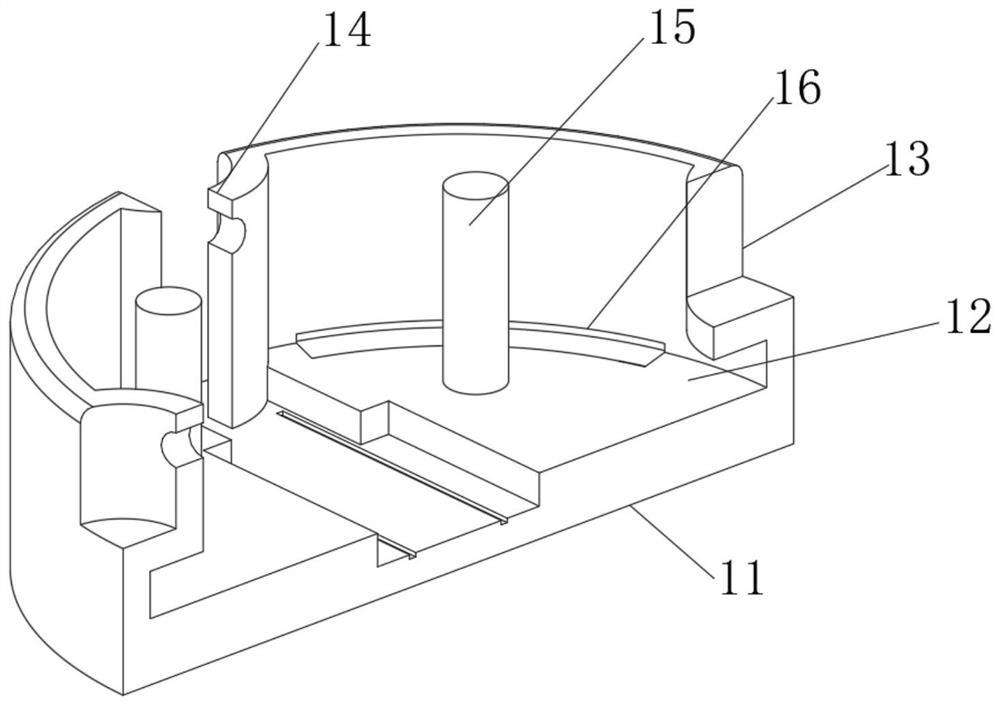

Metal piece clamping device for metal cutting machine tool machining

InactiveCN108655782AEasy to holdIncrease flexibilityLarge fixed membersPositioning apparatusHydraulic cylinderEngineering

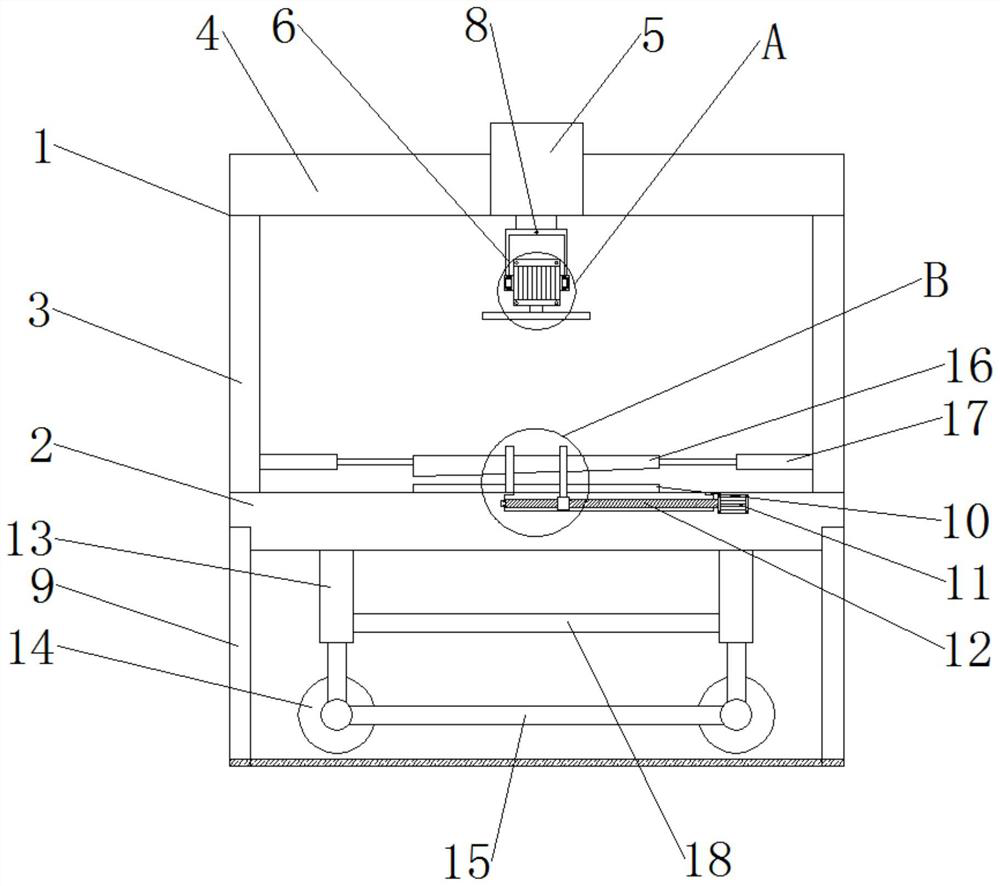

The invention discloses a metal piece clamping device for metal cutting machine tool machining. A base and a rotating table are included, and the dead corners of the bottom outer wall of the base areeach fixedly provided with a hydraulic cylinder through a screw; the outer walls of the sides, away from the base, of the four hydraulic cylinders are each fixedly provided with a supporting leg through a screw; the center axis position of the top outer wall of the base is provided with an installing groove; the inner wall of the bottom of the installing groove is fixedly provided with a first servo motor through a screw; an output shaft of the first servo motor is fixed to the center axis position of the bottom outer wall of the rotating table through a screw; the outer walls of the oppositesides of the base and the rotating table are each provided with an annular groove; and the inner walls of the two annular grooves are connected with same rolling balls in an equal-distance uniform rolling manner. According to the metal piece clamping device for metal cutting machine tool machining, the height and the angle of the device can be adjusted, so that the device conveniently clamp metalpieces, and the distance between two adjusting blocks can be adjusted according to the size of the metal pieces so that the device can be used for clamping the metal pieces in different sizes.

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

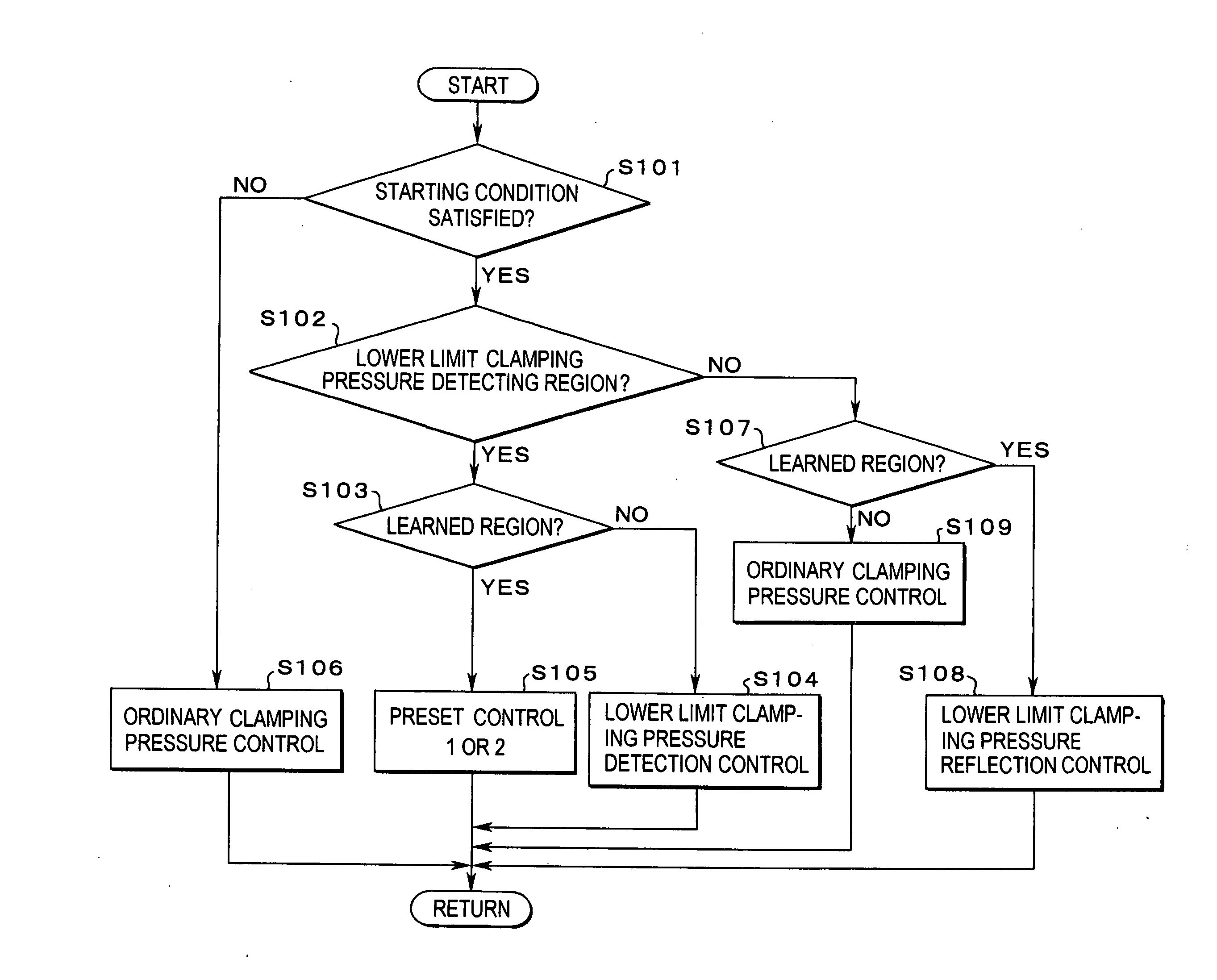

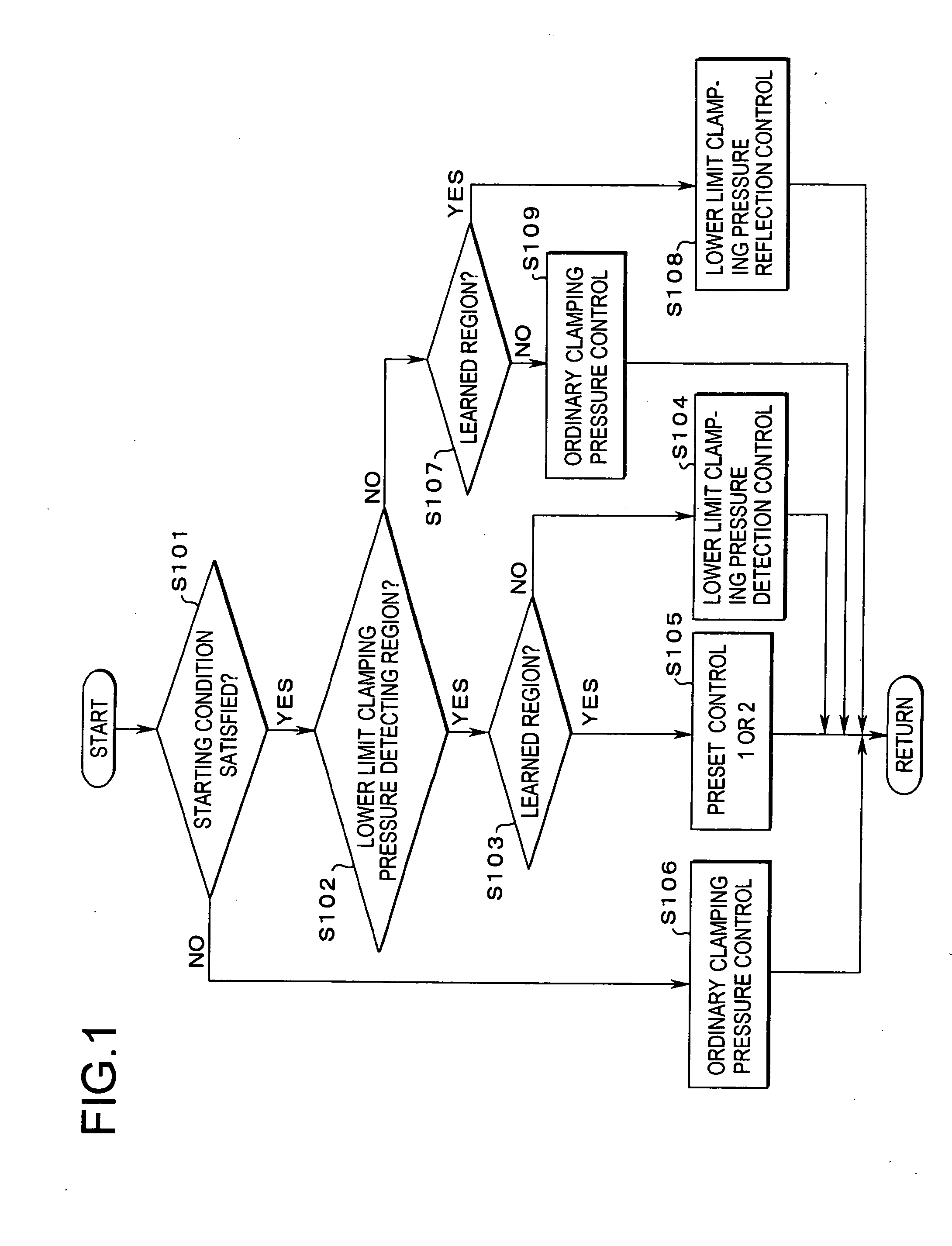

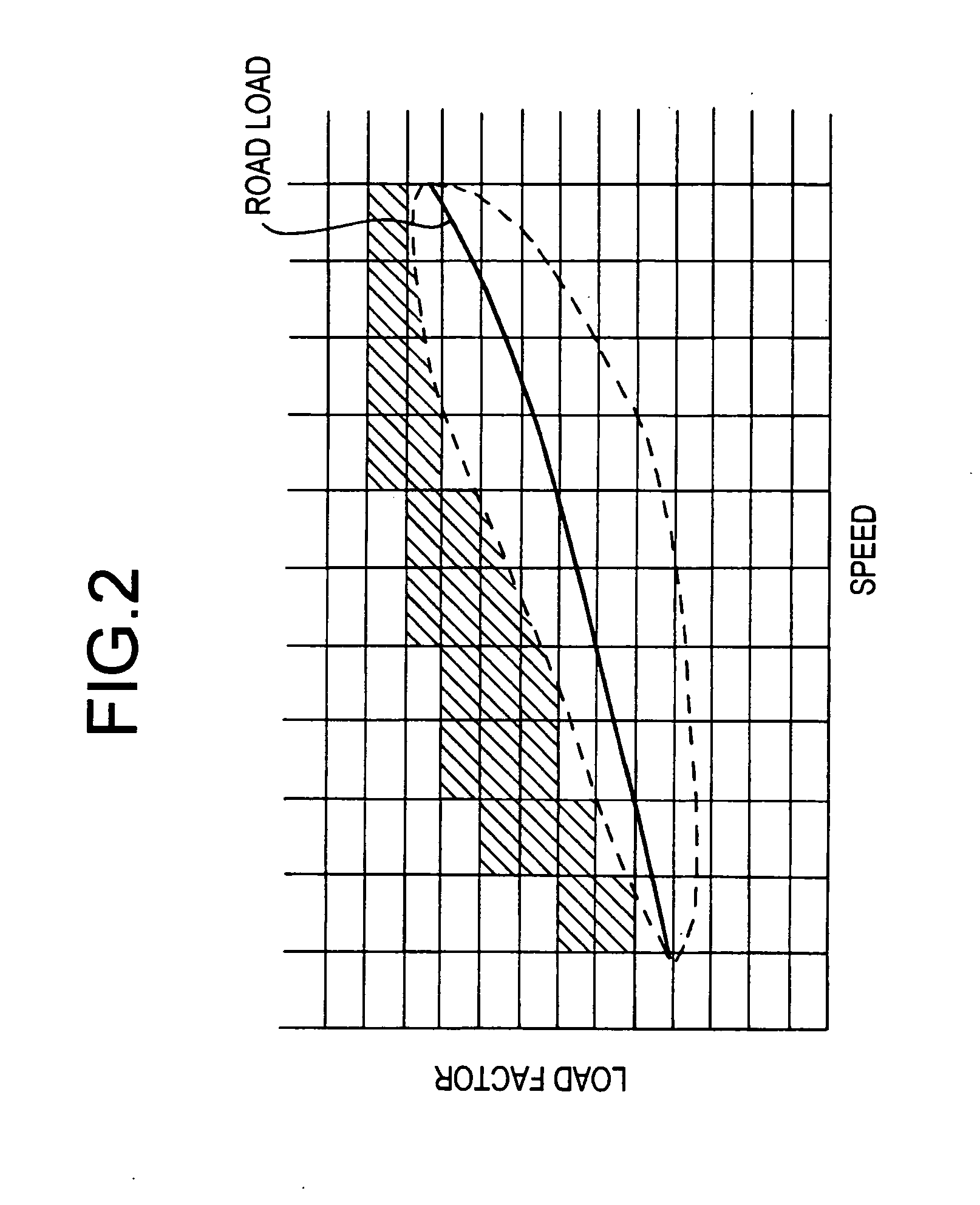

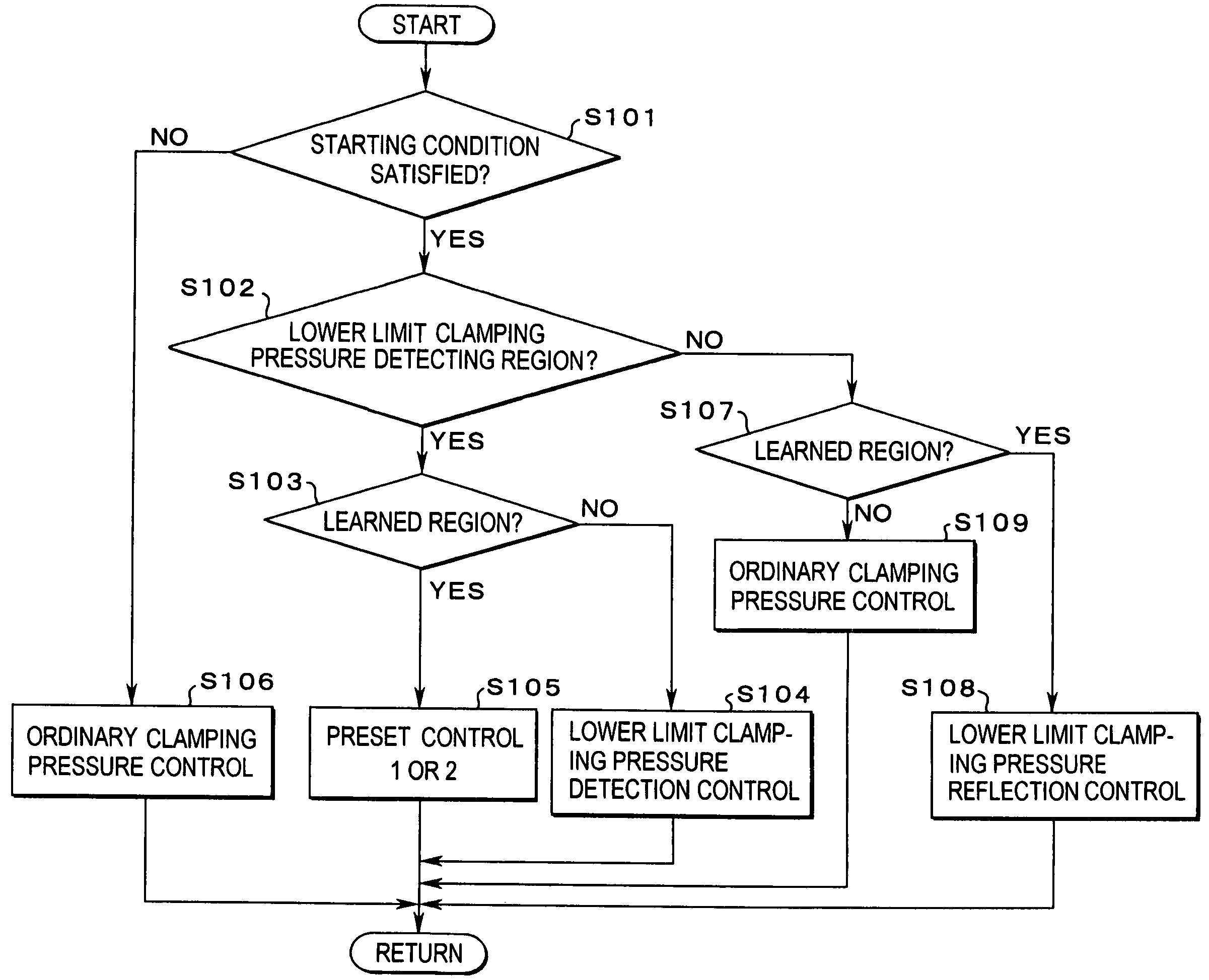

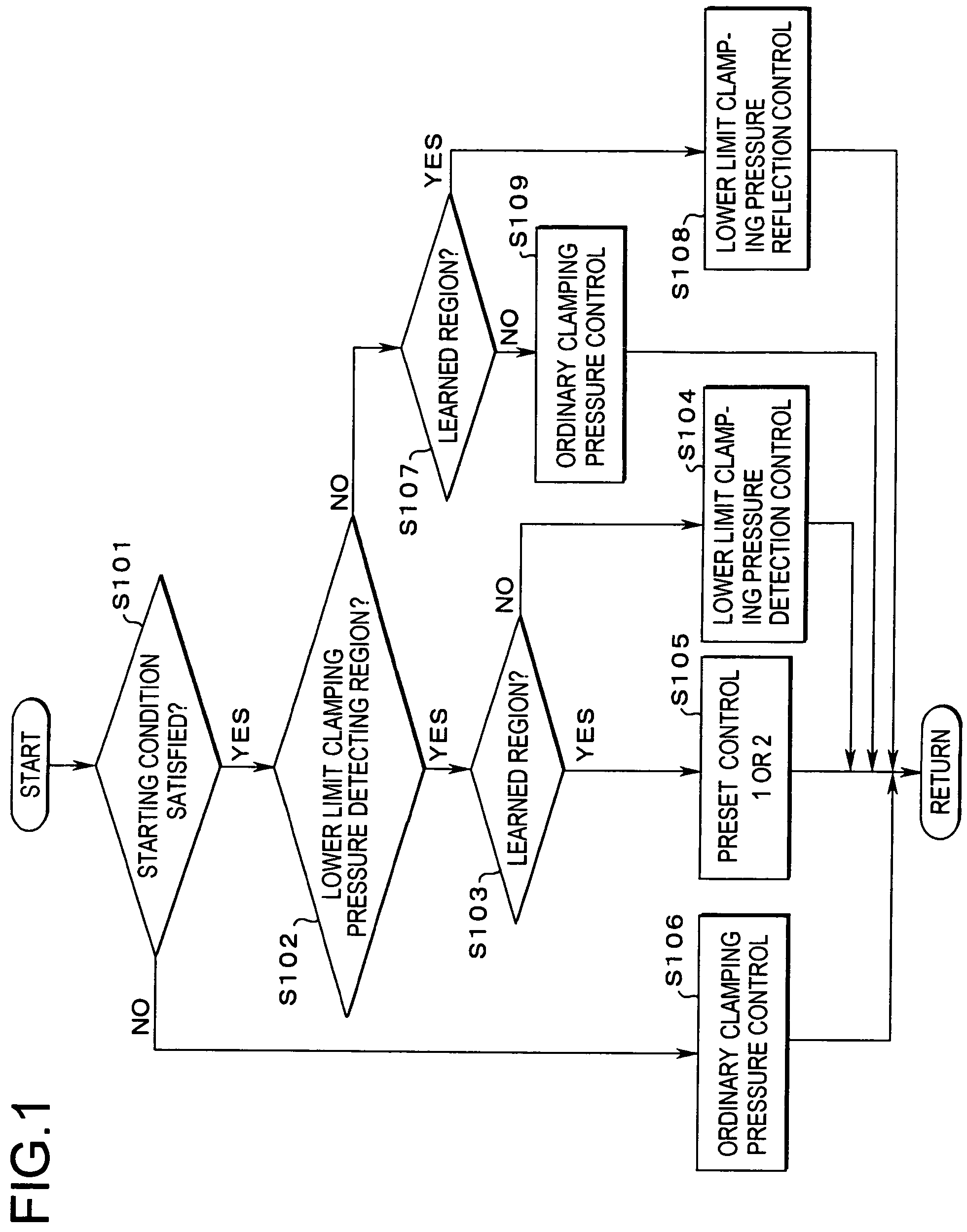

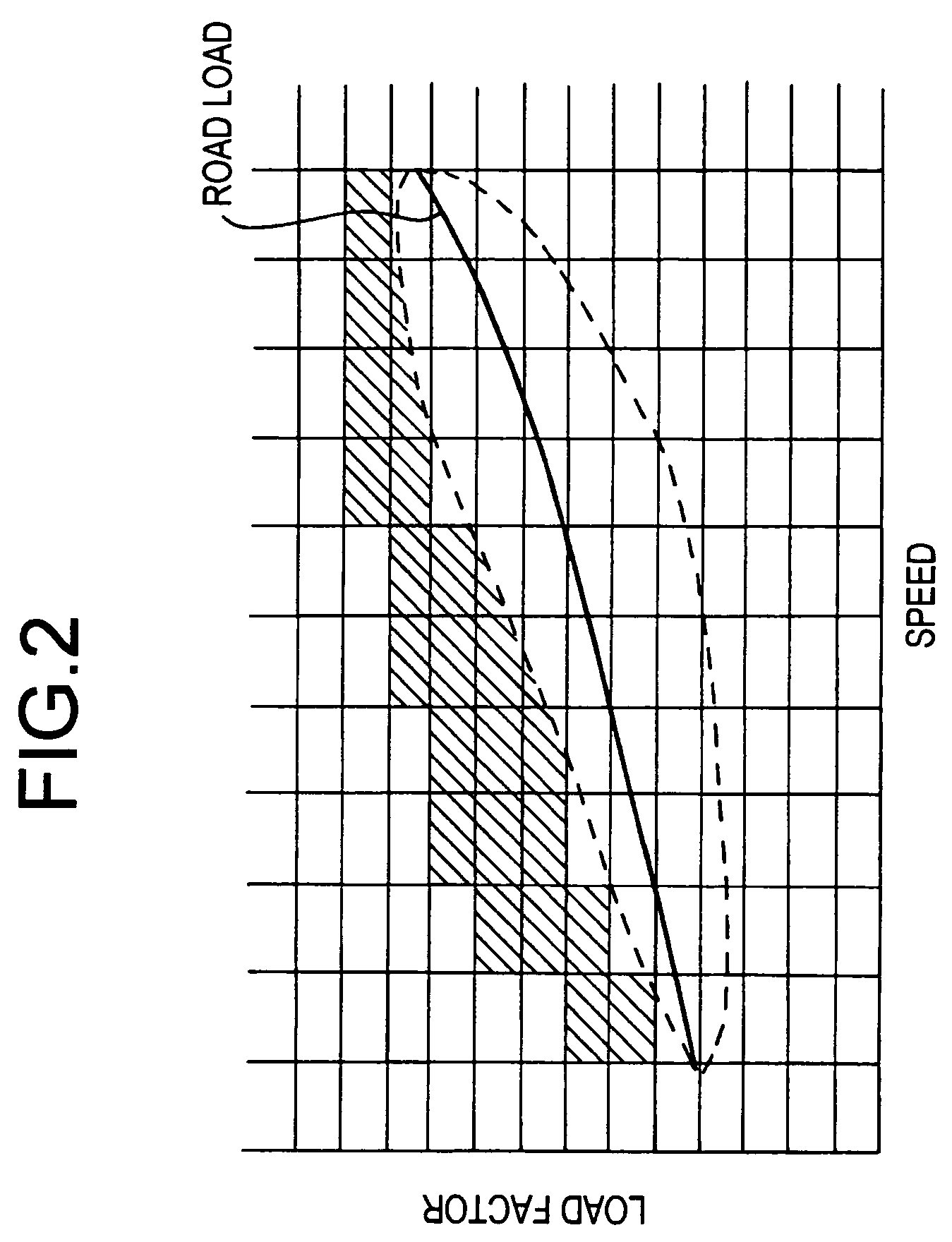

Control system for continuously variable transmission of vehicle

InactiveUS20050181909A1Expand the clamping rangeAvoid changeOperating modesGearingVariatorEngineering

A control system for a continuously variable transmission of a vehicle, in which a clamping pressure of rotary members to clamp a transmission member is learned and set in every operating state of a prime mover connected to an input side of the continuously variable transmission having those rotary members and transmission member. The control system comprises: an operating state changing mechanism for an operating state of the prime mover in response to a satisfaction of learning execution condition of the clamping pressure; a torque change suppressing mechanism for suppressing a change in a torque resulting from the change in the operating state of the prime mover; and a clamping pressure learning device for learning the clamping pressure in the operating state of the prime mover after the change, while the operating state of the prime mover is being changed and the change in the torque resulting from the change in the operating state of the prime mover is being suppressed by the torque change suppressing means.

