Triple anti-counterfeiting material based on perovskite composite structure and its application

A composite structure and composite material technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of single anti-counterfeiting and insufficient use, and achieve the effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

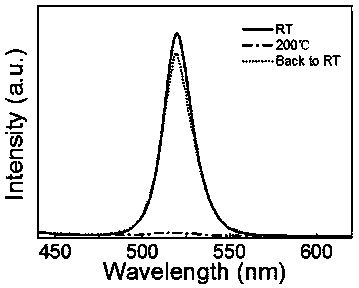

[0027] see figure 1 , figure 2 and image 3 As shown, the triple anti-counterfeiting material based on the perovskite composite structure of the present invention is prepared by the preparation method of the triple anti-counterfeiting material based on the perovskite composite structure. The preparation method comprises the following steps:

[0028] 1), combine CsX and PbX 2 Dissolved in an organic solvent to obtain CsPbX 3 Perovskite precursor solution, where, CsX and PbX 2 The molar ratio is 1:1. Among them, CsX and PbX in the perovskite precursor solution 2 The concentration is 0.1~0.5mol / L. Organic solvents are DMSO, DMF and γ-butyrolactone. CsX and PbX 2 In X all are Cl, Br or I.

[0029] 2), CsPbX in step 1) 3 An organic amine and an organic acid are added to the perovskite precursor solution and mixed evenly to obtain a mixed solution, and ZIF-8 powder is immersed in the mixed solution and left to stand to obtain a mixture. Both organic amines and organic ac...

Embodiment 1

[0035] 1) Synthesize metal-organic framework ZIF-8 powder by methanol method;

[0036] 2) Combine 0.532 g CsBr and 0.923 g PbBr 2 Dissolved in 8 g of DMSO, and sonicated to dissolve completely, formulated as CsPbBr 3 Precursor solution;

[0037] 3) Take 3 mL of CsPbBr 3 Add 75 μL oleic acid and oleylamine to the precursor solution, soak ZIF-8 powder in it, and let it stand for 12 h;

[0038] 4) Freeze-dry the mixture in step 3) at -80°C cold trap temperature for 36 h, then grind to obtain CsPbBr 3 / ZIF-8 composite material;

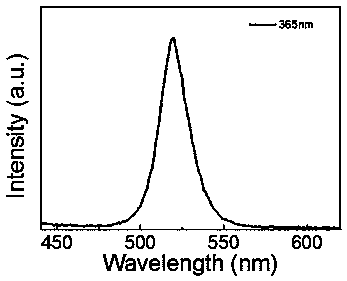

[0039] 5) Excite the composite with UV light with a wavelength of 365 nm.

Embodiment 2

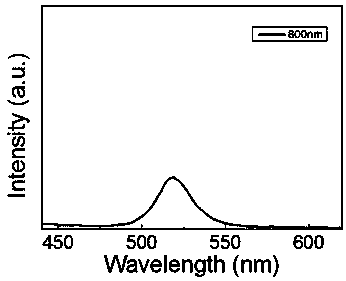

[0041]The same process as in Example 1 was adopted, with the difference that the 365 nm ultraviolet excitation light in step 5) in Example 1 was replaced with 800 nm infrared excitation light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com