Adjustable G shaped clip

An adjustable and clamping technology, applied in the field of G-shaped clamps, can solve the problems of insufficient stability of the clamped objects, inconvenient carrying and installation, and narrow adjustable range, etc., to achieve a larger clamping range, simple structure, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

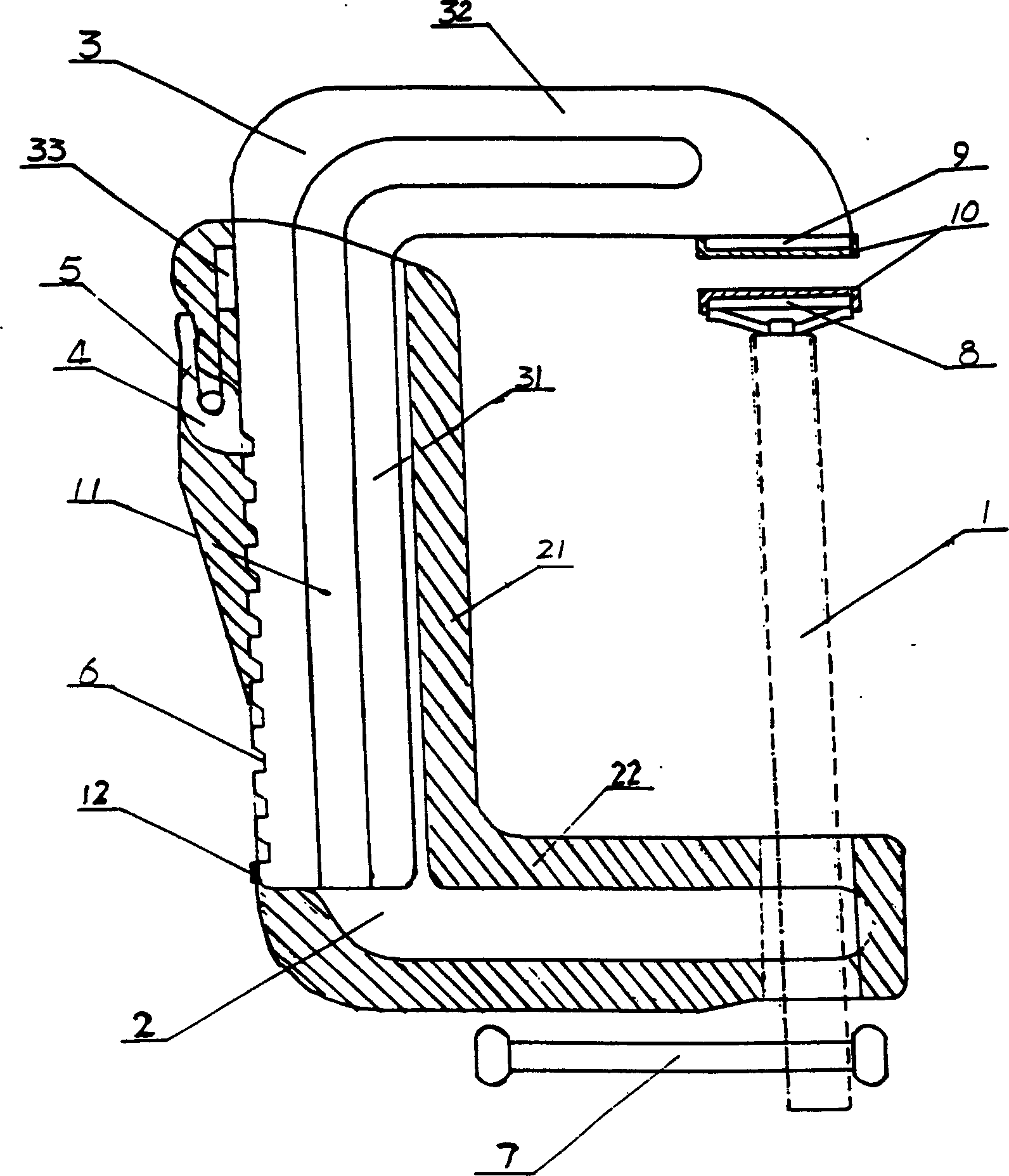

[0014] like figure 1 The adjustable G-shaped clamp shown has a clamp body and a screw rod 1. Unlike the common G-shaped clamp, the clamp body is composed of an outer frame 2 and a telescopic body 3. The outer frame 2 is composed of an outer frame column 21 and the outer frame cross bar 22, the telescopic body 3 is composed of the telescopic body column 31 and the telescopic body cross bar 32, and the telescopic body column 31 is provided with reinforcing ribs 11, the outer frame column 21 and the outer frame cross bar 22 and the telescopic body The body column 31 and the telescopic body cross bar 32 are all integral structures and the angle between them is a right angle. The outer frame 2 is stamped and welded by iron plates. The outer frame column 21 is a semi-closed structure with openings on the outside. The telescopic body column 31 It is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com