Patents

Literature

99results about How to "Improve curing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-resistance electric heating curing method for resin-based carbon fiber composite material

The invention provides a self-resistance electric heating curing method for a resin-based carbon fiber composite material. Heat required for resin curing is provided in such a manner of performing ohmic heating on carbon fibers, and simultaneously, in combination with pressure molding implemented by a pressure tank, a desired part finally can be obtained. The self-resistance electric heating curing method for the resin-based carbon fiber composite material is characterized in that the electric heating manner is applied to a fiber-reinforced composite material, and ohmic heating is carried out on a preformed body of the resin-based carbon fiber composite material and the temperature of the preformed body is controlled in such a manner of controlling a power current; by adopting such a heating manner, the temperature is easy to control, the heating time is short, and the heating efficiency is high; a temperature distribution condition of the preformed body during heating curing can be improved, and finally, a resin-based carbon fiber composite material part with the quality meeting the requirements can be obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

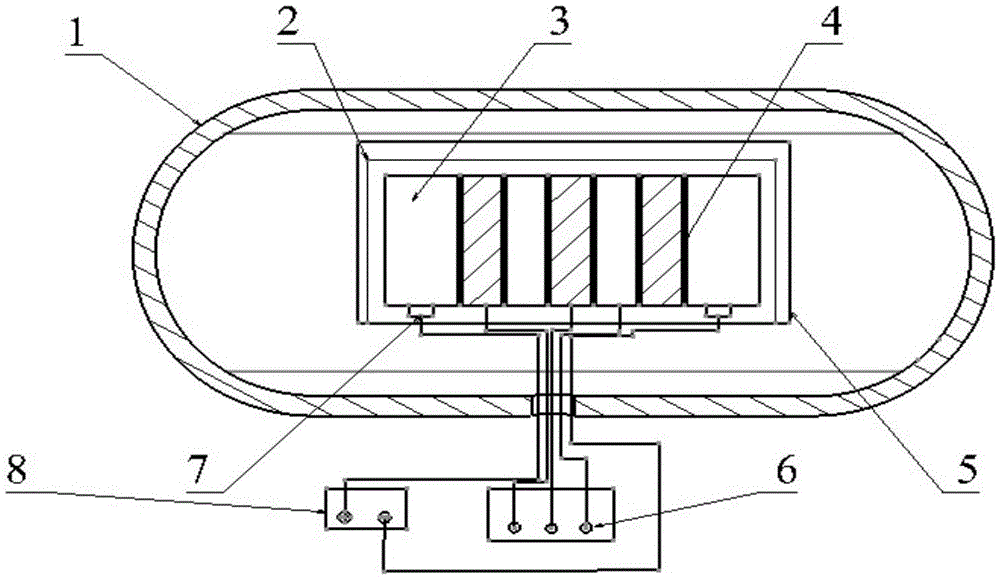

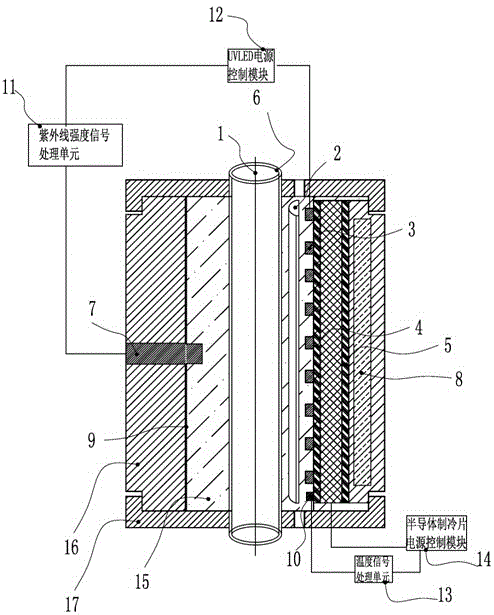

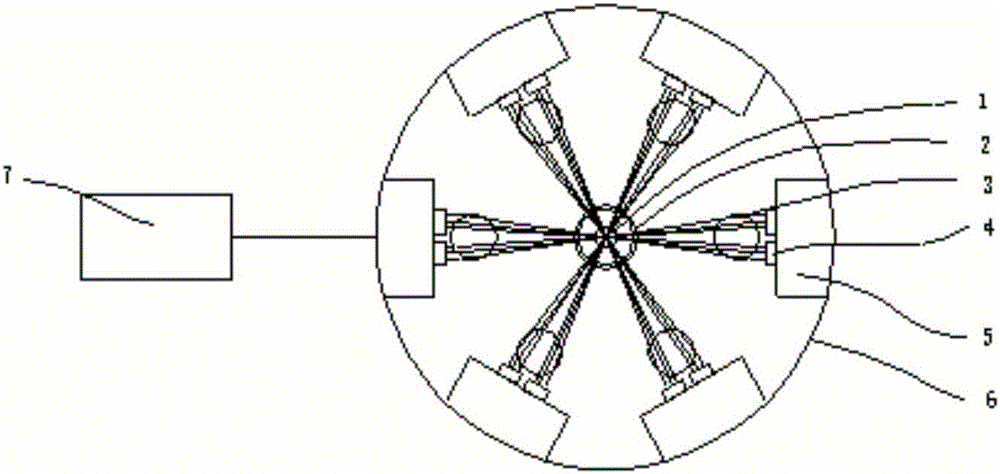

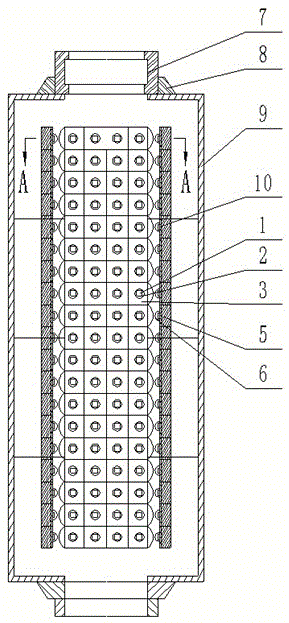

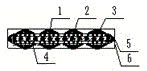

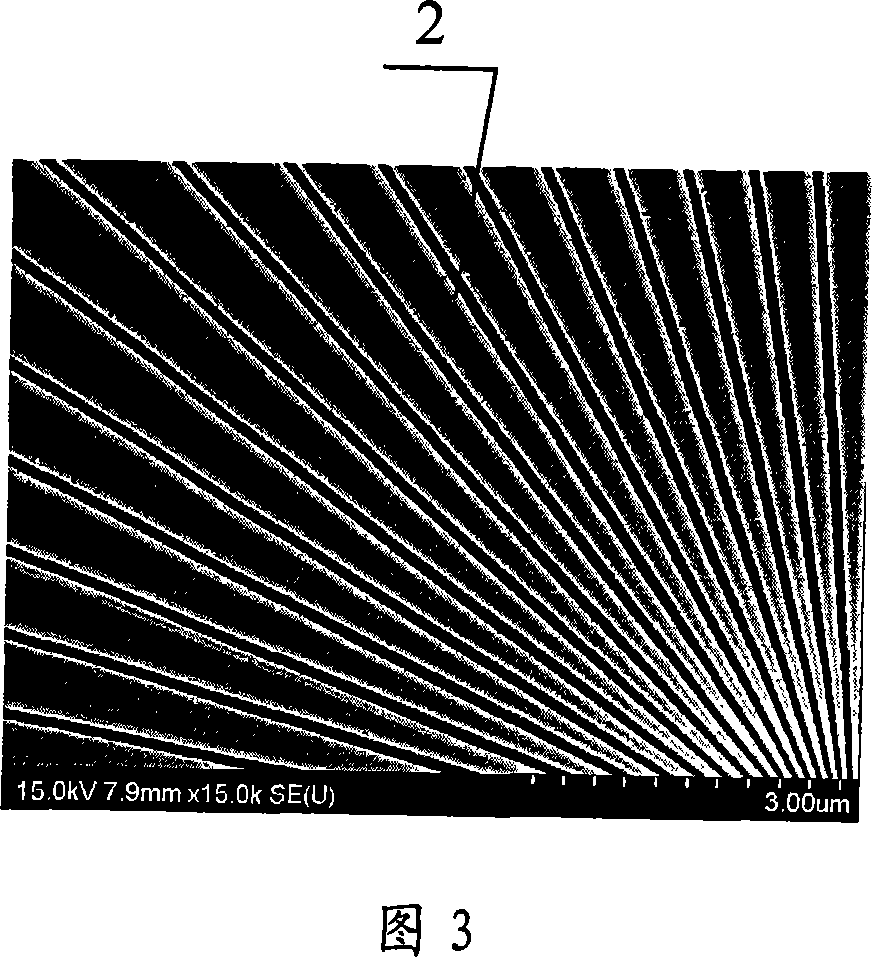

Light intensity-adjustable fiber coating layer ultraviolet curing apparatus

ActiveCN105060739AEfficient use ofSmall operating temperature fluctuationsElectrical apparatusElectroluminescent light sourcesClosed loopUltraviolet lights

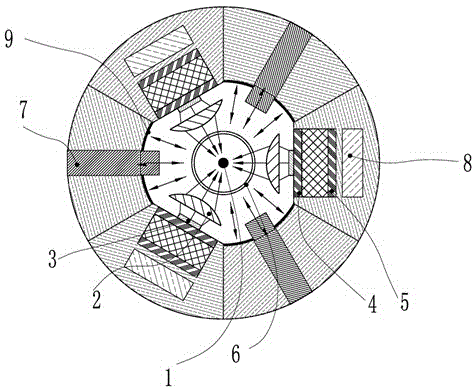

The invention relates to a light intensity-adjustable fiber coating layer ultraviolet curing apparatus. The apparatus comprises a cylindrical mounting base, UVLED light source modules are circumferentially and axially arranged in the inner cavity of the cylindrical mounting base, a cylindrical focusing lens is arranged in front of the luminescence surfaces of the UVLED light source modules to make ultraviolet lights emitted by the UVLED light source modules focused on a curing axis, an ultraviolet sensor is arranged in the inner cavity of the cylindrical mounting base, the ultraviolet sensor is connected with an UVLED power supply control module through an ultraviolet intensity signal processing module, and the UVLED power supply control module is connected with the UVLED light source modules to make the fiber drawing speed and the ultraviolet intensity form a control closed loop. The apparatus allows the output of UVLED light sources and the fiber drawing speed to be adjusted and matched in real time in order to guarantee and improve the fiber coating layer curing quality, efficiently utilize the UVLED light sources and save electric energy; and the apparatus has the advantages of reasonable and simple structure, high curing efficiency, less energy consumption, high automation degree, good coating layer quality and simple use.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

