A clamping device for hinged and fixed circuit board production

A technology of clamping device and fixing device, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of circuit board clamping and fixing device clamping, high cost and trouble of clamping device, and achieve easy installation and disassembly, The effect of enhancing the range of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

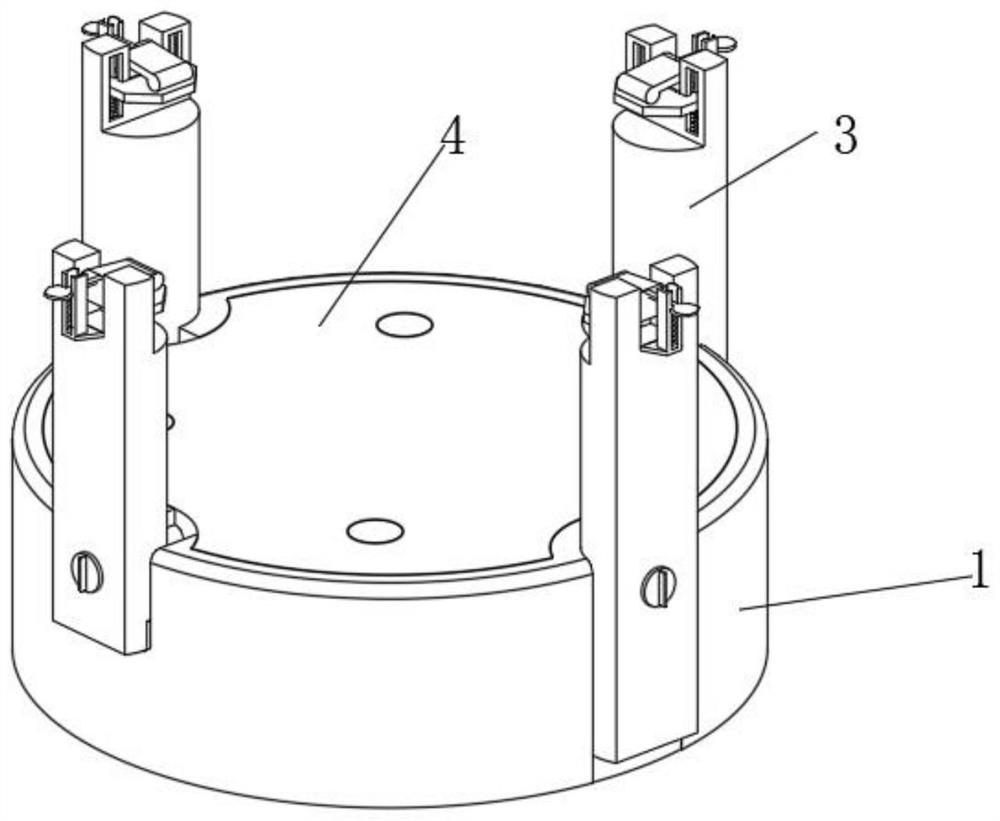

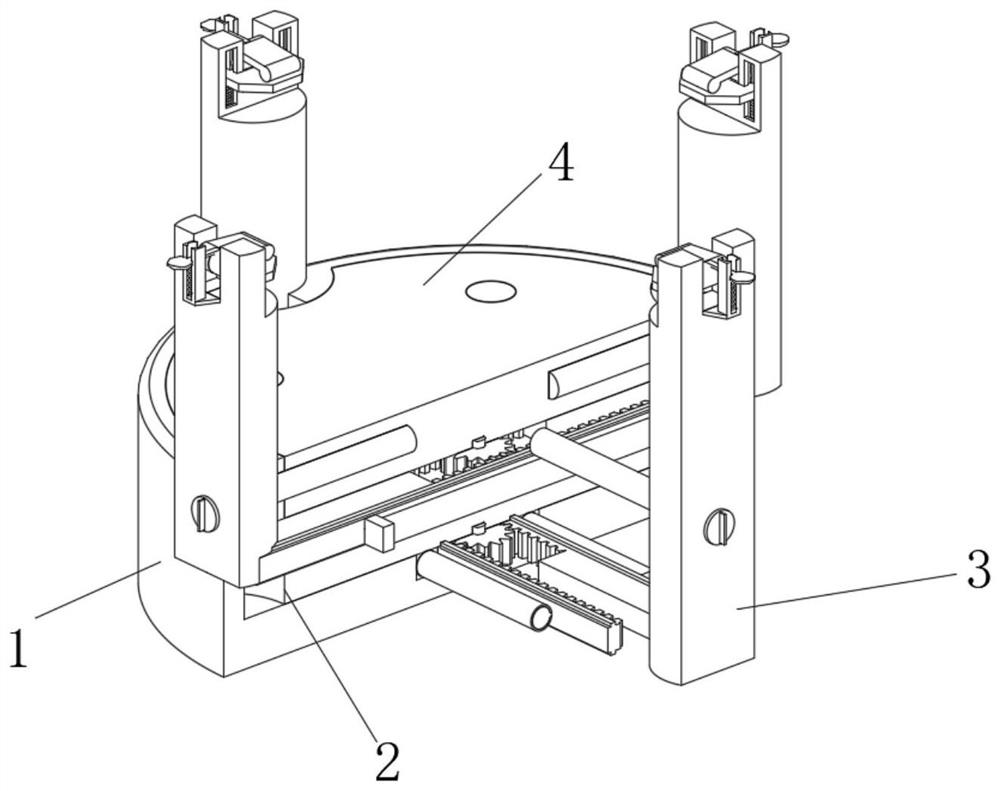

[0047] see Figure 1-Figure 10 As shown, a clamping device for producing a hingedly fixed circuit board is provided, comprising a protective seat 1, a bottom receiving and pressing device 2 is provided inside the protective seat 1 at a position close to the bottom side, and the bottom of the protective