Scanning-type rail traffic infrared coating and curing equipment

A technology for rail transit and rail transit vehicles, which is applied in the field of scanning rail transit infrared coating curing equipment, which can solve the problems of slow cooling time in the drying room, affecting operation efficiency, and low efficiency, so as to improve curing speed and quality, and improve operation Efficiency and the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

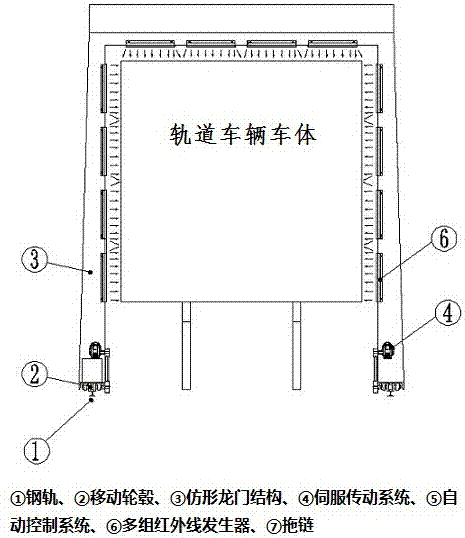

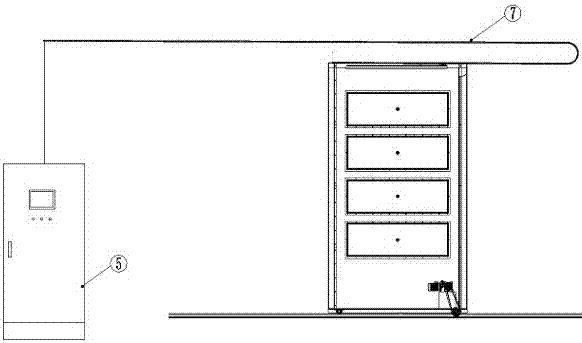

[0018] see figure 1 , figure 2 , this example is a scanning rail transit infrared coating curing equipment, including ① steel rail, ② moving hub, ③ profiling gantry structure, ④ servo drive system, ⑤ automatic control system, ⑥ multiple sets of infrared generators, ⑦ drag chain , in which 12 sets of infrared generators are arranged on the left, right and top of the rail transit vehicle in a profiling manner. When the infrared generator is activated, the equipment will scan along the vehicle body at a set speed, and the equipment will automatically stop running after the scanning time is over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com