Owner:TOYOTA JIDOSHA KK

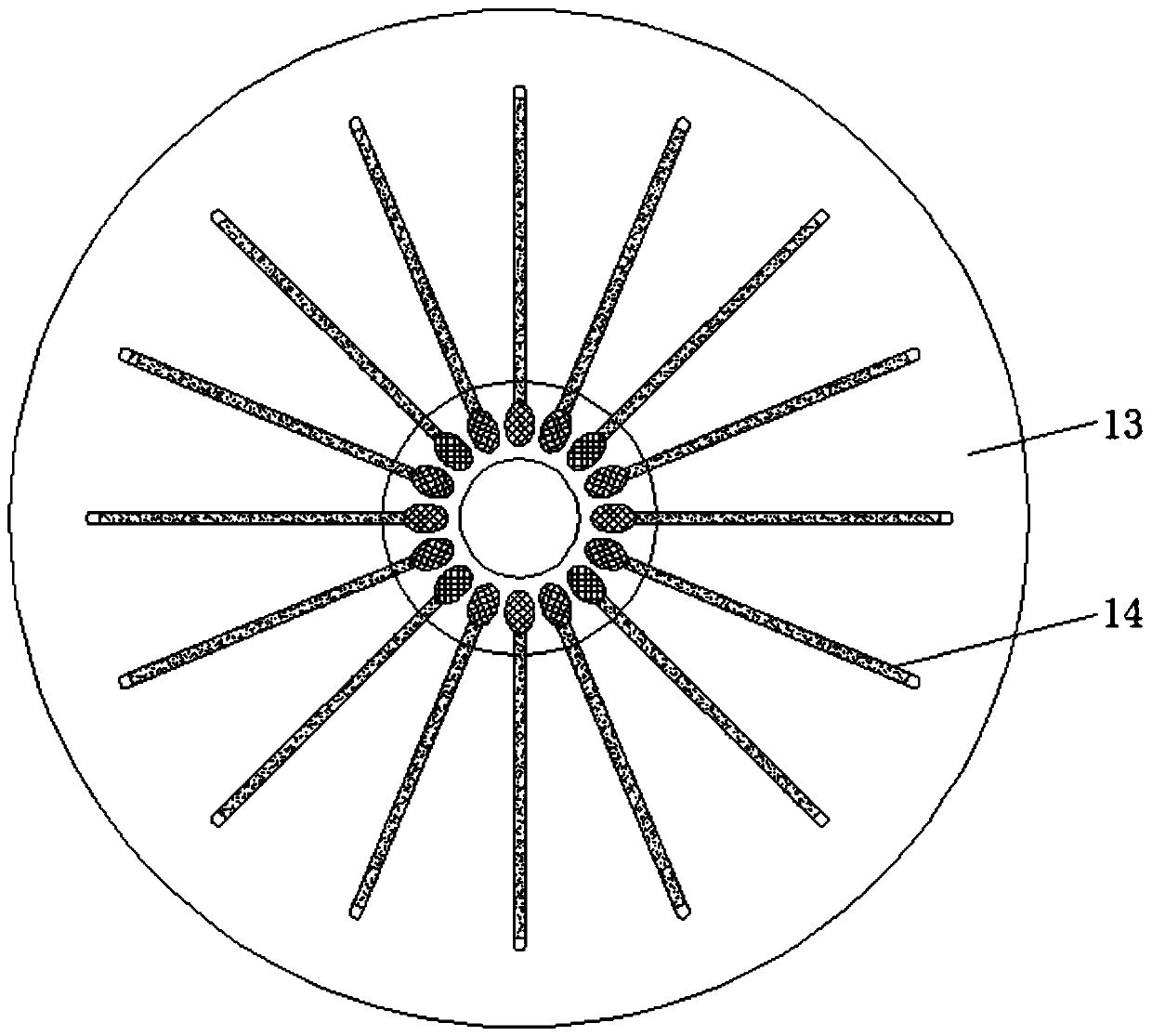

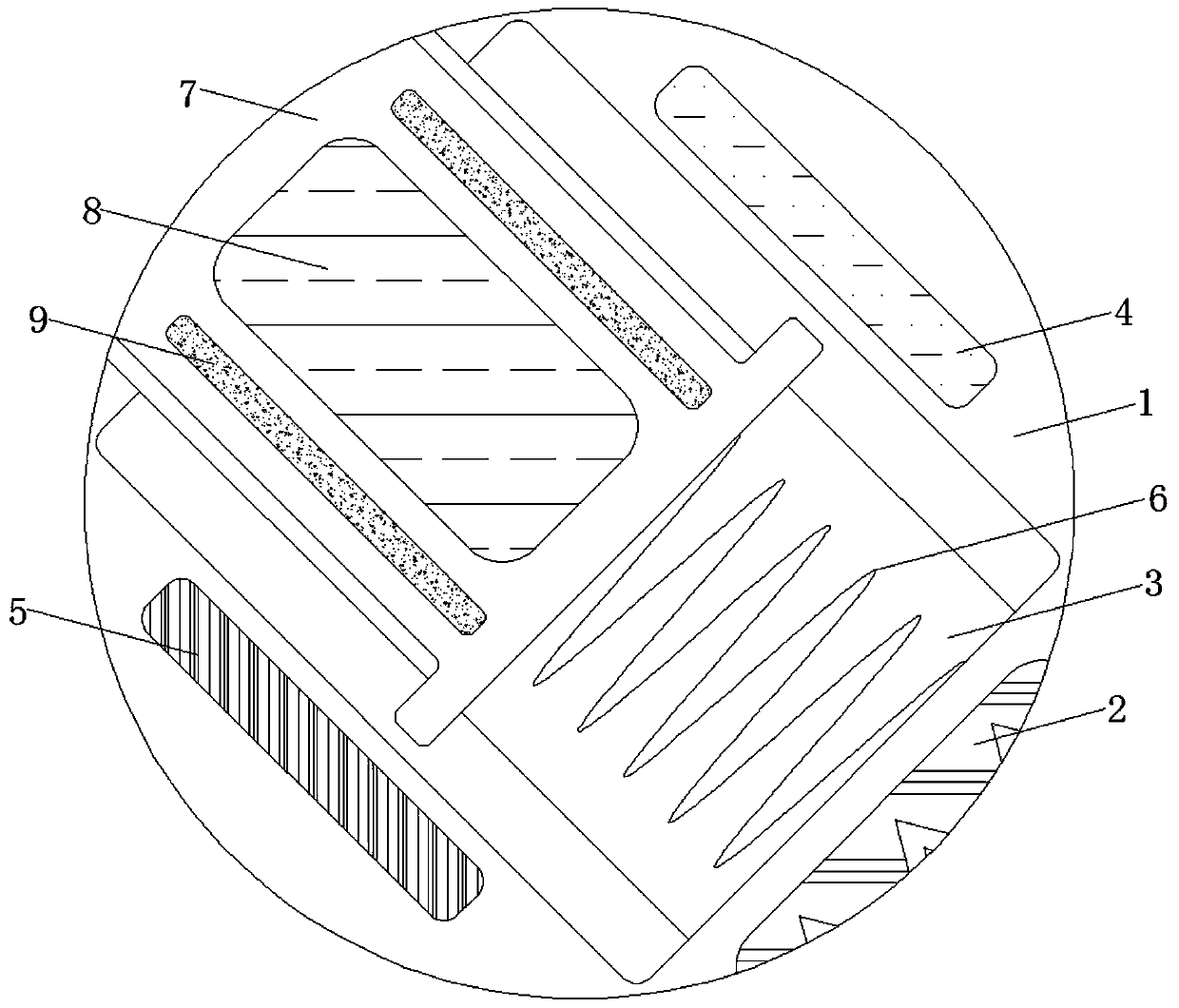

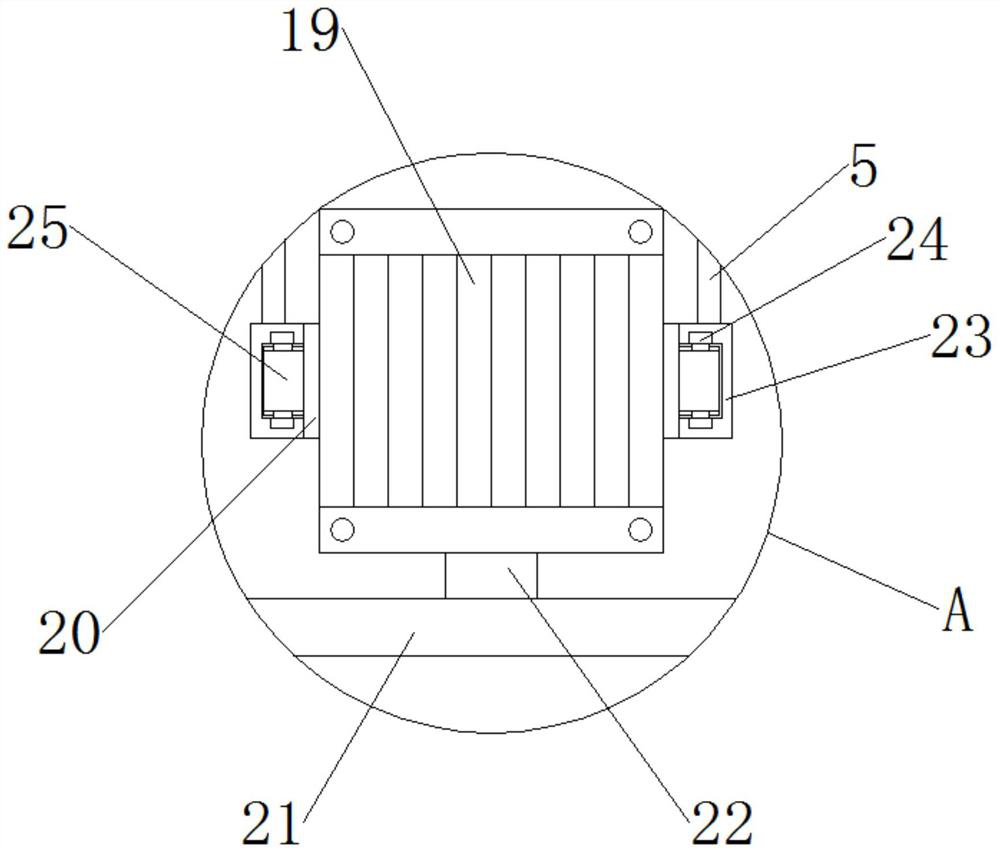

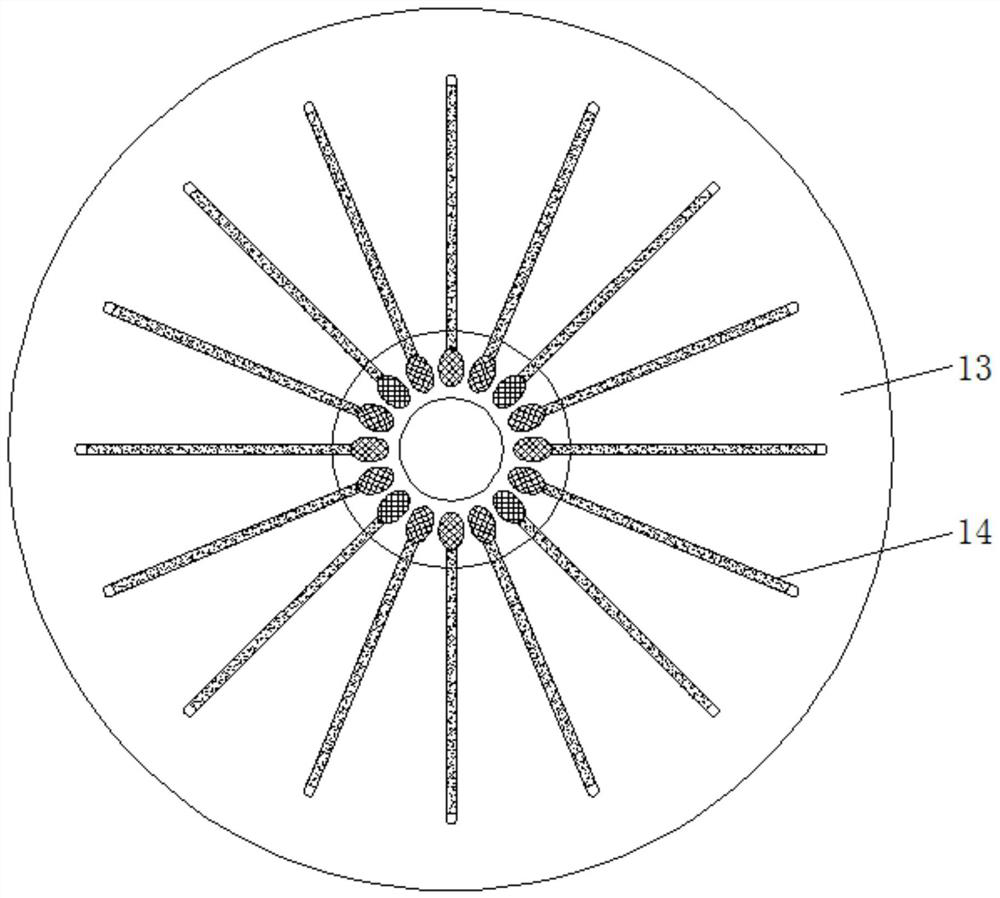

Centring and self-generating fixing device for environment-friendly steel pipe rust removal

ActiveCN110883668AEven contactTo achieve a calming effectGrinding drivesGrinding machinesEngineeringMechanical engineering

The invention provides a centring and self-generating fixing device for environment-friendly steel pipe rust removal relates to the technical field of environmental protection. The device comprises afixing pipe, an inner wall of the fixing pipe is fixedly connected with uniformly distributed electromagnetic devices 1, and the inner wall of the fixing pipe is provided with uniformly distributed movable grooves. According to the fixing device, the electromagnetic devices 2 and electromagnetic devices 2 are matched for use, since all the electromagnetic devices 1 have the same magnetism, the electromagnetic devices 2 have the same magnetism and the magnetism of inner sides of the electromagnetic devices 1 is the same as that of the outer sides of the electromagnetic devices 2, the electromagnetic devices 1 and the electromagnetic devices 2 repel each other, meanwhile, movable blocks can move towards the inner sides by the same length under the repulsive action of the electromagnetic devices 1 and the electromagnetic devices 2 such that rolling wheels are clamped and located in the center of the fixing pipe, the centering effect is achieved, the rust removal work is effectively guaranteed, an outer side of a steel pipe makes uniform contact with the rust removal device, and the rust removal quality is improved.

Owner:山东东正钢构有限公司

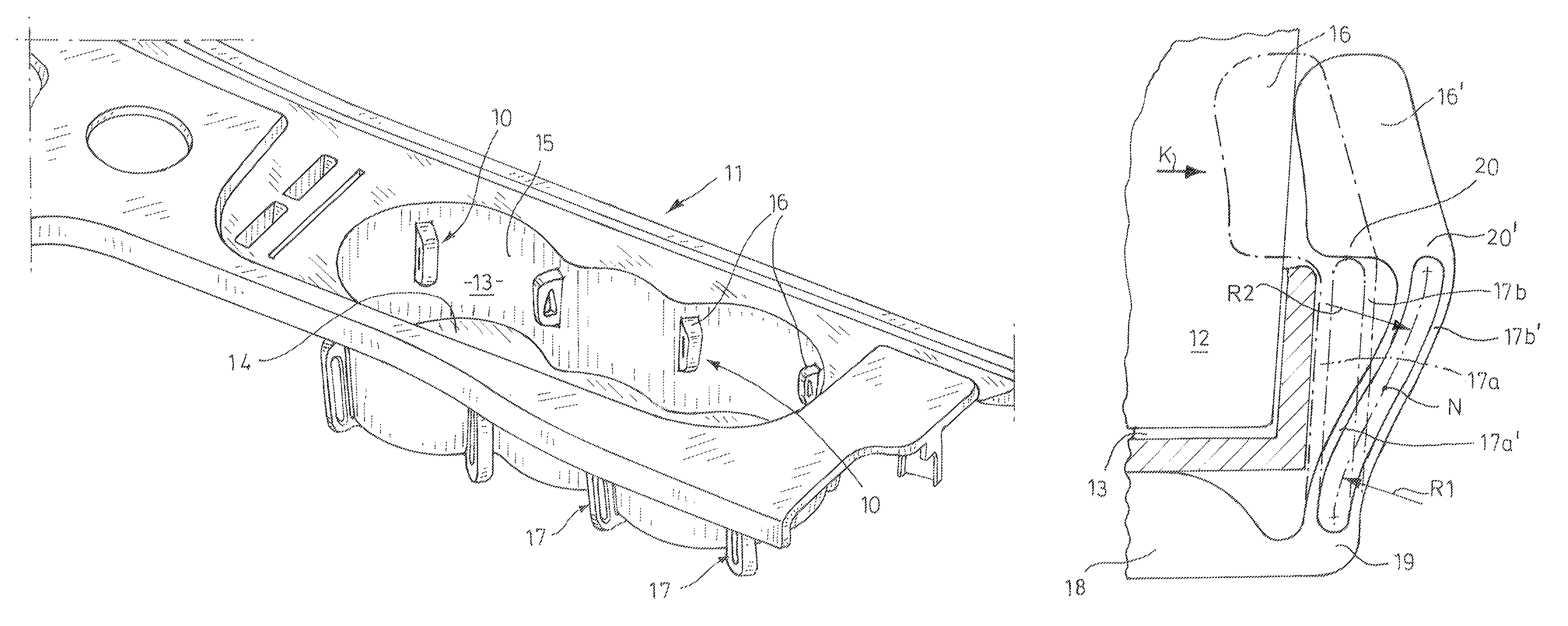

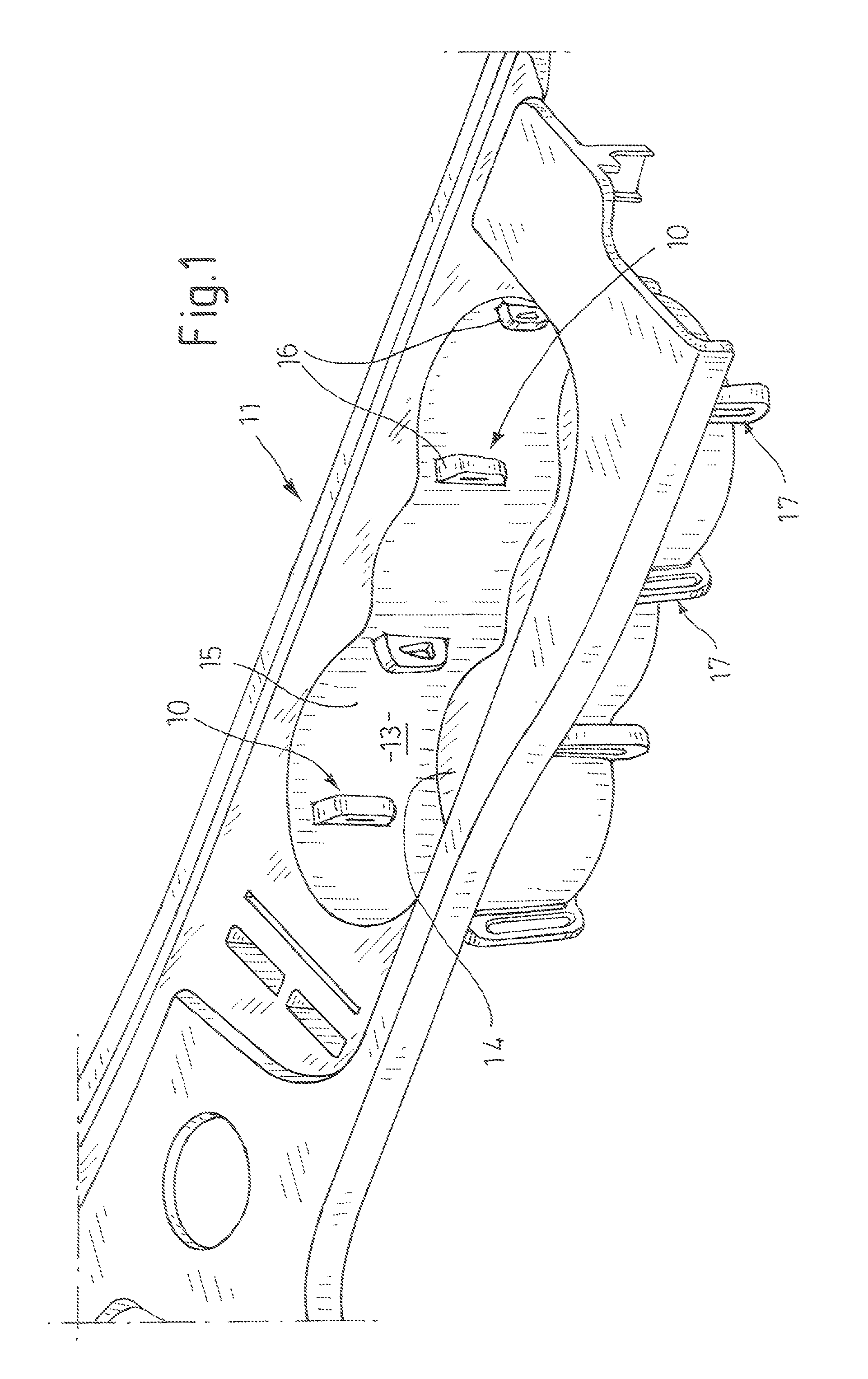

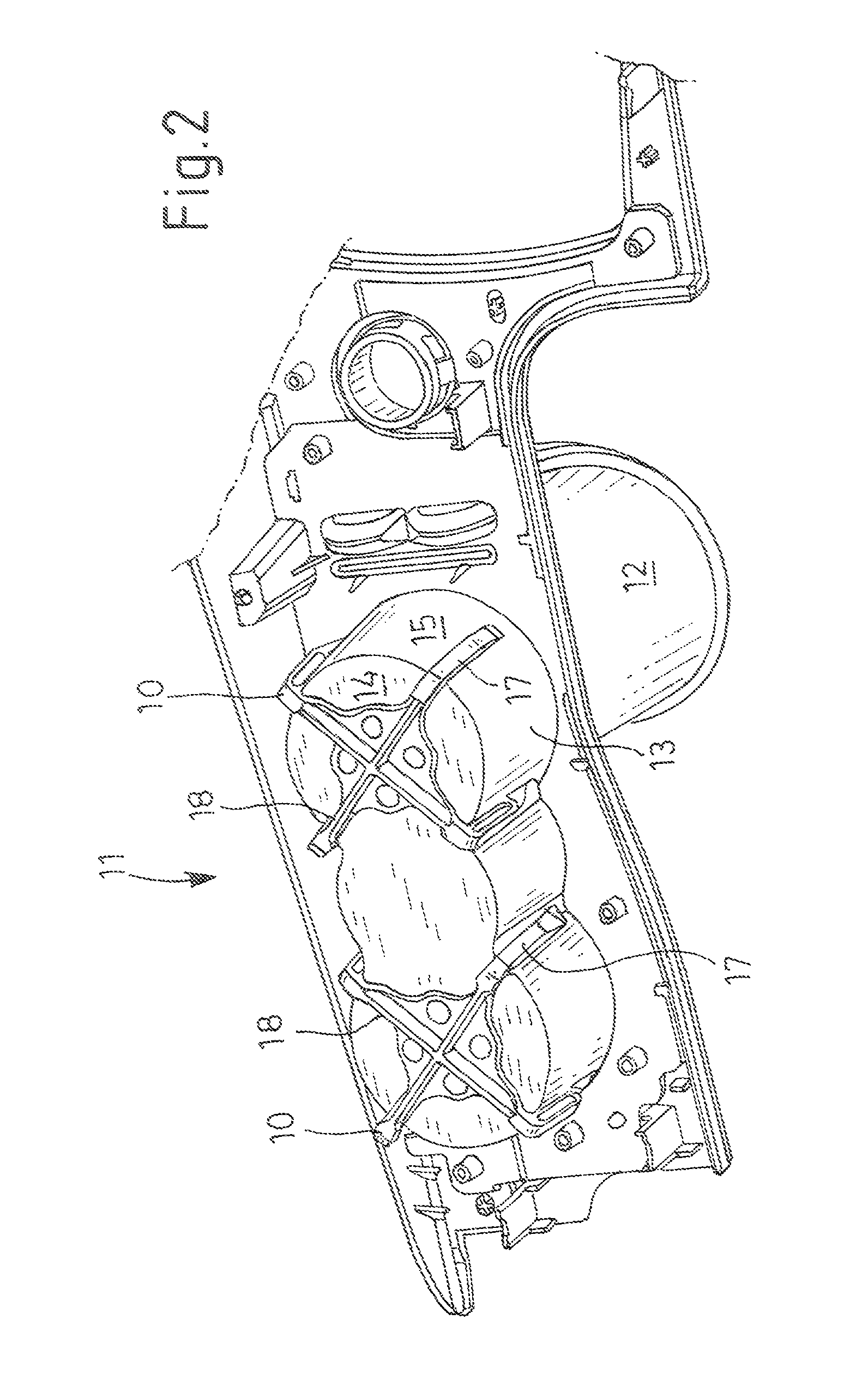

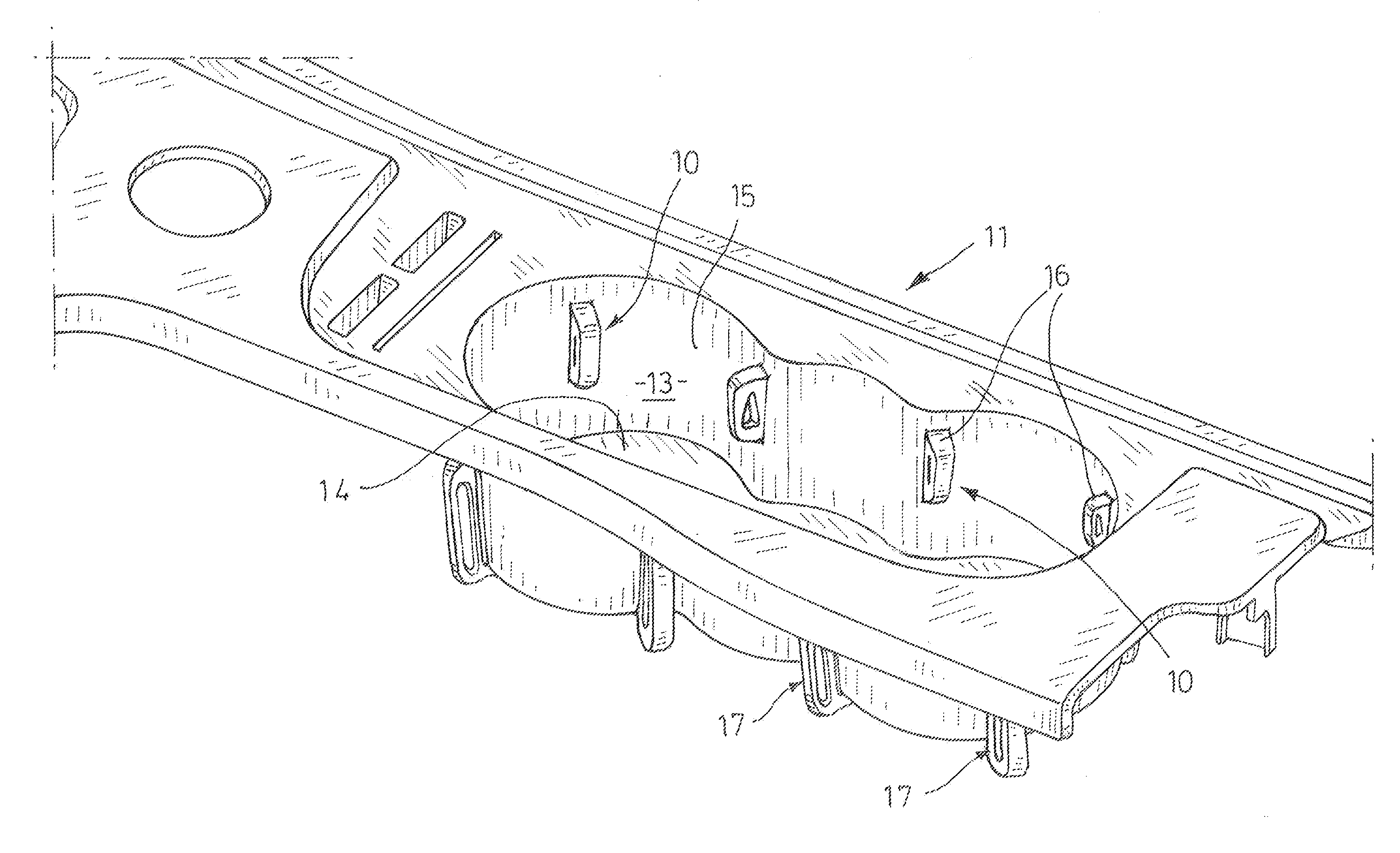

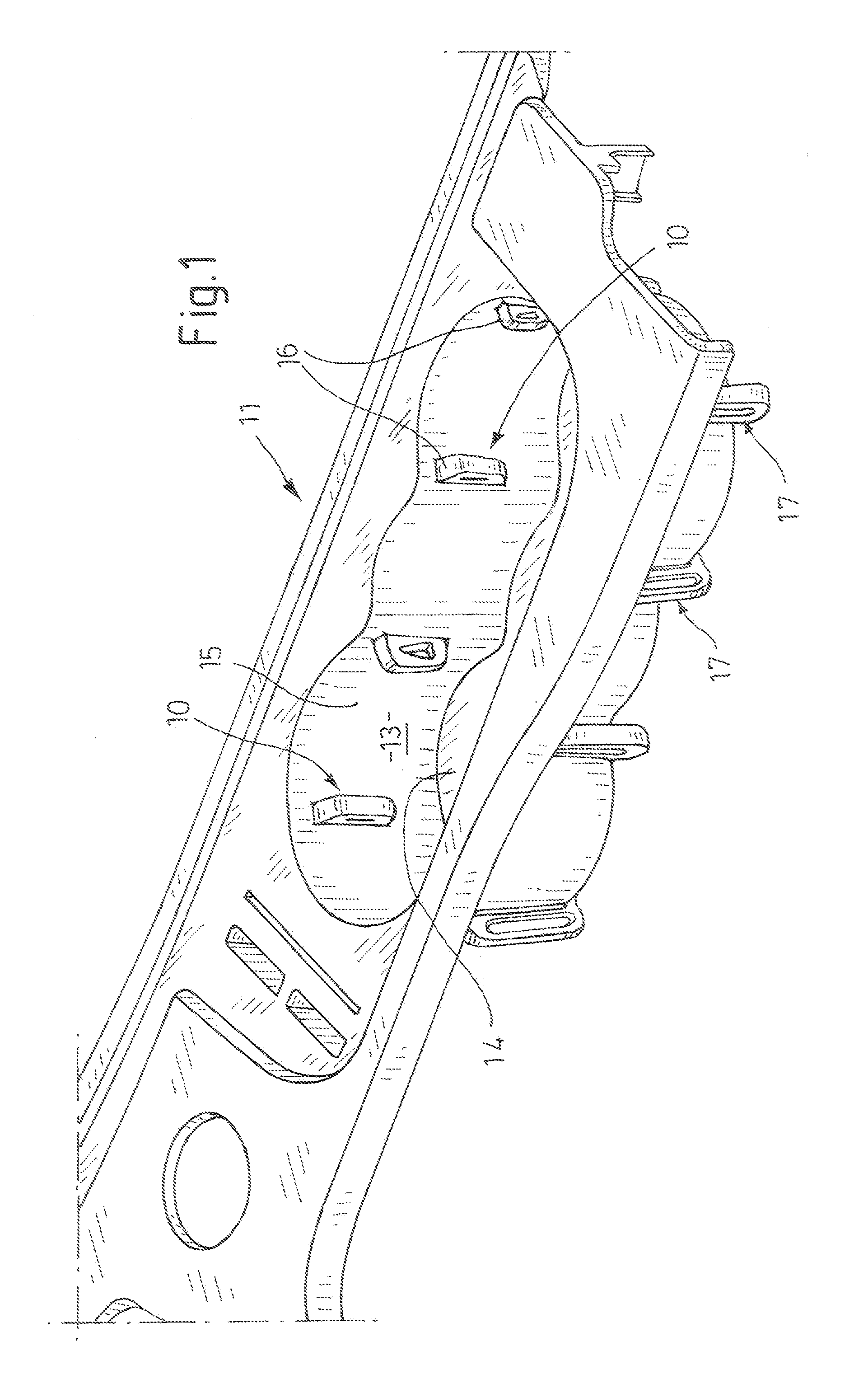

One-piece plastic clamping device for holder for beverage containers

InactiveUS8733724B2Improve clamping devicesSolve the blockageVehicle arrangementsPicture framesMobile vehicleEngineering

Owner:FORD GLOBAL TECH LLC

Control system for continuously variable transmission of vehicle

InactiveUS7189184B2Expand the clamping rangeAvoid changeOperating modesGearingControl systemEngineering

The control system comprises: an operating state changing mechanism for an operating state of the prime mover in response to a satisfaction of learning execution condition of the clamping pressure; a torque change suppressing mechanism for suppressing a change in a torque resulting from the change in the operating state of the prime mover; and a clamping pressure learning device for learning the clamping pressure in the operating state of the prime mover after the change, while the operating state of the prime mover is being changed and the change in the torque resulting from the change in the operating state of the prime mover is being suppressed by the torque change suppressing mechanism.

