Annular steel belt continuous beancurd skin processing device and method

An annular steel belt and processing device technology, which is applied in the field of annular steel belt continuous bean hull processing devices, can solve the problems of low degree of automation, low utilization rate, effective adjustment, etc., so as to improve the freshness and storage time, improve the curing quality, The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

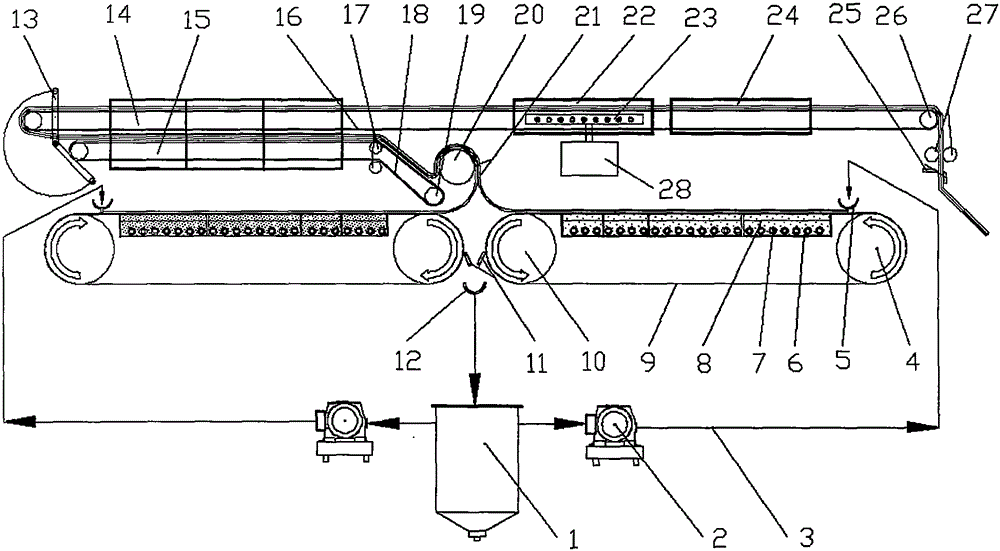

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

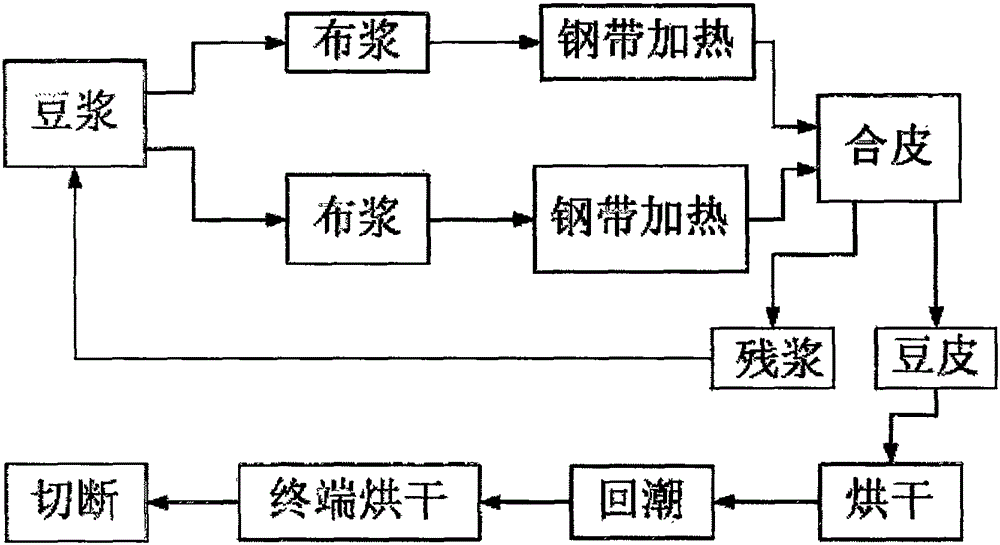

[0036] 1. Continuous bean curd processing technology with endless steel belt:

[0037] a Distributing slurry: Stir the liquid soybean milk in the slurry tank 1 slowly and at a constant speed, and spray it evenly on the two sets of steel belts 9 arranged symmetrically through the slurry pump 2 and the slurry distributing device 5;

[0038] b steel strip heating: the steel strip 9 passes through the oil tank 6 heating zone below it at a slow and uniform speed to be heated for about 15-20 minutes, and the heating temperature is kept at about 80-90°C, and then solidified soybean skin 21 is formed on the surface of the soybean milk;

[0039] c combined skin: the soya-bean milk with solidified skin on the 2 groups of steel belts 9 is pressed by the combined skin roller 20 to stick the skin and form the skin 21;

[0040] d Drying: the bean curd 21 is conveyed by the lower me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com