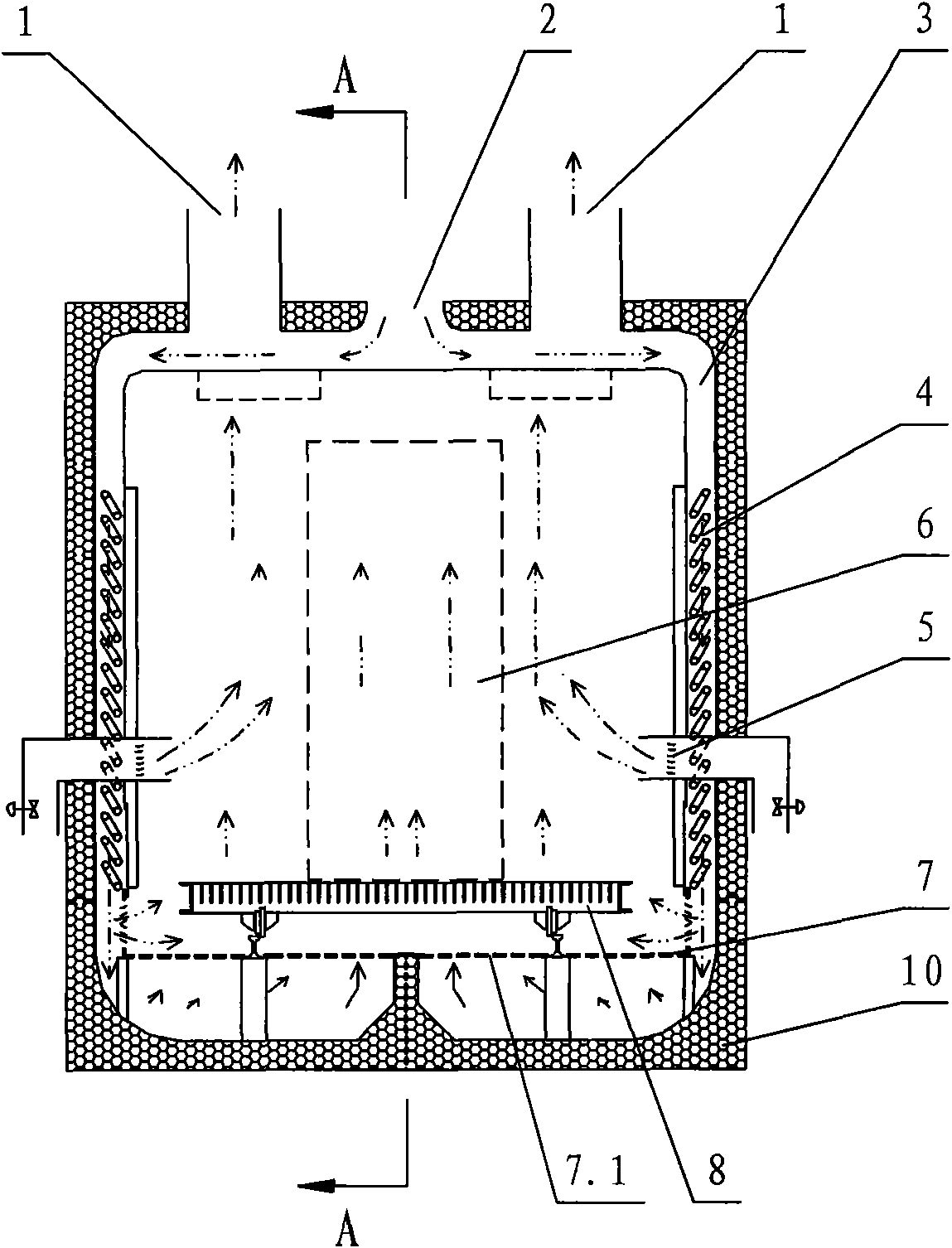

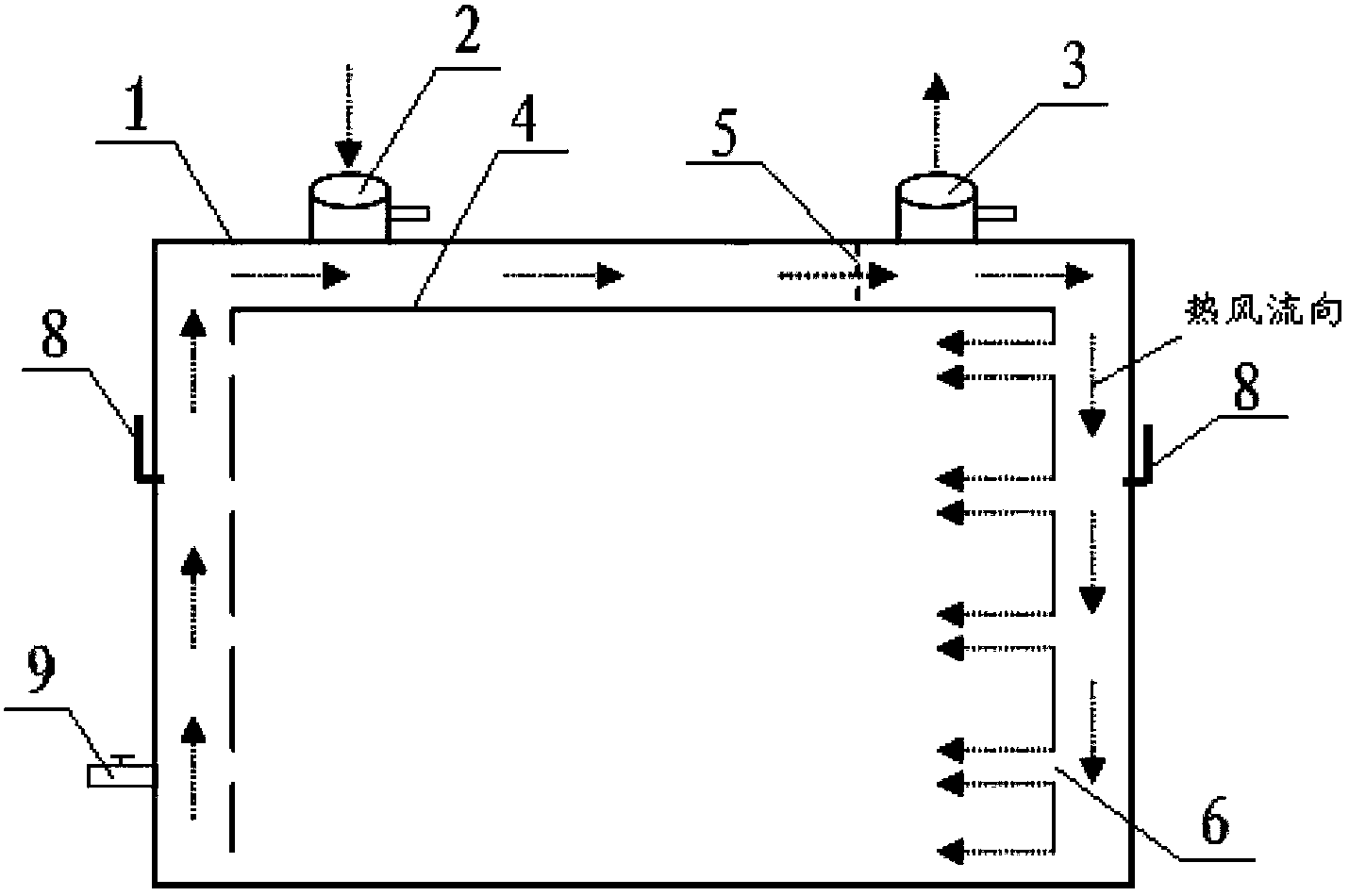

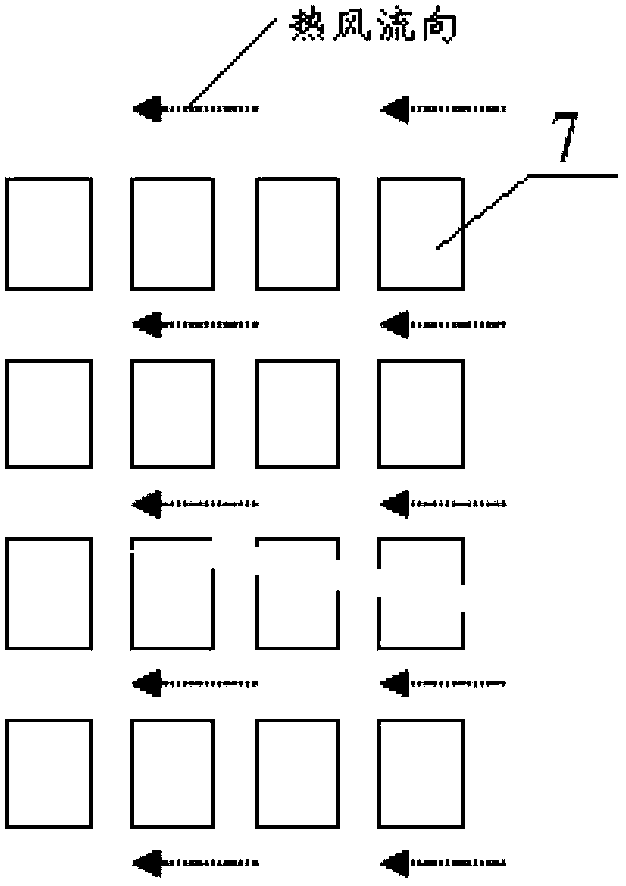

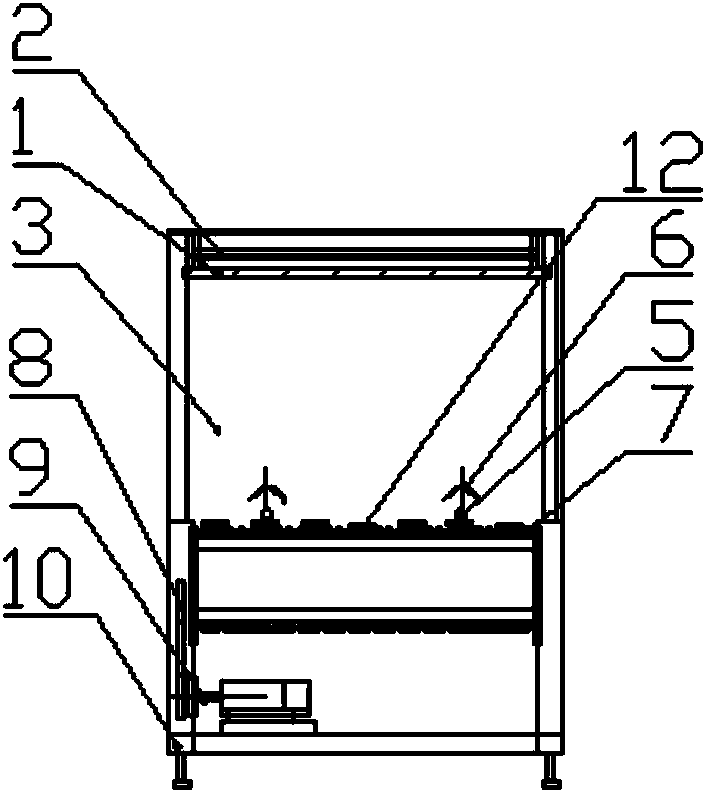

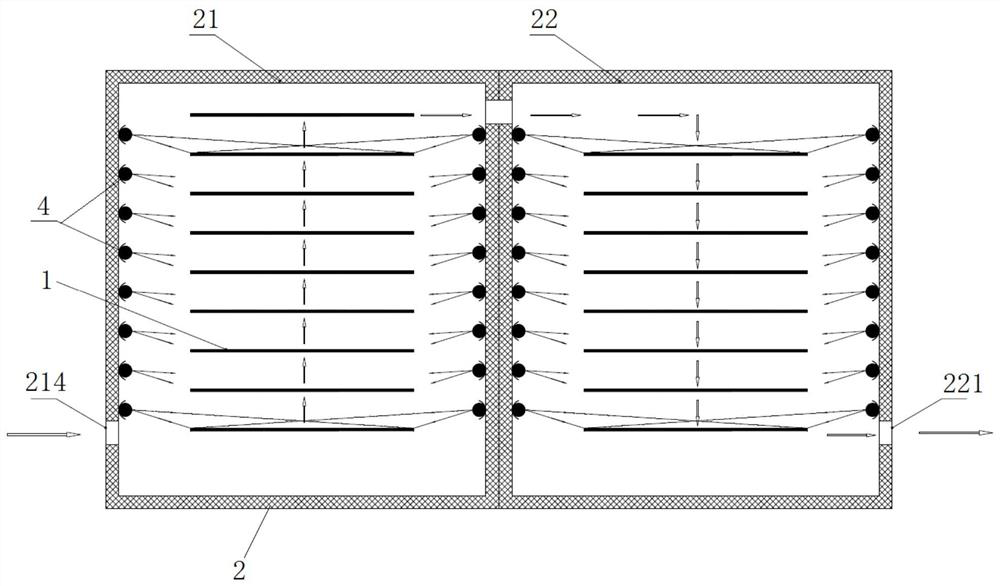

Special oven used for manufacturing cured epoxy resin dry type transformer coil and manufacturing method thereof

ActiveCN101599359ASimple structureEasy to operateFurnace typesCoils manufactureBiochemical engineeringTransformer

The invention provides a special oven used for manufacturing cured epoxy resin dry type transformer coil and a manufacturing method thereof. The top part of the special oven is provided with an exhaust air outlet and an air inlet, wherein, the exhaust air outlet is communicated with an inner chamber of the special oven and the side wall of the special oven is internally provided with an air channel; the air inlet is communicated with one end of the air channel; the air channel is internally provided with an electric heater; the middle lower part of the air channel is provided with an opening which is communicated with the inner chamber; bidirectional shutters are arranged on the opening; the bottom part of the special oven is provided with a base plate; the base plate and the bottom part of the special oven together enclose a lower chamber; the lower chamber is communicated with the other end of the air channel; the base plate is provided with an upturned air-out hole which is communicated with the inner chamber; a pouring mould is arranged on the base plate; the bottom part of the pouring mould is provided with a temperature sensor; a cavity is internally provided with a trolley; the pouring mould and the temperature sensor are arranged on the trolley. The invention is characterized by simple and reasonable structure, easy operation, good cure quality and high production efficiency.

Owner:顺特电气设备有限公司

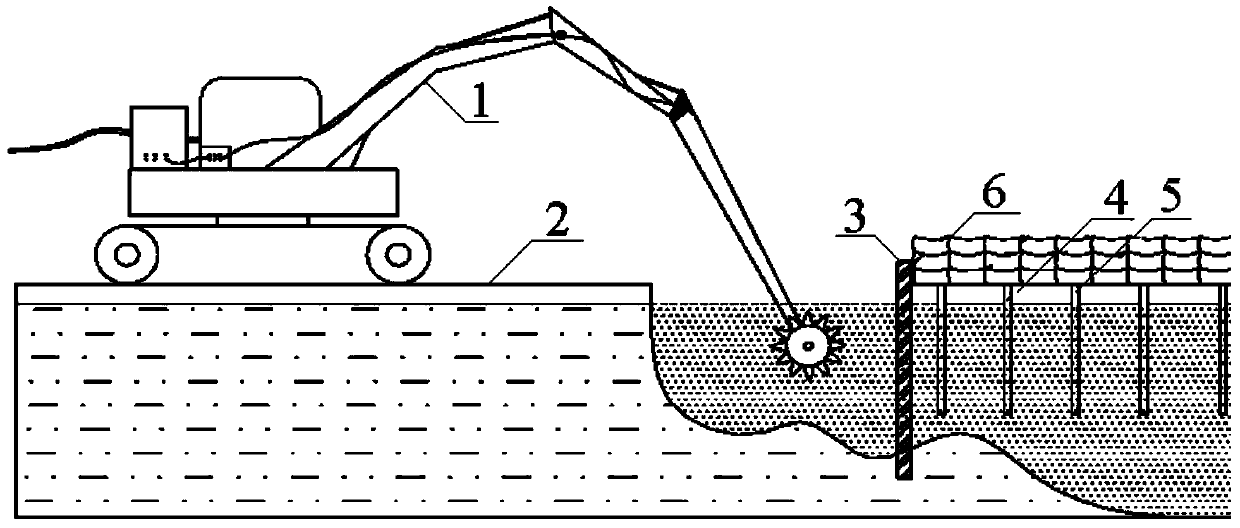

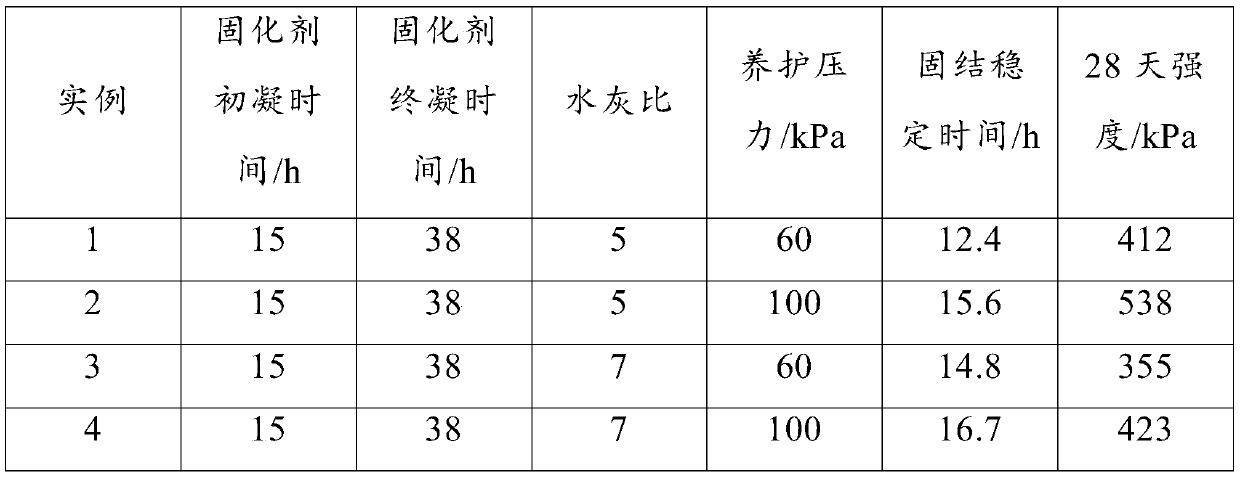

High-efficiency curing method for soft soil site with high moisture content

The invention belongs to the technical field of environment rock-soil engineering and discloses a high-efficiency curing method for a soft soil site with high moisture content. The high-efficiency curing method comprises an in situ chemical curing step and a preloading drainage step; the in situ chemical curing step comprises investigating sites, determining physical and chemical indexes such as depth, area, moisture content, organic matter content, liquid plastic limit and salt content of the soft soil site; blending a curing agent, determining the types, adding ratio, and initial and final setting time of the curing agent based on the physical and chemical indexes; blocking the site, and building partition walls for site blocking in the soft soil site; carrying out chemical curing construction, and uniformly mixing the blended curing agent with to-be-cured soft soil; carrying out preloading drainage construction according to three construction modes of vacuum preloading or surchargepreloading or vacuum surcharge preloading; unloading and repairing the site; after preloading time reaches 28 days, swabbing off drained water from the upper surface layer of curing blocks, unloadingand injecting cement slurry into a drain board for secondary repair and reinforcement by adopting a high-pressure grouting pump.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