Owner:TOYOTA JIDOSHA KK

One-piece plastic clamping device for holder for beverage containers

InactiveUS20120153113A1Increase heightSolve the blockageVehicle arrangementsPicture framesEngineeringMechanical engineering

Owner:FORD GLOBAL TECH LLC

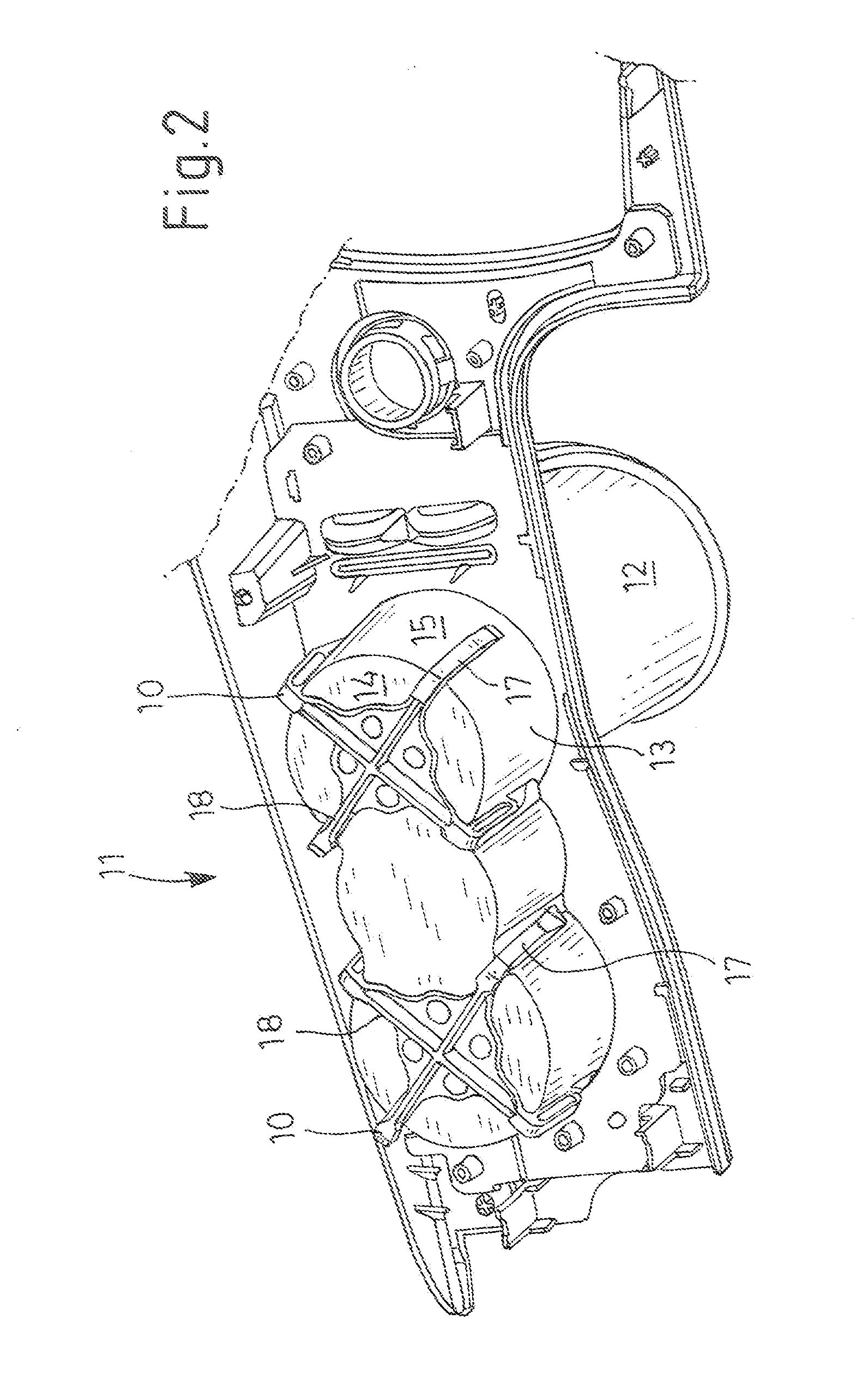

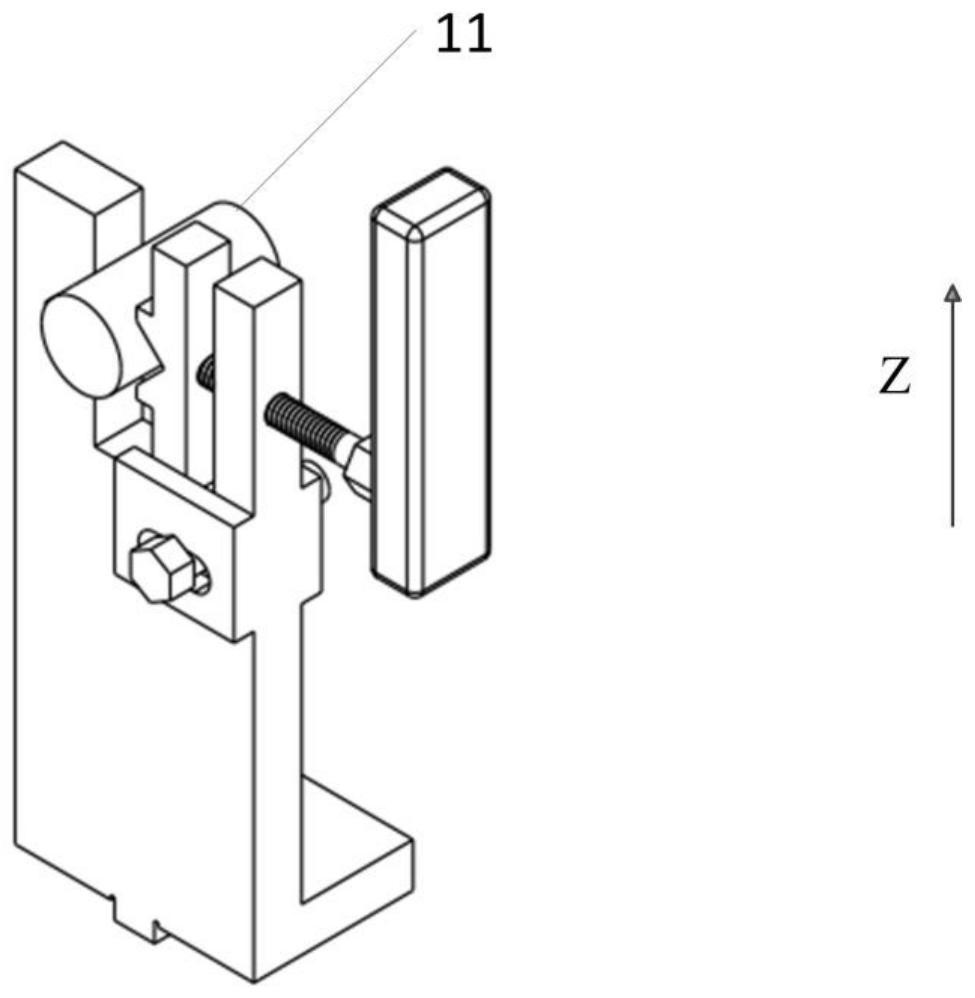

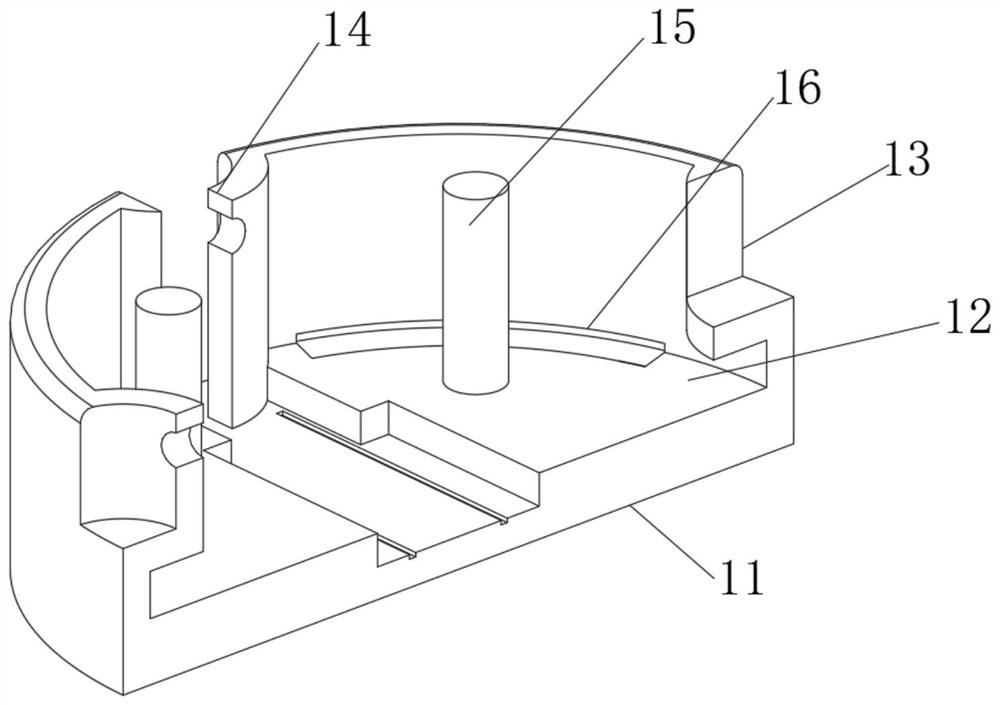

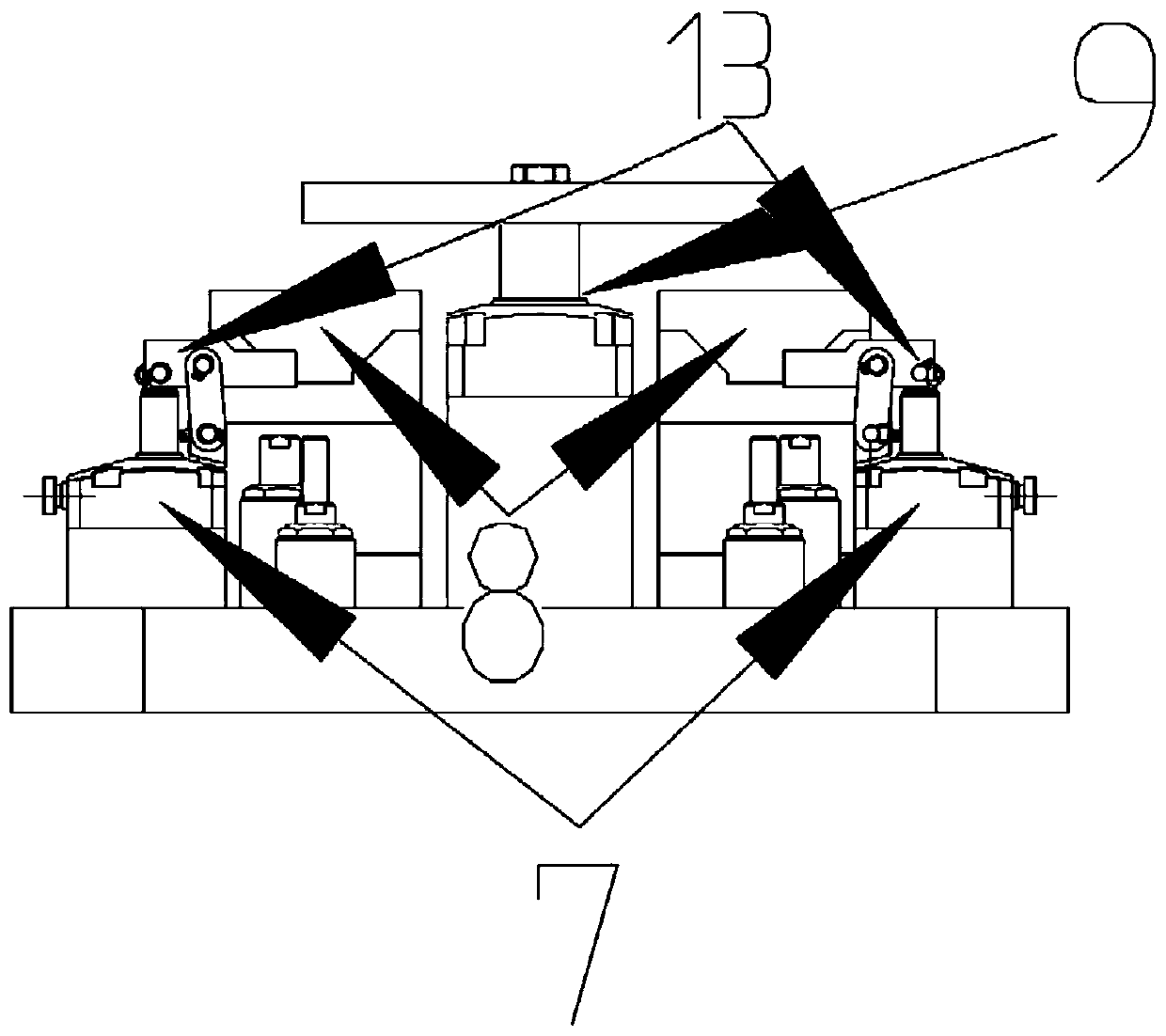

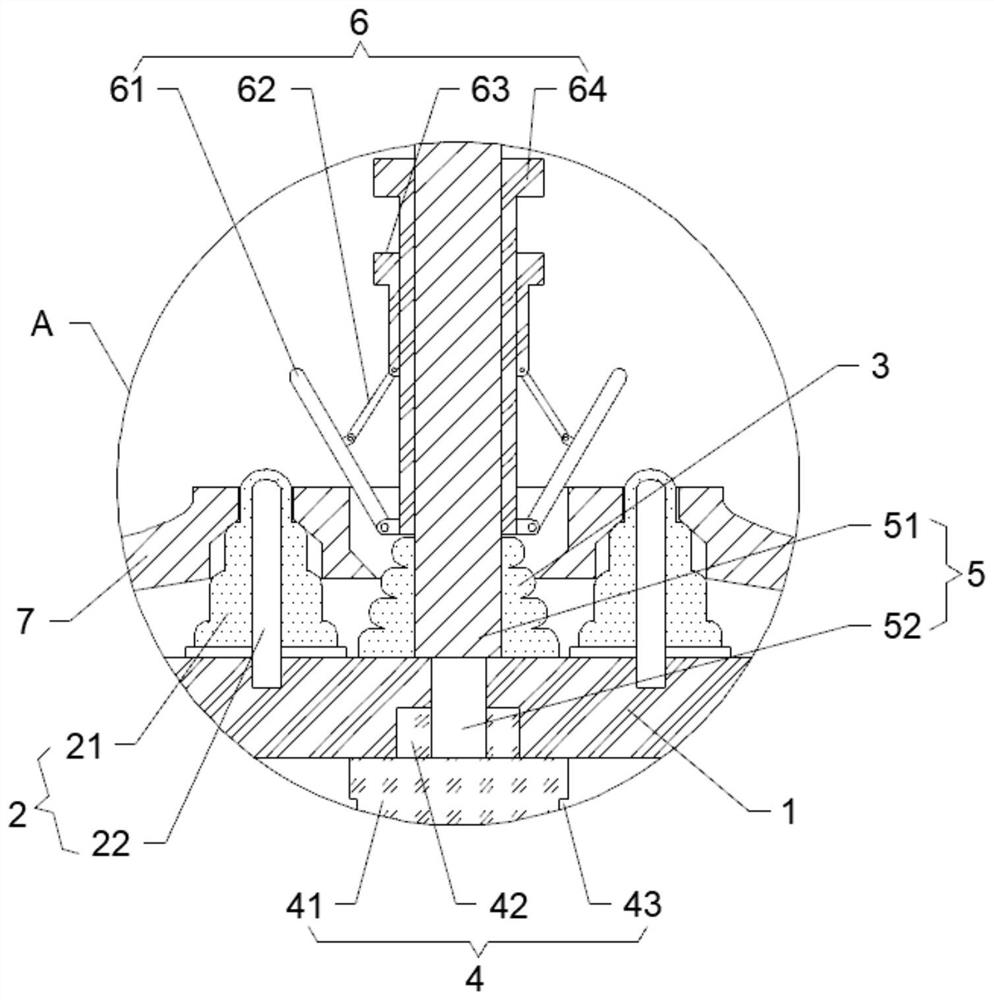

Fixing device for machining end covers of motorcycle engines

InactiveCN107378556AEffective and stable clampingEasy to adjust at multiple anglesPositioning apparatusMetal-working holdersEngineeringCounterbore

The invention discloses a fixing device for motorcycle engine end cover processing, which comprises a base. The inside is provided with a thread groove, and the thread groove is screwed and connected with the external thread on the surface of the fixing seat. The upper surface of the gland is provided with a through hole, and the through hole communicates with the thread groove. The inside of the fixing seat is provided with A counterbore, the counterbore is arranged vertically, and a column is arranged inside the counterbore, and the column vertically extends through the through hole to the outside of the gland. The present invention adopts two oppositely arranged clamping mechanisms, and adopts the up-and-down expansion and contraction of the column and the horizontal opposite movement of the screw rod to realize the clamping of the workpiece, which can achieve effective and stable clamping of workpieces with various shapes, and is convenient for multiple angles of the workpiece The adjustment improves the workpiece clamping range and effectively improves the processing efficiency.

Owner:湖州精特新材料有限公司

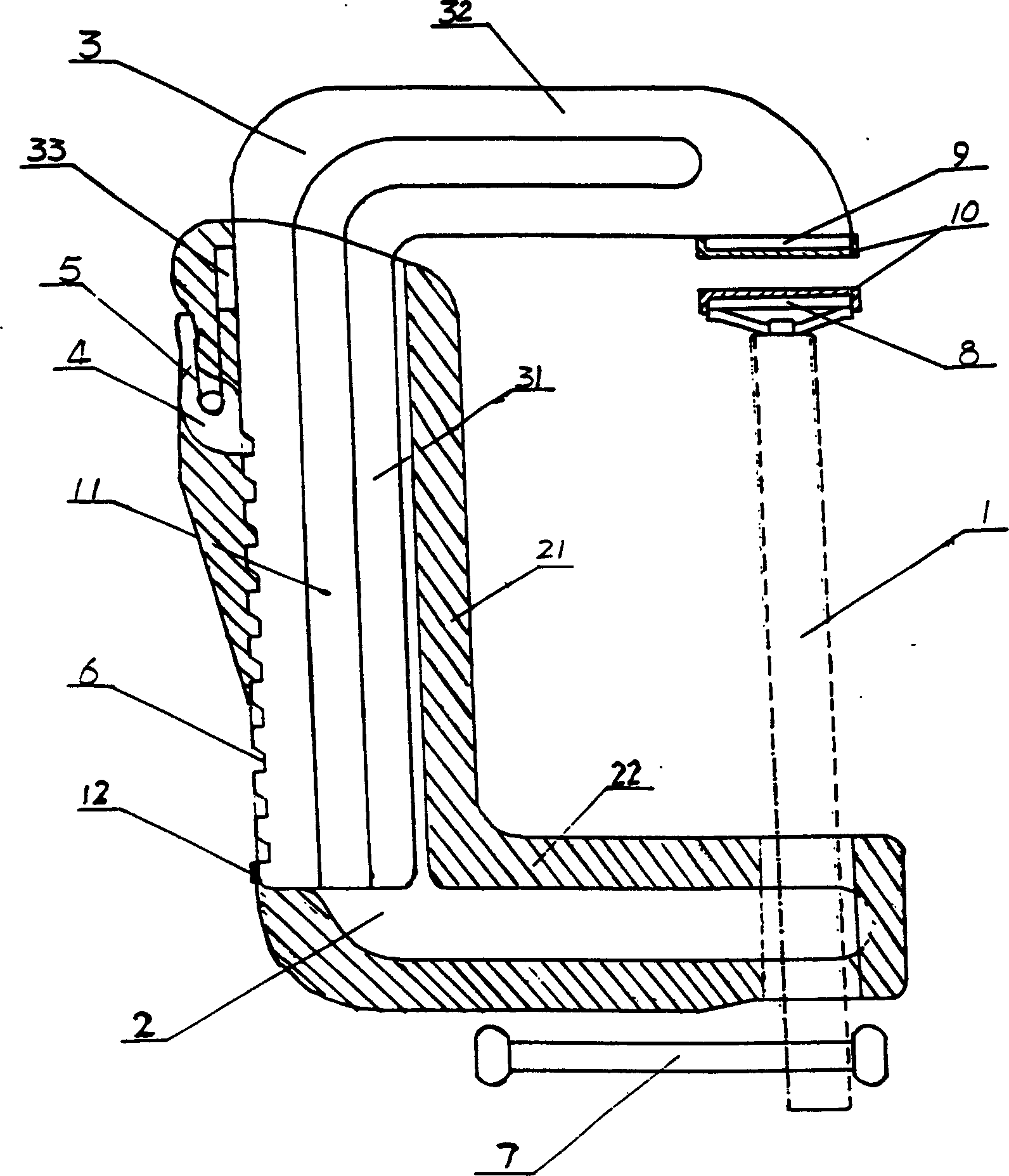

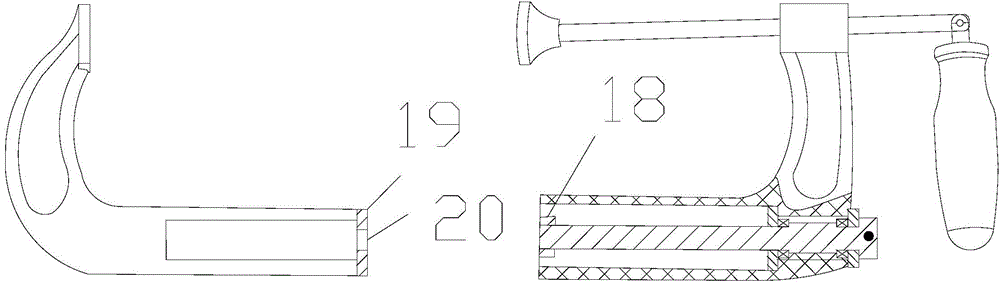

Adjustable G shaped clip

This invention relates to a clamping device, especially a G clip for fixing object to weld and process, which comprises body composed by outer frame comprising frame column and bar attached with lead screw thread, and extension body attached with outer frame column; wherein, the outer frame column is semi-enclosed structure with opening on its outer side, and opening is equipped with ratchet, and the extension body is equipped with teeth meshing the ratchet, lead screw's one end is mounted with rotary bar, the other end with top tablet, and extension body bar is also equipped with top tablet. The invention has the advantages of simple structure, convenient usage, extending its clamping range via adjusting the clip to improve the practicability.

