Optical fiber coloring and curing equipment

A curing equipment and optical fiber technology, which is applied in the field of efficient curing equipment, can solve the problems of uneven light receiving in the gap, affecting the curing quality of the coating, and low energy utilization of the mercury lamp, so as to achieve good curing uniformity and solve the problem of separation , Reduce the effect of curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

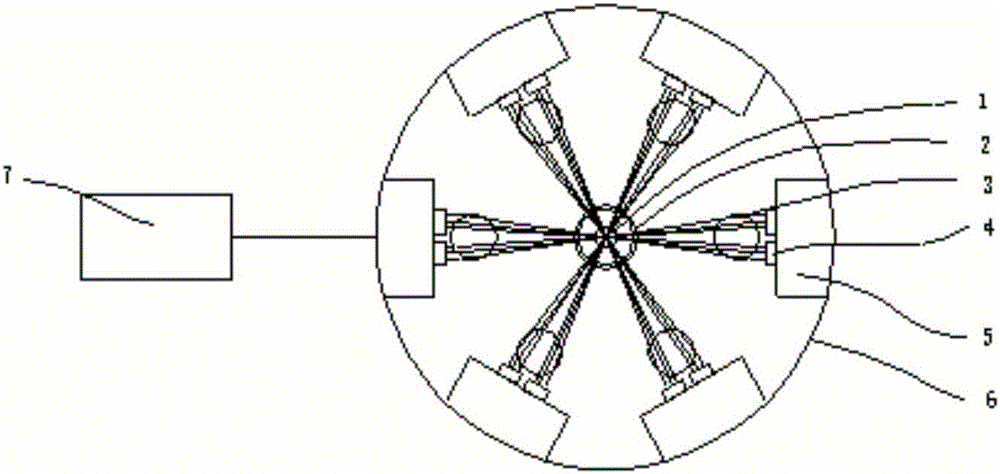

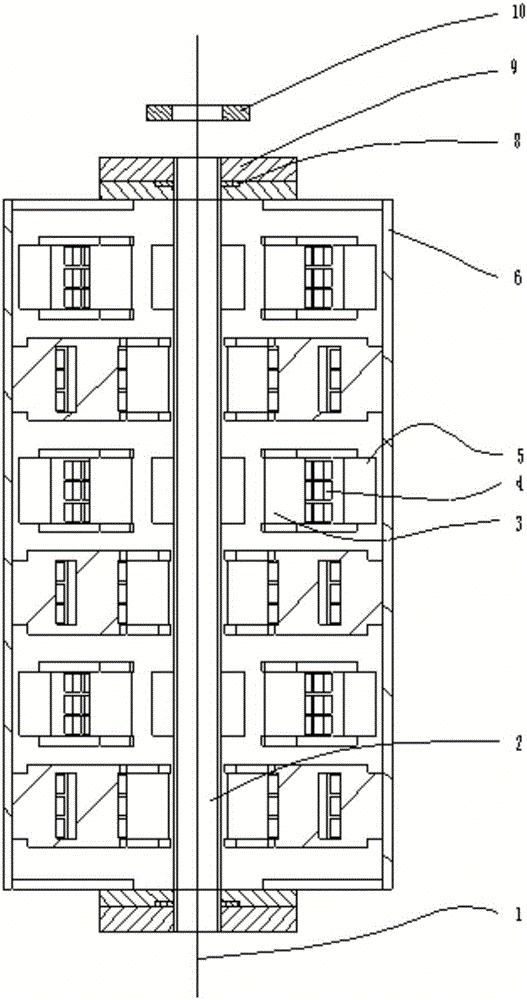

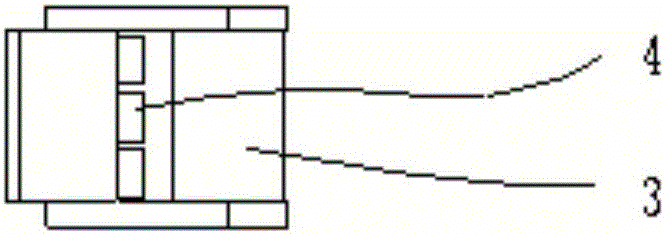

[0024] Such as Figure 1-4 As shown, this embodiment provides a kind of optical fiber coloring and curing equipment, which includes a cylindrical mounting base 6, a UVLED light source module is installed in the inner cavity of the cylindrical mounting base along the circumferential and axial directions, and the The inner cavity is divided into 6 layers of UVLED light source modules along the axial direction, and each layer has 6 UVLED light source modules. The UVLED light source modules installed along the axial direction are arranged at a staggered angle of 20°. The UVLED light source modules include heat dissipation bases 5. The UVLED light source 4 and the cylindrical focusing lens 3, wherein the focusing lens 3 is arranged on the heat dissipation base 5 and is located in front of the UVLED light source 4. The UV light source wavelengths of the UVLED light source 4 are 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com