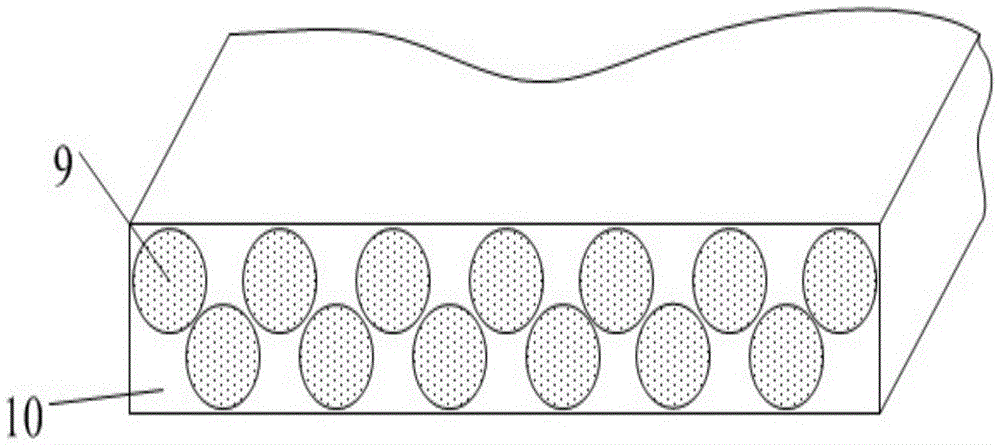

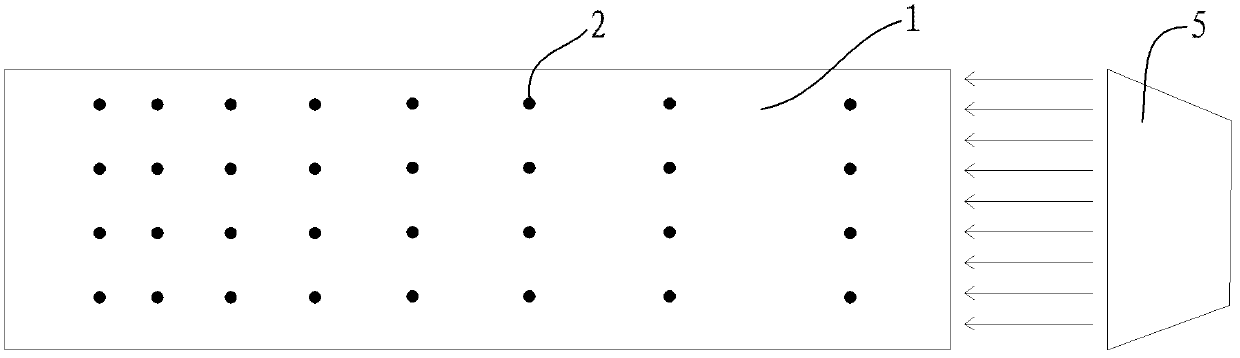

Optical fiber coloring and curing equipment

The invention discloses optical fiber coloring and curing equipment which comprises a cylindrical installing base. UVLED light source modules are installed in an inner cavity of the cylindrical installing base in the peripheral direction and the axial direction. Cylindrical surface focusing lenses are arranged in front of the light-emitting faces of the UVLED light source modules, and therefore ultraviolet light rays transmitted by the UVLED light source modules can be focused on a curing axis. The equipment is characterized in that the UVLED light source modules vertically arranged in the axial direction are arranged in a staggered mode in the peripheral direction, and one cylindrical surface focusing lens is correspondingly configured in front of each UVLED light source module. As the UVLED light source modules, arranged in the axial direction, of the adjacent sets are arranged in the staggered mode, light received by the surfaces of optical fibers is more uniform, the equipment has higher curing efficiency and better curing uniformity, curing time is shortened, and working efficiency and coating curing quality of optical fiber drawing are improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

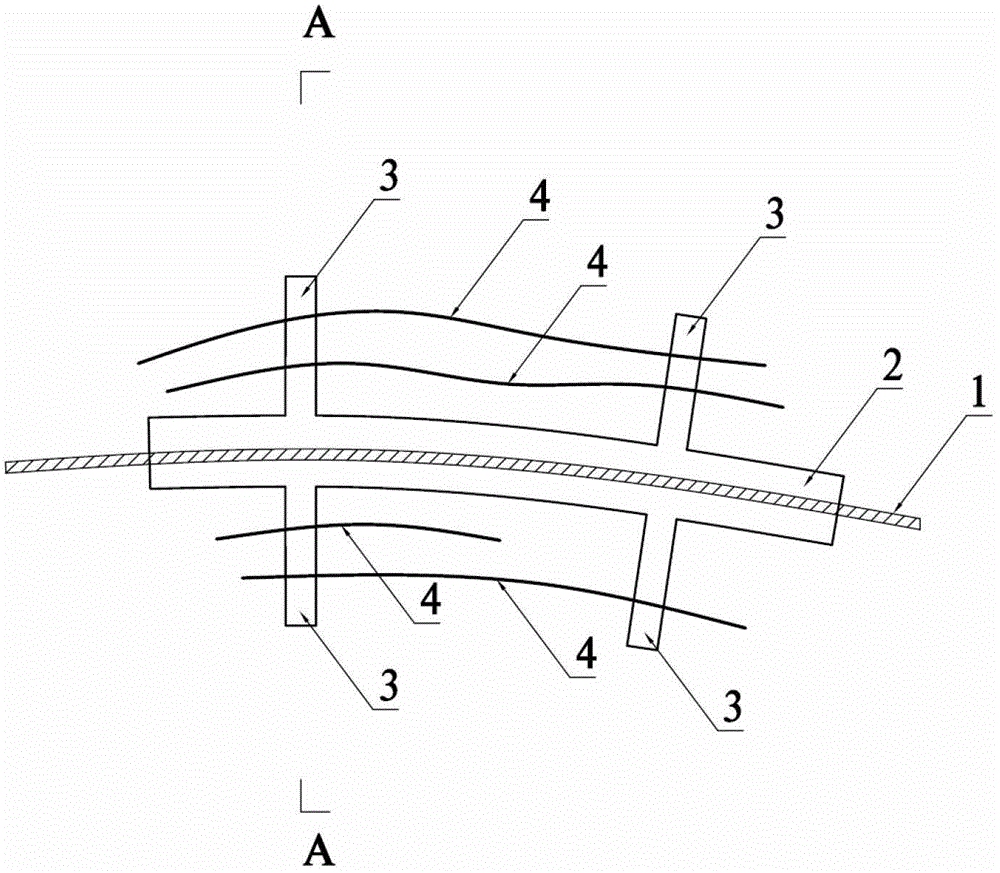

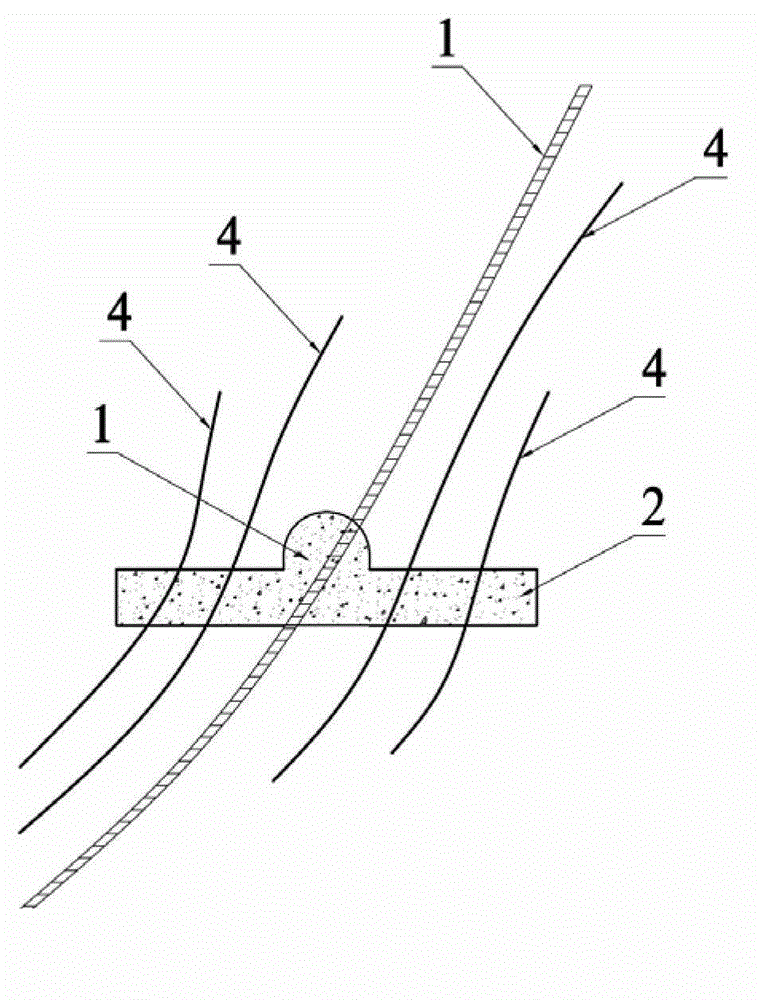

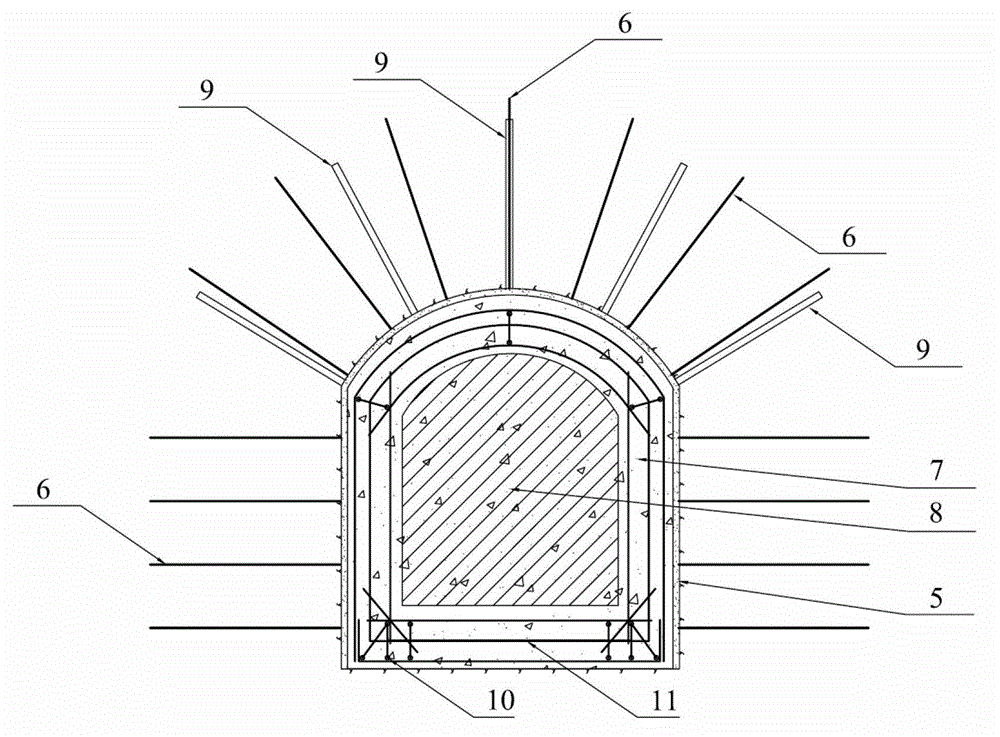

Construction method and structure for reinforcing large rock slope deep weak structural plane

ActiveCN102979531AEnough heat dissipationEnough cooling areaTunnelsSoil preservationStructure of the EarthRebar

The invention discloses a reinforcement construction method and particularly relates to a construction method for reinforcing a large rock slope deep weak structural plane. The construction method comprises the following steps: A, excavating a main tunnel along the direction of the deep weak structural plane of a rock slope, performing temporary support, and then drilling drainage holes on a tunnel soffit; B, excavating branch tunnels from two side walls of the main tunnel to the top wall and bottom wall directions of the deep weak structural plane, performing temporary support and then drilling drainage holes on tunnel soffits; and C, backfilling concretes into the main tunnel and the branch tunnels, and arranging steel bars to reinforce the backfilled concrete, wherein concrete backfilling is at least divided into two following construction period: in the first construction period, the backfilled concretes are backfilled along the peripheral inner walls of the main tunnel and the branch tunnels in a covering way, backfilling layers of the first construction period are formed on the walls of the main tunnel and the branch tunnels after the first construction period of concrete backfilling is finished, and the residual spaces of the main tunnel and the branch tunnels are utilized as grouting galleries; and after the backfilled concretes of the first construction period are solidified, the backfilled concretes of the residual construction period are utilized to fill the whole grouting galleries.

Owner:POWERCHINA CHENGDU ENG

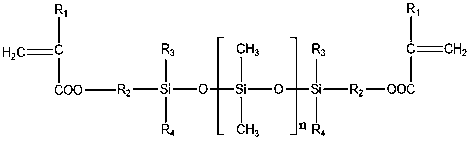

Ultraviolet)/moisture/thermal triple curing organic silicone adhesive

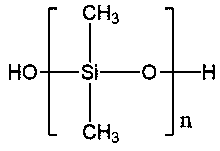

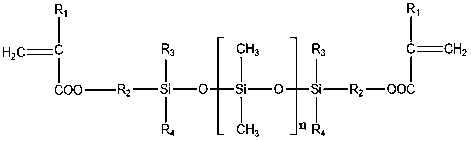

InactiveCN110396391AFast, efficient, energy-saving and environmentally friendlyUnfixed Problem SolvingNon-macromolecular adhesive additivesUltravioletDimethyl siloxane

The invention discloses an ultraviolet) / moisture / thermal triple curing organic silicone adhesive which comprises the following components in parts by weight: 100 parts of (methyl) acroloyl-oxy alkyl urea alkoxy silicon terminated dimethyl siloxane, 0.5-5 parts of a photoinitiator, 0.5-5 parts of a moisture curing catalyst, 0.5-5 parts of a free radical photoinitiator and 1.0-40 parts of fumed silica. The organic silicone adhesive can be applied to adhesion or encapsulation, a part exposed in the air can be rapidly cured through ultraviolet rays, a shadow area or a lighttight part can be curedthrough moisture or heating, the production efficiency can be greatly improved, and the problem that organic silicon is long in curing time and low in curing efficiency in mere moisture curing or thermal curing can be avoided.

Owner:郝建强 +1

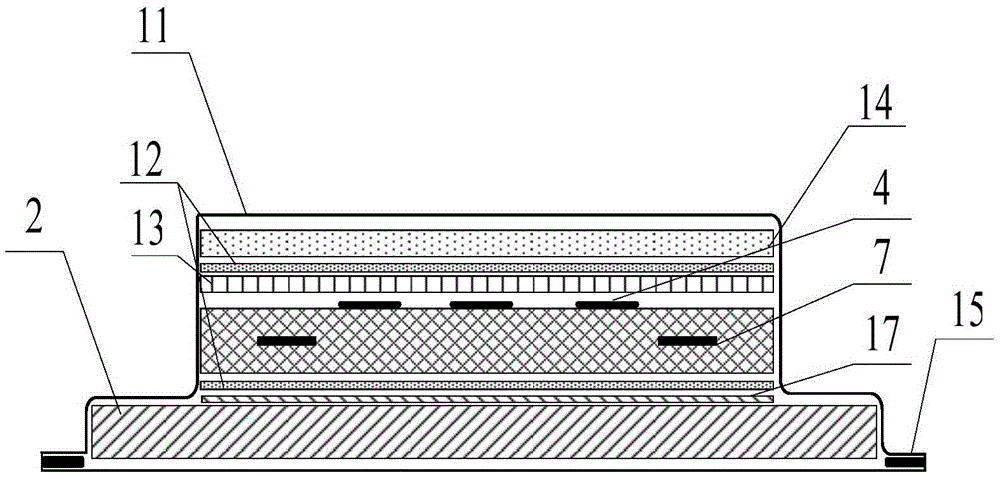

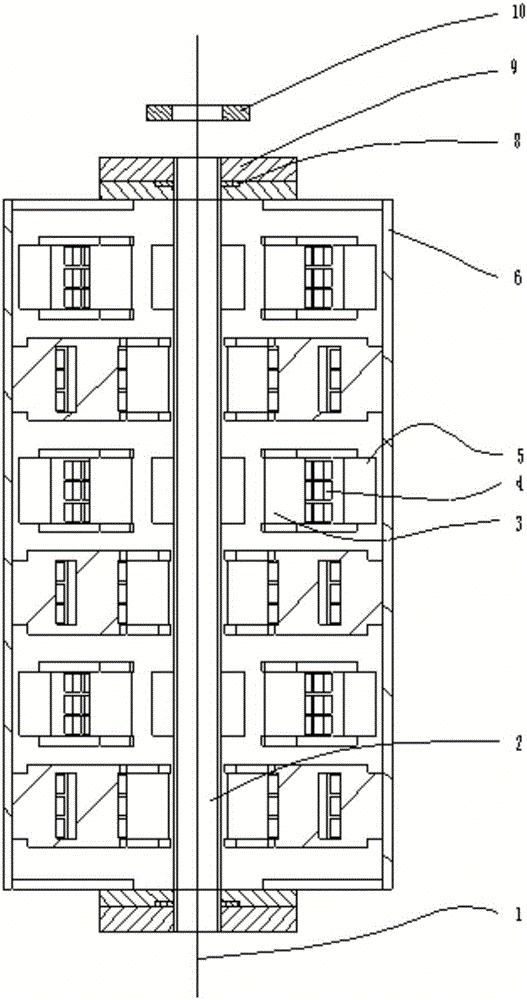

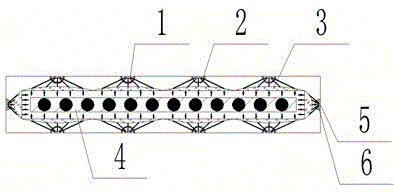

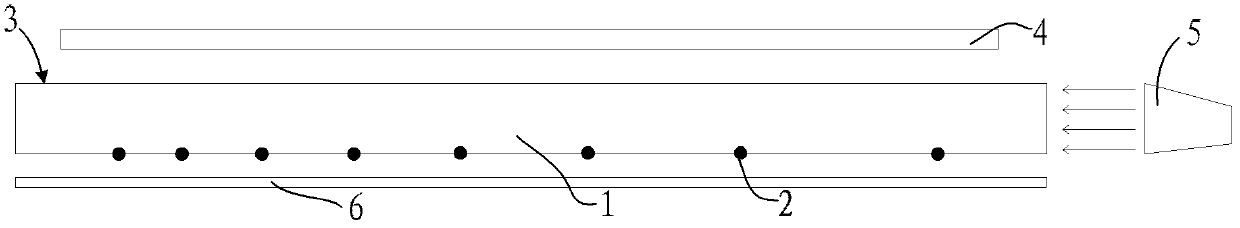

Optical fiber ribbon curing equipment

ActiveCN105521932AUniform radiationUniform light receivingPretreated surfacesCoatingsUltraviolet lightsEngineering

