Holographic anti-counterfeiting heat transfer printing product and printing method thereof

A holographic anti-counterfeiting and thermal transfer printing technology, which is applied in the field of anti-counterfeiting, can solve the problems of not having product value-added functions, polluting the environment, continuous transfer printing, etc., and achieves the effects of avoiding malicious reuse, fast curing speed, and improving curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

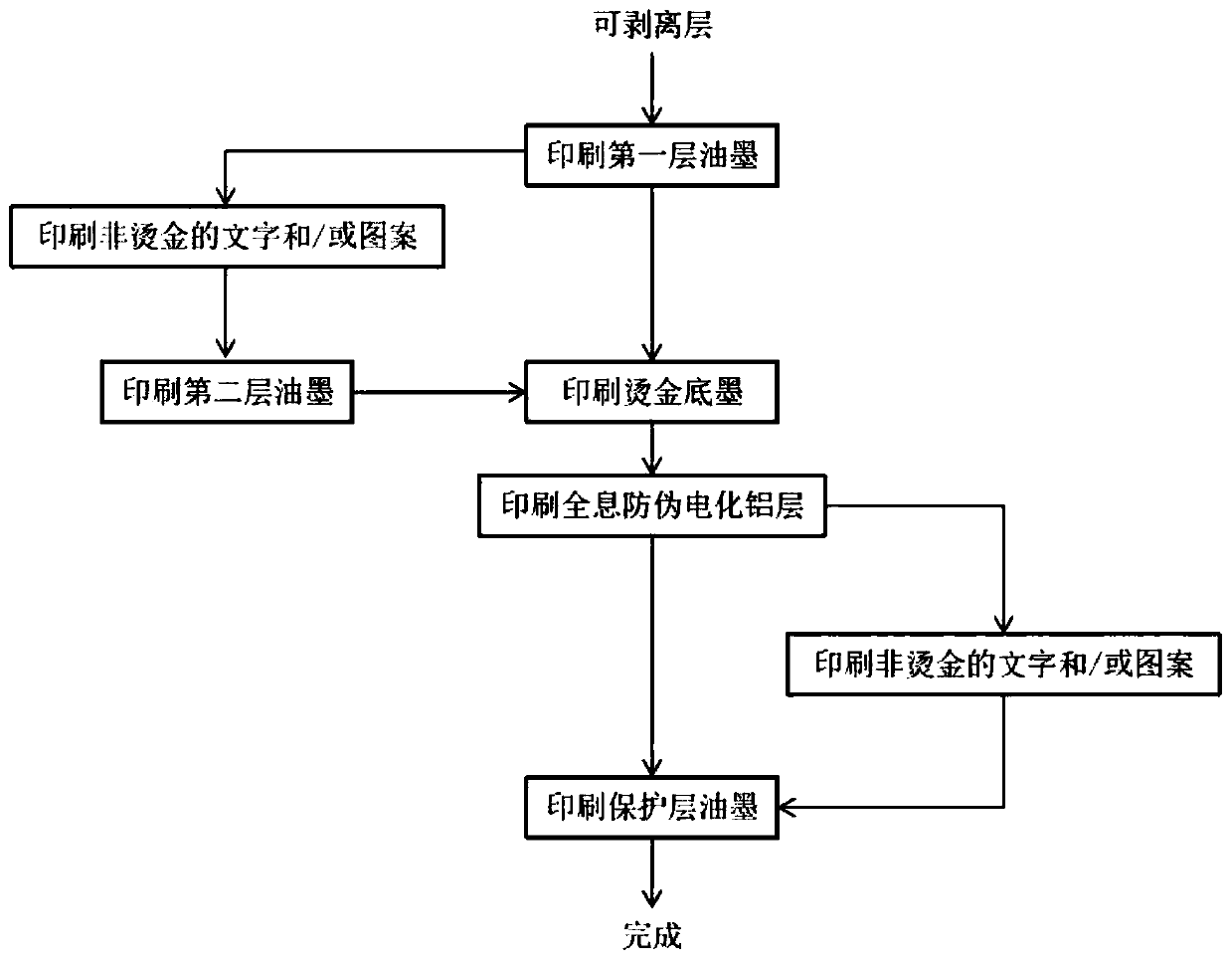

Image

Examples

Embodiment 1

[0043] First, prepare LED resin ink according to the following components and mass percentages: 15% pigment, 60% radiation curable resin polyester acrylate, 12% photoinitiator methyl benzoyl formate, 9% reactive diluent pentaerythritol triacrylate, 2% nanometer rare earth material nano europium oxide, 2% additive tris (N-nitroso-Nphenylhydroxylamine) aluminum salt. The ingredients are mixed in a batching kettle, stirred at 1000r / min for 50min to obtain a slurry, which is fully ground by a Buhler three-roller. After the slurry fineness is less than 5um, the LED resin ink is prepared.

[0044] Then, follow the steps below to print a holographic anti-counterfeiting thermal transfer product:

[0045] S1. Making text: using a computer to make text in two colors (red, blue);

[0046] S2. Making a screen printing plate: According to the different colors of the text produced in step S1, the same color is used to make the same film, two film films are made respectively, and the film film mad...

Embodiment 2

[0055] Follow the steps below to print a holographic anti-counterfeiting thermal transfer product:

[0056] S1. Making patterns: using a computer to make text in two colors (silver, blue);

[0057] S2. Making a screen printing plate: According to the text and / or patterns of different colors produced in step S1, the method of making the same screen printing plate in the same color, using CTS laser (computer direct screen printing using laser direct imaging technology) Make screen printing plates separately for each layer. For example, the silver one needs hot stamping, and the blue one does not need hot stamping;

[0058] S3. Printing ink: Use the screen printing plate produced in step S2 to print the first layer of UV ink on the position corresponding to the hot stamping text and / or pattern, non-hot stamping text and / or pattern of the first release layer of the PET film ;

[0059] S4. Printing non-stamping characters and / or patterns: using the screen printing plate produced in step S...

Embodiment 3

[0067] Follow the steps below to print a holographic anti-counterfeiting thermal transfer product:

[0068] S1. Making text and / or patterns: using a computer to make patterns in two colors (red, blue).

[0069] S2. Making a screen printing plate: According to the patterns of different colors produced in step S1, the same method of making the same screen printing plate in the same color, using digital direct layering to make two screen printing plates respectively, among which, red and blue All the patterns need hot stamping;

[0070] S3. Printing ink: Print the first layer of solvent type at the positions corresponding to the hot stamping text and / or pattern, non-hot stamping text and / or pattern on the first release layer of the PET film of the screen printing plate prepared in step S2 Ink

[0071] S4. Making the holographic anti-counterfeiting hot stamping film: lithographically mold the holographic information on the red and blue hot stamping films and set the second alignment poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com