UV glue-dispensing curing machine and curing process

A curing machine and dispensing technology, applied in the field of dispensing machines, can solve the problems of uneven cutting quality of copper wires, poor dispensing and curing quality, and high labor intensity of workers, so as to improve the quality of dispensing and curing, Guarantee dispensing and curing effect, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

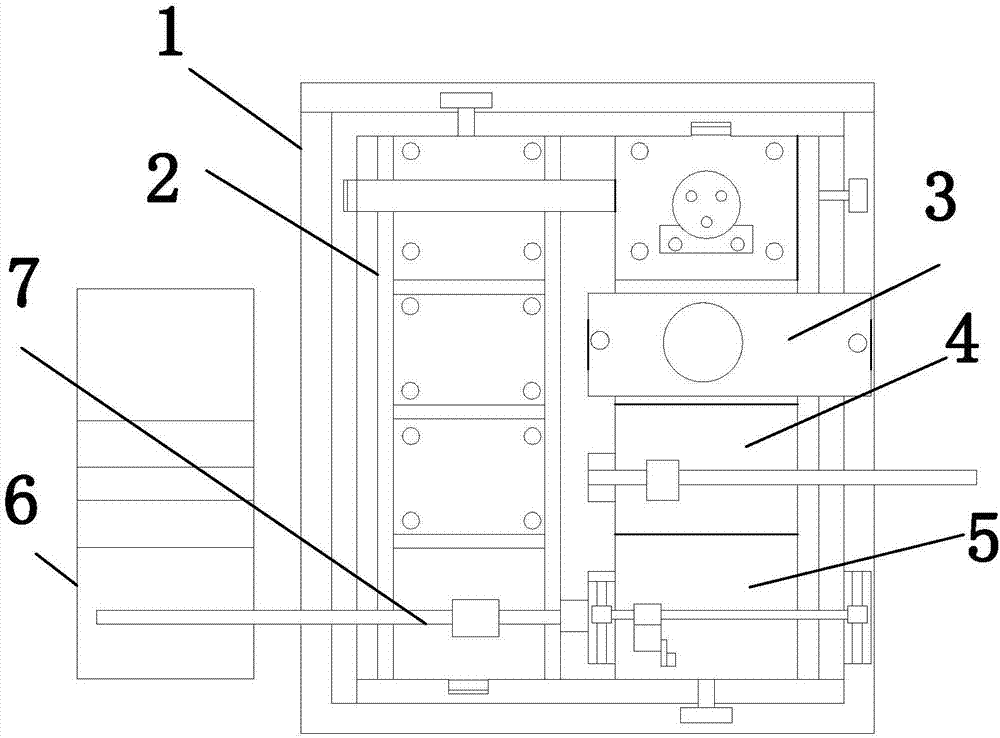

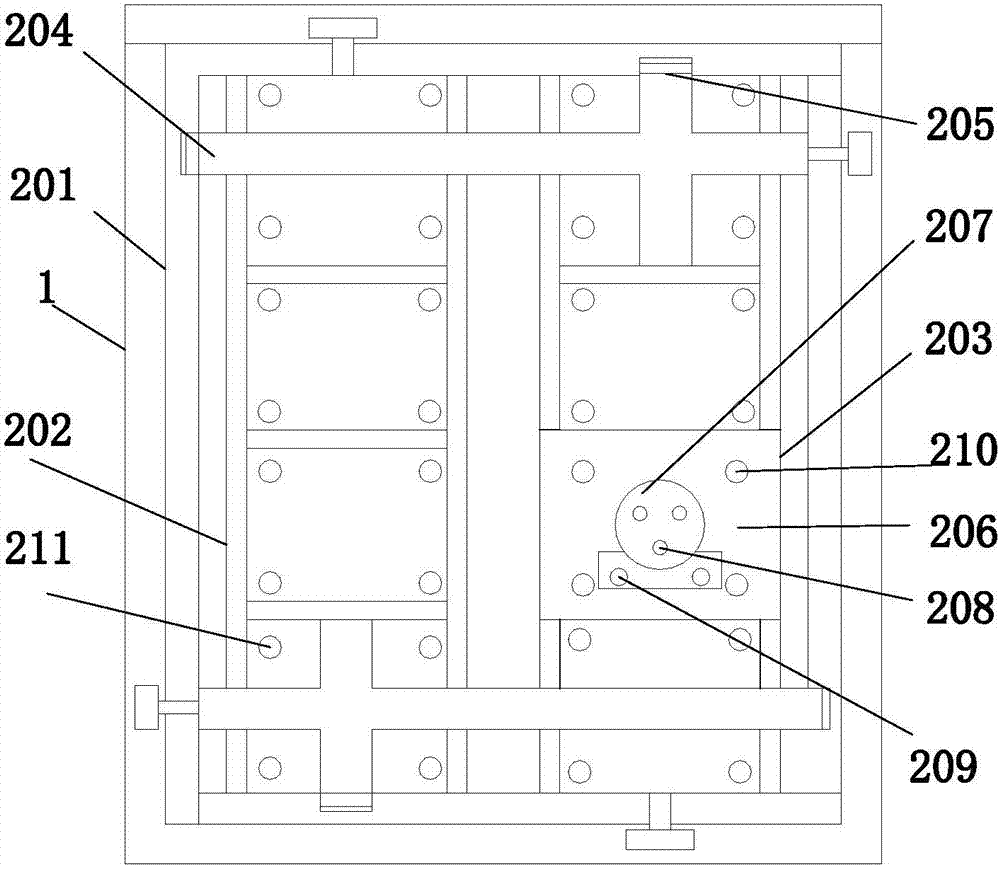

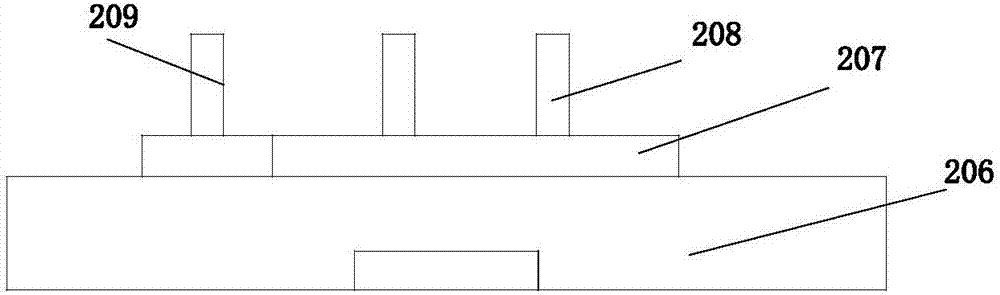

[0027] Examples. A UV dispensing curing machine, composed as Figure 1 to Figure 10 As shown, the frame 1 is included. The frame 1 is provided with a stator conveying device 2, and the stator conveying device 2 is sequentially provided with a stator wire cutting device 3, a waste recycling device 4, and a glue dispensing device 5 fixed to the frame 1; The side of the frame 1 is provided with a curing device 6, and a reclaiming device 7 is provided between the curing device 6 and the dispensing device 5; the stator conveying device 2 is provided with an infrared sensor 8, which is connected to a controller 9. The controller 9 is respectively connected with the stator conveying device 2, the stator thread cutting device 3, the waste recycling device 4, the glue dispensing device 5, the curing device 6 and the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com