The invention discloses optical fiber ribbon curing equipment. The optical fiber ribbon curing equipment comprises a barrel-shaped base, and an optical fiber ribbon inlet and an optical fiber ribbon outlet are respectively formed in the upper end and the lower end of the barrel-shaped base. The optical fiber ribbon curing equipment is characterized in that UVLED light source modules are arranged in an inner cavity of the barrel-shaped base in the optical fiber ribbon passing direction and respectively correspond to the front surface and the rear surface of an optical fiber ribbon; luminous surfaces of the UVLED light source modules face inwards correspondingly; and a hemispherical diffuser and a hemispherical lens light uniformizing film are arranged in the front of each UVLED light source module. The UVLED light source modules serve as UV radiation sources, so that energy consumption of the equipment can be reduced remarkably, and the purposes of energy conservation and environmental friendliness are achieved; the UVLED light source modules are respectively arranged on the front surface, reverse surface and two sides of the optical fiber ribbon, so that radiation of ultraviolet light is even; and the surface of the optical fiber ribbon is illuminated evenly so that the equipment has high curing efficiency and good curing uniformity, curing time is shortened, work efficiency of optical fiber ribbon combination is improved, and curing quality of coatings is also improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Vacuum electroplating glass process

The invention discloses a process for performing vacuum plating on glass. The method comprises the following steps of: (1) cleaning the surface of a glass semi-finished product, namely soaking the glass semi-finished product in cleaning liquid medicine for 5 to 10 minutes; (2) performing electrostatic dust removal on the glass semi-finished product; (3) spraying primer, heating the primer and the semi-finished product to the temperature of between 60 and 80 DEG C, wherein the line speed of a production line is between 6 and 12 meters / minute; (4) illuminating by ultraviolet rays, namely illuminating for 5 to 10 seconds, wherein the distance between an ultraviolet (UV) tube and a product is between 15 and 20 centimeters, and the distance between key positions or dead angle positions of the UV tube and the product is between 10 and 15 centimeters; (5) plating a film under vacuum, wherein the thickness of the film is between 15 and 500 nanometers, and a film plating layer is an aluminum layer or a chromium layer; (6) spraying finishing paint, namely heating the finish paint and a film plating finished product to the temperature of between 60 and 80 DEG C uniformly, wherein the line speed of the production line is between 6 and 12 meters / minute; and (7) illuminating by the ultraviolet rays, namely illuminating for 5 to 10 seconds, wherein the distance between the UV tube and the product is between 15 and 20 centimeters, and the distance between key positions or dead angle positions of the ultraviolet tube and the product is between 10 and 15 centimeters. By the process for performing vacuum plating on the glass, the adhesive force of coatings is enhanced, and the curing quality of coating layers is improved.

Owner:HANGZHOU SANJING ART CRAFT PLASTIC

Method for improving curing forming quality of L-shaped composite material laminated plate

The invention discloses a method for improving a curing forming quality of an L-shaped composite material laminated plate. The method comprises the following steps that (1), an elastomer material is selected, and an elastomer buffer flexible film is manufactured according to the contour dimension of a component; (2) vent holes are uniformly formed in the elastomer buffer flexible film in the thickness direction after the elastomer buffer flexible film is formed; and (3) the L-shaped composite material component is prepared, a prepreg laminated layer is paved on a rigid die according to the paving ratio, the outer surface of the laminated layer is covered with the prepared elastomer buffer flexible film, and a vacuum bag pressing method or a drying oven is adopted for curing and forming according to the set temperature and pressure curves. According to the method, the pressure borne by a part with the curvature of the composite material component in the forming process can be balanced through the introduction of the elastomer buffer flexible film, fibers can be prevented from generating micro-bending in the forming process, fiber wrinkles are prevented from being generated on the surface of the composite material laminated plate, and therefore the surface quality of the composite material laminated plate is improved, and the stability of the outer side dimension of the compositematerial component with the curvature is ensured.

