Optical fiber ribbon curing equipment

A technology for curing equipment and optical fiber ribbons, which can be used in pretreatment surfaces, coatings, devices for coating liquids on surfaces, etc. Curing quality and other issues to achieve the effect of improving work efficiency, reducing energy consumption, and improving curing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

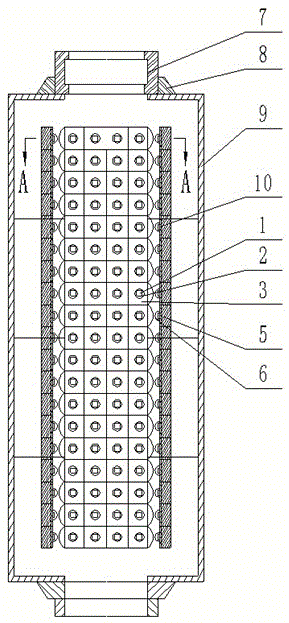

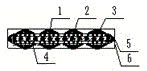

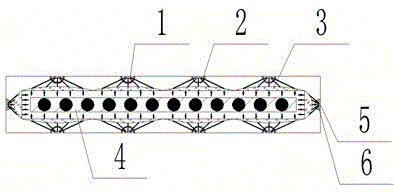

[0019] Including a cylindrical base 9, the cross-section of the cylindrical base is rectangular, the upper and lower ends of the cylindrical base are respectively provided with an optical fiber ribbon inlet and an optical fiber ribbon outlet, and the optical fiber ribbon inlet at the upper end of the cylindrical base is connected by The seat 8 is equipped with an optical fiber ribbon and has a mold 7 . During the production process of optical fiber ribbon, the optical fiber ribbon is bonded and coated by resin material in the mold, and then passes through the inner cavity of the cylindrical base of the curing equipment along the curing axis. In the inner cavity of the cylindrical base along the direction of travel of the optical fiber ribbon, UVLED light source modules 1 are respectively installed on the front and back sides of the corresponding opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com