Owner:钱小强

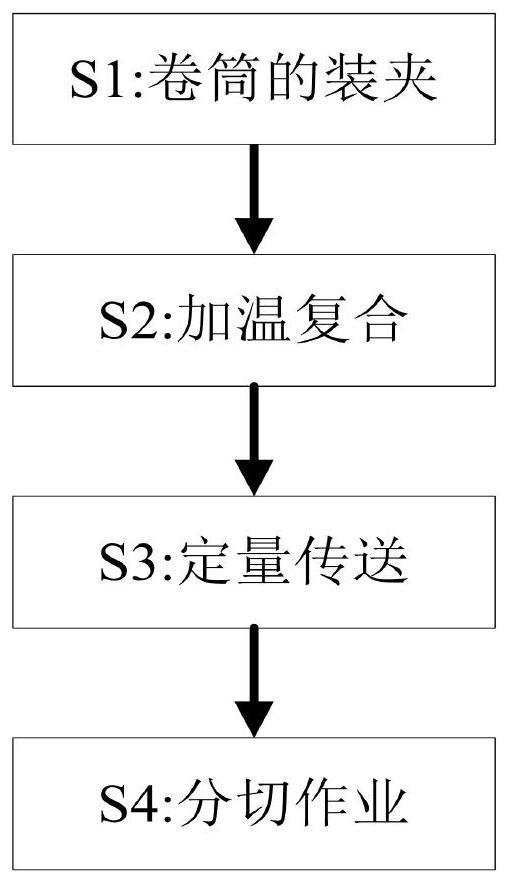

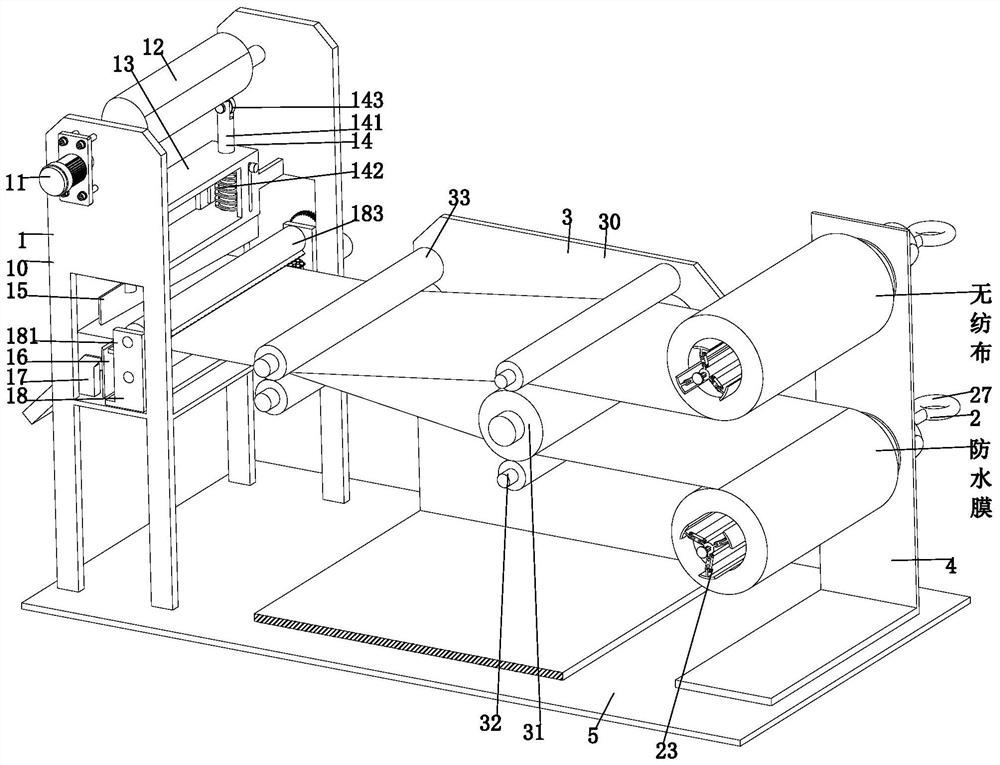

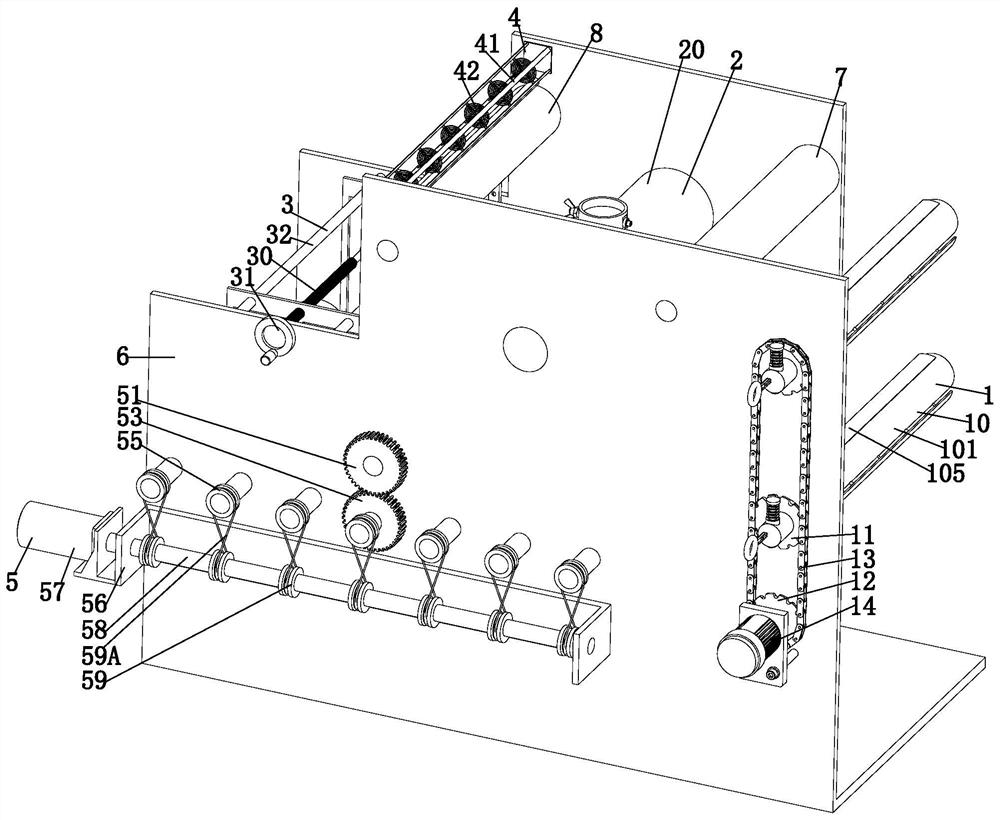

Waterproof non-woven fabric bag producing and processing method

InactiveCN113059861AReduce cutting burrsReduce resistanceBag making operationsPaper-makingNonwoven fabricMechanical engineering

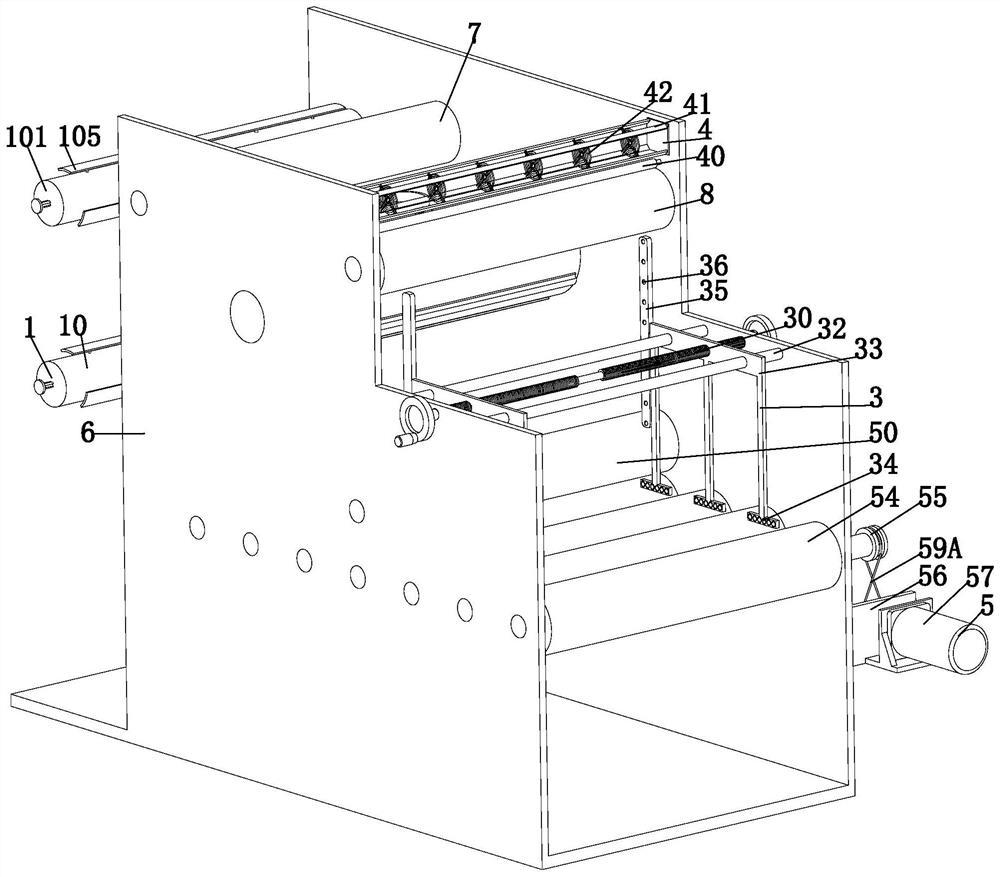

The invention provides a waterproof non-woven fabric bag producing and processing method. The waterproof non-woven fabric bag producing and processing method comprises a slitting mechanism, a clamping mechanism, a rolling and conveying mechanism, an L-shaped vertical plate frame and a bottom plate, wherein the rolling and conveying mechanism is mounted on the bottom plate; the slitting mechanism is arranged on the left side of the rolling and conveying mechanism, and installed on the bottom plate; the L-shaped vertical plate frame is installed on the end face of the bottom plate; the L-shaped vertical plate frame is located on the right side of the rolling and conveying mechanism; and clamping mechanisms are installed on the L-shaped vertical plate frame in a longitudinally-symmetrical mode through bearings. According to the waterproof non-woven fabric bag producing and processing method, the problems that the manufacturing requirements of waterproof non-woven fabric bags of different sizes cannot be met in existing manufacturing of waterproof non-woven bag production raw materials since non-woven fabric winding drums and waterproof film winding drums of different models and sizes cannot be clamped, the required size for slitting and manufacturing waterproof non-woven fabric bags cannot be met since the non-woven fabrics are prone to slip and rotate to cause errors during quantitative conveying of the non-woven fabrics, and the manufacturing requirements of the waterproof non-woven fabric bags cannot be met since a plurality of burrs are formed in the notches of the non-woven fabrics and the like are solved.

Owner:义乌市云翰纺织科技有限公司

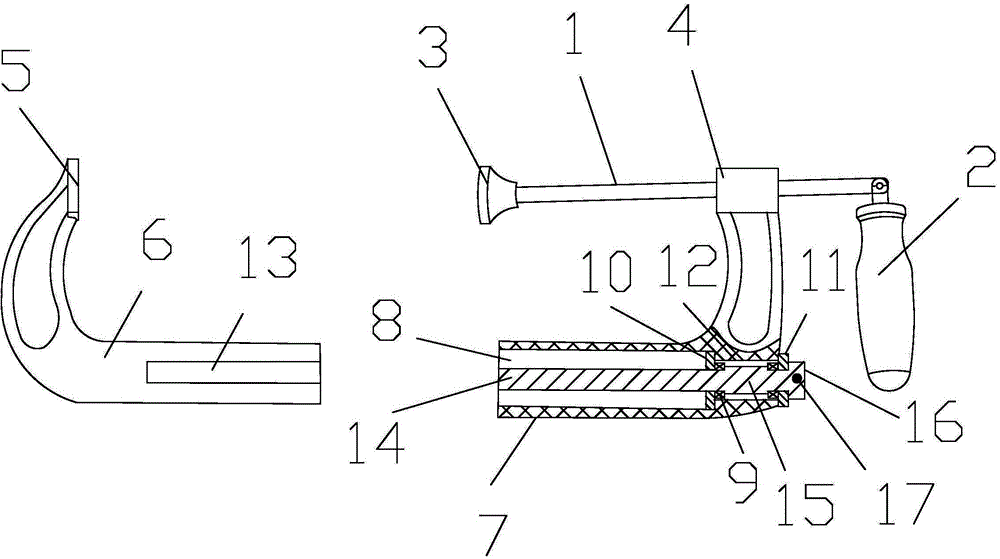

Telescopic G-shaped clamp

The invention relates to a telescopic G-shaped clamp which comprises a G-shaped clamp body, a screw rod, a handle and a moving head. The clamping body is provided with a clamping end and a mounting end. The mounting end is provided with a thread hole. The screw rod is in thread connection with the thread hole. The handle and the moving head are arranged at the two ends of the screw rod respectively. The moving head is arranged right opposite to the clamping end. The clamping body comprises a moving clamp and a fixed clamp. The moving clamp and the fixed clamp both comprise horizontal sections and vertical sections. The vertical section of the moving clamp is provided with a groove hole in which the vertical section of the fixed clamp can be contained. The vertical section of the fixed clamp is movably arranged in the groove hole of the vertical section of the moving clamp in a sleeved mode. The vertical section of the moving clamp and the vertical section of the fixed clamp are connected though a connecting mechanism. According to the scheme, the fixed clamp and the moving clamp are arranged, telescopic adjusting of the clamp body is achieved, and the clamping range of the G-shaped clamp is increased.

Owner:CHANGZHOU HOUXIAO YUHENG CURTAIN WALL

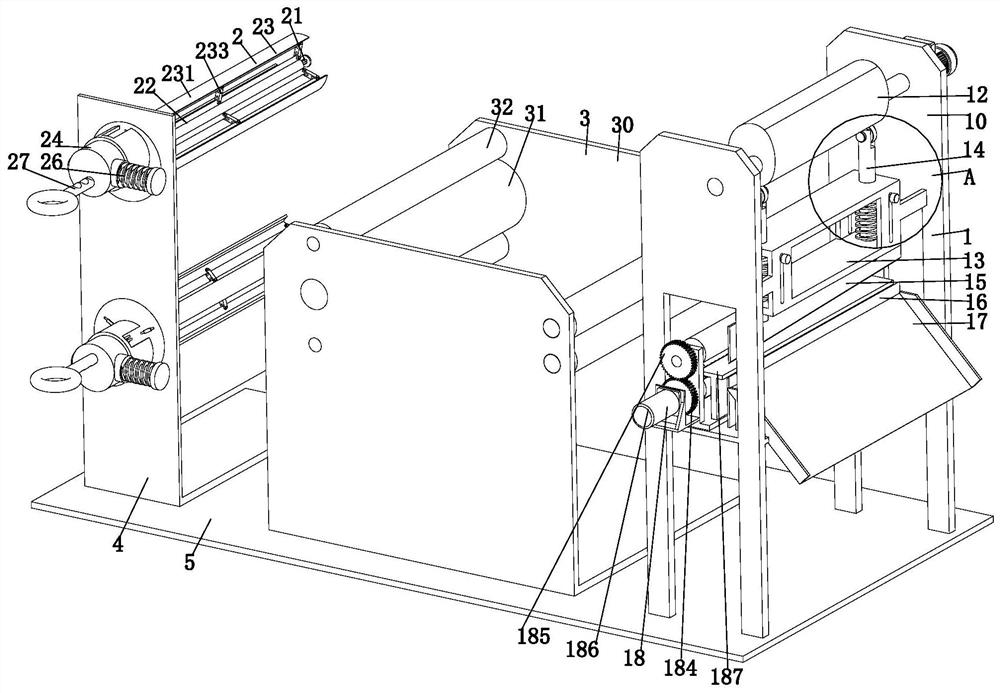

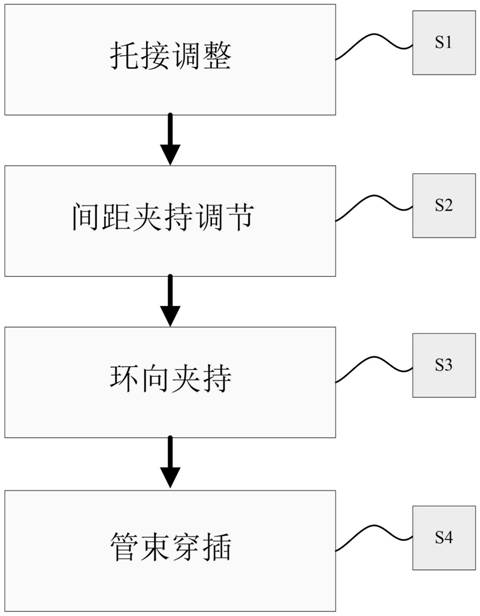

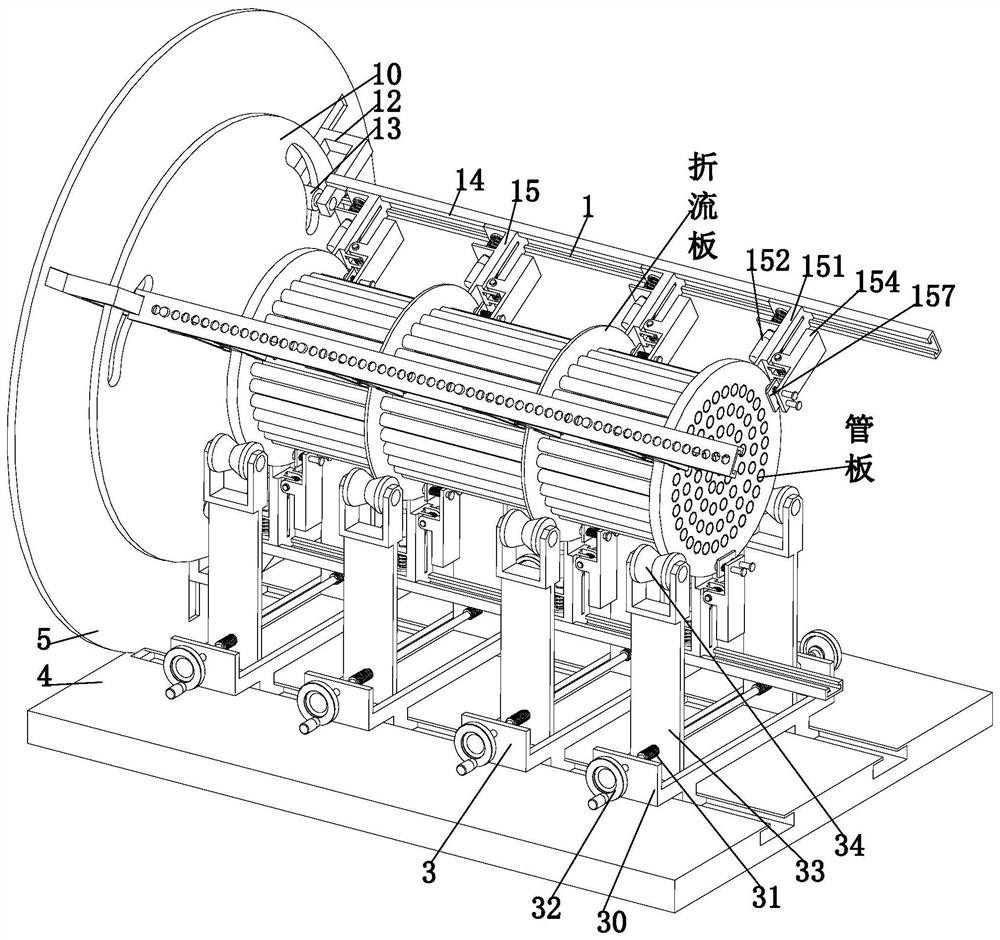

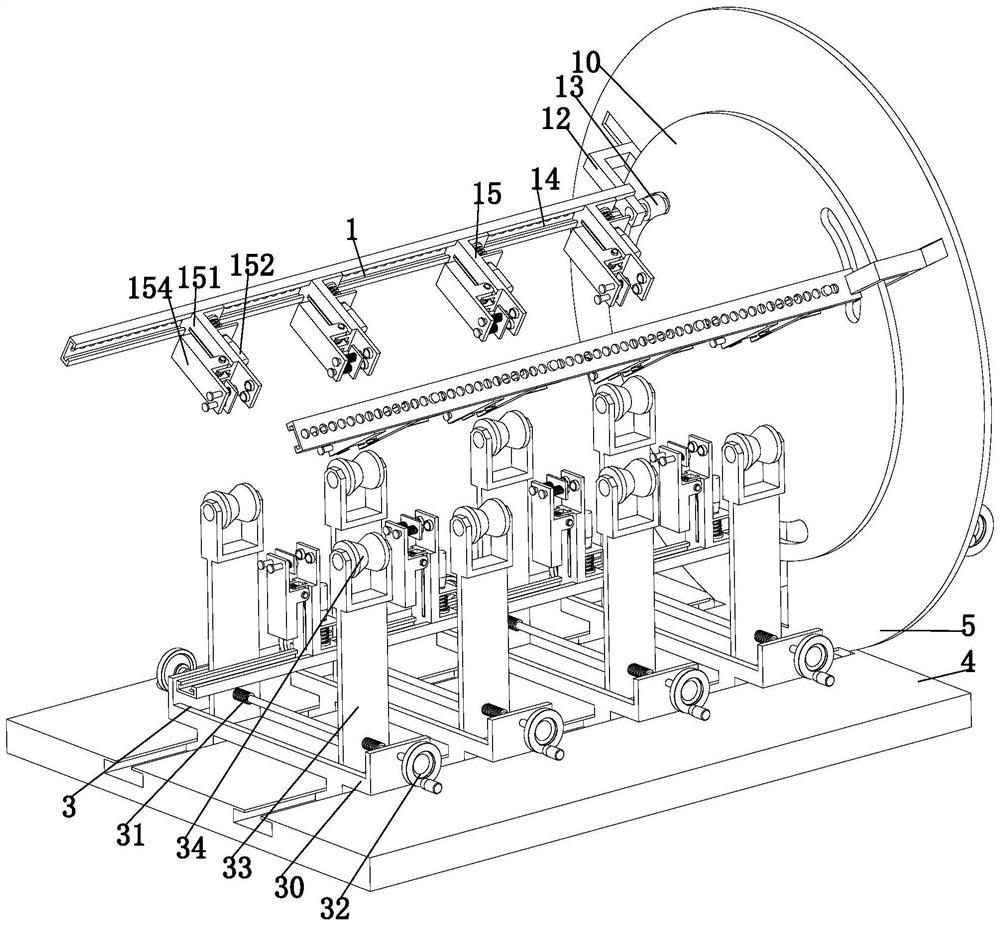

Shell-and-tube heat exchanger manufacturing and machining method

InactiveCN113146198AExpand the clamping rangeSatisfy the requirement of hoop clampingPositioning apparatusMetal working apparatusEngineeringManual handling

The invention provides a shell-and-tube heat exchanger manufacturing and machining method which involves a clamping mechanism, a regulation and control mechanism, bottom support mechanisms, a bottom plate and a ring stand vertical plate. The method solves the problems that when a heat transfer tube bundle is installed at present, tube plates at the two ends are clamped and fixed through clamps, then the spacing position of baffle plates is moved and fixed, and finally, the heat transfer tube bundle is inserted into the tube plates and the baffle plates; in the mode, manual operation is tedious, flexible and adjustable fixing clamps are not arranged to assist in the insertion process of the heat transfer tube bundle, the efficiency of the whole operation process is reduced, and large-scale production operation cannot be achieved; and the clamps can only clamp and fix the tube plates and the baffle plates with specified sizes, flexible adjustment cannot be achieved, and market requirements cannot be met.

Owner:韩洵

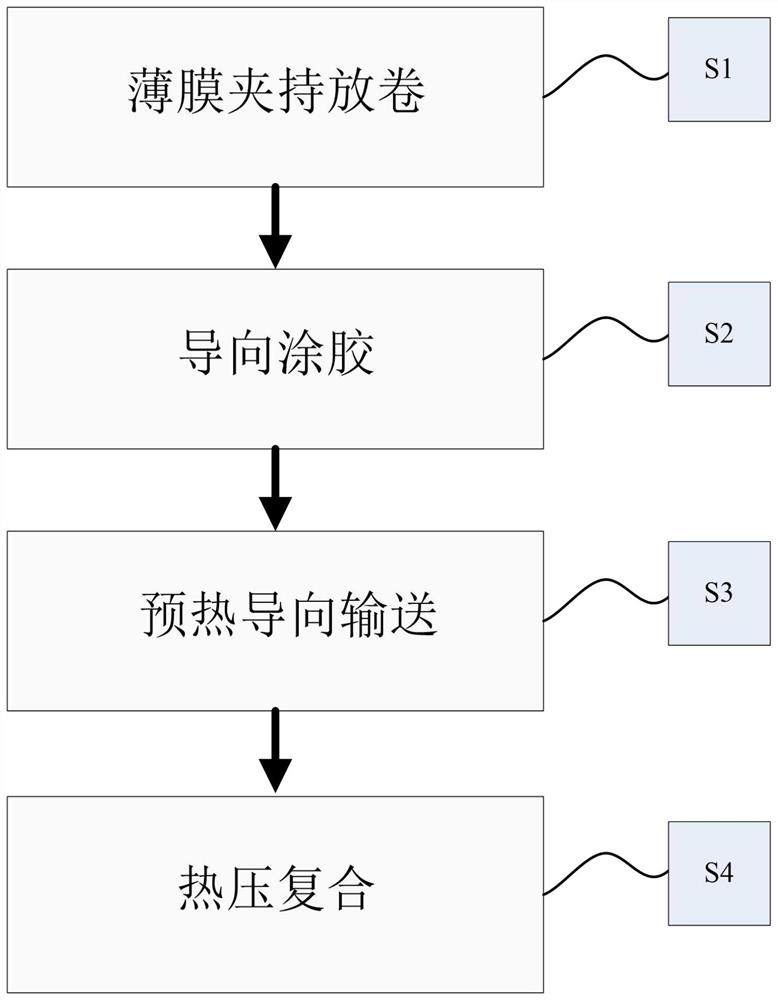

Film coating process for manufacturing packaging container

InactiveCN113500820ATension remains constantPrevent unbalanced transmission forcePaper-makingBox making operationsAdhesiveMechanical engineering

The invention provides a film coating process for manufacturing a packaging container. The film coating process comprises a winding mechanism, a coating mechanism, a guide mechanism, a drying mechanism, a conveying mechanism, a main beam plate frame, a guide roller I and a guide roller II. The film coating process solves the problems that clamping and fixing of an unwinding winding drum and a winding drum have limitation at present, and winding drums with different types and sizes cannot be clamped, so that the manufacturing of the film coating process is relatively single, and production and processing of film coating processes with different sizes cannot be realized; in the winding and unwinding processes, the execution actions cannot be synchronized, the tension in the film coating process is influenced to be constant, the film transmission stress is unbalanced, and the film is wrinkled or torn; no guide motion track exists for the transmission of paper printed matters and films, the deviation condition is easily caused after the films and the paper printed matters are compounded, and the film coating quality is influenced; and the coating of an adhesive on the surfaces of the films cannot be uniformly controlled, the coating flow speed of the adhesive cannot be controlled, and the film coating process is influenced.

Owner:武汉众诚科技有限公司

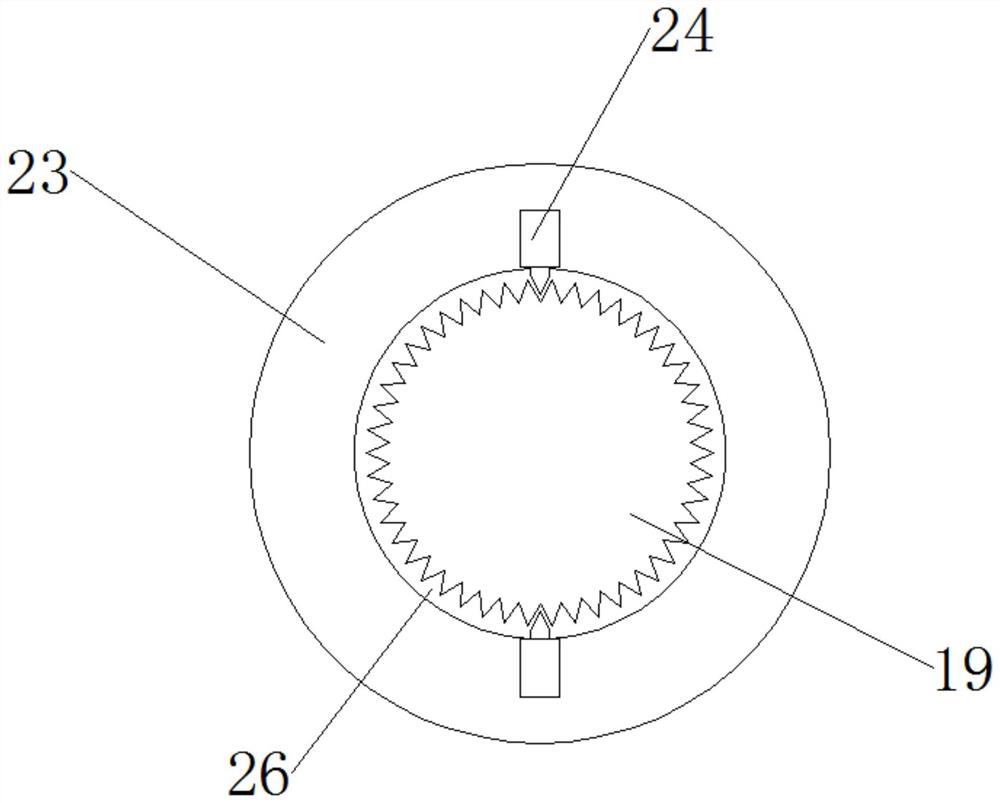

Section polishing equipment for hot-dip galvanized steel strand machining

PendingCN114523352ATo achieve the effect of fixed angleEasy to adjustGrinding carriagesGrinding drivesElectric machineLap joint

The section polishing equipment for hot-dip galvanized steel strand machining comprises an equipment whole, a supporting seat and a connecting frame, a connecting plate is fixedly connected to the top of the equipment whole, supporting rods are fixedly connected to the two sides of the bottom end of the connecting plate, a lifting column is fixedly connected to the middle of the connecting plate, and the connecting frame is fixedly connected to the bottom end of the lifting column; a second motor is connected to the middle of the bottom of the connecting frame in a lap joint mode, side columns are fixedly connected to the two sides of the second motor, rotating teeth are movably connected to the middles of the side columns, and a plurality of triangular grooves are formed in the periphery of the rotating teeth, so that the electric push columns can be embedded into the adjacent grooves when stretching out; when the motor II rotates, the motor II cannot rotate due to the fact that the rotating teeth on the side column are clamped by the electric push column, so that the angle fixing effect is achieved, correspondingly, a user can conveniently adjust the rotating angle of the motor II according to the actual situation, and a grinding wheel at the position of the motor II can grind the sections of the hot-dip galvanized steel strands cut at different angles.