Owner:WUHAN UNIV OF TECH

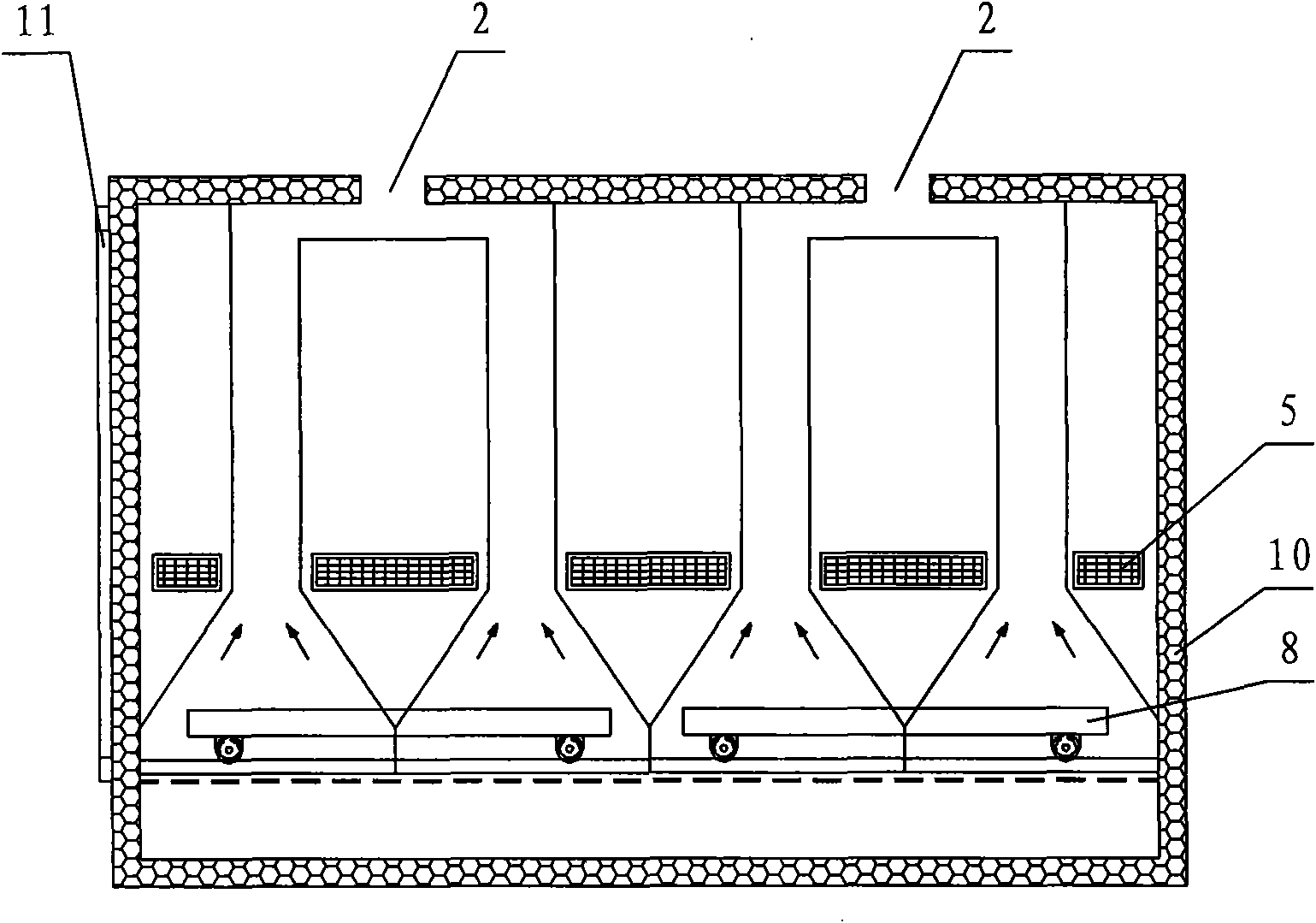

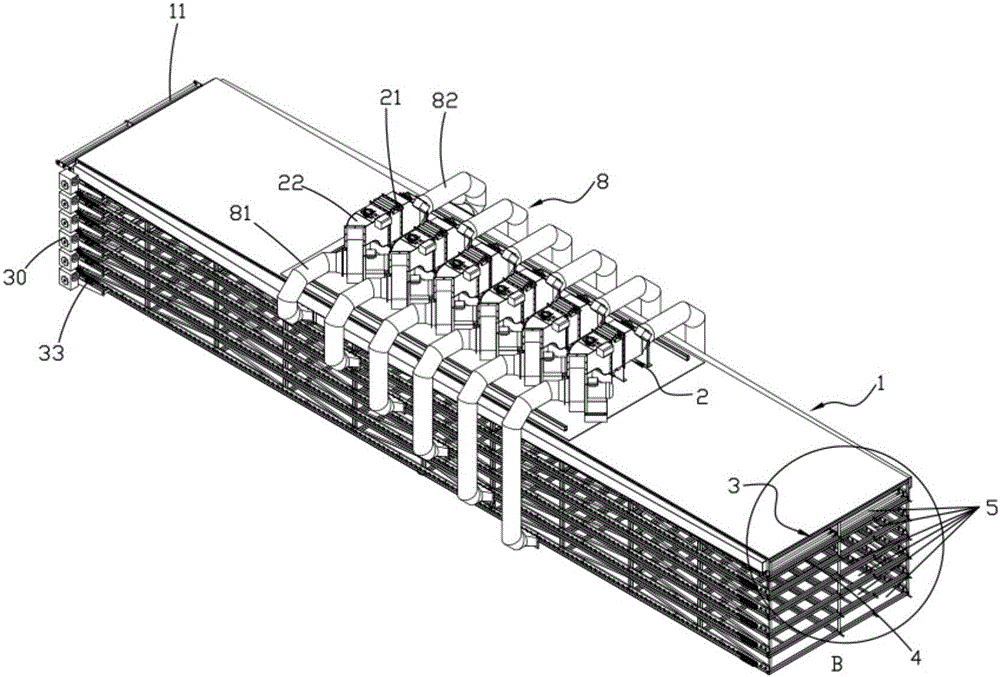

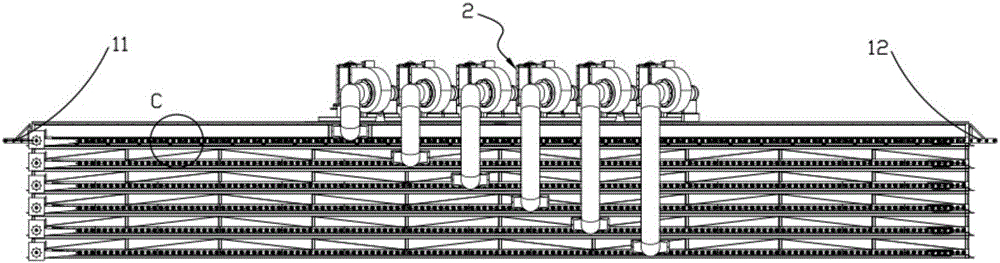

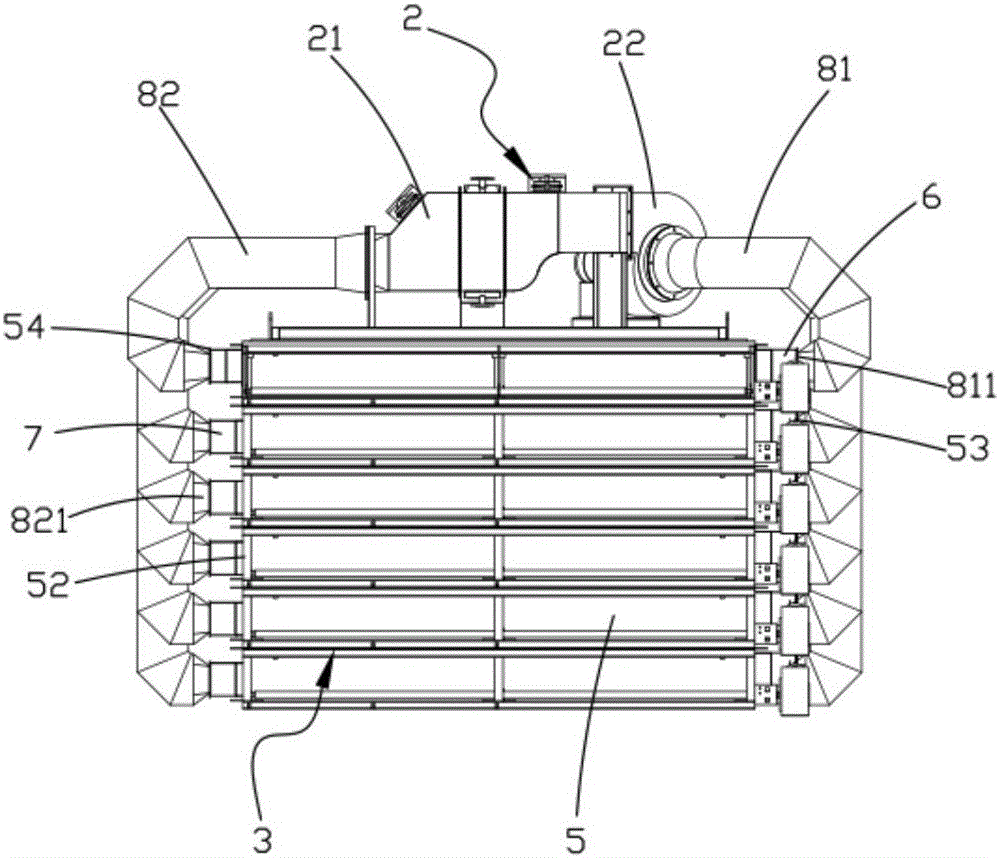

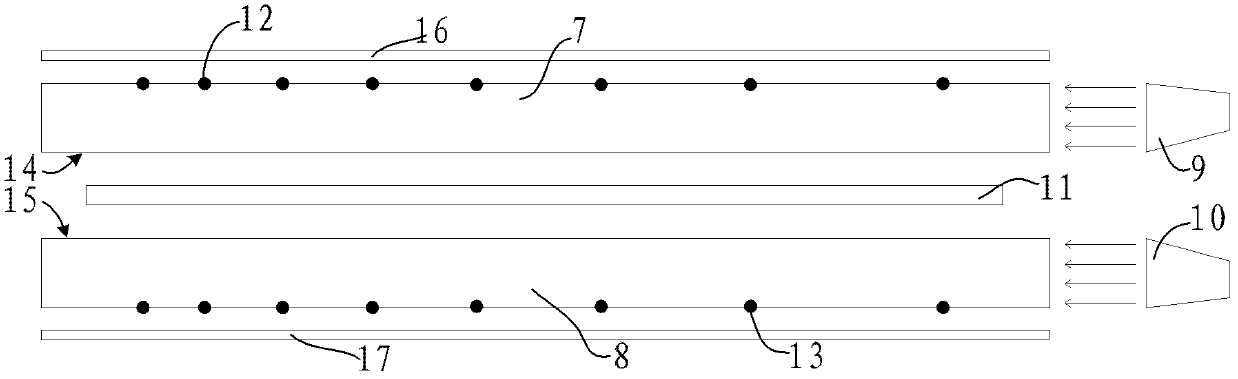

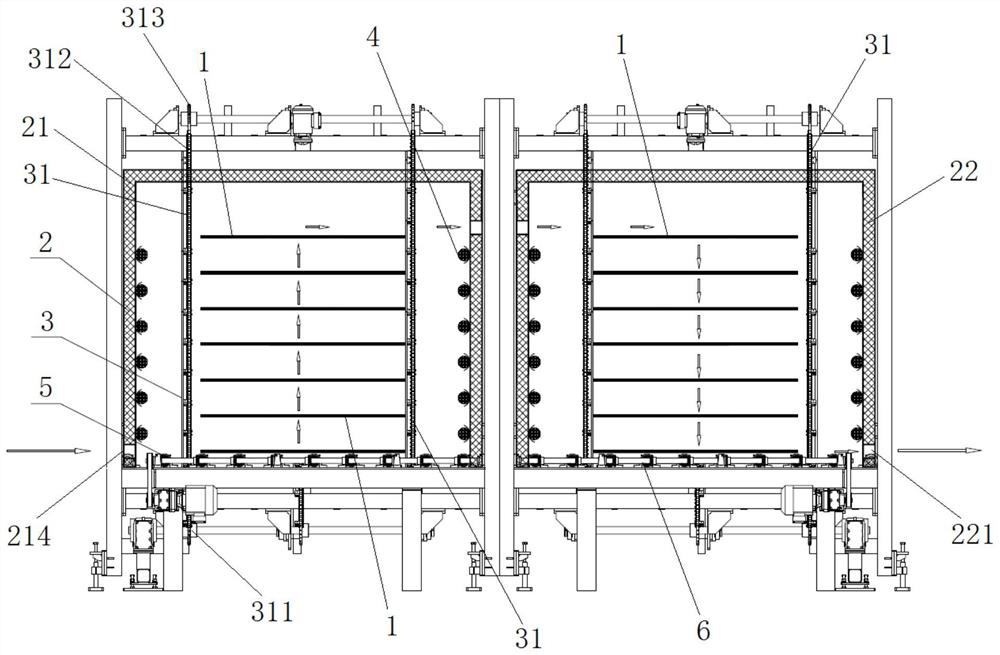

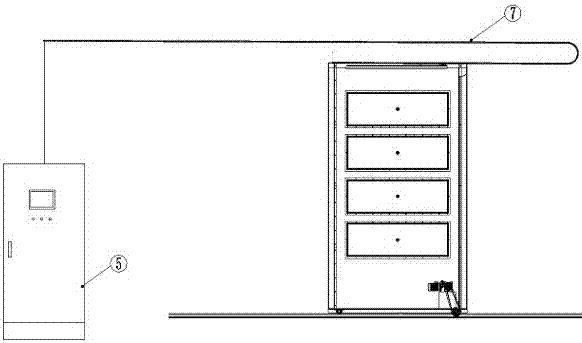

Continuous automatic drying solidification device

ActiveCN105964518ACompact and reasonable structureSmall footprintPretreated surfacesLead-acid accumulator electrodesEngineeringHumidity

The invention relates to a continuous automatic drying solidification device. The continuous automatic drying solidification device comprises a solidification room and heat exchange systems. Each heat exchange system comprises a humidification heater and an air draft unit. At least two sets of horizontal conveying units arranged in a layered mode from top to bottom are arranged in the solidification room. A partition plate is fixedly arranged at the bottom of each layer of conveying unit. Independent solidification chambers are formed by closed spaces between the partition plate on the first layer and the top of the solidification room, between two adjacent partition plates and between the partition plate on the tail layer and the bottom of the solidification chamber. An air inflow channel and an air outlet channel communicated with each solidification chamber are formed between a first outer shield plate and a second outer shield plate and the two side walls of the solidification chamber, wherein the first outer shield plate and the second outer shield plate are arranged on the outer portions of the two side walls of the solidification chamber respectively. Each solidification chamber is provided with one independent heat exchange system. A flow guide mechanism is arranged in each air inflow channel. The independent solidification chambers are formed in the solidification room, different products can be operated at the same time, the product placement intensity is high, the heat utilization rate is high, and temperature and humidity fields in the solidification chambers are stable.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

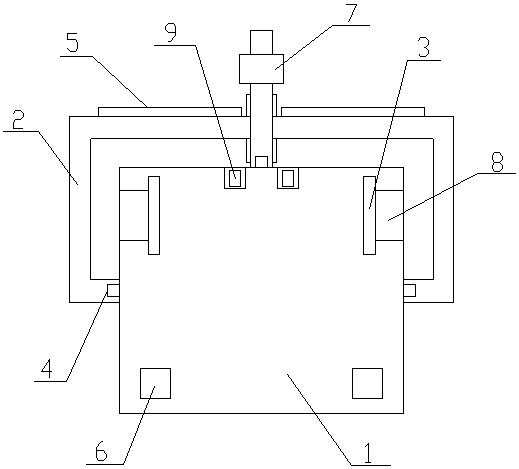

Touch screen shadow region solidifying device

ActiveCN103272750AImprove efficiencyImprove curing qualityPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a touch screen shadow region solidifying device which comprises a machine frame, a solidifying table, a lifting mechanism and a circulating material feeding mechanism. The lifting mechanism ejects products to be solidified up and conveys the products to the solidifying table, wherein the products to be solidified are horizontally placed and conveyed by the circulating material feeding mechanism, and the lateral surface parts of the products to be solidified correspond to four groups of solidifying lamps respectively so as to enable solidifying light to enter shadow regions of the products from lateral seams for solidifying. The touch screen shadow region solidifying device can finish circumferential solidifying operation by one-time position, meanwhile can adapt to the products to be solidified with different specifications and has the advantages of being high in efficiency, high in solidifying quality and the like.

Owner:XIAMEN LIJU AUTOMATION TECH

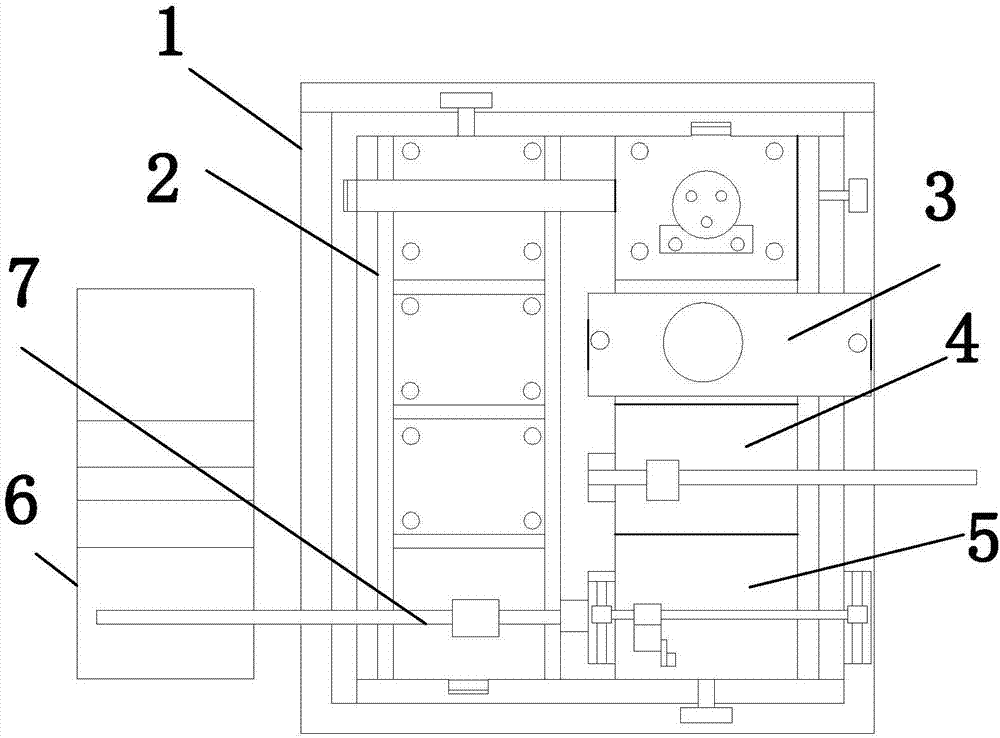

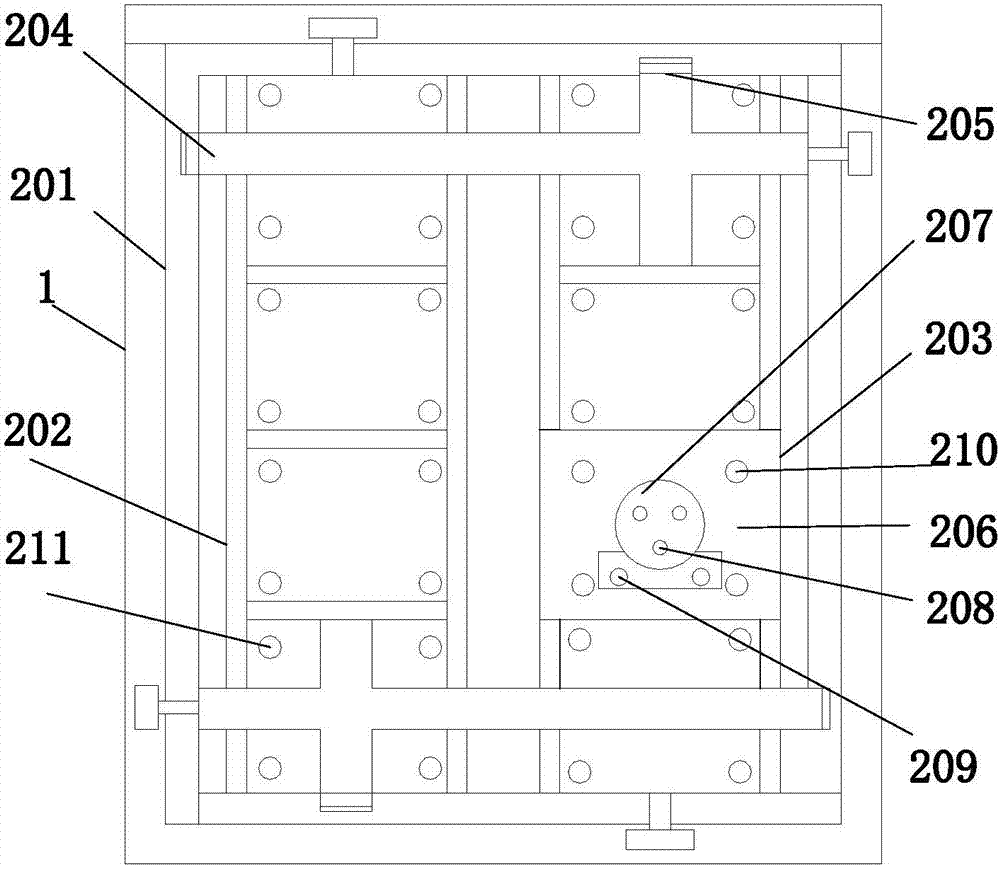

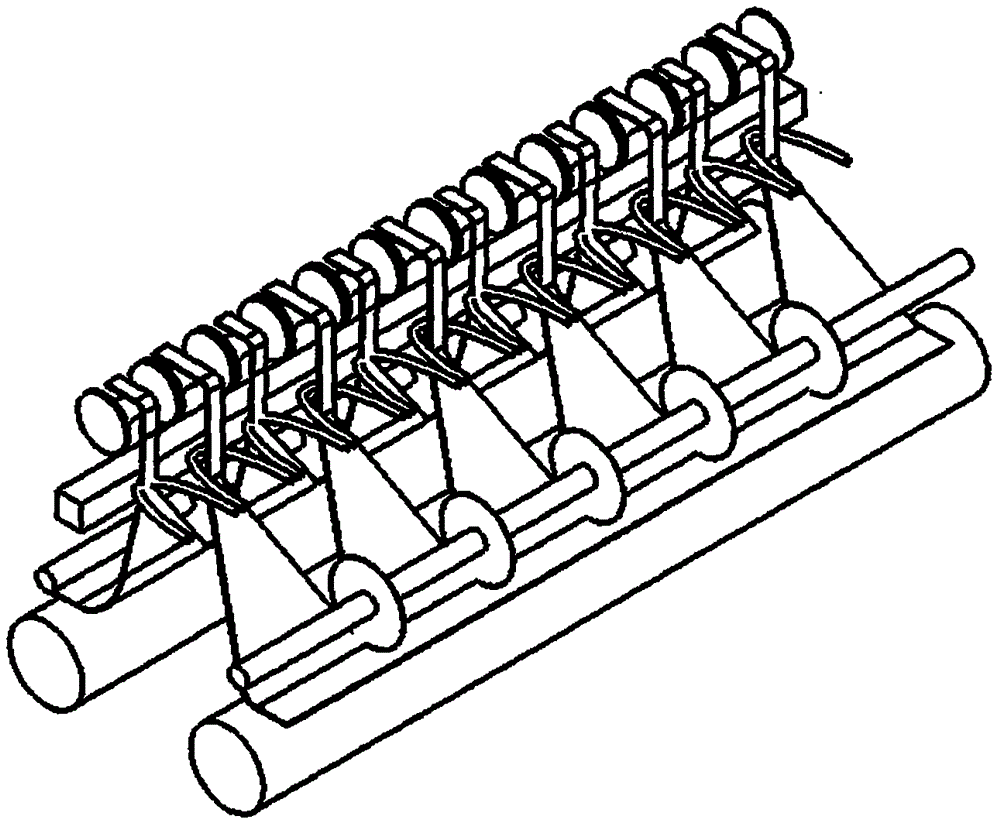

UV glue-dispensing curing machine and curing process

ActiveCN107240996AIncrease productivityImprove overall qualityLiquid surface applicatorsManufacturing dynamo-electric machinesStatorUV curing

The invention discloses a UV glue-dispensing curing machine and a curing process. The UV glue-dispensing curing machine comprises a stator conveying apparatus (2), a stator line-cutting apparatus (3), a waste material recycling apparatus (4) and a glue-dispensing apparatus (5) which are arranged on a rack (1); the UV glue-dispensing curing machine also comprises a curing apparatus (6) arranged on the side surface of the rack (1); and a material-taking apparatus (7) is arranged between the curing apparatus (6) and the glue-dispensing apparatus (5). Redundant lines can be cut off by the stator line-cutting apparatus; then the recycled waste material is clamped through the waste material recycling apparatus; next, the stator is coated with glue through the glue-dispensing apparatus; and the glue-dispensed stator is moved to the curing apparatus through the material-taking apparatus to perform UV curing. The UV glue-dispensing curing machine and the curing process have the characteristics of effectively improving production efficiency, lowering production cost, relieving labor intensity of workers and improving the glue-dispensing and curing quality.

