Laminated inorganic pipeline and preparation method thereof

A pipeline and inorganic technology, applied in the field of interlayer inorganic pipeline and its preparation, can solve the problems of unsuitable interlayer transportation pipeline, length limitation, unstable quality, etc., and achieve the effects of easy popularization and application, improved mechanical properties, and improved curing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing an interlayer inorganic pipeline, comprising the steps of:

[0045] 1) Add organic monomers or polymer resins into the reaction kettle, and according to the material performance and According to the requirements of process performance, select diluent, initiator, coupling agent and other auxiliary agents; initiate polymerization and control the conversion rate of monomer; add inorganic modified powder treated with or without coupling agent under high-speed stirring, and prepolymerize The mass ratio of body and inorganic modified powder is 1:0.01~3.0, and then vacuum degassing or not to obtain slurry;

[0046] 2) Rinse and clean the inorganic pipeline with conventional cleaning agent solution and water and dry it;

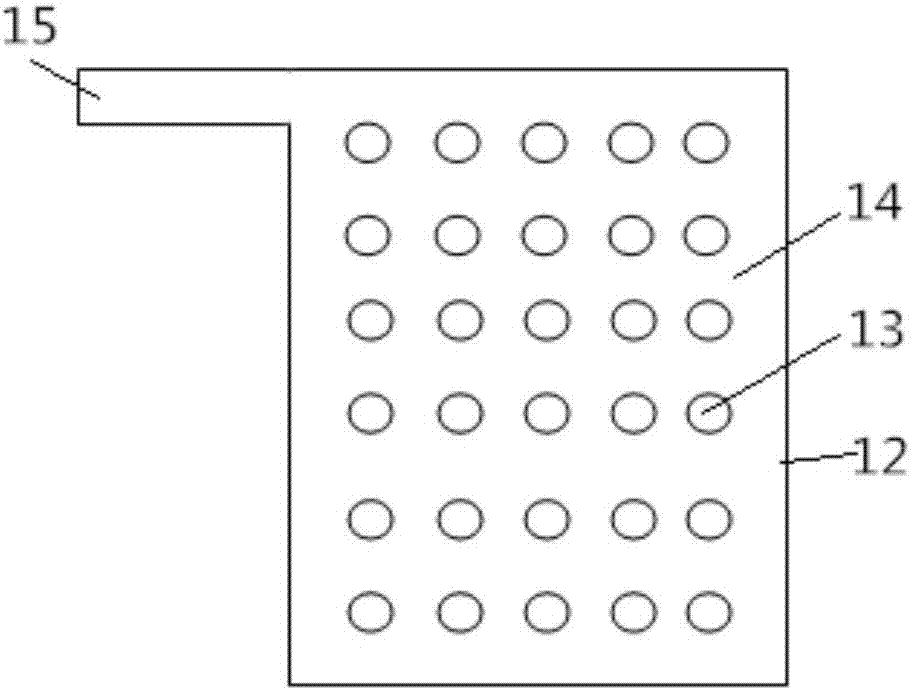

[0047] 3) The first diameter pipe 7 and the second diameter pipe 8 are nested together to form a set of nested inorganic pipes; wherein, the first diameter pipe 7 and the second diameter pipe 8 are inorganic pipes with a diameter differ...

example 1

[0059] Step 1) Add a certain amount of polymer monomers, diluents, initiators, coupling agents, curing agents and other additives into the reactor to initiate polymerization and control the conversion rate of monomers; Inorganic modified powder treated with coupling agent, the mass ratio of prepolymer and inorganic modified powder is 1:0.01~3.0, and then vacuum degassing or not to obtain slurry;

[0060] Step 2) washing and drying the borosilicate glass pipes or silicate glass pipes of the first diameter pipe 7 and the second diameter pipe 8 with cleaning agent solution and water;

[0061] Step 3) nesting the first diameter pipe 7 and the second diameter pipe 8 together to form a set of nested inorganic pipes; wherein, the first diameter pipe 7 and the second diameter pipe 8 are inorganic pipes with a diameter difference greater than 1.0mm;

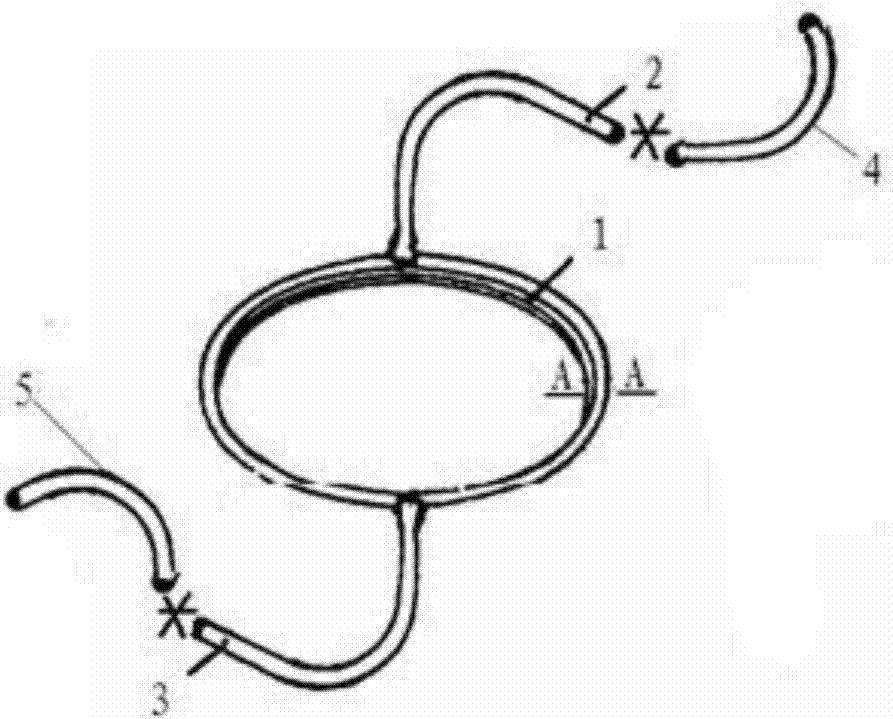

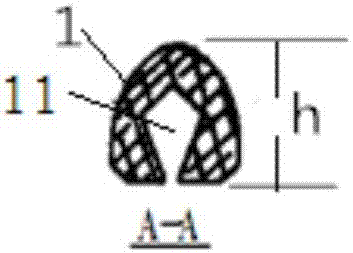

[0062] Step 4) Put one or more U-shaped ring grooves 11 of the upper elastic rubber sealing ring 1 with a height of 20-40mm on the upper...

example 2

[0068] Step 1) First add methyl acrylate, dibutyl ester, benzoic acid, silane, benzoyl peroxide, coupling agent and other auxiliary agents in the reaction kettle according to the weight ratio to initiate polymerization and control the monomer conversion rate; high-speed stirring Next, add inorganic modified powder treated with or without coupling agent, the mass ratio of prepolymer and inorganic modified powder is 1:0.01~3.0, and then vacuum degassing or not to obtain slurry;

[0069] Step 2) Rinse and dry lithium-aluminosilicate glass-ceramic pipes of different diameters, and / or borosilicate glass or silicate glass pipes with cleaning agent solution and water;

[0070] Step 3) nesting the first diameter pipe 7 and the second diameter pipe 8 together to form a set of nested inorganic pipes; wherein, the first diameter pipe 7 and the second diameter pipe 8 are inorganic pipes with a diameter difference greater than 1.0mm;

[0071] Step 4) Cover the U-shaped ring groove 11 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| collision energy | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com