Owner:锦锐乾源通信设备科技有限公司

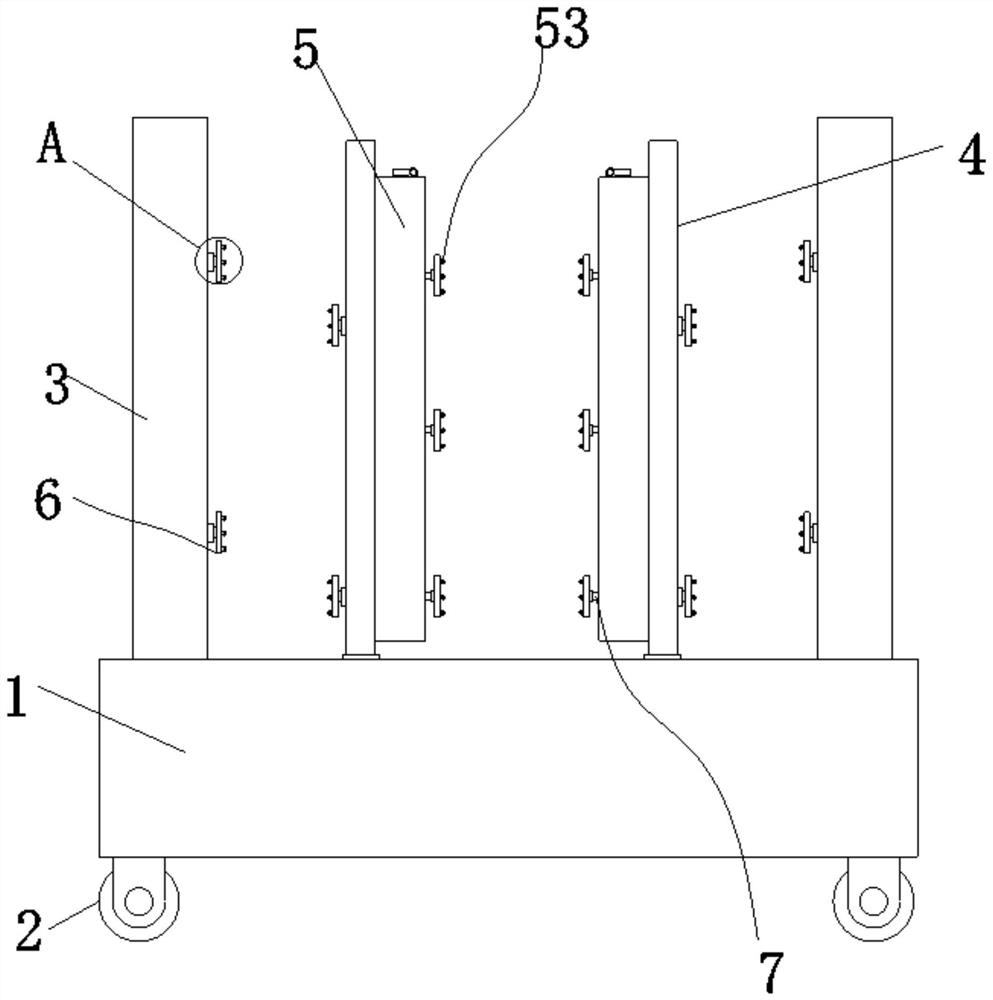

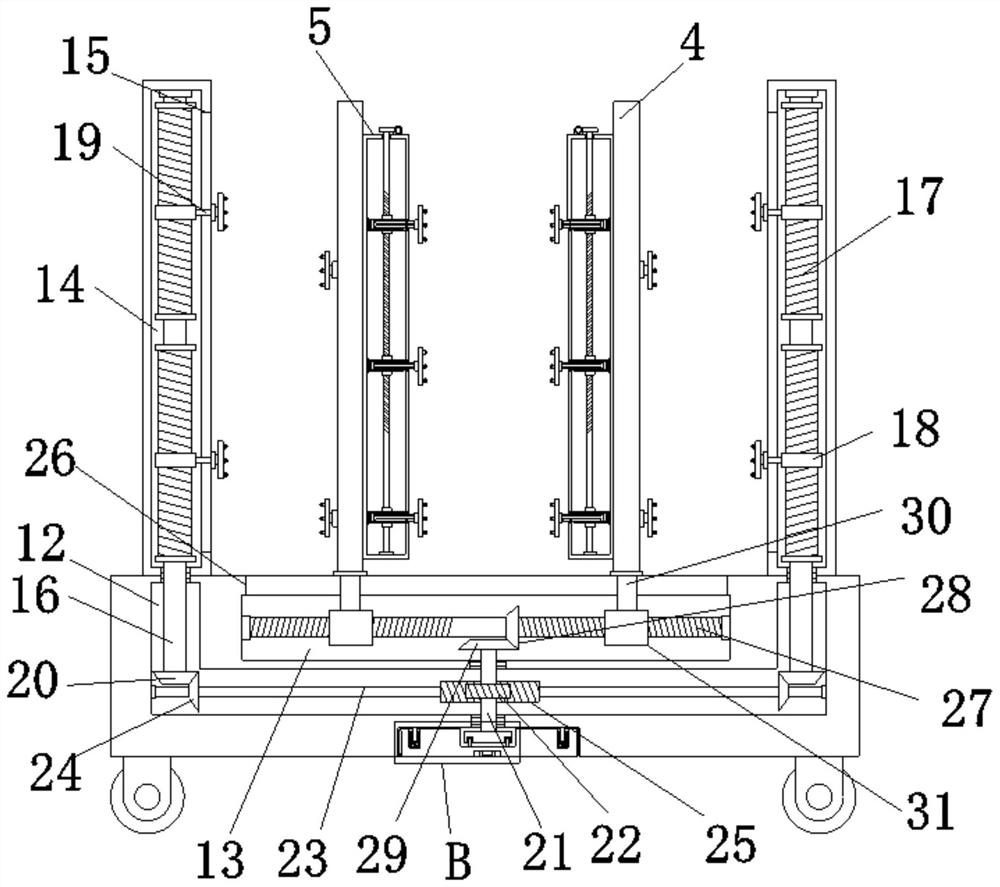

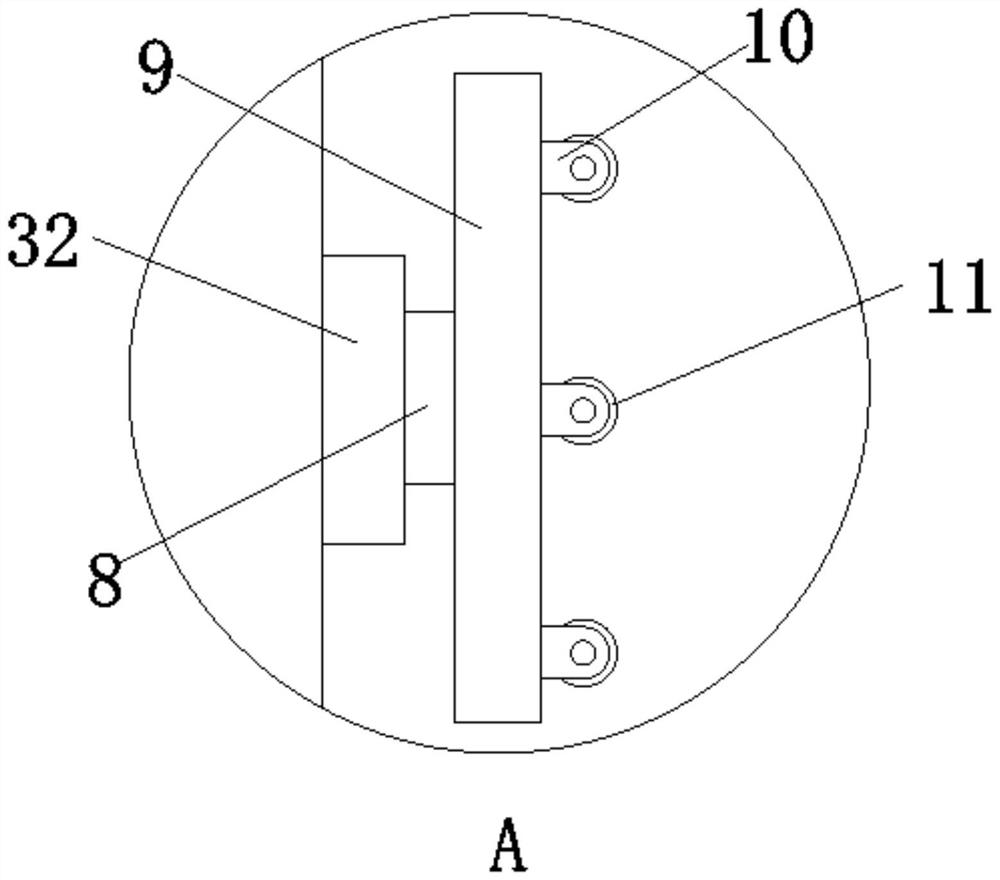

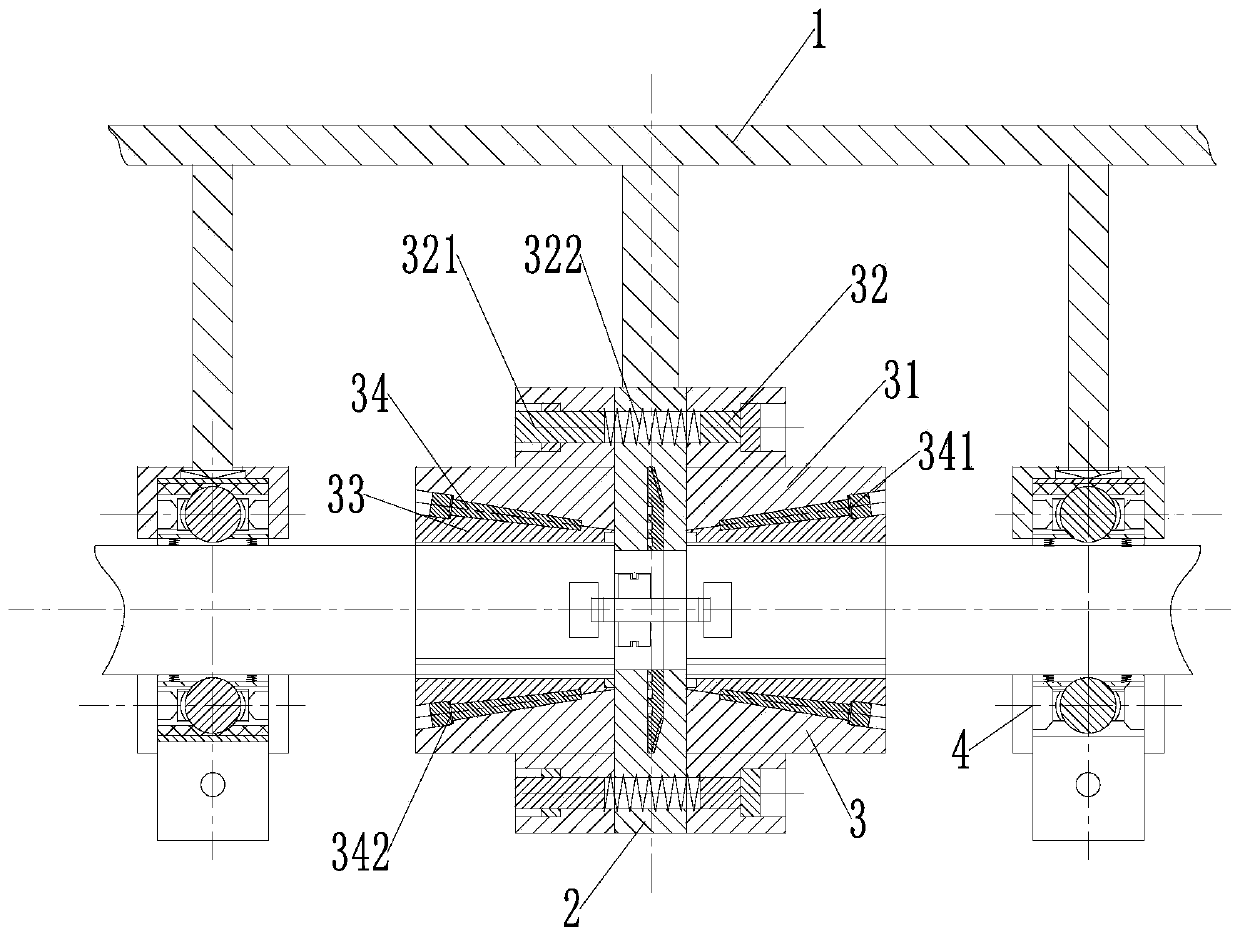

Novel insulator curing equipment

PendingCN114141457AEasy to cure simultaneouslyImprove curing qualityInsulatorsStructural engineeringMechanical engineering

The invention relates to the technical field of insulator processing, and discloses novel insulator curing equipment, which solves the problems that an insulator inner core can only be singly cured during curing and an insulator is unstable to place to cause deformation, the novel insulator curing equipment comprises a base, moving wheels are symmetrically arranged at the bottom end of the base, and the moving wheels are arranged at the bottom end of the base. Supporting plates are symmetrically arranged on the two sides of the top end of the base, movable plates located between the two supporting plates are symmetrically arranged at the top end of the base, the two movable plates are connected through a distance adjusting mechanism, and fixed plates are arranged on the sides, close to each other, of the two movable plates. By arranging the base, the moving wheels, the supporting plate, the movable plate, the fixed plate, the first clamping piece and the second clamping piece, the first clamping piece on the supporting plate and the first clamping piece on the movable plate and the opposite second clamping piece can clamp an insulator inner core conveniently, then the fixing stability of the insulator inner core is improved, deformation of the insulator inner core during curing is avoided, and the service life of the insulator inner core is prolonged. And the curing quality of the insulator is further improved.

Owner:江西正强电瓷电器有限公司

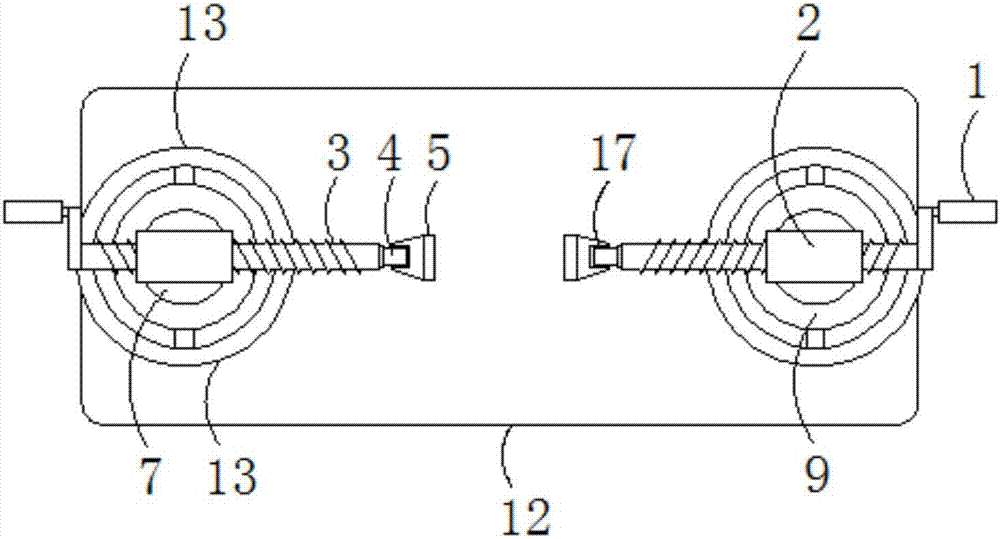

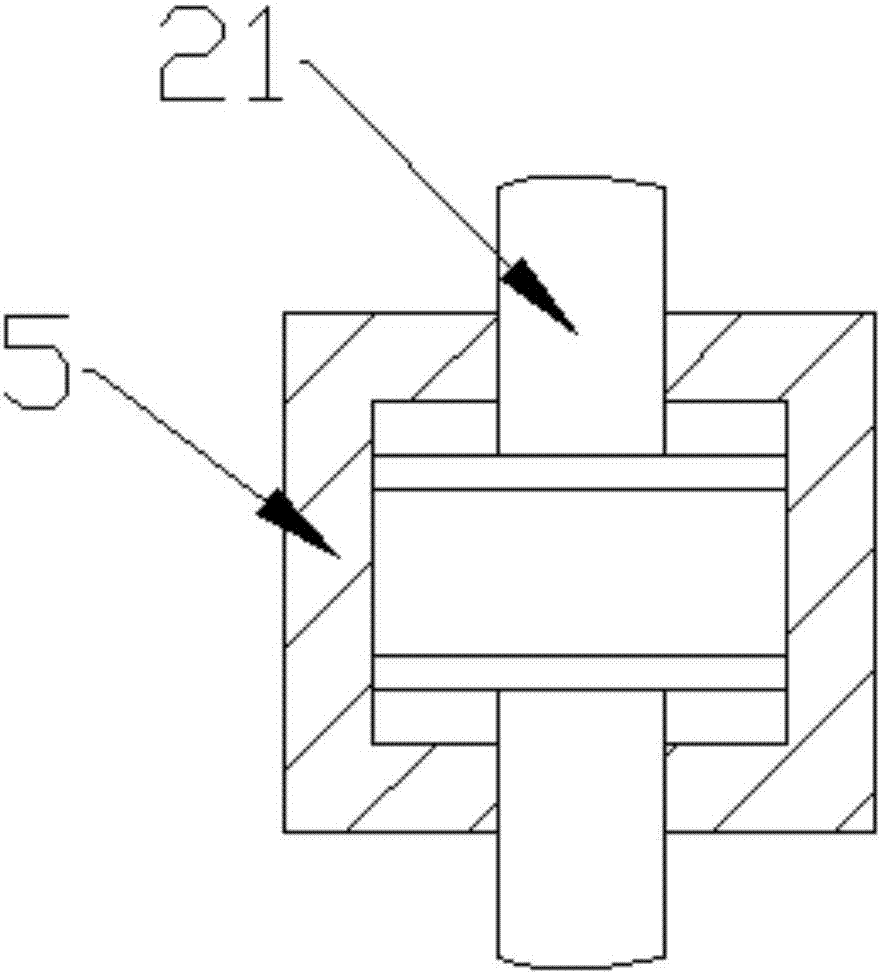

Portable coupling

The invention relates to a portable coupling. The portable coupling comprises a bracket, a fixed shaft mechanism, a shaft coupling mechanism and bearing mechanisms, wherein the fixed shaft mechanism is installed at the rod tail end of the middle of the bracket; the left side and the right side of the fixed shaft mechanism are connected with the shaft coupling mechanism through screws; the bearingmechanisms are installed at the rod tail ends of the left side and the right side of the bracket; the fixed shaft mechanism comprises a fixed shaft shell, a three-jaw chuck, a fixed shaft fixing plate, a spring leaf and a large arc clamping plate; the shaft coupling mechanism comprises a coupling shell, a spring screw, a conical bushing and a conical fastening piece; and each bearing mechanism comprises an omega-shaped fastening piece, a detachable ball bearing, a rubber ring and a telescopic spring plate. A shaft is fixed through the three-jaw chuck, so that the shaft is in coaxial matching,and the stress of the shaft is more uniform; and the conical bushing is matched with the conical fastening piece for use, the coupling can fix and clamp the shaft with multiple diameters, and finally,the purpose of improving the use effect of the coupling is achieved.

Owner:WENZHOU QIFANG NEW ENERGY CO LTD

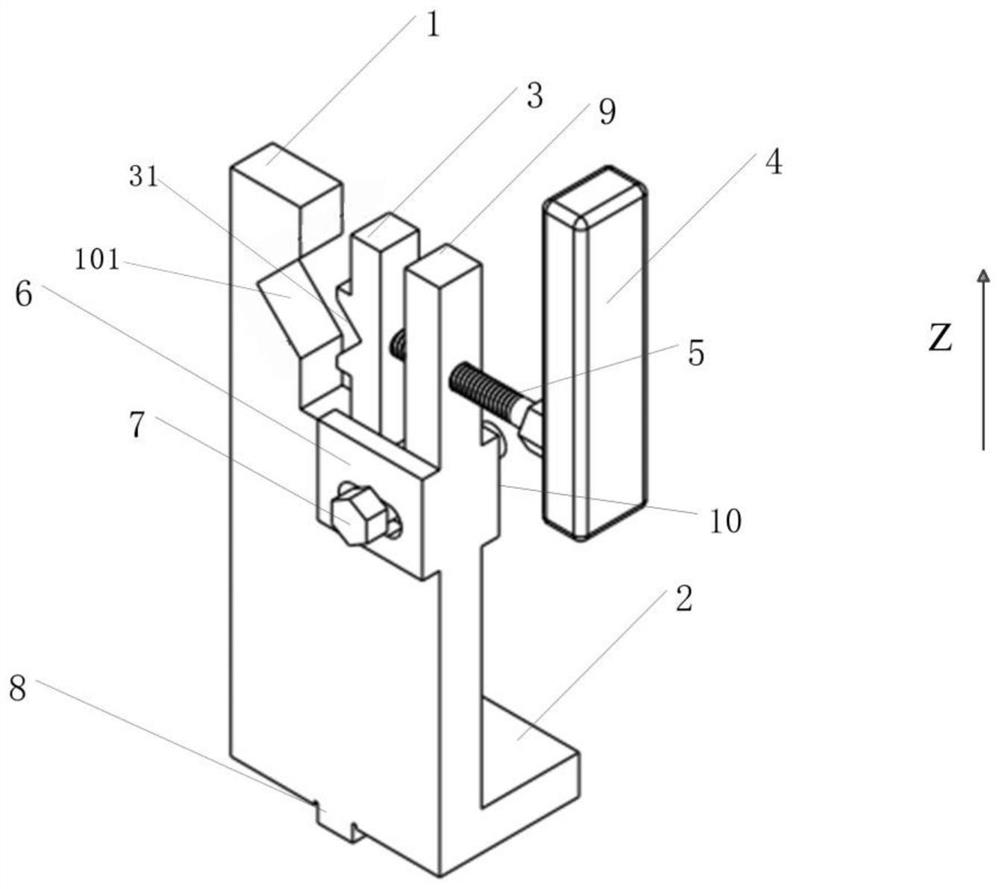

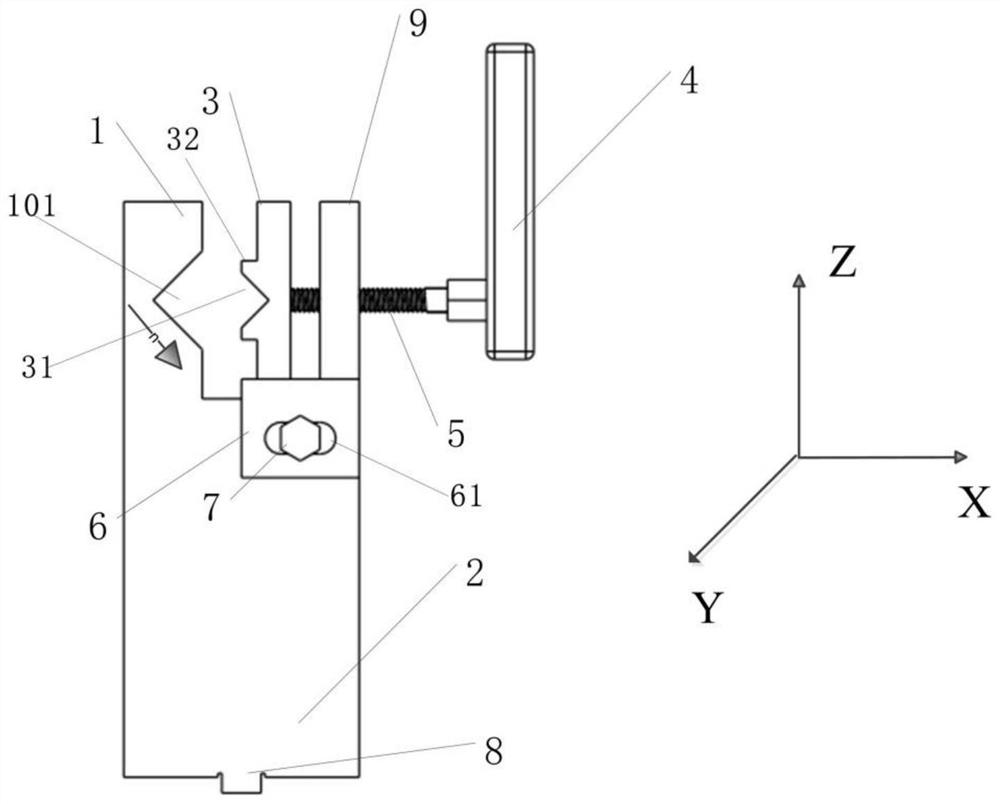

Form and position measurement flexible clamp and form and position measurement method for columnar part

PendingCN114734392AAvoid Duplicate PositioningImprove flexibilityMeasurement devicesWork holdersStructural engineeringMechanical engineering

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Special-shaped component clamping fixture

PendingCN107116380AReduce setup timeExpand the clamping rangePositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

A special-shaped component clamping fixture comprises a lower mold plate and an upper mold plate. A plurality of supporting rods are welded to the upper surface of the lower mold plate. The upper mold plate is fixed to the upper ends of the supporting rods. Supporting plates are welded to the left side and the right side of the upper mold plate. Movable connecting blocks are arranged on the upper portions of the supporting plates and movably connected in the lower surface of a second bottom plate. A plurality of chip removing grooves are formed in the upper surface of the middle of the second bottom plate. A fixed clamping block is fixed to the right sides of the chip removing grooves. A movable connecting plate is arranged on the right side of the fixed clamping block. A sliding block is installed in the movable connecting plate. Third bottom plates are connected to the right side of the sliding block. Sliding grooves are formed in the middles of the third bottom plates. Movable clamping blocks are movably connected in the sliding grooves. Movable threaded rods are installed at the right ends of the movable clamping blocks and penetrate through fixed blocks. The fixed blocks are welded to the upper surfaces of the third bottom plates. A plurality of telescopic connecting rods are welded to the back portion of the second bottom plate and connected into telescopic connecting blocks. The telescopic connecting blocks are arranged on the two sides of the movable connecting plate. The special-shaped component clamping fixture is good in clamping stability, convenient to operate and capable of relieving the labor intensity of workers.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