Owner:浙江伟康电机有限公司

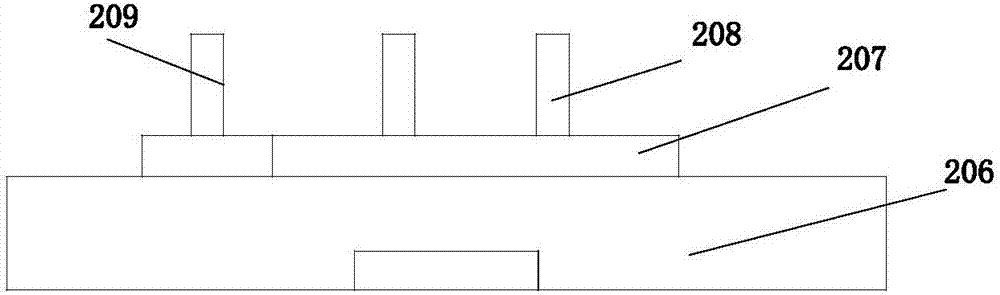

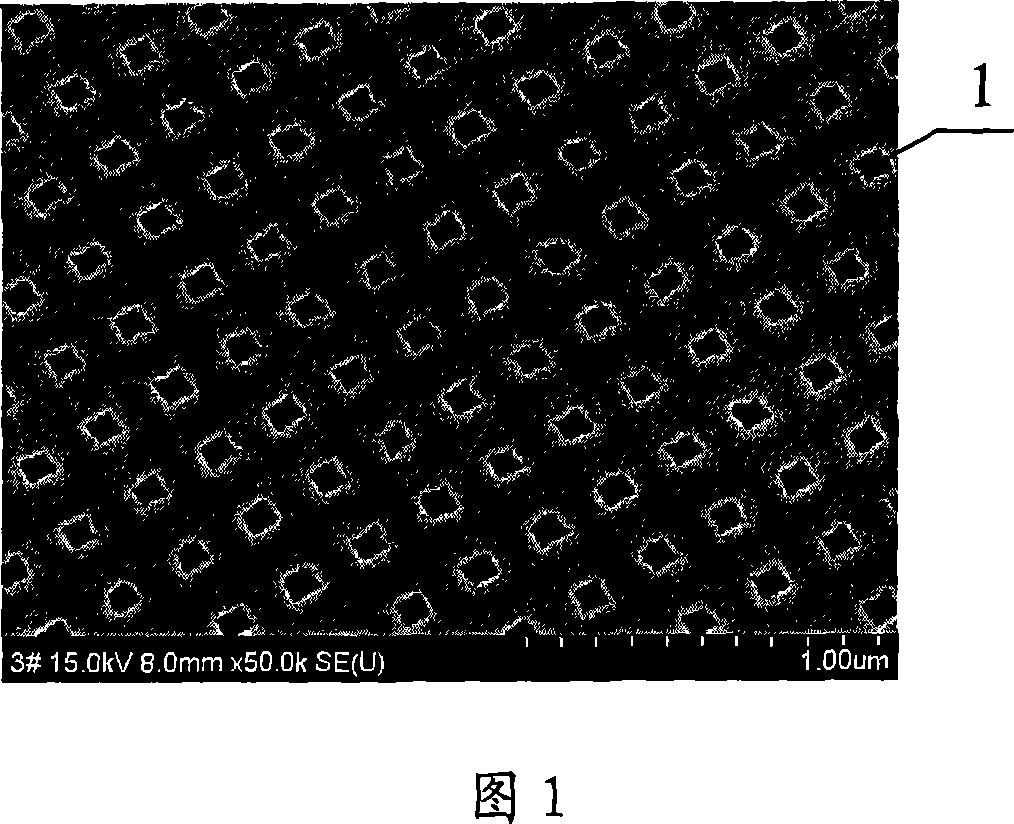

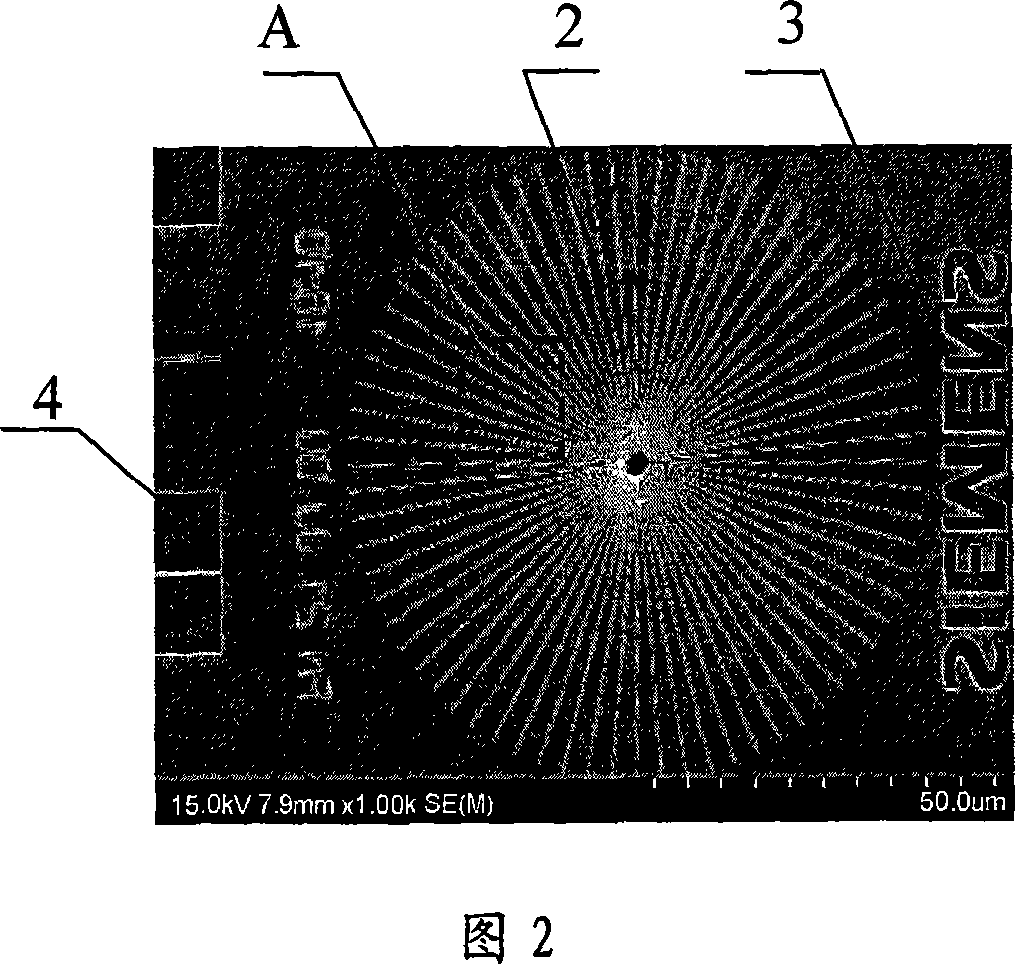

Ultraviolet photo-cured radical type etching glue for micro nano structure imprinting and copying

InactiveCN101055419AIncreasing the thicknessGood chemical resistancePhotomechanical apparatusMicro nanoTripropylene glycol

The invention relates to a micro-nano structural imprint-copy-used ultraviolet light curing free radical type etching gum which has the composing of: a curing body 1 is bisphenol A-epoxy acrylic ester or phenolic epoxy acrylic ester which is 24 to 48% by weight, a curing body 2 also a thinner is tripropylene glycol genus acrylic ester which is 20 to 46% by weight, a curing auxiliaries is dipentaerythritol-6-acrylic ester or GP-537 or GP-71-SS which is 5 to 16% by weight, a photo-initiation is 2,4,6-methylbenzene formyl radicel diphenyl phosphine oxide which is 5 to 16% by weight, the sum of each weight of the component is 100%. In addition, in order to regulate the viscosity of the solution, the thinner 1,6hexandiol twain acrylic ester is added until the viscosity of the solution is satisfied. Compared with the other gum, the gum of the invention has the advantages of: high curing speed, small constringency, low viscosity, high adhesive force, strong against corrosion, simple confect art and convenient application.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

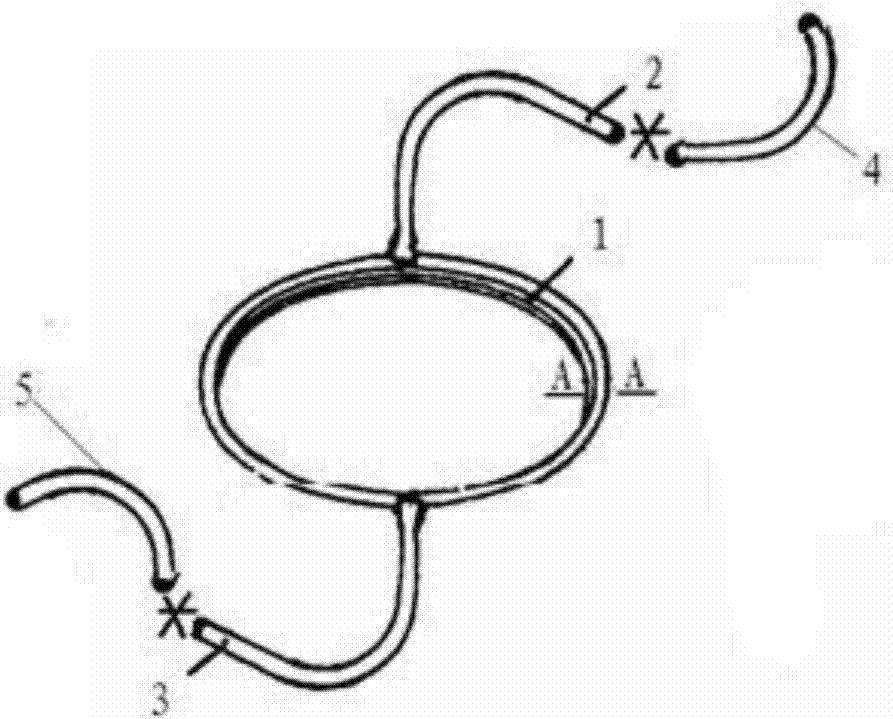

Ultraviolet curing irradiation device, system and method

InactiveCN103287088AUniform irradiationUniform curingPrinting press partsLight guideUltraviolet lights

The invention provides an ultraviolet curing irradiation device comprising a light guide plate and at least one ultraviolet light source, wherein a workpiece to be irradiated is arranged on the emergent side of the light guide plate; the at least one ultraviolet light source is arranged outside the light guide plate and on the side vertical to the emergent surface of the light guide plate; and lattice points on the light guide plate reflects ultraviolet rays emitted by the ultraviolet light source to the workpiece to be irradiated. The invention also provides an ultraviolet curing irradiation system and an ultraviolet curing irradiation method. According to the technical scheme of the invention, uniform curing of a film can be realized, the film is flat and does not warp after being cured, and the curing quality is improved.

Owner:HISENSE VISUAL TECH CO LTD

Laminated inorganic pipeline and preparation method thereof

ActiveCN107202203APrecise Polymerization and CuringStable polymerization curingSynthetic resin layered productsLaminationPipeline transportSlurry

The invention discloses a laminated inorganic pipeline and belongs to the technical field of pipeline transportation. The laminated inorganic pipeline comprises a first-diameter pipeline body and a second-diameter pipeline body with different diameters. The first-diameter pipeline body is sleeved with the second-diameter pipeline body to form the laminated inorganic pipeline. A central hole is formed in the first-diameter pipeline body. An interlayer is formed between the first-diameter pipeline body and the second-diameter pipeline body. The interlayer is filled with slurry, and the slurry solidifies to form a polymer middle layer. The slurry comprises a prepolymer and inorganic modified powder. The mass ratio of the prepolymer to the inorganic modified powder is 1:(0.01-3.0). The invention further discloses a preparation method for the laminated inorganic pipeline. According to the laminated inorganic pipeline, the inorganic modified powder is added into the prepolymer, and the mechanical property is remarkably improved; the prepolymer can aggregate and solidify in a more accurate and more stable environment, and the solidification quality is improved; and the preparation method provided by the invention is simple in process, easy to apply and popularize, and quite good in practicability.

Owner:SUZHOU SHINWU OPTRONICS TECH

Smelting process for high strength and ductility die-cast A356 aluminum alloy

The invention belongs to the technical field of smelting of aluminum alloy and particularly relates to a smelting process for high strength and ductility die-cast A356 aluminum alloy. The smelting process for the high strength and ductility die-cast A356 aluminum alloy comprises the steps of raw material melting, deslagging and refining, wherein molten aluminum liquid is treated through a combinedrefining modificator obtained by mixing mixed rare earth, Al-Zn intermediate alloy and Al-Ag intermediate alloy in Al-Ti-B, Al-Ti-C, Al-Sr and Al-Zr; the additive amount of the mixed rare earth is 0.01-0.03wt% of the total amount of the molten aluminum alloy liquid, the additive amount of the Al-Zn intermediate alloy is 0.012-0.02wt% of the total amount of the molten aluminum alloy liquid, and the additive amount of the Al-Ag intermediate alloy is 0.04-0.09wt% of the total amount of the molten aluminum alloy liquid. According to the smelting process, the molten aluminum liquid is treated by adding the combined refining modificator, and a traditional air suction reaction caused by Al-Sr modification is avoided while a long-time modification effect is maintained; and besides, by the adoption of a combined refiner provided by the invention, a special-shaped core is formed in melt more efficiently, the solidification efficiency and solidification quality of the aluminum alloy are improved, and the obtained A356 aluminum alloy has the technical characteristic of high strength and ductility.

