Radio frequency anti-fake water transfer printing calico paper and printing method thereof

A technology of water transfer printing paper and water transfer printing, which is applied in the field of anti-counterfeiting, can solve the problems of being easy to be imitated and difficult to distinguish the authenticity of the decal paper, and achieve the effect of convenient continuous printing, reducing the output power and saving the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

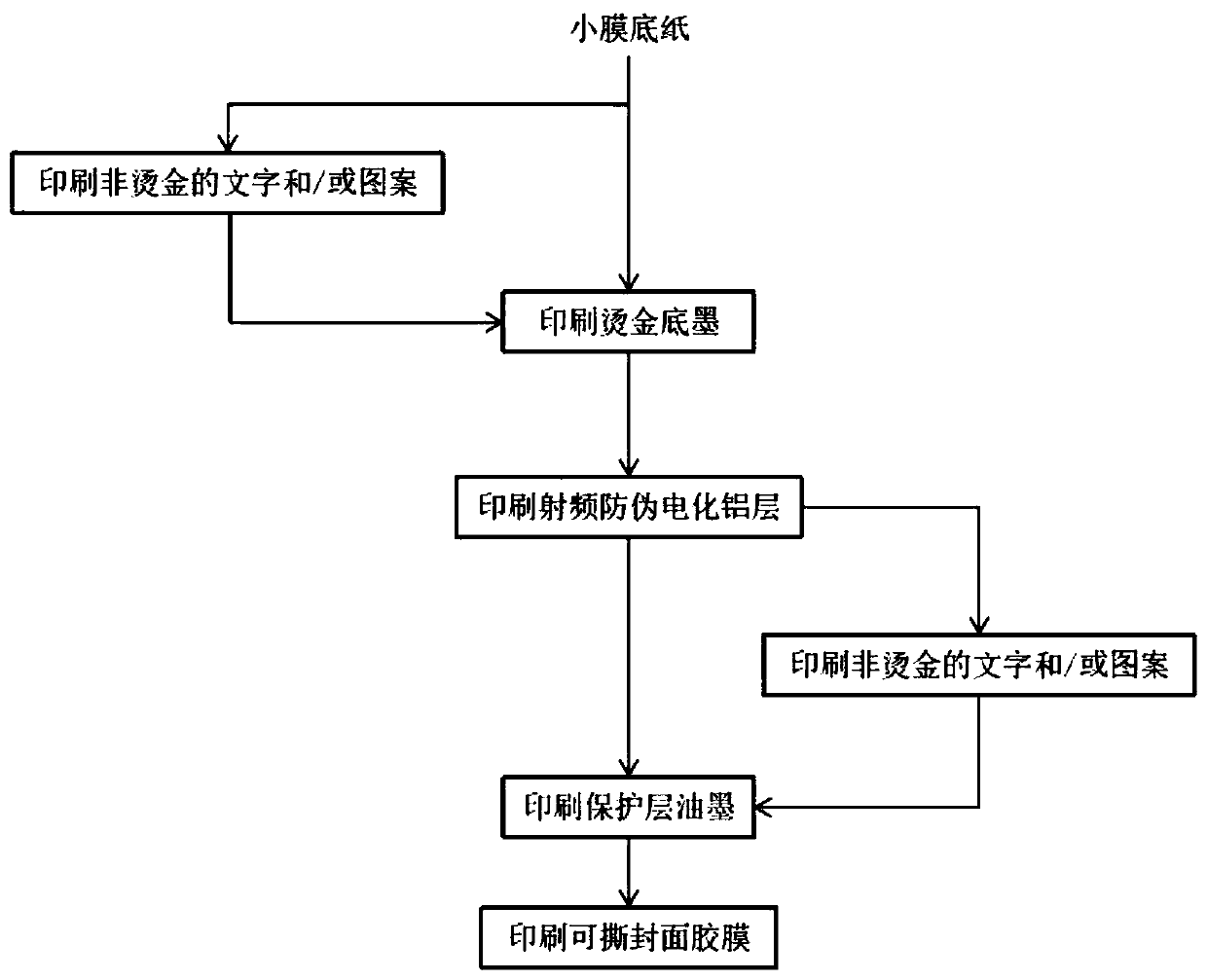

[0044] Follow the steps below to print a radio frequency anti-counterfeiting water transfer printing paper:

[0045] S1. Making characters and / or patterns: using a computer to make characters in two colors (red and blue).

[0046] S2, making screen printing version: according to the text and / or patterns of different colors made in step S1, according to the method of making the same screen printing version in the same color, use CTS laser (computer direct screen printing adopts laser direct imaging technology) directly Make two screen printing plates in layers, among which, the red one needs hot stamping, and the blue one does not need hot stamping;

[0047] S3, printing non-bronzing text and / or pattern, radio frequency serial number: adopt the silk screen printing plate that makes in step S2, the non-bronzing blue text and radio frequency serial number are printed on the dry small film bottom paper;

[0048] S4. Printing ink: print a layer of UV ink on the side of the non-bro...

Embodiment 2

[0056] First prepare LED resin ink according to the following components and mass percentages: 15% pigment, 60% radiation curing resin polyester acrylate, 12% photoinitiator benzoylformate, 9% reactive diluent pentaerythritol triacrylate, 2% nanometer rare earth material nano europium oxide, 2% additive tris(N-nitroso-Nphenylhydroxylamine) aluminum salt. Mix the ingredients in a batching kettle, stir at 1000r / min for 50min to obtain a slurry, and grind it fully with a Buhler three-roll machine until the slurry has a fineness of less than 5um to prepare an LED ink.

[0057] Then, according to the following steps, a kind of radio frequency anti-counterfeiting water transfer printing paper is printed:

[0058] S1. Making characters and / or patterns: using a computer to make characters in two colors (silver and blue).

[0059] S2, making screen printing plate: according to the text of different colors that step S1 makes, according to the method for making the same film of the same...

Embodiment 3

[0068] Follow the steps below to print a radio frequency anti-counterfeiting water transfer printing paper:

[0069] S1. Make patterns: use a computer to make patterns of two colors (red, blue).

[0070] S2, making screen printing plate: According to the text and / or patterns of different colors made in step S1, according to the method of making the same screen printing plate in the same color, use digital layering to make two printing screen plates respectively, wherein red, All blue patterns need hot stamping;

[0071] S3, printing the first layer of hot stamping base ink: adopt the screen printing plate made in step S2, print the hot stamping base ink on the small film backing paper, the shape / outline of the hot stamping base ink is consistent with the shape / outline of the red hot stamping pattern Adaptation, curing the bronzing base ink under ultraviolet radiation, and setting the first counterpoint on the small film base paper at the same time;

[0072] S4. Making radio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com