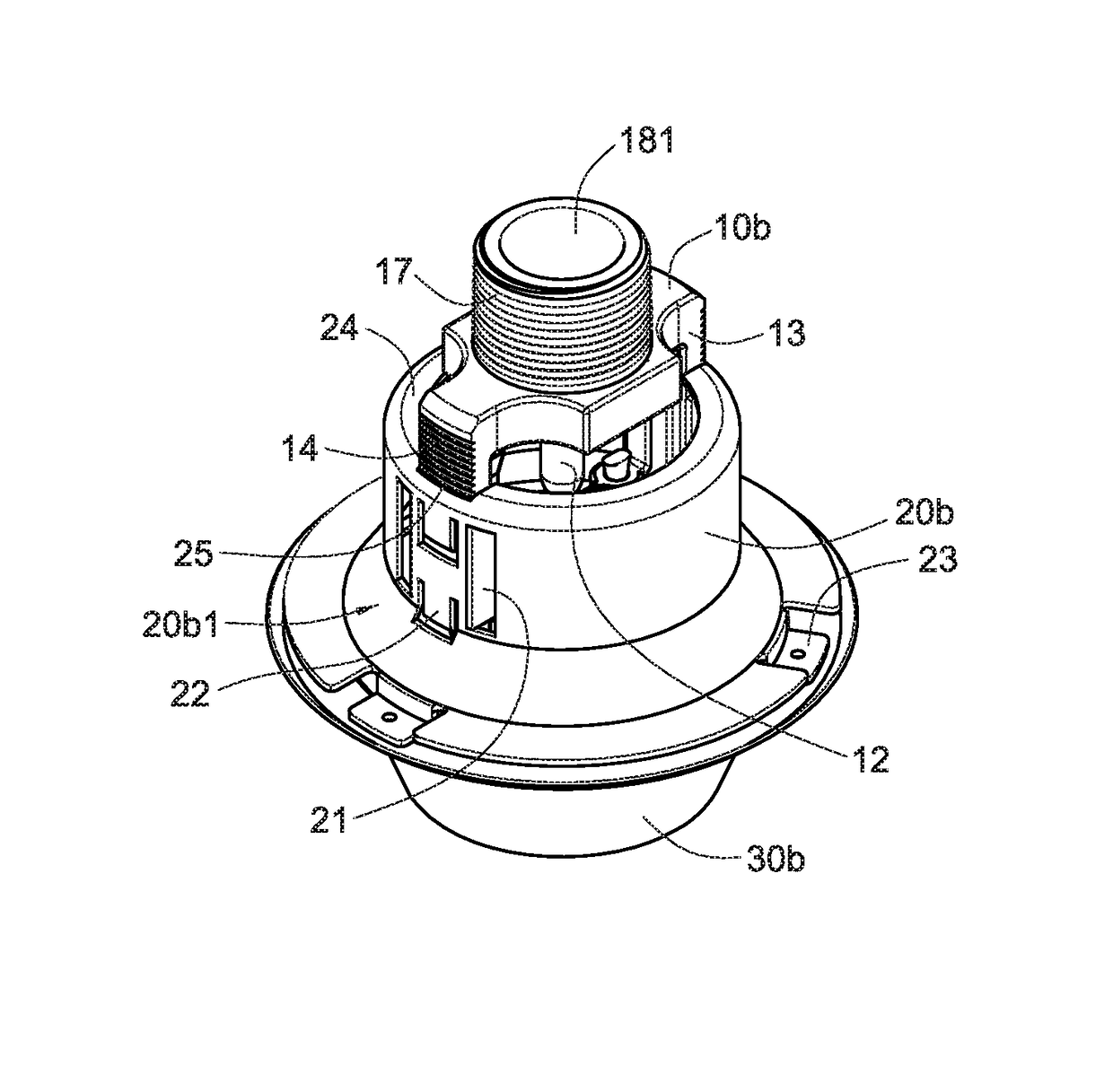

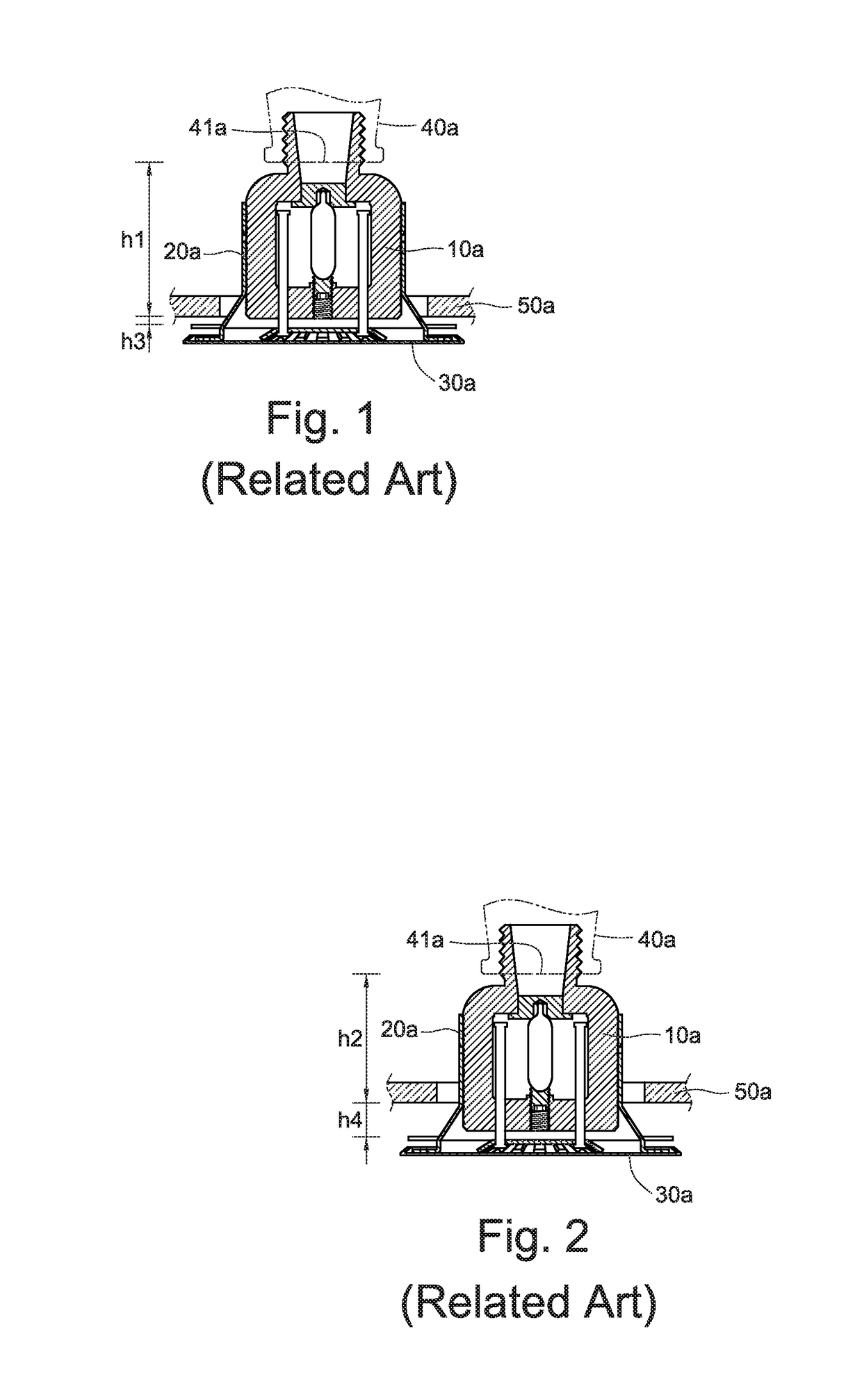

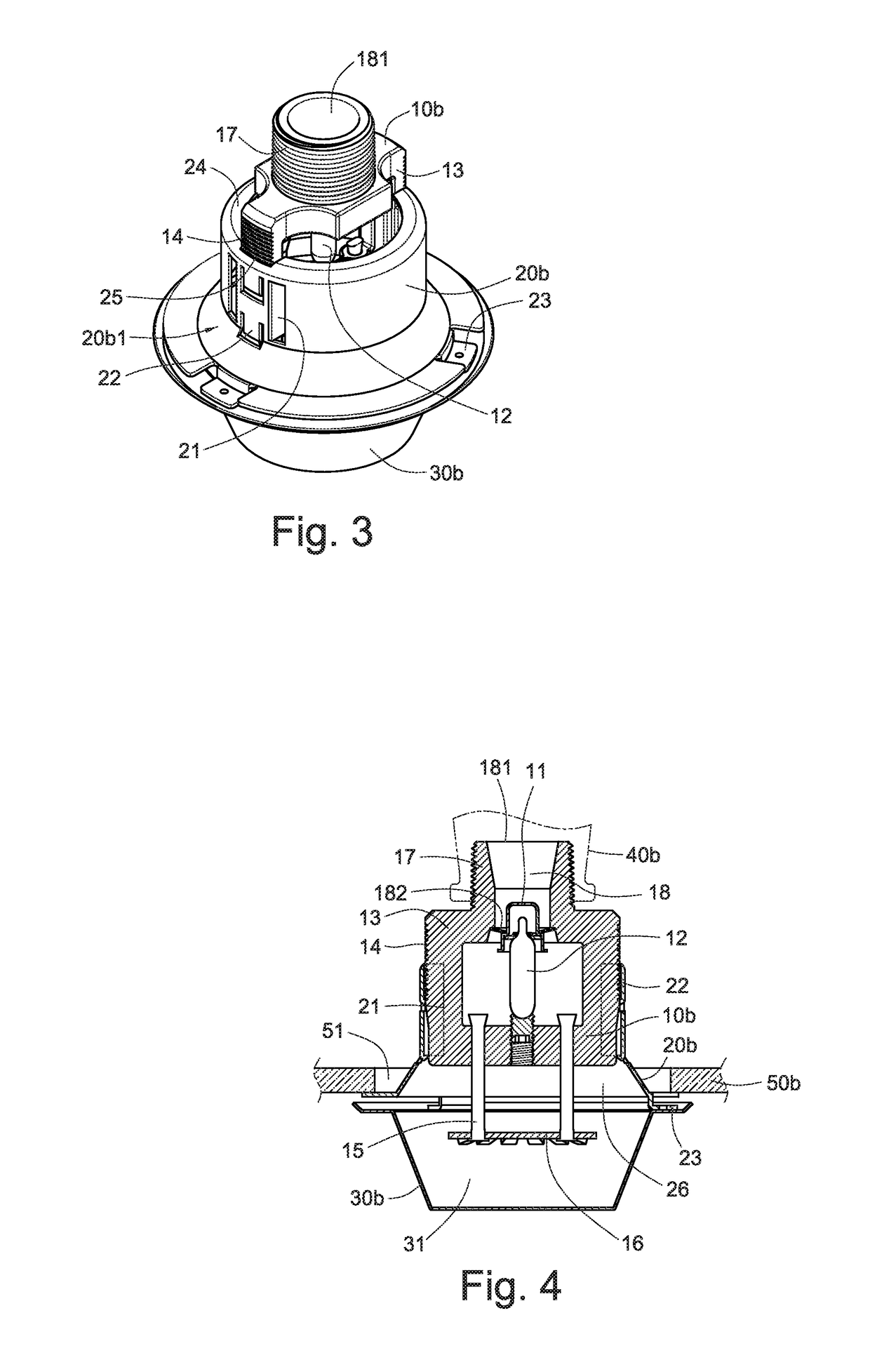

Concealed sprinkler head cover adjusting device

ActiveUS9821182B2Expand the clamping rangeReduce height differenceFire rescueRestriction siteEngineering

A concealed sprinkler head cover adjusting device includes a valve body formed with a flow channel therein. Both sides of the valve body are formed with an opposing bar along the axial direction of the flow channel. A shell is clamped on the opposing bars and is formed with a first accommodating space. A bottom cover is fixed to the bottom of the shell and is inwardly concaved formed a second accommodating space. A restriction site is formed on the outer wall of the opposing bars along the axial direction of the flow channel, both sides of the shell are symmetrically formed with a guiding part and a plurality of clamping parts, and the guiding parts guide the opposing bars to allow the clamping parts adjust the clamping position on the restriction site, thereby adjusting the position of the valve body in the first and second accommodating spaces.

Owner:PROTECTOR SAFETY IND LTD

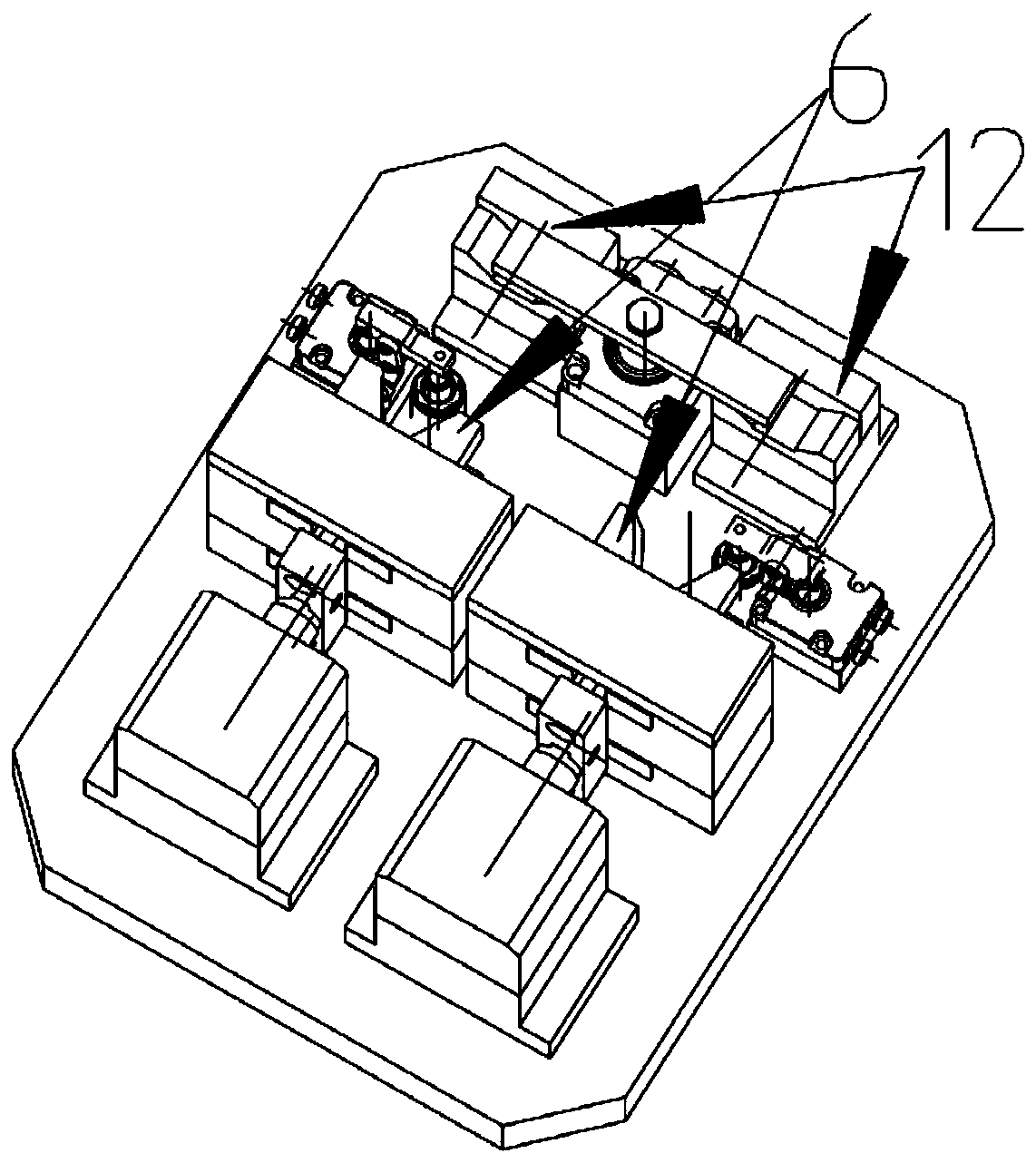

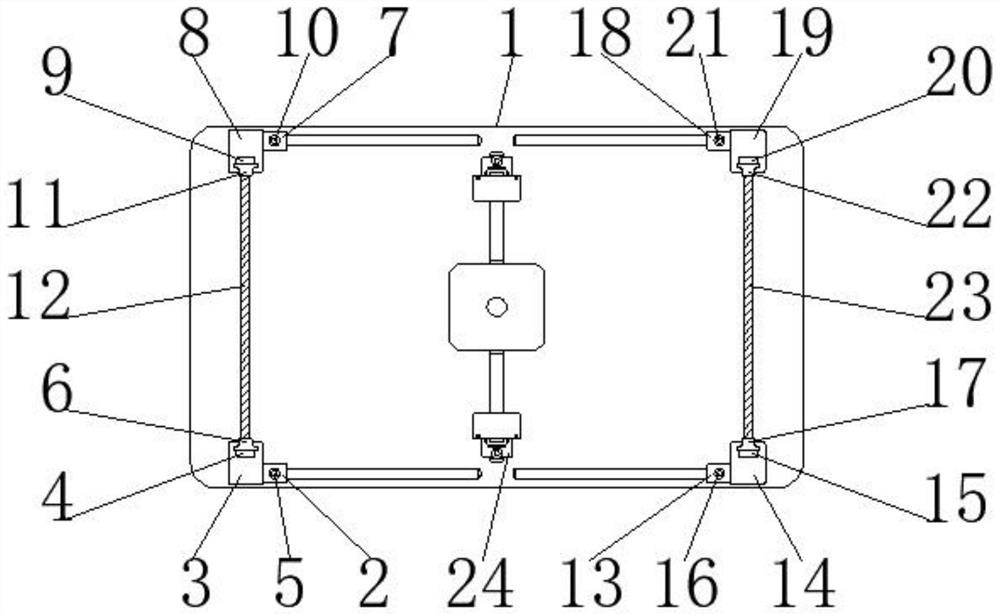

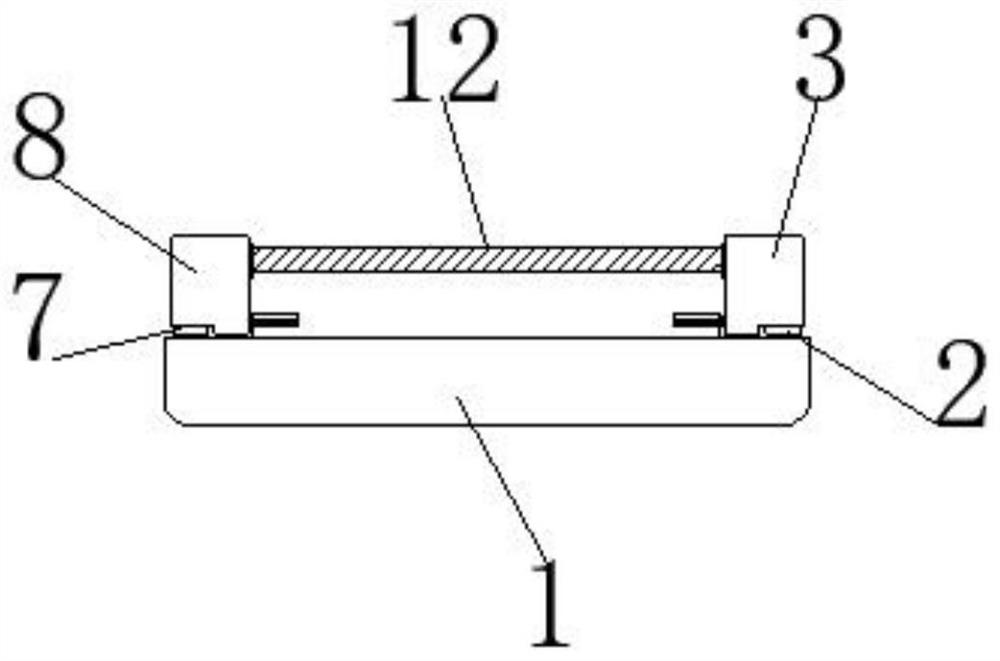

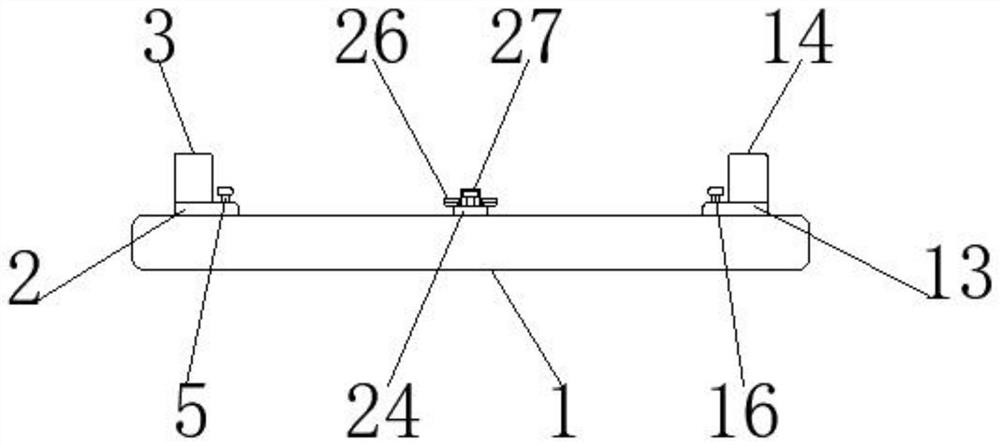

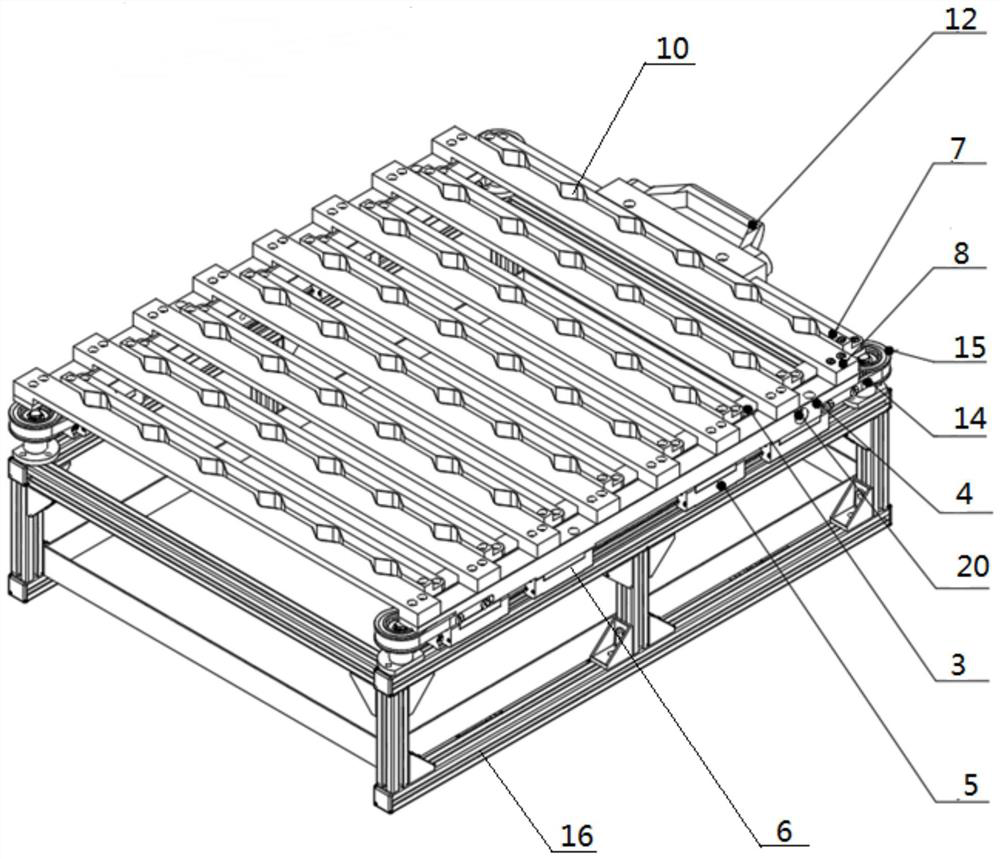

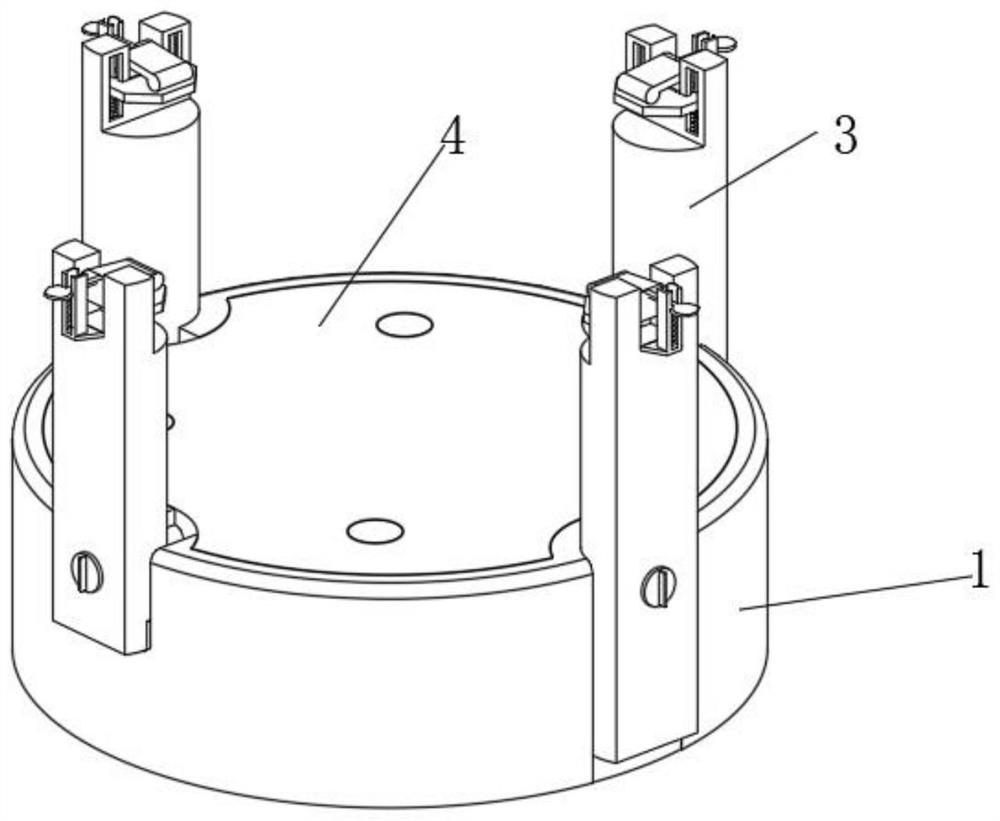

Clamping device for hinged fixed circuit board production

ActiveCN112757189AExpand the clamping rangeEasy to useWork holdersStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of circuit board clamping, in particular to a clamping device for hinged fixed circuit board production. The clamping device comprises a protection seat; a bottom bearing and pressing device is arranged at the position, close to the bottom side, in the protection seat; an upper cover fixing device on the upper side of the bottom bearing and pressing device inside the protection seat; two sets of clamping and positioning devices are arranged up and down in a central symmetry manner on the side wall of the protection seat; and the two sets of clamping and positioning devices are arranged between the protection seat and the upper cover fixing device and between the bottom bearing and pressing device and the upper cover fixing device correspondingly. Each clamping and positioning device comprises two moving devices which are arranged in a central symmetry manner, a middle limiting gear is arranged at the position, close to the middle, between the two moving devices of each clamping and positioning device, and rebounding devices are arranged on the sides, away from each other, of the two moving devices of each clamping and positioning device. The clamping device mainly solves the problem that when circuit boards of different models are used or circuit boards are replaced with other circuit boards, circuit board clamping devices of other models need to be replaced to clamp the circuit boards, and use is quite troublesome.

Owner:东莞市华音电子科技有限公司

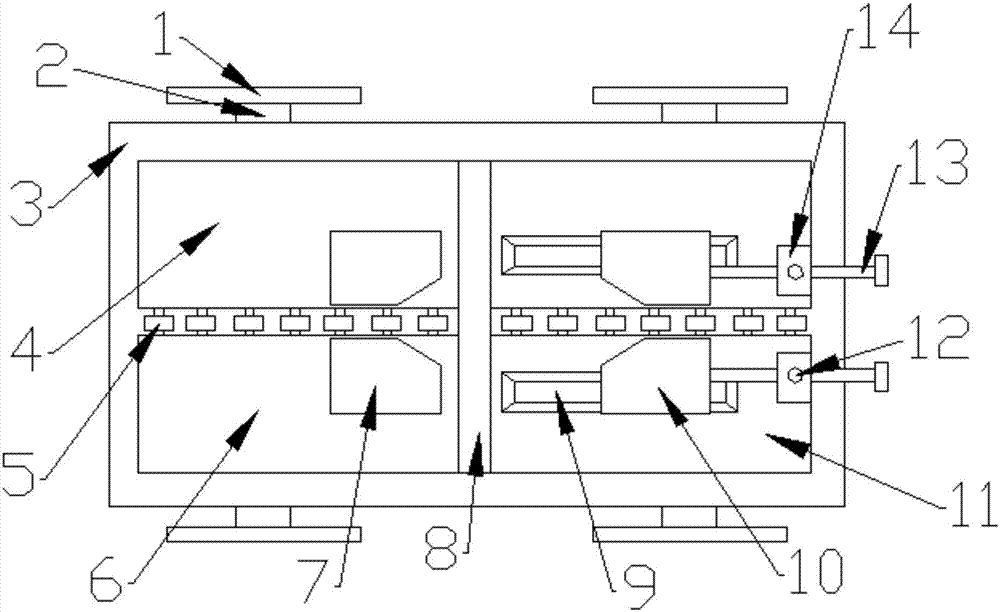

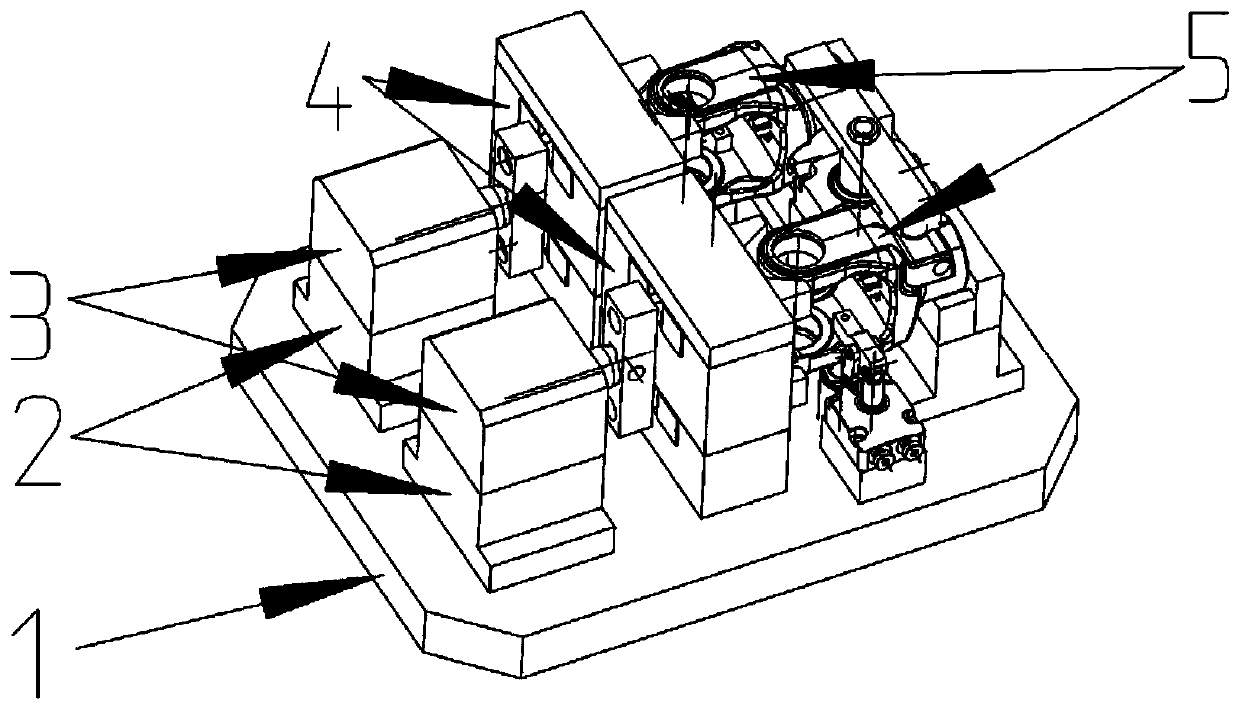

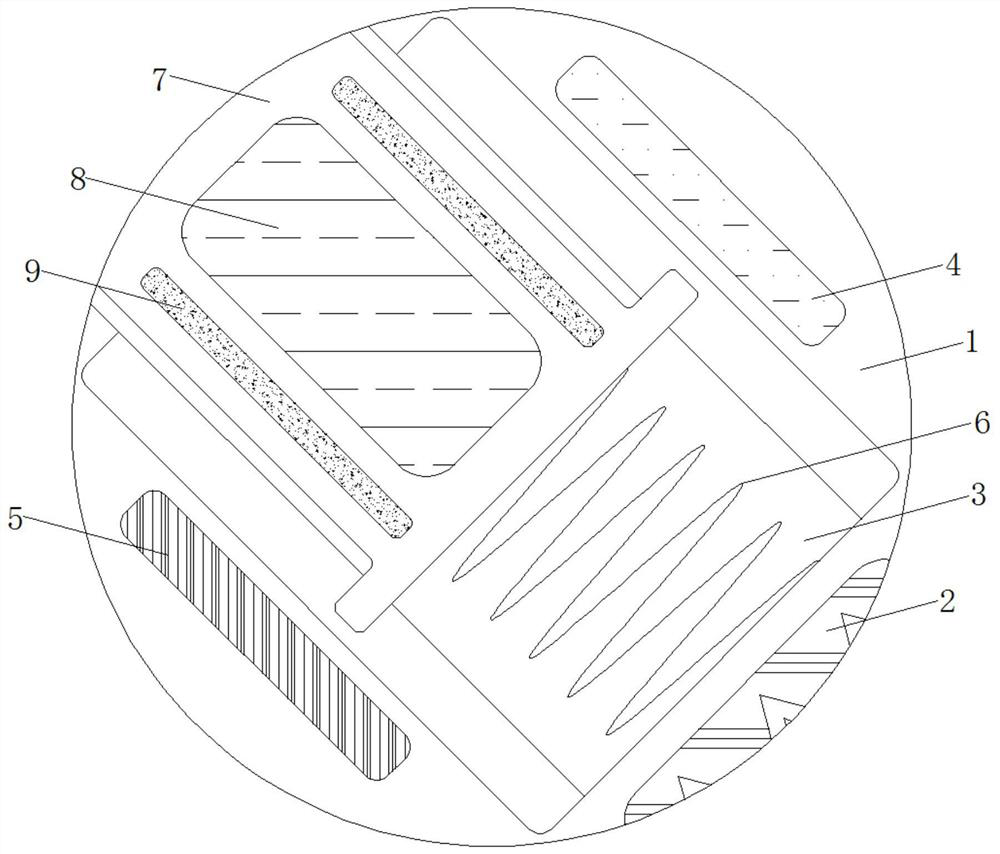

A compact pneumatic tooling

ActiveCN108687552BImprove reliabilityMeet the actual processing requirementsPositioning apparatusMetal-working holdersEngineeringMechanical field