Owner:ZHEJIANG QIANGGUANGJIAN PRECISION CASTING CO LTD

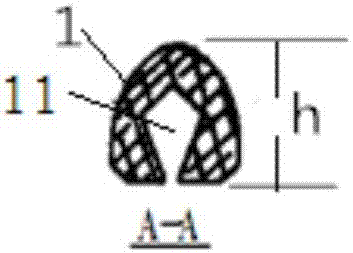

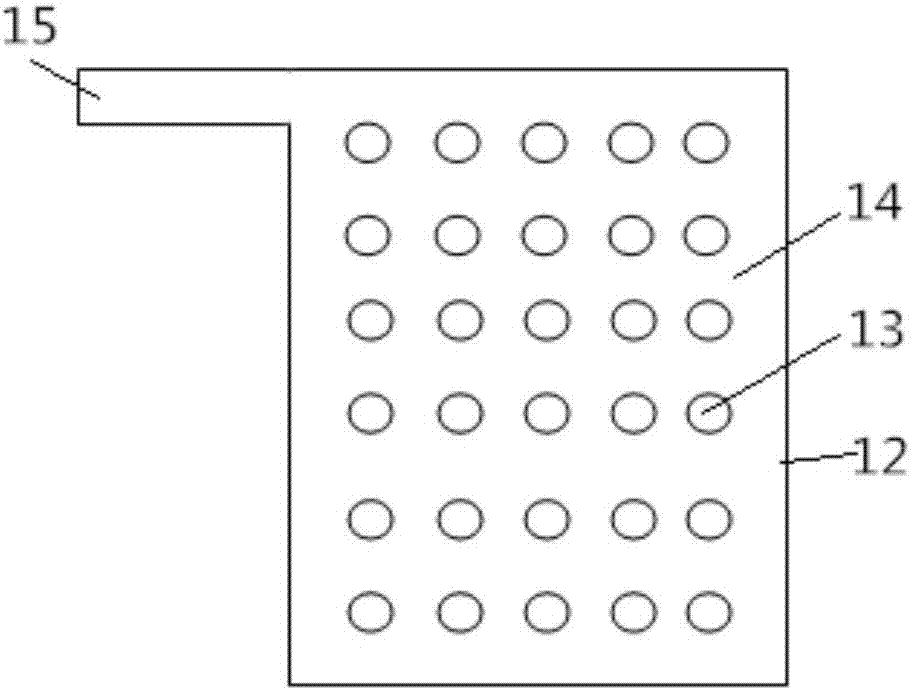

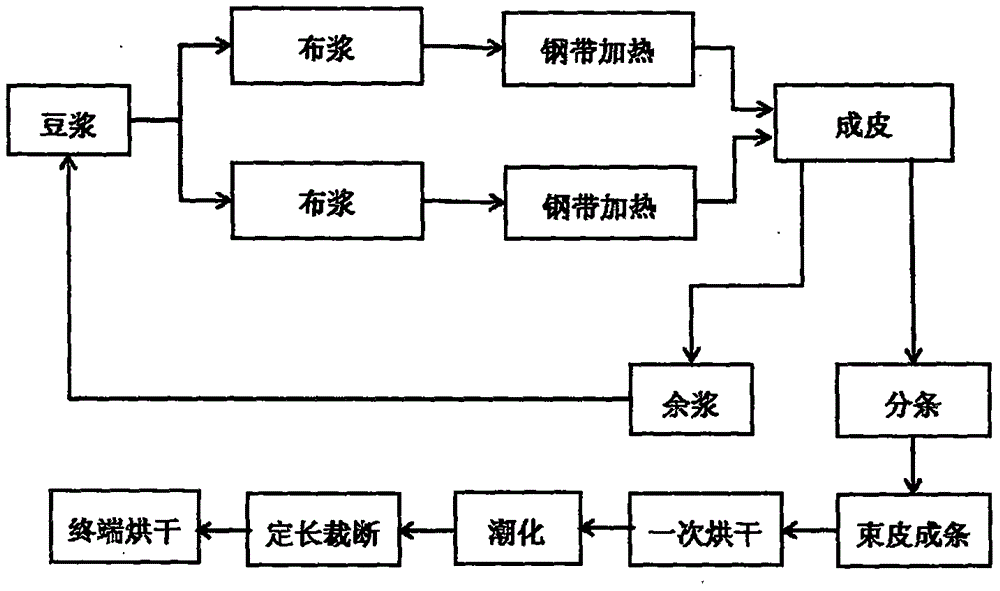

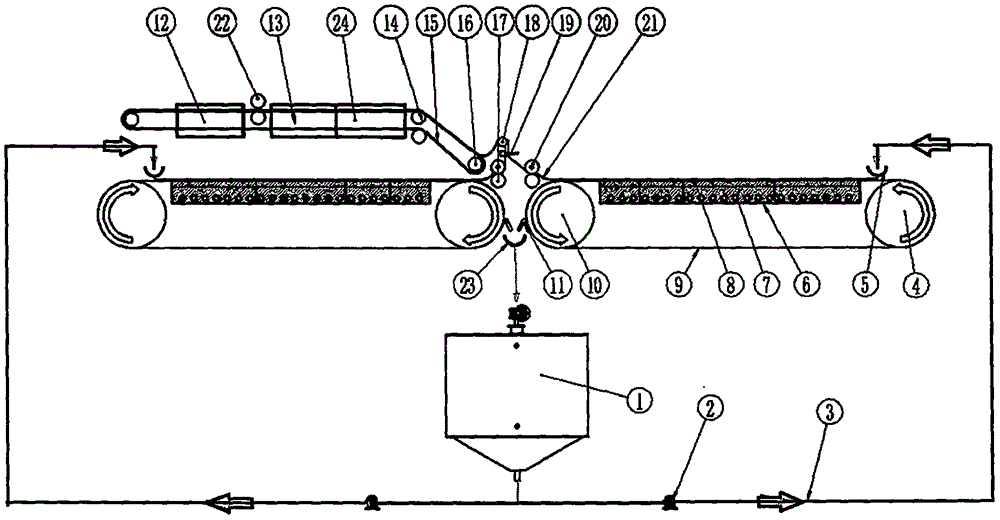

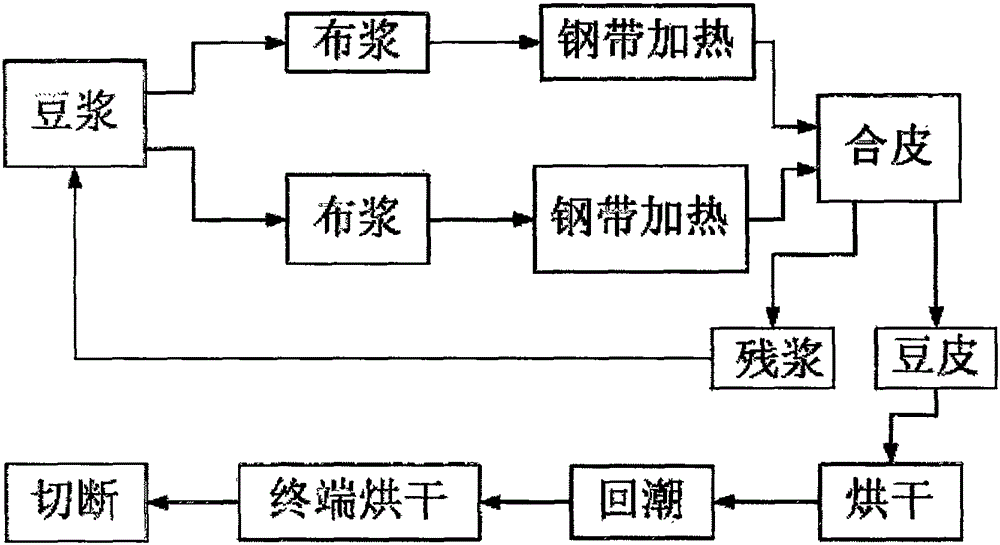

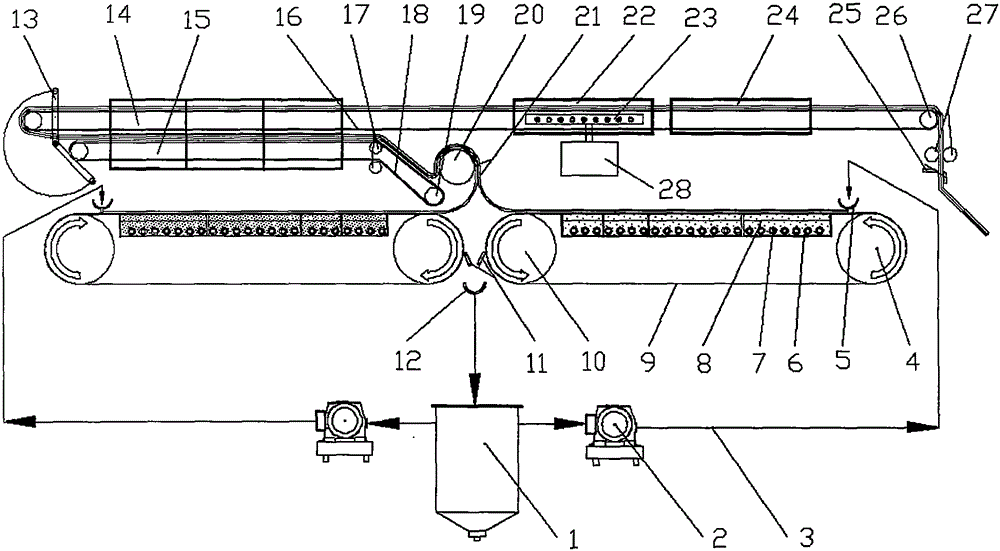

Annular-steel-strip process and device for continuous dried beancurd stick processing

PendingCN105767210AUniform heat curingImprove curing qualityCheese manufactureFood scienceTemperature controlVegetable oil

The invention discloses an annular-steel-strip process and device for continuous dried beancurd stick processing. The device comprises a milk distribution system, a steel strip heating unit, a cutting-knife strip slitting and bundling system, a dampening unit, a baking unit, a remnant milk collecting device, a fixed-length cutting unit and the like. According to the process and the device, dried beancurd sticks are heated through steel strips by using vegetable oil, so that the uniform-heated curing of the dried beancurd sticks can be achieved; gradient temperature control is achieved according to stations where the dried beancurd sticks are located, so that the quality of curing of the dried beancurd sticks is effectively improved. The process and device for automated and continuous dried beancurd stick production, disclosed by the invention, are different from the traditional dried beancurd stick processing modes, have the characteristics of high efficiency, stable and controllable quality, and the like and are applicable to the processing of a mass production line for the dried beancurd sticks.

Owner:HEILONGJIANG ORIENT AOFA BEAN PROD CO LTD

Battery electrode plate solidifying drying room of which humidity is adjustable

InactiveCN103528357ANo crackShort curing timeElectrode manufacturing processesDrying solid materialsEngineeringMechanical engineering

The invention discloses a battery electrode plate solidifying drying room of which the humidity is adjustable. The battery electrode plate solidifying drying room comprises a box body, an air inlet door, an air outlet door, humidometers and a humidifier, wherein the air inlet door and the air outlet door are arranged on the top of the box body, and the humidometers and the humidifier are connected with the box body. The humidity in the box body of the drying room can be adjusted, and therefore it is ensured that a leaded battery electrode plate does not craze in the solidifying process; meanwhile, electrode plate solidifying time is shortened, and solidifying quality is improved.

Owner:JIANGSU OLITER ENERGY TECH

Method for solidifying nail polish

The invention belongs to the technical field of makeup, and particularly relates to a method for solidifying nail polish. The method for solidifying the nail polish comprises the following steps that 1, the surface of a nail is coated with bottom color coating, and the bottom color coating is heated and solidified through near infrared rays; 2, the surface of a paint film obtained in the step 1 is coated with decoration coating, and the decoration coating is heated and solidified through near infrared rays; 3, the surface of a paint film obtained in the step 2 is coated with transparent finishing paint, and the transparent finishing paint is solidified through LED ultraviolet light. A coating film obtained through the method has the advantages of being high in solidifying speed, free of bubbles and attractive.

Owner:浙江明泉新材料科技有限公司

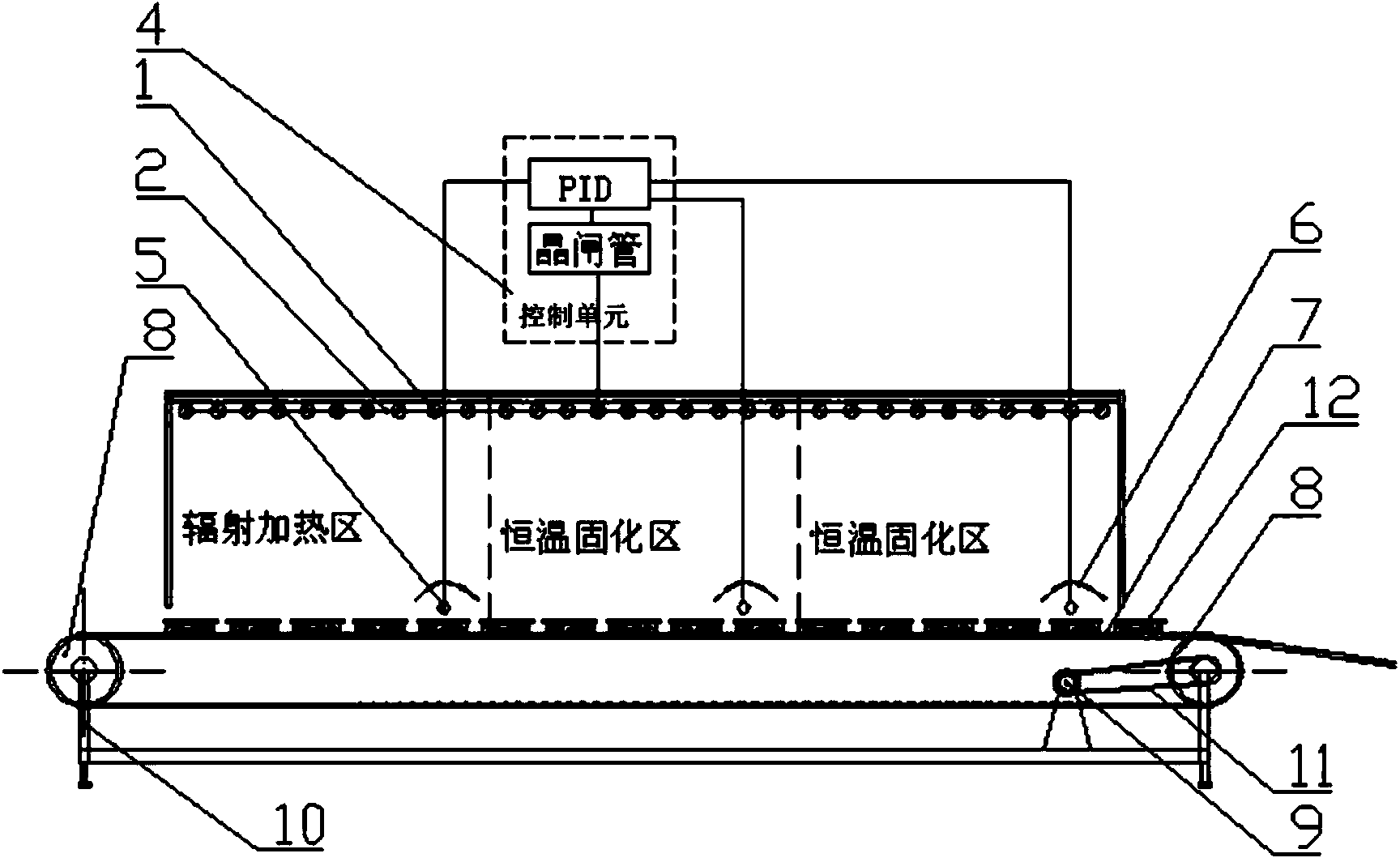

High-infrared curing device and method for brake pad steel back

ActiveCN103639102ALow Temperature Control AccuracyLow thermal efficiencyPretreated surfacesCoatingsTemperature controlControl system

The invention relates to a high-infrared curing device and method for a brake pad steel back. The high-infrared curing device comprise a conveyor, a high-infrared radiator, a radiator support, a curing chamber and a temperature control system, the conveyor is provided with a frame and a metal mesh conveying belt for conveying brake pads, the metal mesh conveying belt and the frame positioned above the metal mesh conveying belt enclose a space to form the curing chamber, the radiator support is fixed on the frame at the top of the curing chamber, the high-infrared radiator is mounted on the radiator support, and the temperature control system adjusts the power of the high-infrared radiator according to the temperature of the curing chamber, so that the temperature of the curing chamber reaches and keeps the preset constant temperature. The curing device is simple in structure, high in temperature control automation degree, fast in curing, low in energy consumption, the curing method is high in production efficiency, product quality is high, and production cost can be effectively reduced.