seat 1 is provided with a bottom bearing and pressing The upper side of the device 2 is provided with an upper cover fixing device 4, and the center of the side wall of the protective seat 1 is symmetrical with two sets of clamping and positioning devices 3 arranged up and down. Undertake between the pressing device 2 and the upper cover fixing device 4;

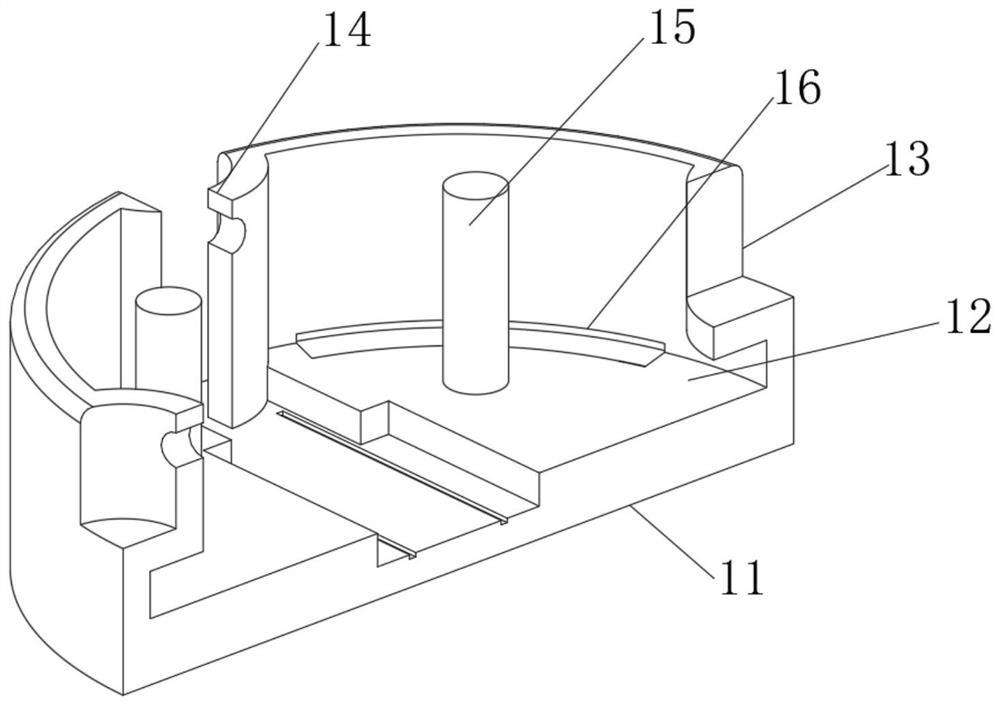

[0048] The protective seat 1 includes a protective casing 11. A rod slot 13 is arranged in an annular arrangement on the side wall of the protective casing 11. A plate slot 14 is opened on the side wall of the rod slot 13 near one side, and the interior of the protective casing 11 is provided with Passing through the placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com