The invention discloses a compact pneumatic fixture, and belongs to the mechanical field. The fixture comprises a fixed bottom plate, a push cylinder fixed seat, a main push cylinder, a clamp retainer, a clamp clamping part, an auxiliary pressing cylinder, a workpiece location block, a main pressing cylinder, a front support block, a rear support block and a workpiece. Due to the mutual cooperation of the clamp clamping part, the front support block and the rear support block, the actual clamping range is expanded, and the actual machining requirements of most of parts can be met; the whole clamp realizes automatic clamping and automatic releasing under the action of the cylinders, so that the reliability of the clamp is improved, and in a working process, the efficiency of placing in theworkpiece and taking out the workpiece is increased; and the whole process is completely pneumatically controlled, so that missing clamping for the workpiece is avoided, and faults in the working process are reduced, and the clamp clamping part and the location block can be adjusted according to the specifications of the workpiece, so that the application range of the clamp is expanded.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

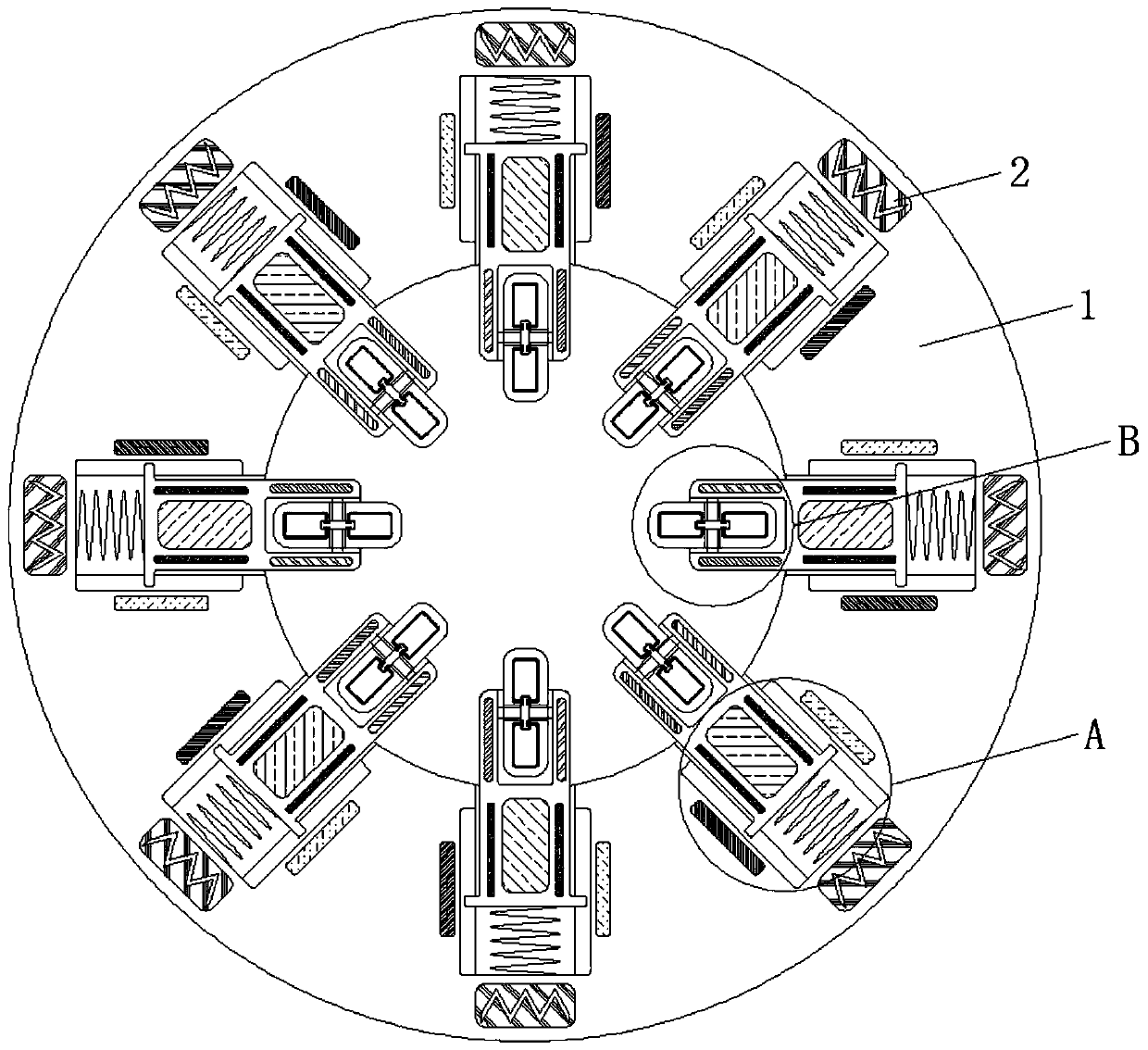

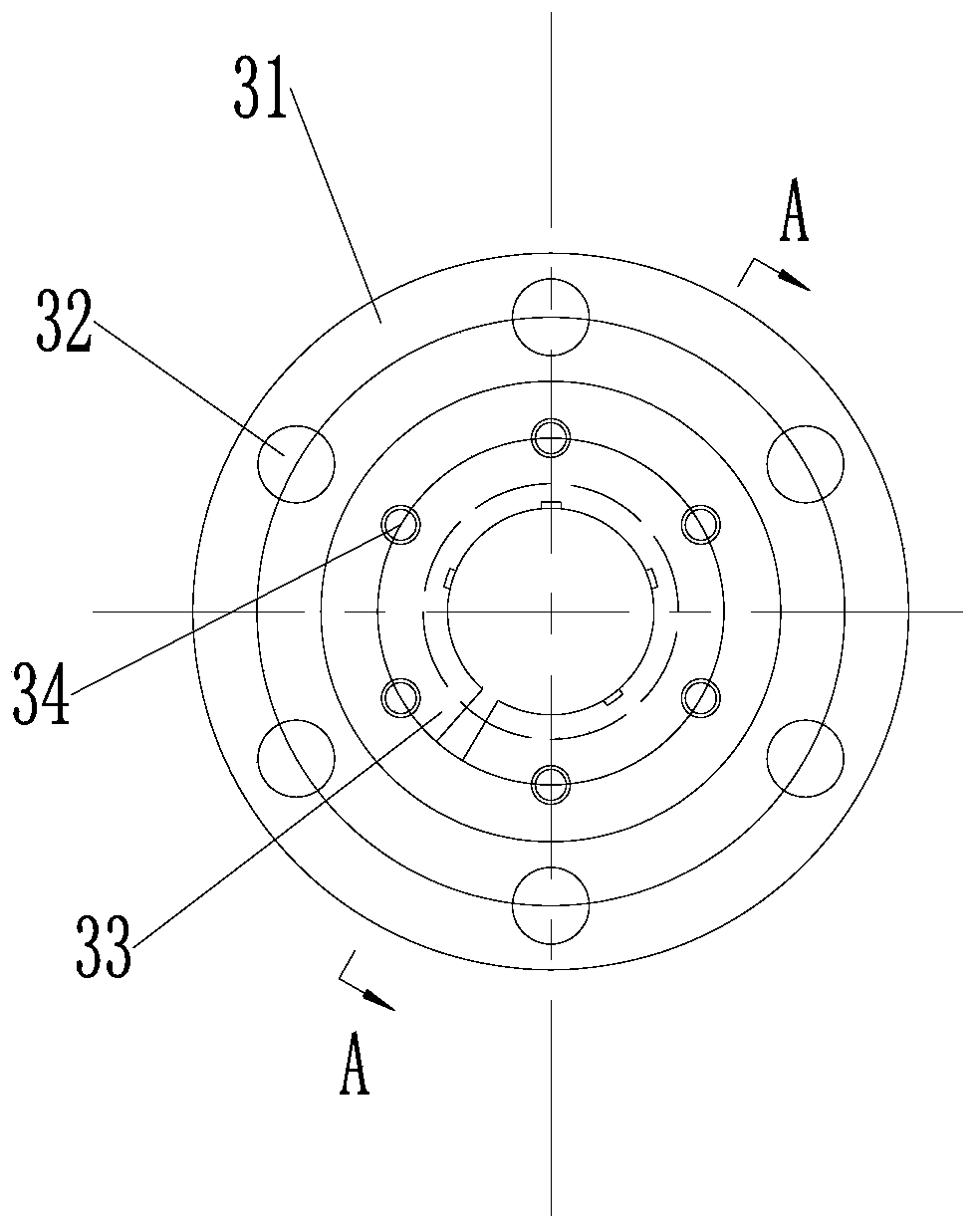

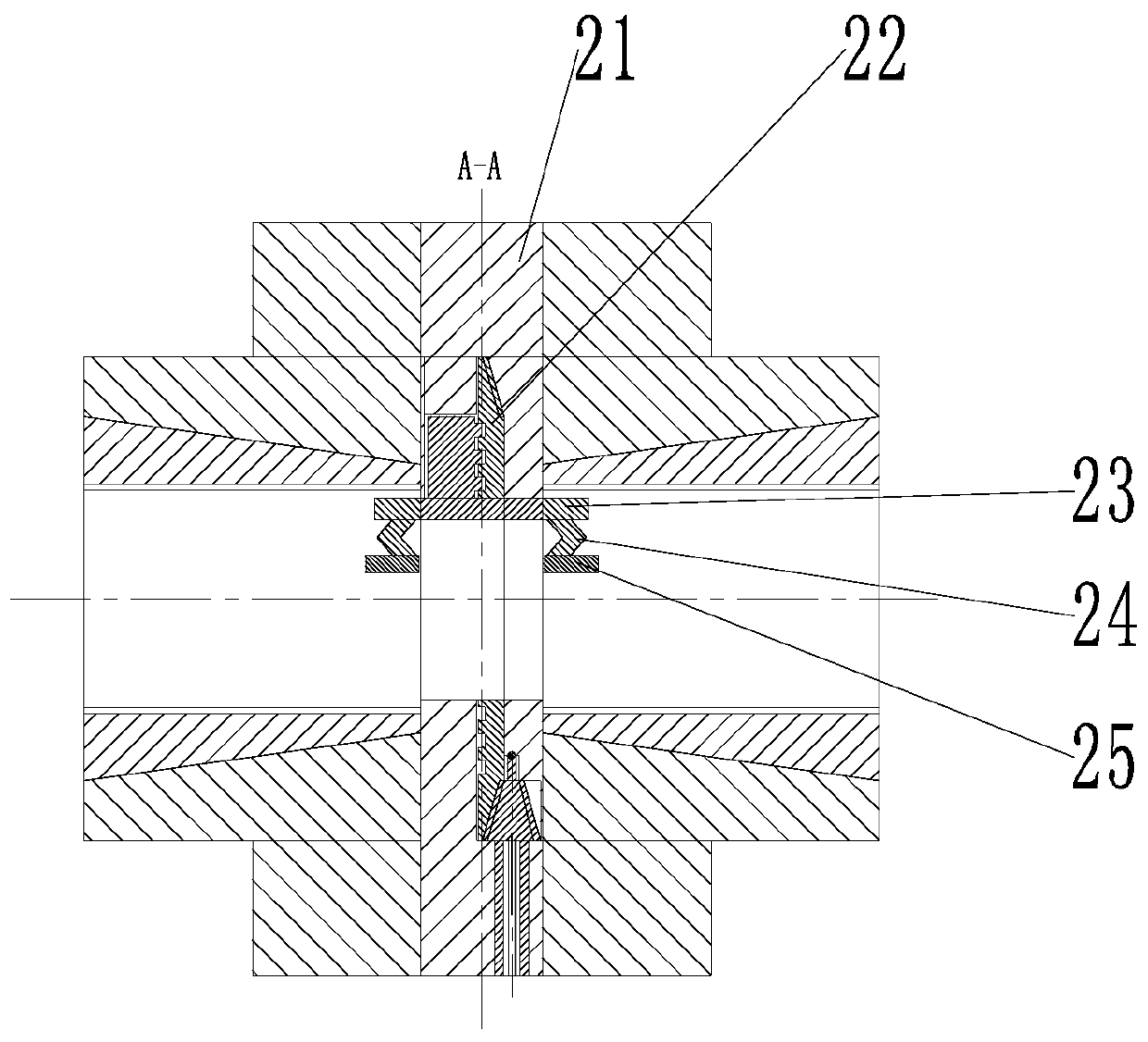

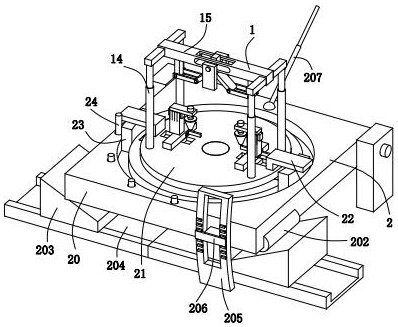

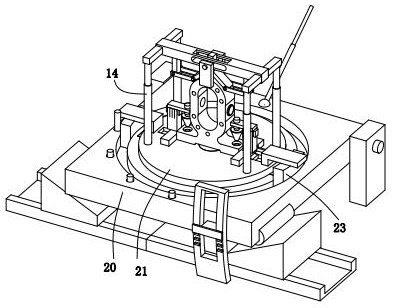

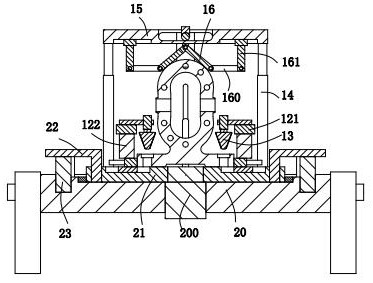

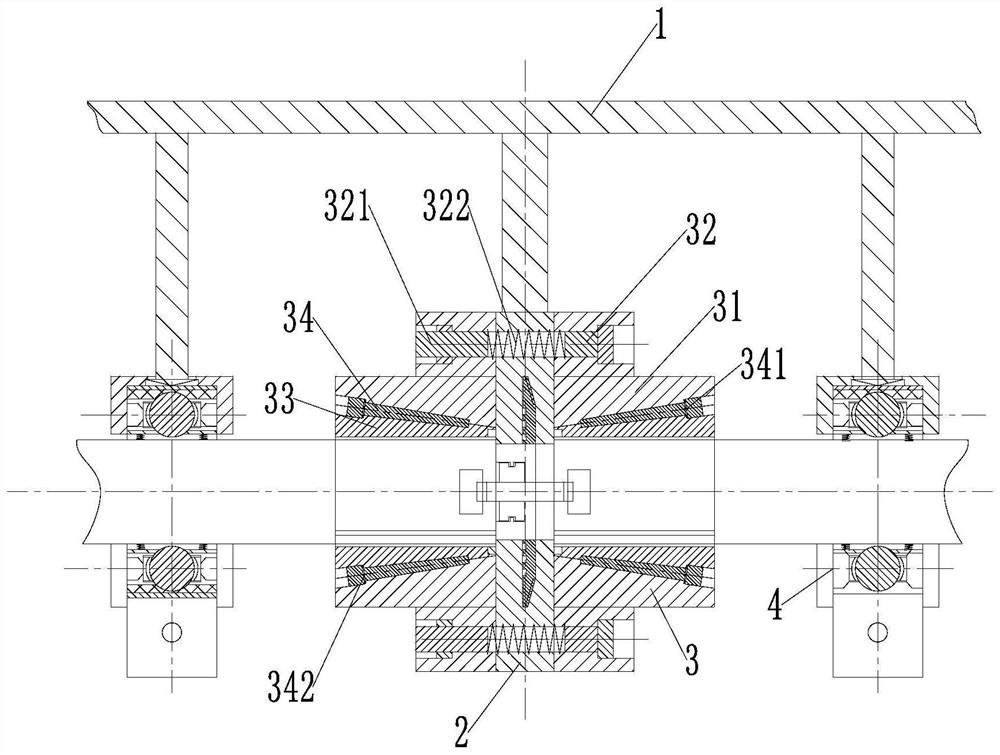

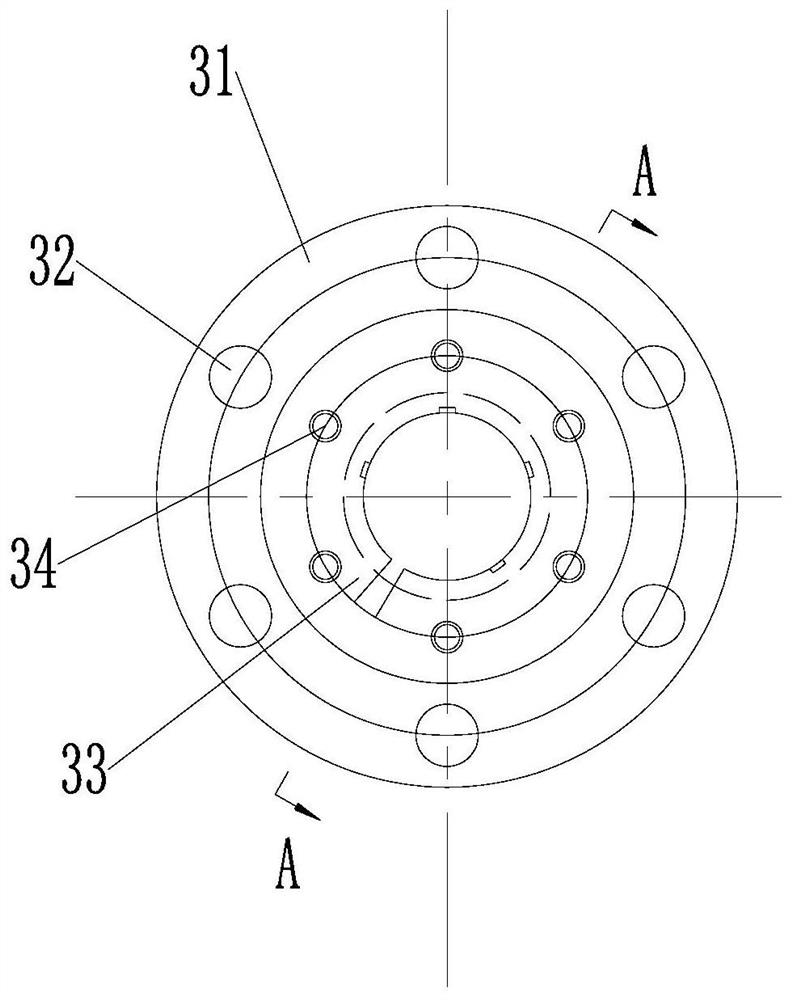

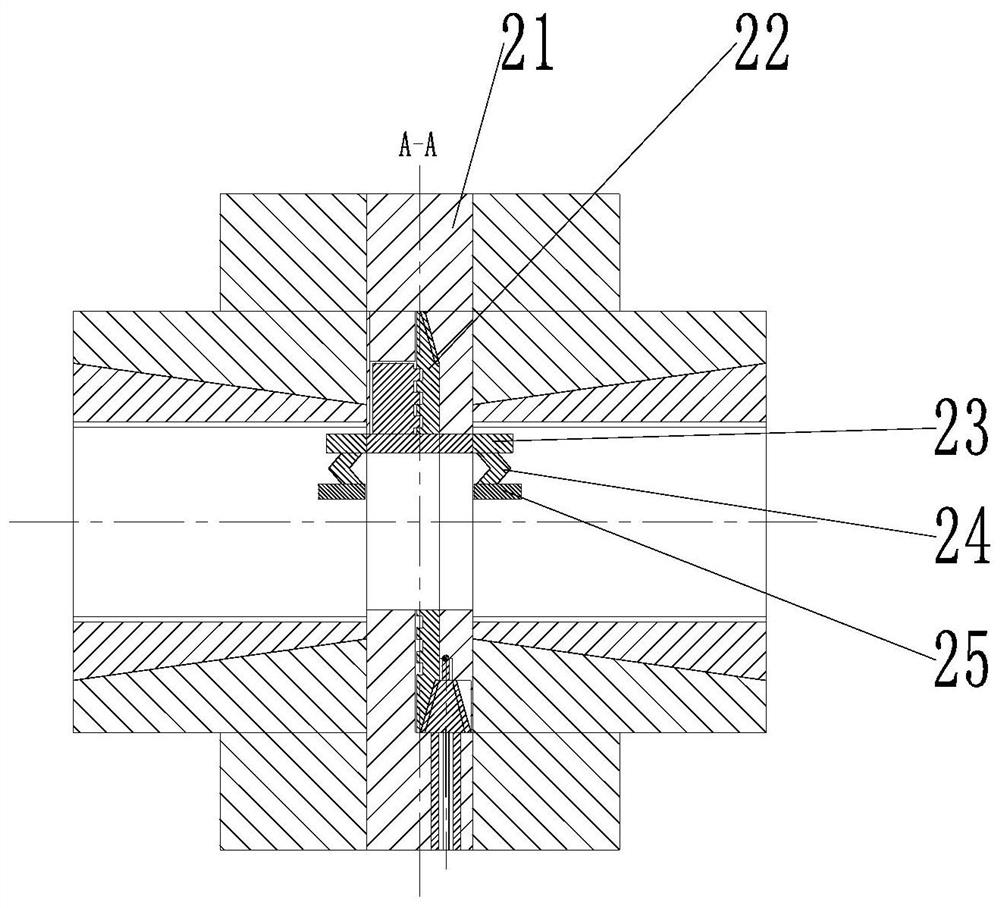

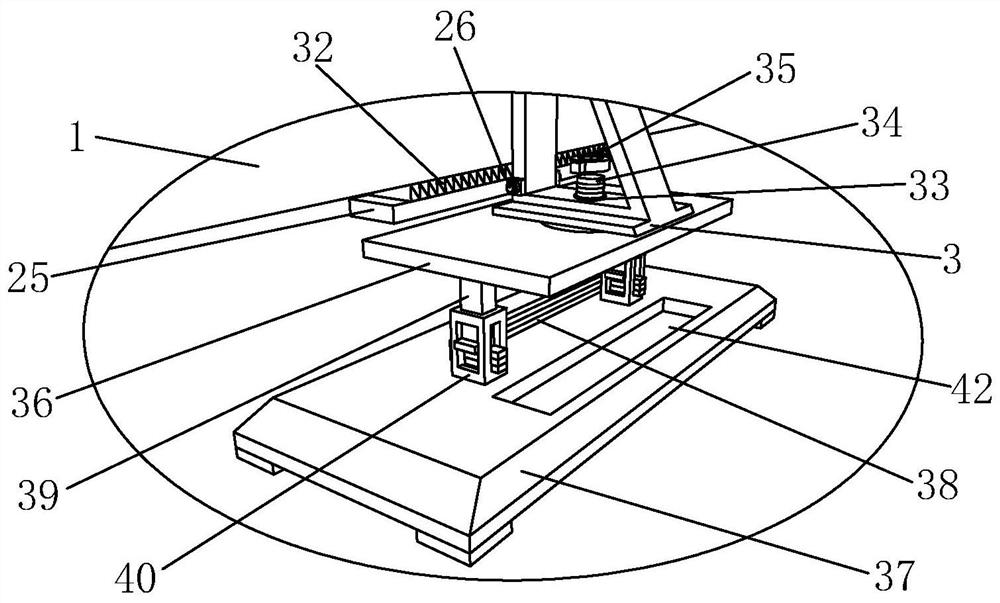

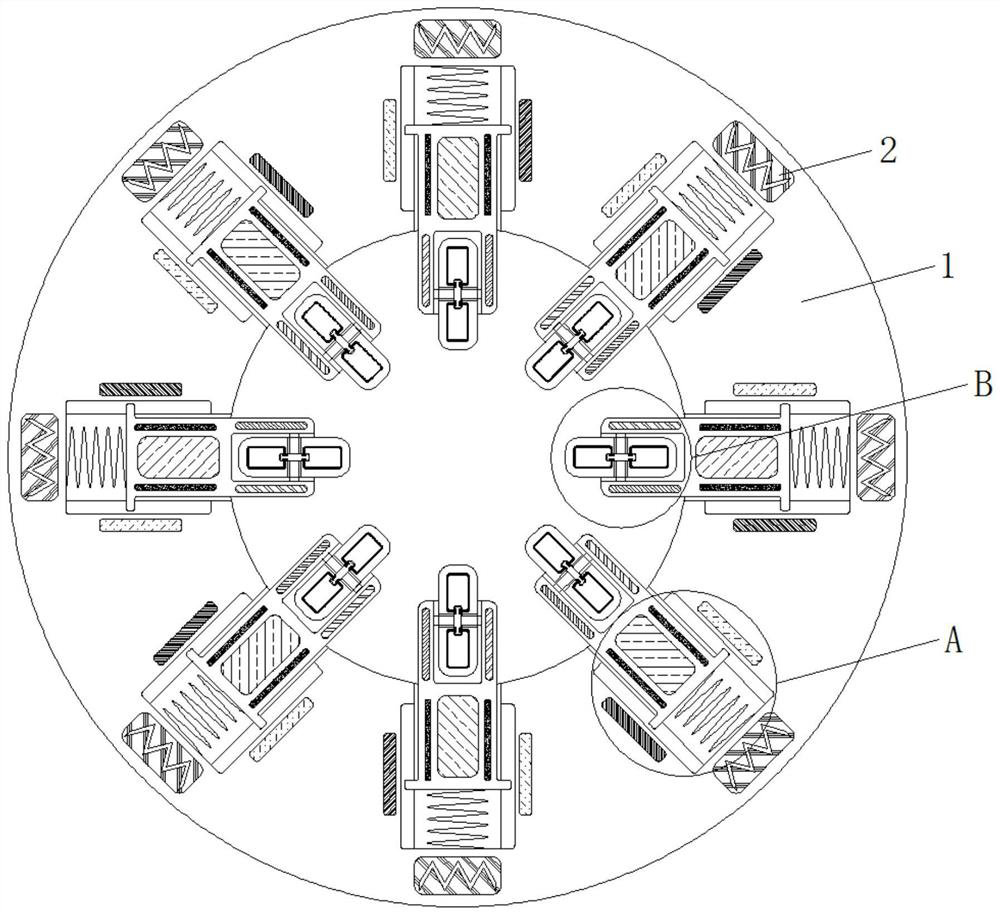

A pump body processing rotary table with clamping function

ActiveCN114603368BExpand the scope of operationReduce labor intensityLarge fixed membersPositioning apparatusMechanical engineeringPhysics

The invention relates to the field of pump body processing, in particular to a pump body processing rotary worktable with clamping function, comprising a clamping part and a rotating part, the rotary worktable has two different rotation centers, which can make the pump The body and the clamping part can be rotated both vertically and horizontally, so that the operator can expand the operating range and increase the number of operable points without frequent transposition. And it can help reduce the labor intensity of the operator and improve the work efficiency. The clamping part used in the present invention can clamp the pump body in multiple directions and at multiple points without hindering the assembly of the pump body, so as to ensure the pump body. Stability and uniform force on the pump body, at the same time, the clamping part can also implement guidance and limit processing during the pump body in place, so as to avoid the position deviation of the pump body and affect the clamping effect.

Owner:XUZHOU XINDALONG CHEM PUMP MFG CO LTD

A convenient coupling

The invention relates to a portable coupling. The portable coupling comprises a bracket, a fixed shaft mechanism, a shaft coupling mechanism and bearing mechanisms, wherein the fixed shaft mechanism is installed at the rod tail end of the middle of the bracket; the left side and the right side of the fixed shaft mechanism are connected with the shaft coupling mechanism through screws; the bearingmechanisms are installed at the rod tail ends of the left side and the right side of the bracket; the fixed shaft mechanism comprises a fixed shaft shell, a three-jaw chuck, a fixed shaft fixing plate, a spring leaf and a large arc clamping plate; the shaft coupling mechanism comprises a coupling shell, a spring screw, a conical bushing and a conical fastening piece; and each bearing mechanism comprises an omega-shaped fastening piece, a detachable ball bearing, a rubber ring and a telescopic spring plate. A shaft is fixed through the three-jaw chuck, so that the shaft is in coaxial matching,and the stress of the shaft is more uniform; and the conical bushing is matched with the conical fastening piece for use, the coupling can fix and clamp the shaft with multiple diameters, and finally,the purpose of improving the use effect of the coupling is achieved.

