Asphalt aging instrument

A technology of asphalt aging tester and material table, which is applied in the field of machinery, can solve the problems that affect the experimental results, the test object is not uniformly exposed to light and sprayed, and achieve the effect of uniform light reception and uniform spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

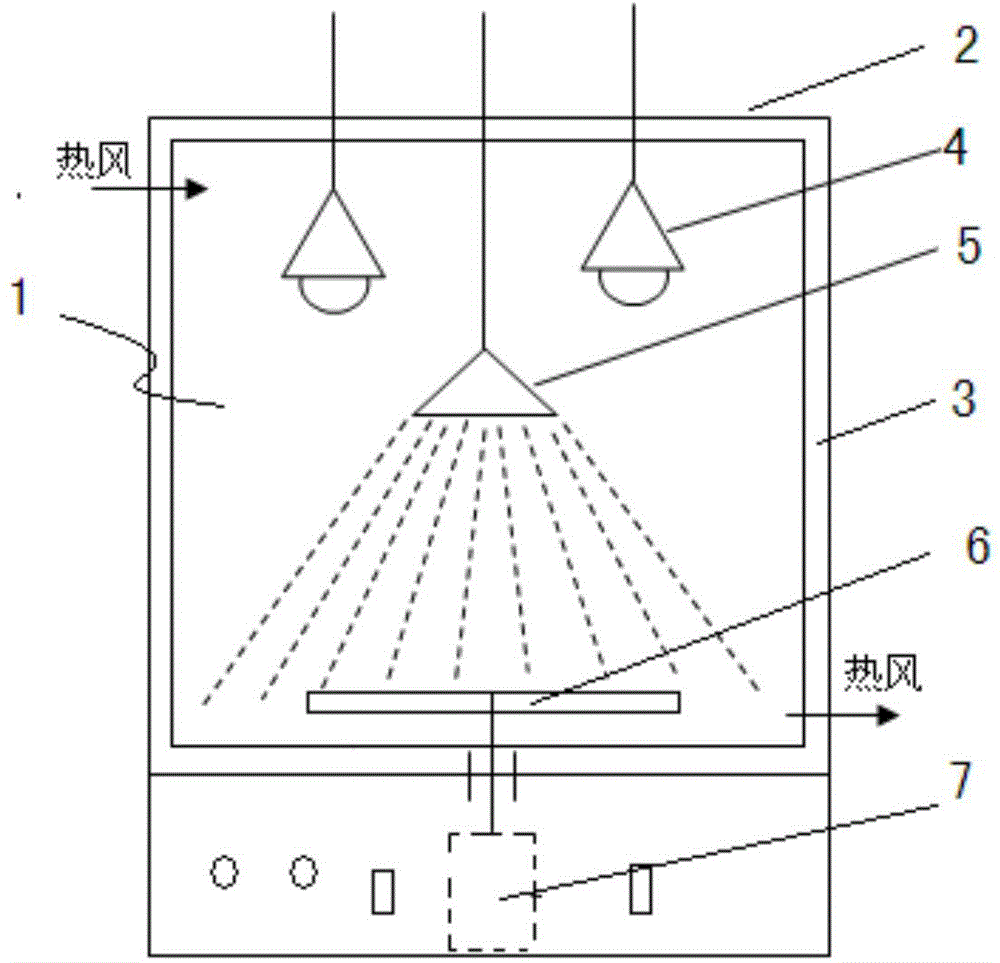

[0014] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. Such as figure 1 An embodiment of the shown asphalt aging instrument, the asphalt aging instrument, comprises an external box shell 2 and an internal working chamber 1, and an insulating layer 3 is formed between the box shell 2 and the working room 1, and the insulating layer 3 is filled with glass fiber , an ultraviolet lamp 4 and a shower head 5 are arranged above the studio 1, a material table 6 is provided near the bottom of the studio 1, and a motor 7 is connected to drive the material table 6; and the asphalt aging meter of the present invention uses a precision RTD sensor The temperature of the working chamber is sampled and transmitted to the controller.

[0015] When turning on the asphalt aging instrument, (1), start the power supply first, use the heating "I" gear when heating up, and set the temperature controller to the required tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com