A compact pneumatic tooling

A pneumatic tooling, compact technology, applied in the direction of manufacturing tools, positioning devices, metal processing equipment, etc., can solve the problems of high cost, actual position error of parts, pain for debugging personnel, etc., to expand the scope of application, avoid leakage clamping, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

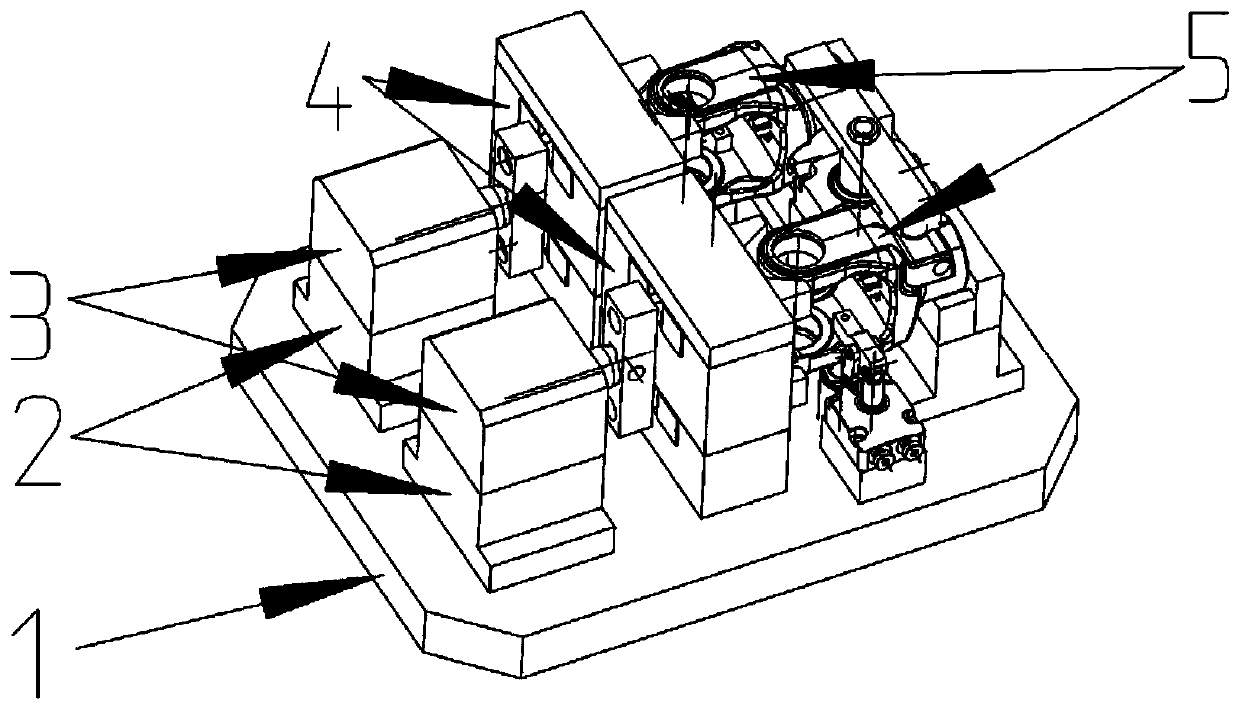

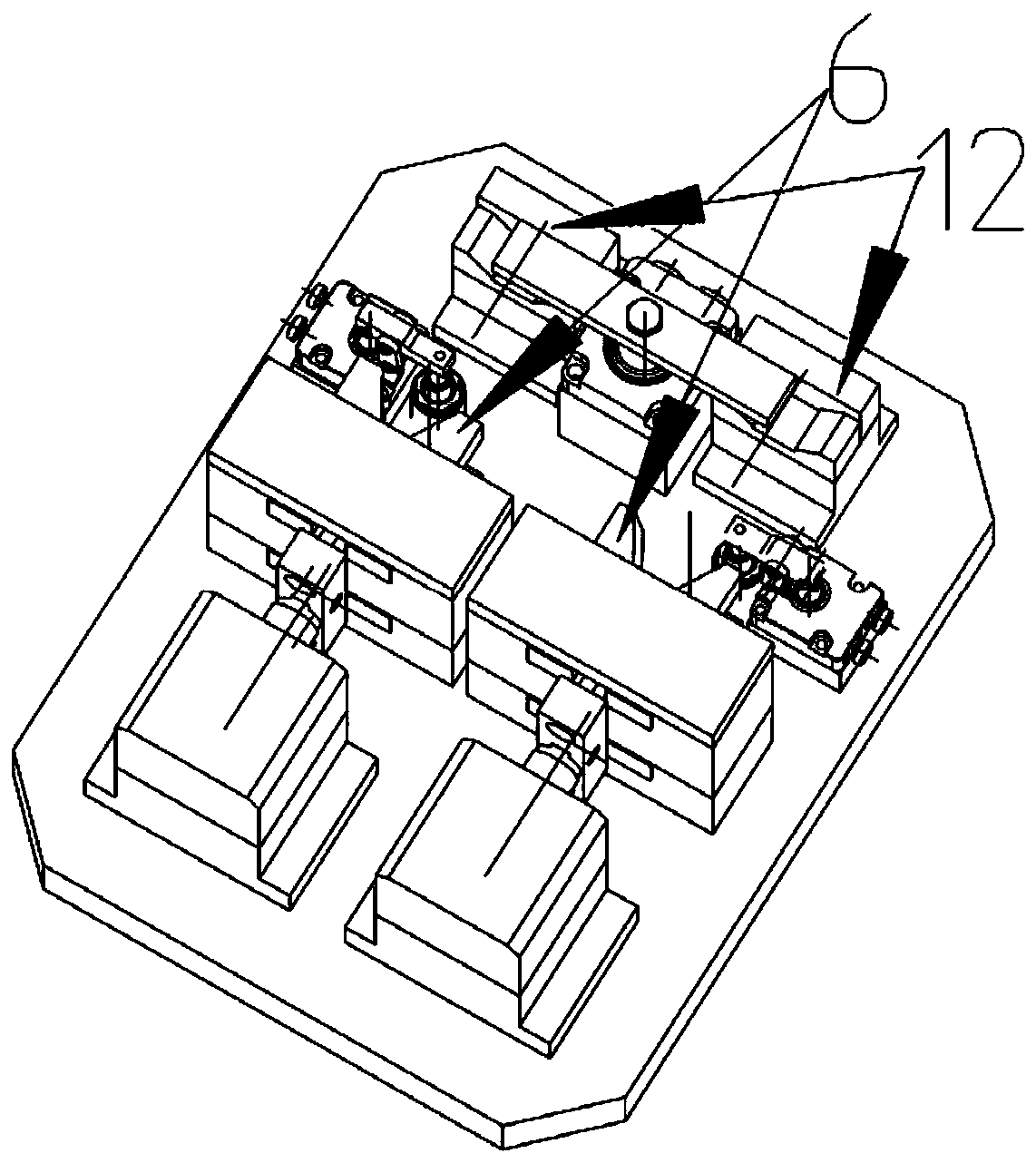

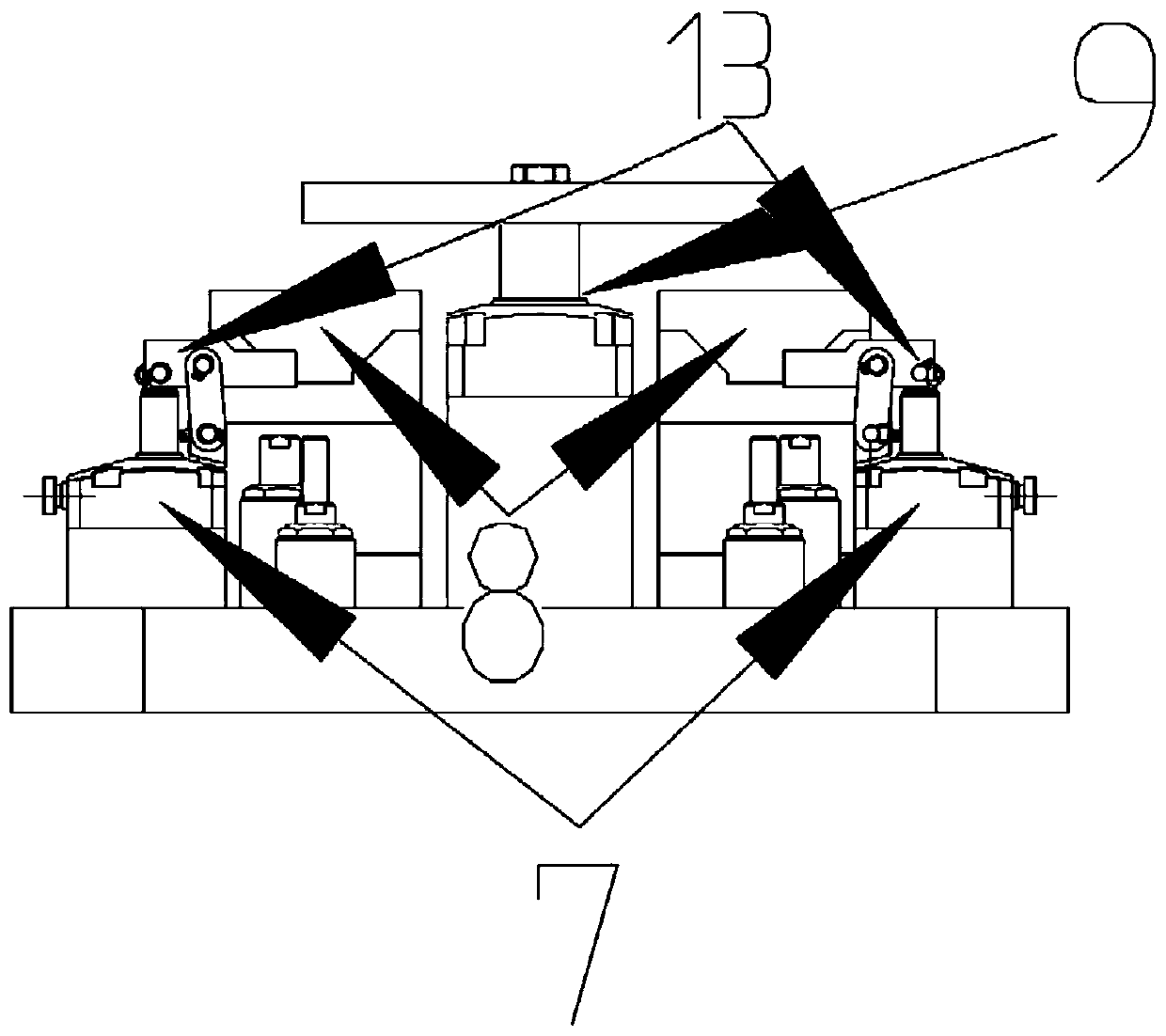

[0026] Such as figure 1 As shown, a compact pneumatic tooling of the present invention includes a fixed base plate (1), two push cylinder fixing seats (2), two main push cylinders (3), two clamp holders (4), two artifact(5); eg figure 2 Shown two fixture clamping parts (6); As shown in Figure (3) two press-down auxiliary cylinders (7), two workpiece positioning blocks (8), a main press-down cylinder (9); Figure 4 The front support block (10) and the rear support block (11) are shown, the push cylinder fixed seat is fixed on the fixed base plate, the main push cylinder is fixed on the push cylinder fixed seat, the clamp holder is fixed on the fixed base plate, the clamping part and the clamp The cage is connected, the auxiliary pressing cylinder is fixed on the fixed base plate, the front support block and the rear support block are connected with the fixed base plate, the workpiece positioning block is fixed above the front support block and the rear support block, and the ...

Embodiment 2

[0030] A compact pneumatic tooling of the present invention includes a fixed base plate, a push cylinder fixing seat, a main push cylinder, a fixture holder, a workpiece, a fixture clamping part, a pressing auxiliary cylinder, a positioning block, a The main push-down cylinder, a support block, the rear support block, the fixed base of the push cylinder is fixed on the fixed base, the main push cylinder is fixed on the fixed base of the push cylinder, the clamp holder is fixed on the fixed base, and the clamping part is connected with the clamp holder , the auxiliary cylinder for pressing down is fixed on the fixed base plate, the front support block and the rear support block are connected with the fixed base plate, the workpiece positioning block is fixed above the front support block and the rear support block, the auxiliary pressing cylinder is fixed on the fixed base plate, and the clamp The cages are connected to form a compact pneumatic tooling containing a station, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com