Owner:HUBEI CHIBI SALFER FRICTION MATERIAL

Glue drying process after glue dispensing of LED device

InactiveCN110420818AGuaranteed stabilityImprove curing qualityPretreated surfacesCoatingsTemperature controlAdhesive glue

The invention discloses a glue drying process after glue dispensing of an LED device. The glue drying process comprises the following steps of 1, preparing a glue drying oven for baking the LED devicewhich is subjected to glue dispensing, improving oven accessories, and changing a drying oven body from original single-section temperature control to existing multi-section temperature control; 2, setting the temperature and the time, required by the glue drying characteristic, of each section, increasing the drying time of glue, and changing a baking operation method; 3, placing the LED devicewith the glue after glue dispensing into the drying oven; and 4, baking the LED device with the glue after glue dispensing in six sections, specifically, baking the glue at the first section of 135 DEG C for 1 minute, baking the glue at the second section of 135 DEG C for 60 minutes, baking the glue at the third section of 135 DEG C for 1 minute, baking the glue at the fourth section of 150 DEG Cfor 1 minute, baking the glue at the fifth section of 150 DEG C for 240 minutes, and baking the glue at the sixth section of 150 DEG C for 1 minute. According to the glue drying process, the stabilityof the LED glue is guaranteed, the situation of characteristic change caused by exposure to air is avoided, the labor efficiency and the curing quality of the LED glue are improved, the step of manually transferring the device to a drying oven in the next stage is omitted, and the product quality is also improved.

Owner:SUZHOU KINGLIGHT OPTOELECTRONICS CO LTD

Annular steel belt continuous beancurd skin processing device and method

PendingCN105192090AGuaranteed supplyRealize continuous productionCheese manufactureFood scienceVegetable oilProcess engineering

The invention discloses an annular steel belt continuous beancurd skin processing device and method. The device comprises a slurry distributing and steel belt heating unit, a skin combining device, a moisture regaining unit, a drying unit, a residual slurry collecting device, a cutting unit and the like. On the basis, the invention discloses the continuous beancurd skin processing method. Vegetable oil is utilized for heating beancurd skin through steel belts, the beancurd skin can be evenly heated and solidified, temperature gradient control is achieved according to the station where the beancurd skin is located, and the solidification quality of the beancurd skin is effectively improved. The automatic and continuous beancurd skin production process and device are different from a traditional beancurd skin processing mode, have the advantages of being high in efficiency, stable and controllable in quality and the like, and are suitable for beancurd skin batch production line processing.

Owner:杨明发

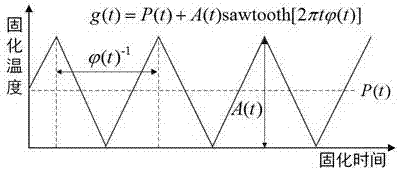

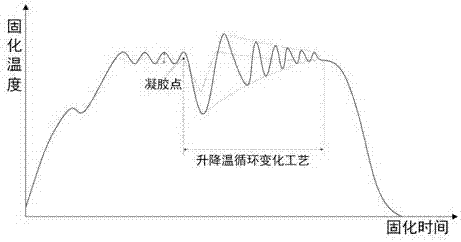

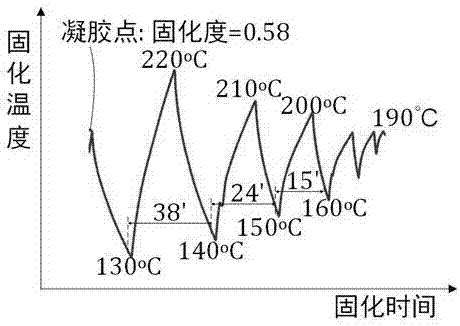

Method for reducing microwave curing stress of composite material

A method for reducing microwave curing stress of a composite material is characterized in that in the microwave curing process of the composite material, a section of periodic change that the curing temperature rises or falls along with time and cyclically changes till the composite material is completely cured is conducted after resin reaches the gel point. By means of the method, the stress generated in the microwave curing process of the composite material can be reduced, the curing quality is improved, an ideal temperature control method is provided for microwave curing of the composite material, a foundation is laid for replacing traditional autoclave curing with microwave curing, the curing stress can be reduced by 80% or above, and use requirements of large structural components can be met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Positive plate high-temperature pressurization curing process

PendingCN109585789AShort curing timeImprove curing qualityFinal product manufactureLead-acid accumulator electrodesEngineeringMechanical engineering

The invention provides a positive plate high-temperature pressurization curing process. By setting five steps in a curing stage, six steps in a conversion stage and six steps in a drying stage, a curing temperature, a time, a humidity, a circulation fan, a circulation cycle, an oxygen supplementation time, and a gas discharge time of each step are adjusted to be optimal, at the same time, the pressure in a curing chamber is controlled, the curing time is shortened, the curing quality is ensured, and the production efficiency is improved.

Owner:TIANNENG BATTERY WUHU

Curing chamber capable of adjusting gas inlet temperature

PendingCN107946540AImprove curing efficiencyImprove curing qualityElectrode thermal treatmentElectricityEngineering

The invention provides a curing chamber capable of adjusting gas inlet temperature. The curing chamber capable of adjusting gas inlet temperature comprises a curing chamber; a gas inlet pipeline is arranged at the upper end of the curing chamber; the gas inlet pipeline is connected with the top and the side surface of the curing chamber; a guide fan is arranged in the curing chamber; a temperaturesensor is arranged on the gas inlet pipeline; an electric heating rod is arranged at the pivot position of the gas inlet pipeline; the temperature sensor is associated with the electric heating rod;and the work of the electric heating rod is controlled by the temperature sensor. The temperature of vapor in the gas inlet pipeline is detected by the temperature sensor, heating is conducted throughthe electric heating rod when the vapor temperature is insufficient, and the temperature of the vapor is accurately controlled, so that the curing efficiency of a polar plate is improved; furthermore, a gas inlet quantity control valve is controlled by a humidity sensor and the humidity in the curing chamber is controlled, so that the curing quality is improved.

Owner:TIANNENG BATTERY WUHU

Abrasion-resistant and anti-fouling film used for mouse touch board glass

InactiveCN105038530AImprove abrasion resistance and stain resistanceImprove stain resistance and corrosion resistanceAntifouling/underwater paintsPaints with biocidesSolventPolyamide

The invention discloses an abrasion-resistant and anti-fouling film used for mouse touch board glass. The abrasion-resistant and anti-fouling film comprises, by weight, 80 parts to 120 parts of polyester resin, 60 parts to 80 parts of epoxy resin E-22, 30 parts to 60 parts of epoxy resin 601, 20 parts to 50 parts of zinc phosphate, 10 parts to 30 parts of aluminum triphosphate, 2 parts to 8 parts of sericite, 3 parts to 9 parts of nanometer kieselguhr, 2 parts to 8 parts of imvite, 1 part to 5 parts of silicon carbide, 3 parts to 5 parts of silica powder, 1 part to 5 parts of ceramic powder, 2 parts to 4 parts of white alundum powder, 1 part to 5 parts of adhesion promoters, 1 part to 5 parts of dispersing agents, 2 parts to 4 parts of flatting agents, 3 part to 5 parts of defoaming agents, 2 parts to 4 parts of chlorcosane, 1 part to 5 parts of titanium dioxide, 2 parts to 4 parts of carbon black, 1 part to 5 parts of polyamide 650, 2 parts to 4 parts of 2,4,6-tri(dimethylamino)mesitol and 2 parts to 6 parts of mixed solvents. The abrasion-resistant and anti-fouling film used for the mouse touch board glass has the excellent cohesiveness, the excellent abrasion resistance and the excellent anti-fouling performance.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

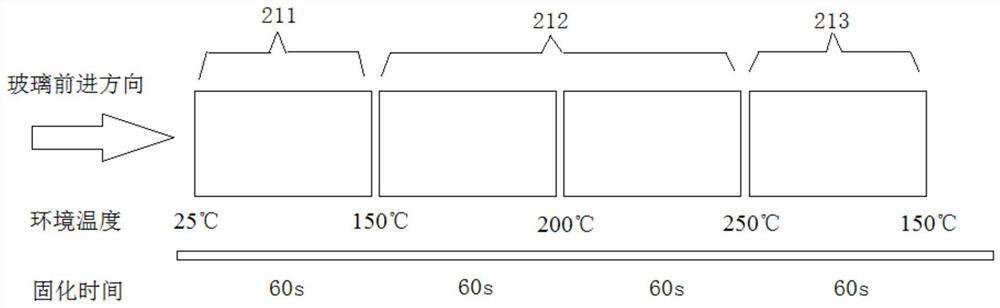

Glass film heating and curing process

The invention provides a glass film heating and curing process which comprises the following steps that a glass plate enters a furnace chamber of a curing furnace, and a lifting conveying device and an infrared heating pipe are arranged in the furnace chamber, the infrared heating pipe is used for heating a film on the surface of the glass plate, and the lifting conveying device is used for driving the glass plate to move vertically. According to the glass film layer heating and curing process, the infrared heating pipe is used for heating the film layer on the surface of the glass plate, theinfrared radiation heating and curing process is adopted, the heating efficiency is high, the film layer can be dried from inside to outside through the heating mode, pinholes and other defects are not likely to be formed, and therefore the curing quality of the film layer is improved. Meanwhile, according to the glass film layer heating and curing process, the adopted curing furnace is short in length in the horizontal direction and small in occupied area, the area of a plant area is saved, and the space in the height direction of the plant area is fully utilized.

Owner:CHINA TRIUMPH INT ENG

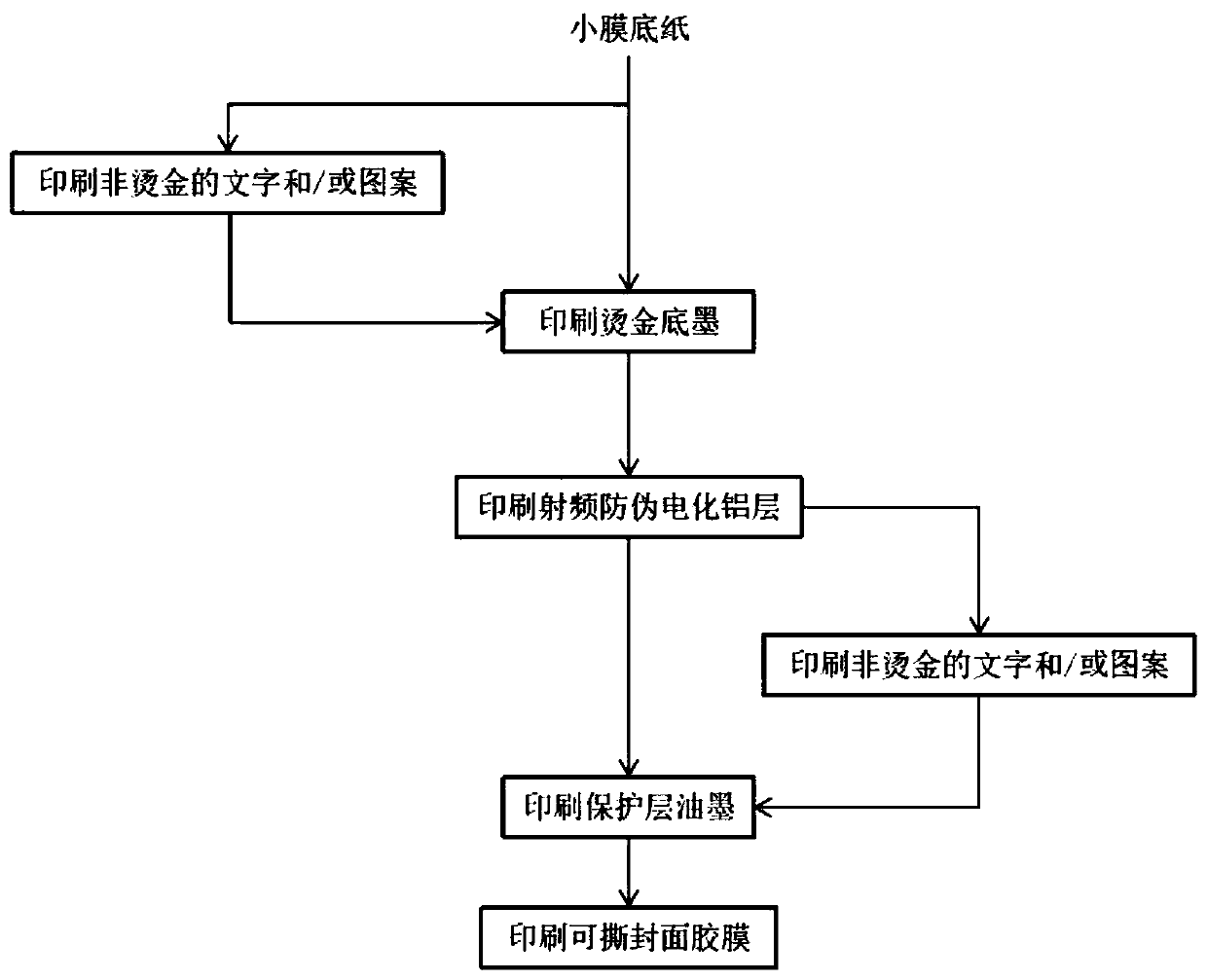

Radio frequency anti-fake water transfer printing calico paper and printing method thereof

InactiveCN111038126AWith multiple anti-counterfeiting functionsJudgment of authenticityDuplicating/marking methodsPattern printingScreen printingEngineering

The invention relates to a printing method of radio frequency anti-fake water transfer printing calico paper. The printing method comprises the following steps that firstly, textures and / or patterns are made; secondly, a film is made, then a silk screen printing plate is made, or the silk screen printing plate is directly made in a CTS laser / digital manner; thirdly, gold blocking ink is printed; fourthly, a radio frequency anti-fake gold blocking film is made; fifthly, gold blocking textures and / or patterns and radio frequency information are subjected to transfer printing; sixthly, protectionlayer ink is printed; and seventhly, a tearable cover rubber film is printed. The printing method is simple, continuous printing can be achieved, production efficiency is high, the ink curing speed is high, and the printed calico paper is not prone to being copied. Consumers can compare radio frequency serial numbers of a radio frequency anti-fake alumite layer with radio frequency serial numbersread by a radio frequency reader or recorded by a database, the aim of authenticity identification is achieved, and the anti-fake function, the function of daily production and management data sourcetracking and the like are achieved.

Owner:安徽江南春包装科技有限公司

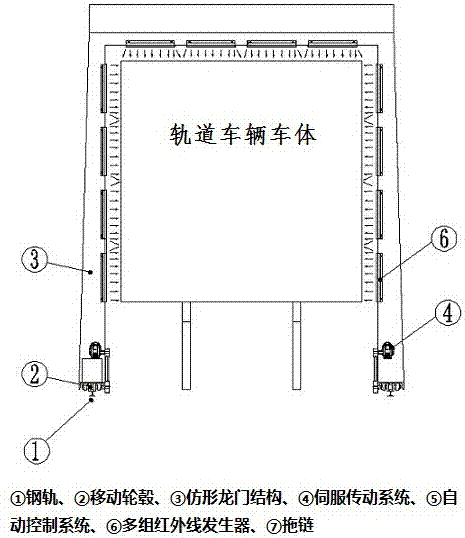

Scanning-type rail traffic infrared coating and curing equipment

InactiveCN107570397AImprove curing speed and qualityReduce energy consumptionPretreated surfacesCoatingsAutomatic controlAutomotive engineering

The invention relates to scanning-type rail traffic infrared coating and curing equipment, in particular to reciprocating scanning infrared irradiated film curing equipment, and belongs to the field of coating and drying. The scanning-type rail traffic infrared coating and curing equipment aims to overcome the defect of hot air curing of an existing rail train and conducts curing on a film of a train body of the rail train. A plurality of sets of infrared generators are installed on the inner wall of a profiling gantry structure. A servo transmission system and a moving hub scan in a reciprocating and circulating mode at the certain speed under the control of an automatic control system according to the set procedure to achieve the purpose of film fast curing. The multiple sets of infraredgenerators can adopt catalytic gas infrared generators which use natural gas as the energy source, and can also adopt electric infrared generators which use power as the energy source in the condition without fuel gas.

Owner:镇江美博红外科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com