Owner:WENZHOU QIFANG NEW ENERGY CO LTD

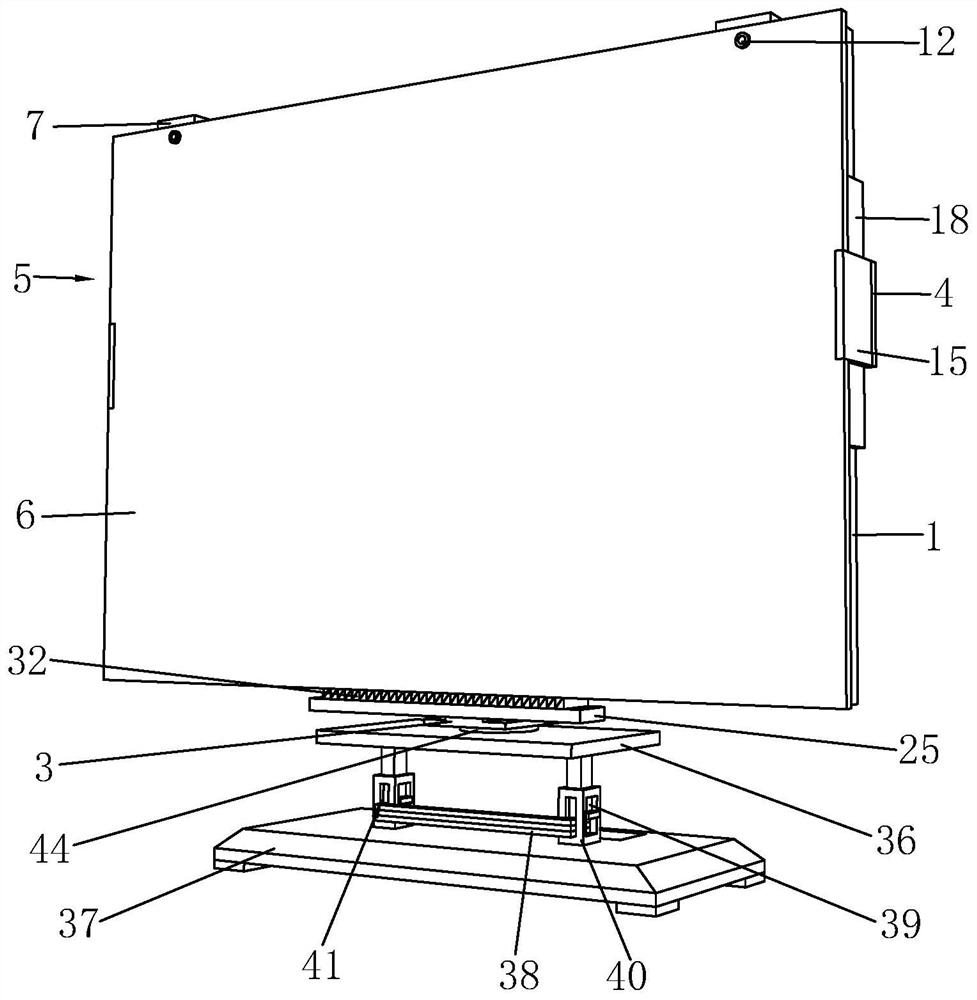

A household appliance display screen with a protective cover structure and its installation method

ActiveCN112145891BEasy to replacePlay a protective effectTelevision system detailsColor television detailsHome applianceProtective shielding

The invention discloses a household appliance display screen with a protective cover structure and an installation method thereof. The display screen includes a display screen body and a protective cover structure. There is a splint on the card board, the display body is arranged between the splints, the back bracket connects the two side clamps, the back bracket is provided with a supporting plate, the back bracket is provided with a shaft sleeve, and the support frame is provided with a shaft sleeve. Corresponding to the fixed shaft, the fixed shaft is threaded with a lock cap, and the lock cap presses the back bracket on the support frame; the installation method includes the following steps: (a) individual component assembly; (b) installing the screen protection cover; (c) side clips; (d) upper shelf. The display screen in the present invention has a novel structure, flexible disassembly and assembly, adjustable viewing angle, can meet the needs of different users, reliable protection, simple installation method, low strength, step by step orderly, convenient for flexible adjustment, convenient positioning, and low installation difficulty. Effectively guarantee the installation quality.

Owner:嘉兴华煜光电科技有限公司

Hub balance repairing tool

ActiveCN113561088AClamp firmlyNo damage to other valuesWork holdersEngineeringMechanical engineering

Owner:上海远迹新材料有限公司

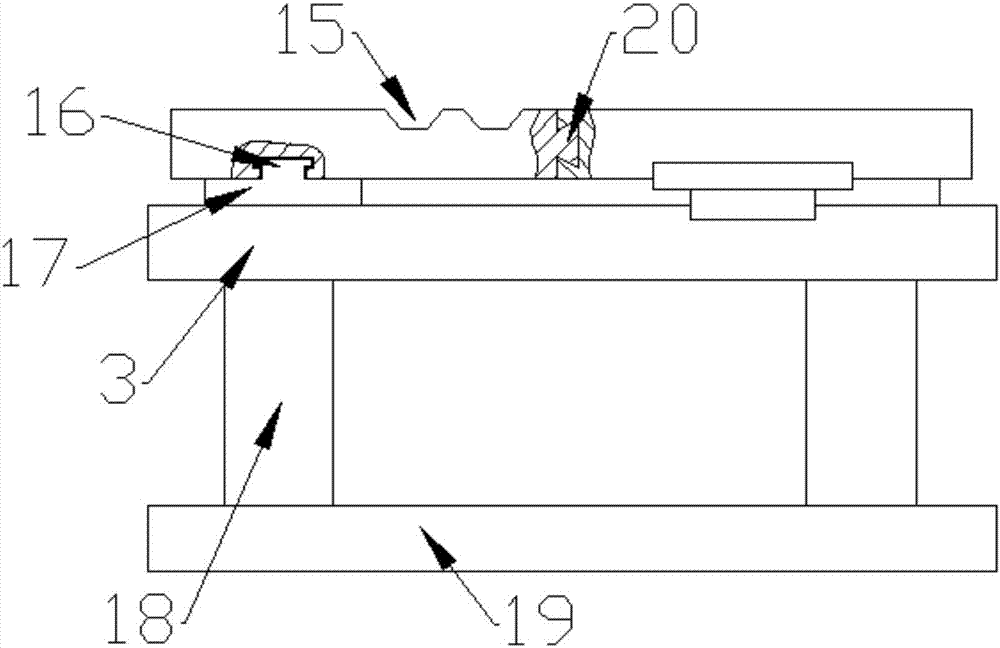

Workpiece clamping device for laser engraving machine machining

InactiveCN112496579AImprove adaptabilitySimple and convenient clamping and fixing operationWelding/cutting auxillary devicesAuxillary welding devicesLaser engravingEngineering

The invention relates to the technical field of laser engraving machines, and discloses a workpiece clamping device for laser engraving machine machining. The device comprises a workbench, a first strap sliding block, a first suction block, a first strap and a second strap, wherein the first strap sliding block is located below the left side of the front surface of the workbench and is slidably connected with the workbench, and the first suction block penetrates through the top end of a first strap mounting seat and is fixedly connected with the first strap mounting seat. According to the device, by arranging the first strap and the second strap and utilizing the elastic deformability of rubber, workpieces in irregular shapes can be fixed, and subsequent laser engraving machine engraving is guaranteed; by arranging the first suction block, a second suction block, a third suction block and a fourth suction block, corresponding strap clamping blocks can be adsorbed and fixed subsequently, and during need, the heights of the first strap and the second strap can be changed by sliding the corresponding strap clamping blocks so as to be suitable for fixing irregular workpieces with different height sizes, so that the fixing adaptability of the first strap and the second strap is high.

Owner:芜湖韩大防伪科技有限公司

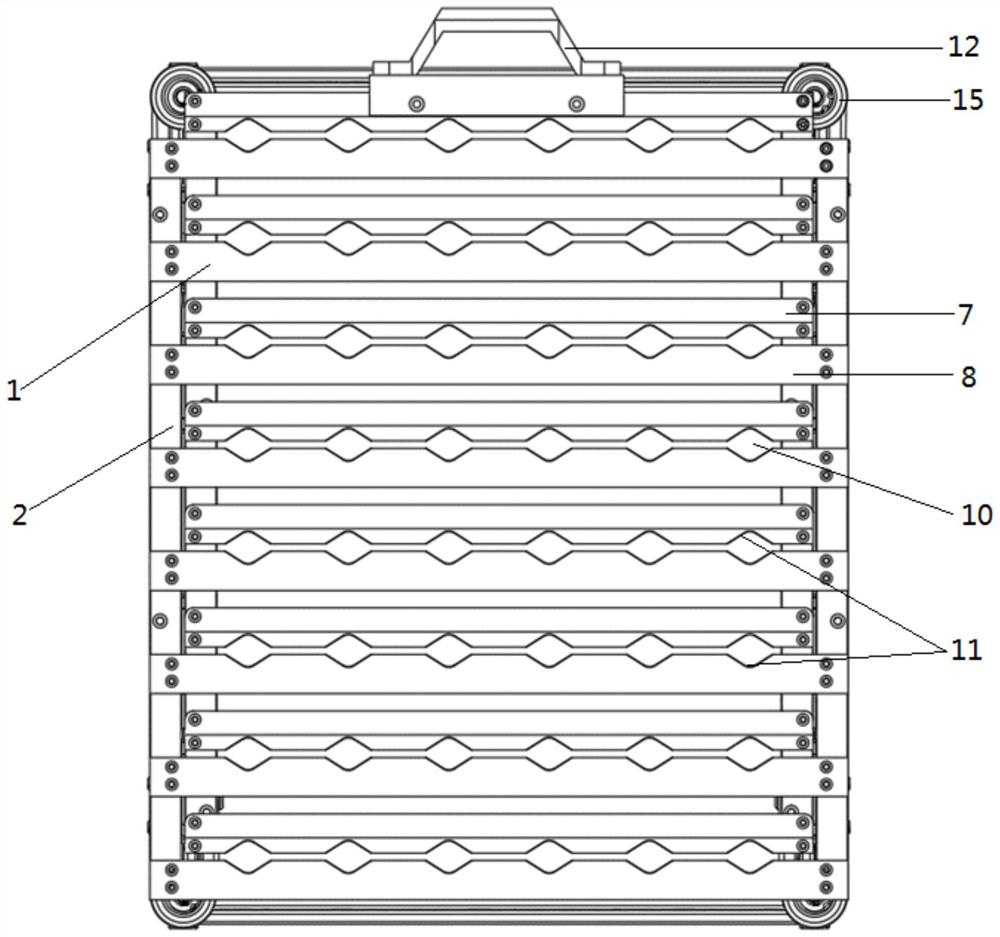

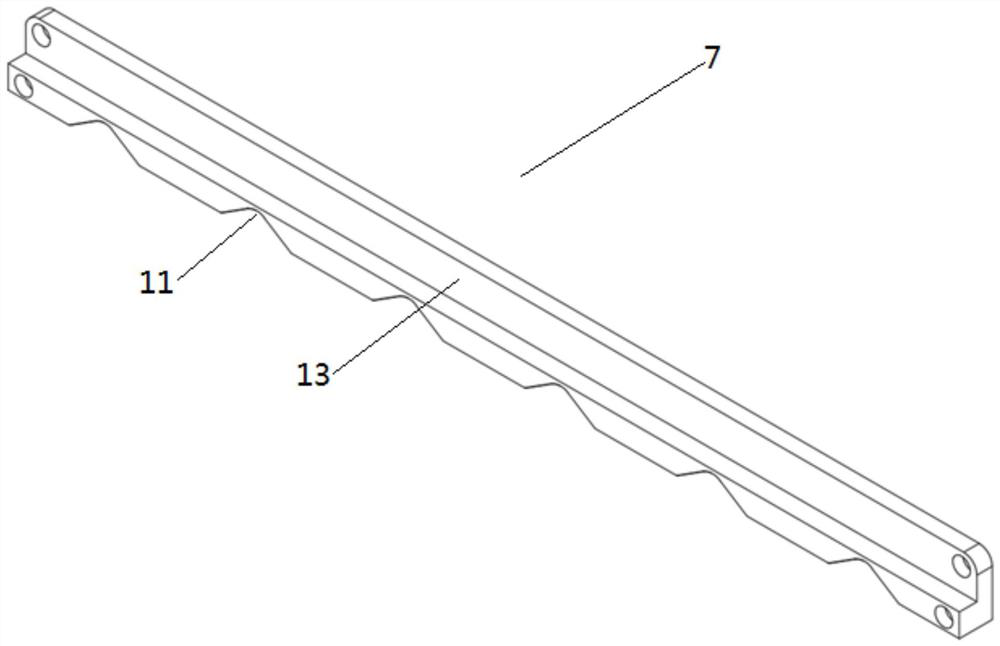

Multi-variety self-adaptive stock bin device

PendingCN113955438AAchieve centering clampingGuaranteed clamping stabilityConveyor partsMechanical conveyorsClassical mechanicsStructural engineering

Owner:CHONGQING HONGJIANG MACHINERY

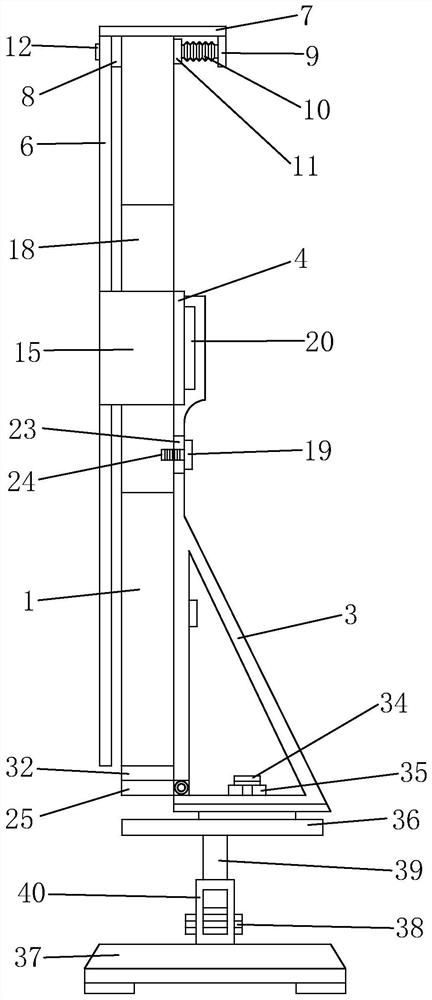

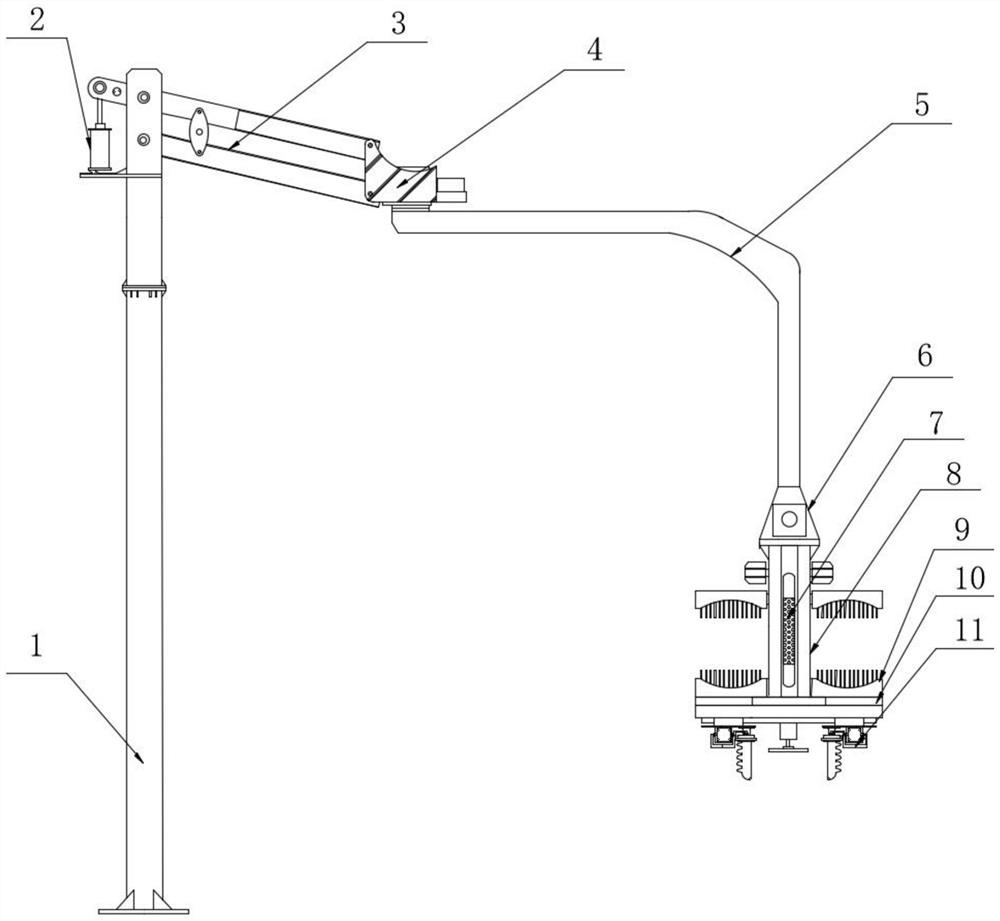

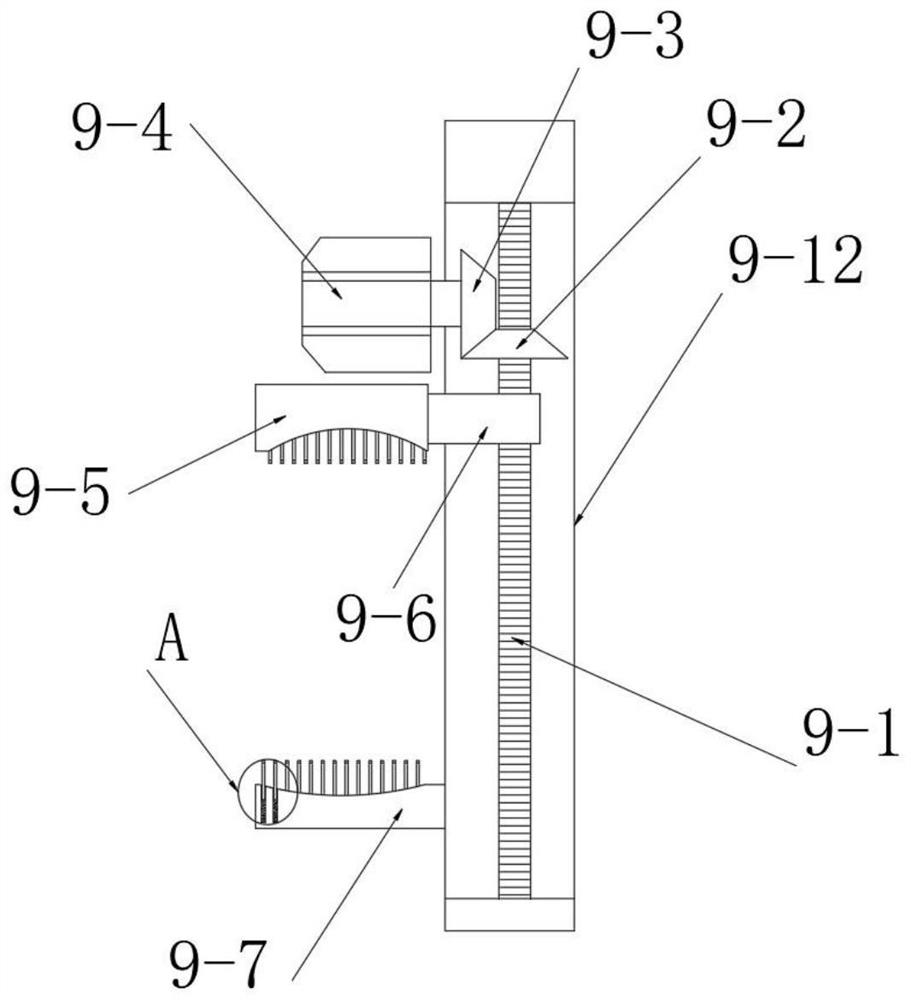

Power-assisting arm clamp system used for carrying irregular packaging materials and used for warehouse

ActiveCN113415565AStable clampingImprove handling efficiencyConveyorsStorage devicesMechanical engineeringIndustrial engineering

The invention relates to a power-assisting arm clamp system used for carrying irregular packaging materials and used for a warehouse. The system comprises a stand column and a secondary arm, the top of the stand column is provided with a main arm through a rotating shaft, the side wall of the stand column is provided with a lifting cylinder, the lifting cylinder is connected with the main arm, one end of the secondary arm is rotationally connected with the main arm through a rotating joint, the other end of the secondary arm is rotationally connected with the top end of a clamp vertical rod through a rotating mechanism, the clamp vertical rod comprises a rod body and a mounting part, the mounting part is integrally arranged at the top end of the rod body, the cross section of the rod body is of an I-shaped steel structure, a web plate of the structure is a connecting column, and wing plates on the two sides and the web plate form two symmetrical mounting grooves which are used for symmetrically mounting first clamps; and a second clamp is coaxially mounted at the bottom of the clamp vertical rod. The first clamps and the second clamp are combined into a whole and are matched for use, so that the use range is greatly widened, and the carrying efficiency is improved.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

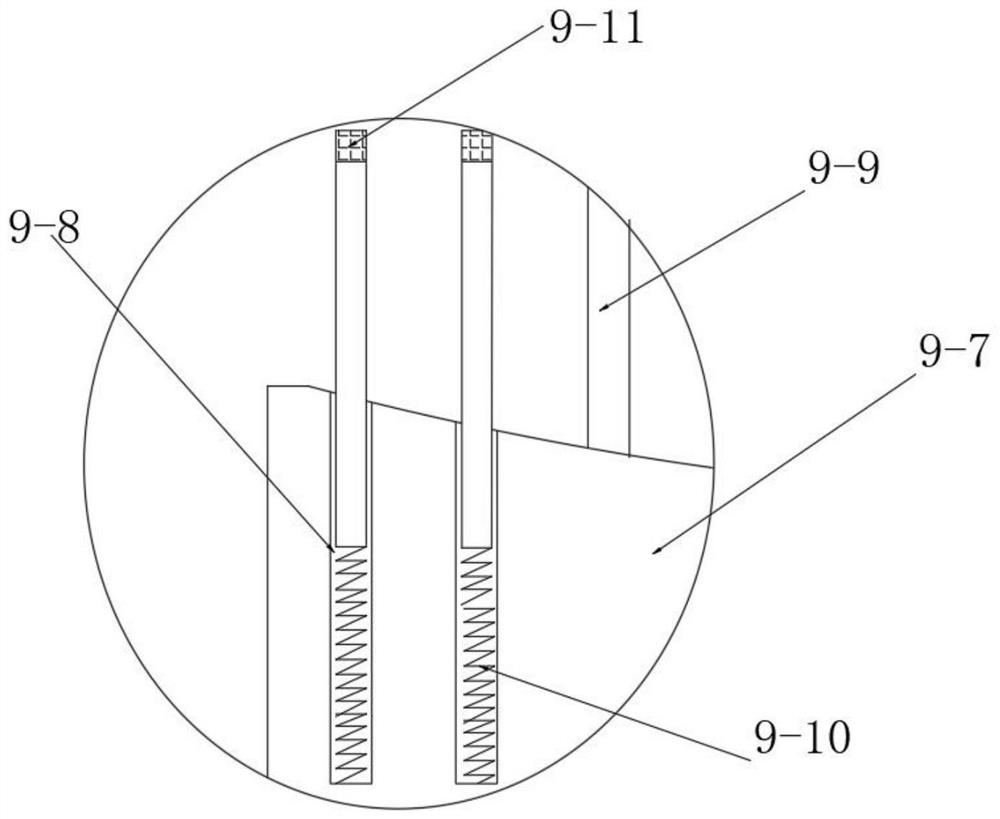

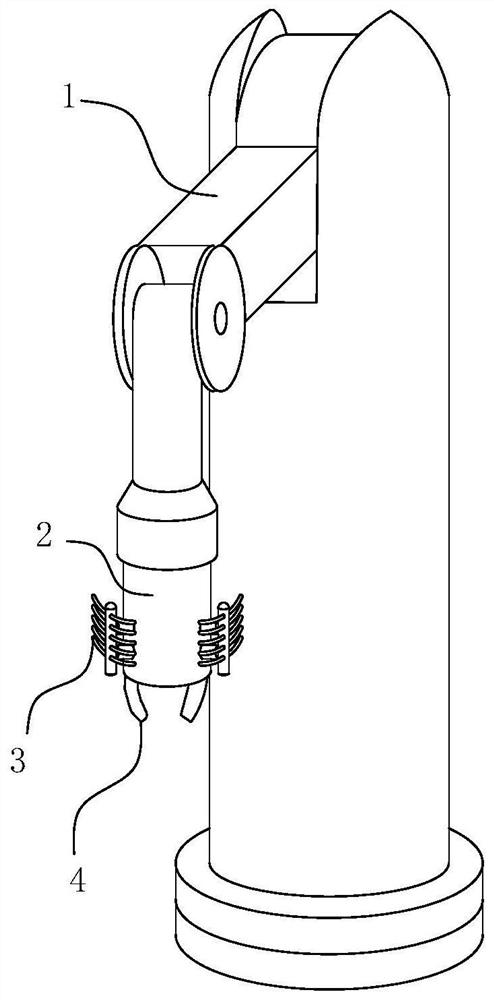

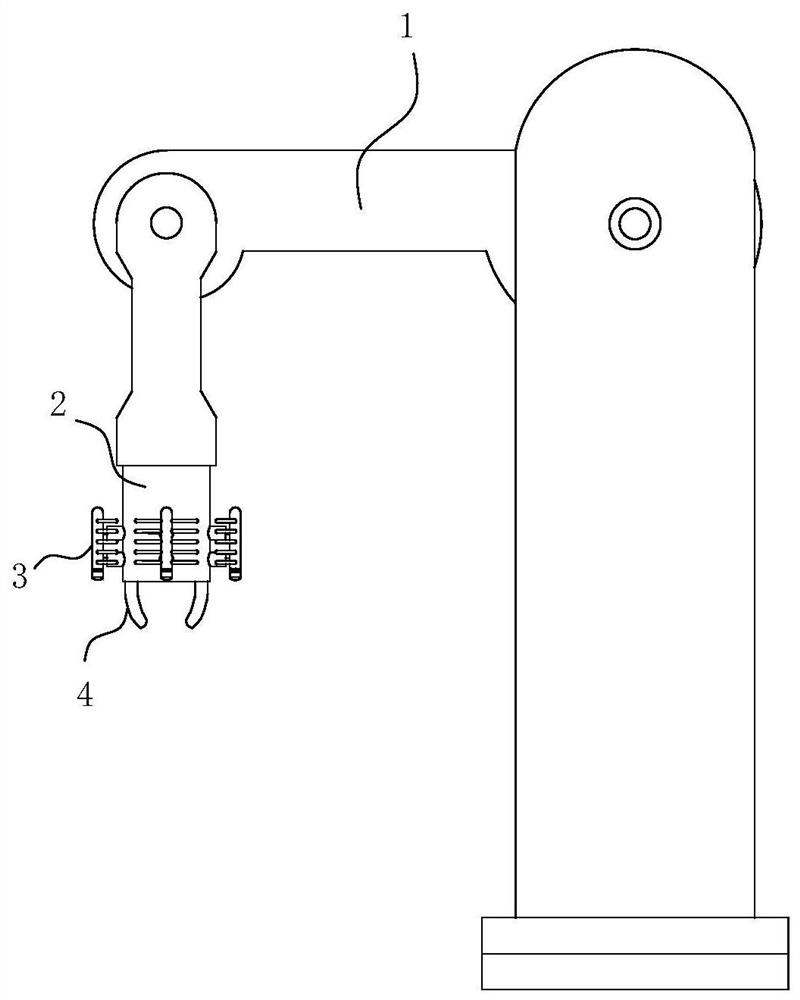

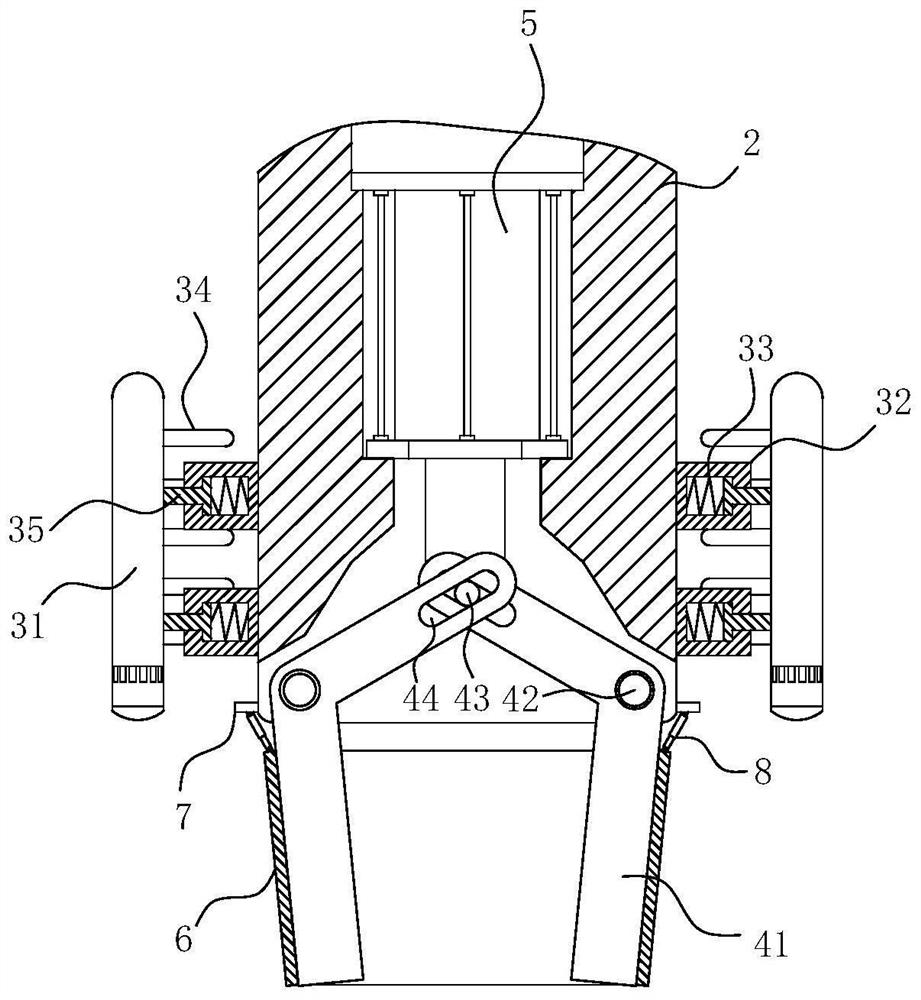

An air-claw manipulator

Owner:西伯瀚(泰兴)传动技术有限公司

A fixing device for rust removal of environmentally friendly steel pipes that can be centered and self-generated

ActiveCN110883668BEven contactTo achieve a calming effectGrinding drivesGrinding machinesEngineeringPipe

Owner:山东东正钢构有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com