Special oven used for manufacturing cured epoxy resin dry type transformer coil and manufacturing method thereof

A technology for curing epoxy resin and dry-type transformers, applied in the direction of coil manufacturing, furnace, furnace type, etc., can solve the problems that the coil quality is greatly affected, the coil surface quality is affected, and the partial discharge exceeds the standard, so as to shorten the curing time, speed up the The effect of curing reaction speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

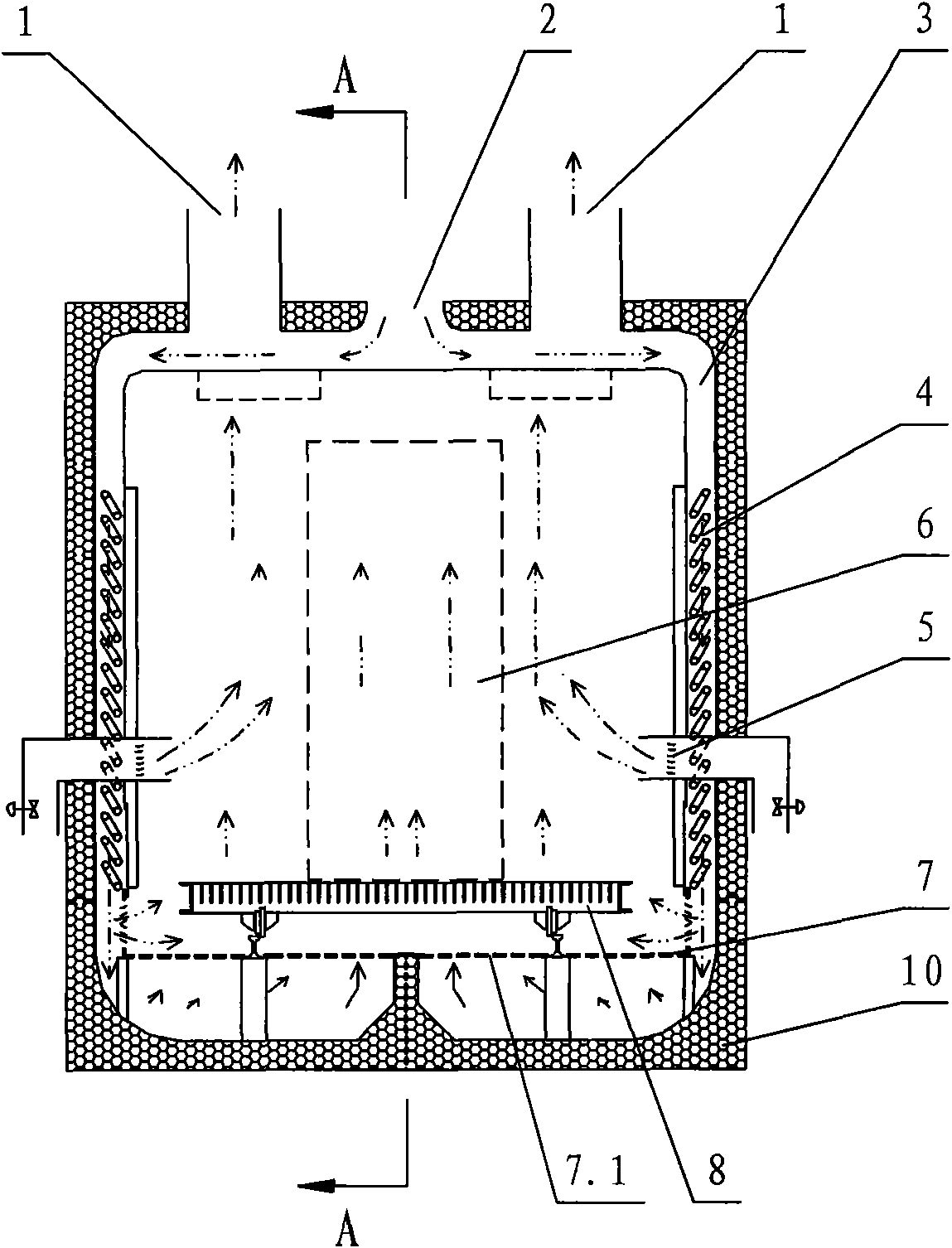

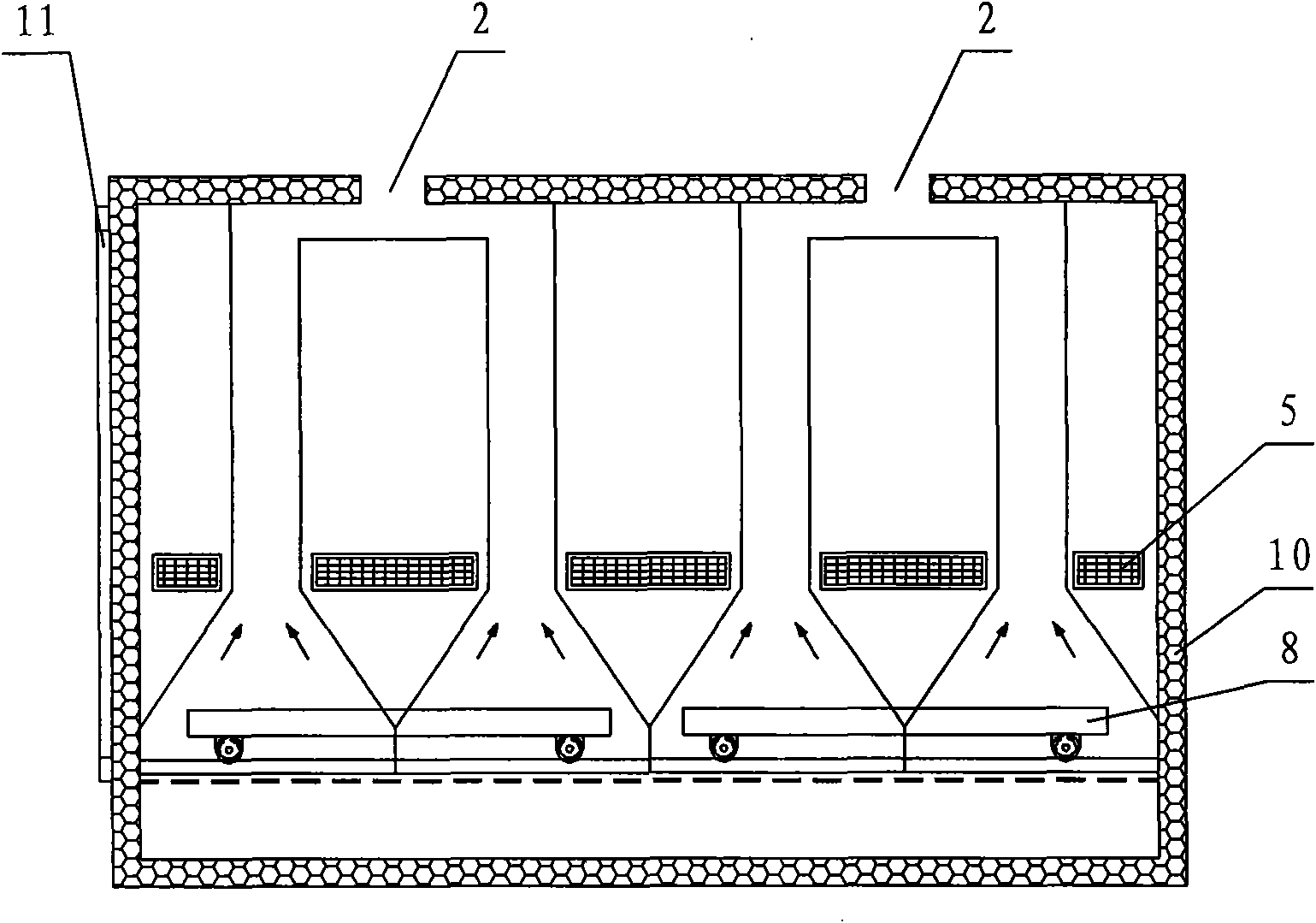

[0021] see Figure 1-Figure 2 , this is a special oven for making coils of cured epoxy resin dry-type transformers. The top of the special oven is provided with an exhaust air outlet 1 and an air inlet 2. The exhaust air outlet 1 communicates with the inner cavity of the special oven. An air duct 3 is respectively arranged on the left and right side walls, the air inlet 2 communicates with one end of the air duct 3, an electric heater 4 is arranged in the air duct 3, and the middle and lower part of the air duct 3 is provided with an opening communicating with the inner cavity, and the opening Two-way blinds 5 are arranged on it. The bottom of the special oven is provided with a base plate 7, the base plate and the bottom of the special oven together form a lower chamber, the lower chamber communicates with the other end of the air duct 3, the base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com