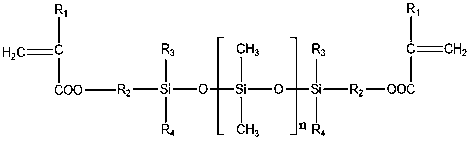

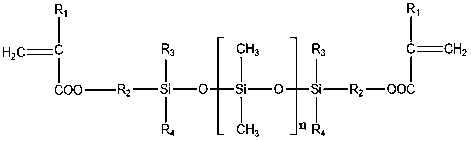

Ultraviolet)/moisture/thermal triple curing organic silicone adhesive

A triple curing, silicone adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of incomplete curing, easy to absorb air dust, poor surface curing, etc., to achieve surface curing improvement , curing quality improvement, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

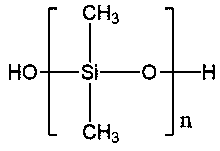

Method used

Image

Examples

Embodiment -1

[0053] [Example-1] 100 parts by weight of oligomer-1 prepared by [Synthesis-1], 1.0 parts by weight of azobisisobutyronitrile, 1.0 parts by weight of chelated tin catalyst, 1.0 parts by weight of photoinitiator TPO, Add 35 parts by weight of fumed silica R972 to a planetary mixer, stir and mix evenly in a vacuum to obtain a paste-like high-viscosity silicone sealant. Test its moisture curing, light curing and thermal curing properties. The results are as follows in the attached table .

[0054] schedule

[0055]

[0056] Note, the meanings of the symbols in the attached table are as follows:

[0057] ◎: The surface has good curability, no fingerprints are left on the finger touch, and the surface is not sticky;

[0058] ○: Surface curability is average, fingerprints are left on the finger touch, and the surface is slightly sticky;

[0059] △: The surface curability is poor, there are oily substances on the surface, and fingerprints are obviously left on the finger touch....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com