Multi-variety self-adaptive stock bin device

An adaptive, multi-variety technology, applied in the field of parts clamping, can solve the problems of increasing the labor intensity of operators, waste of production time, affecting production efficiency, etc., to increase the clamping range, increase the capacity of the silo, and ensure the strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

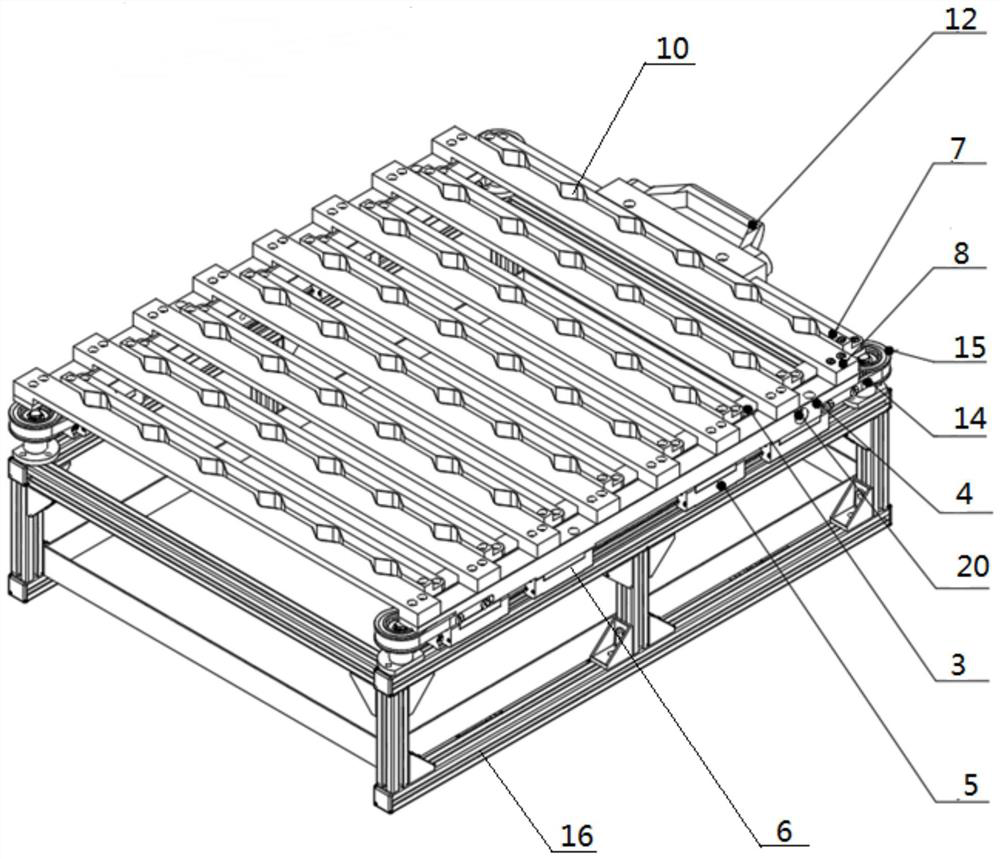

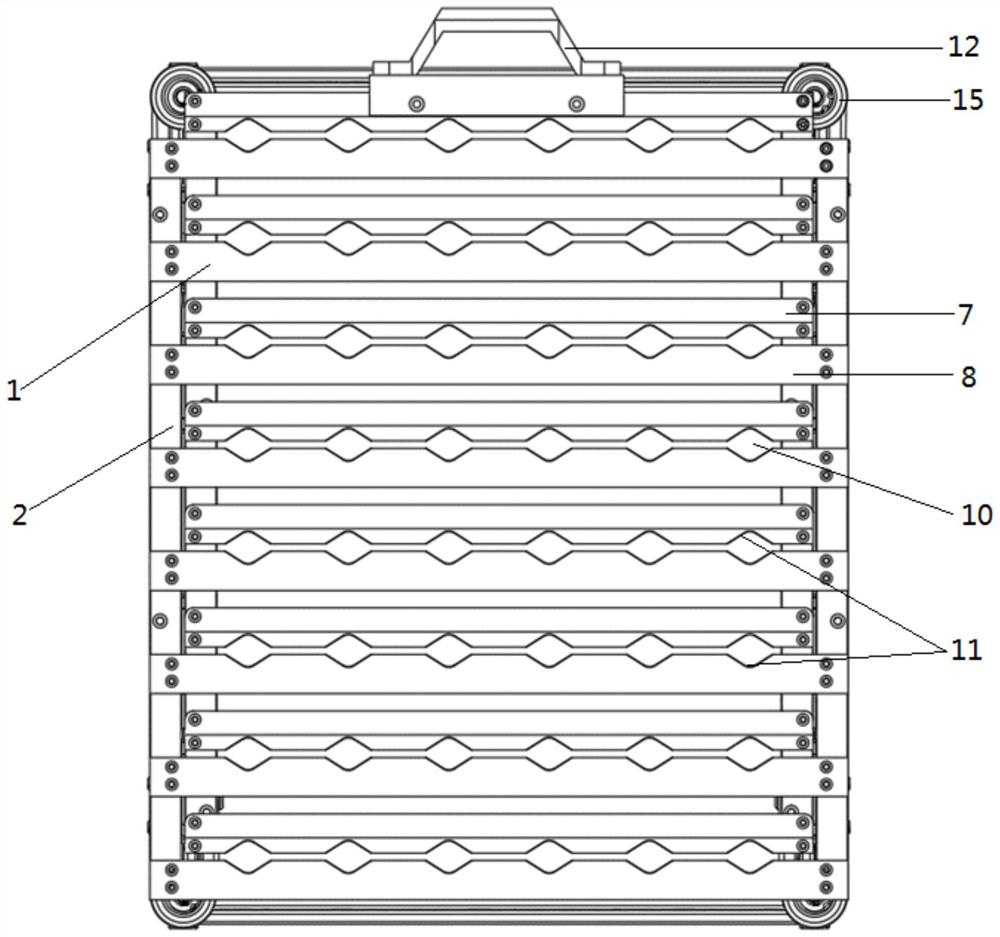

[0031] Embodiment Assembly and use of the device of the present invention

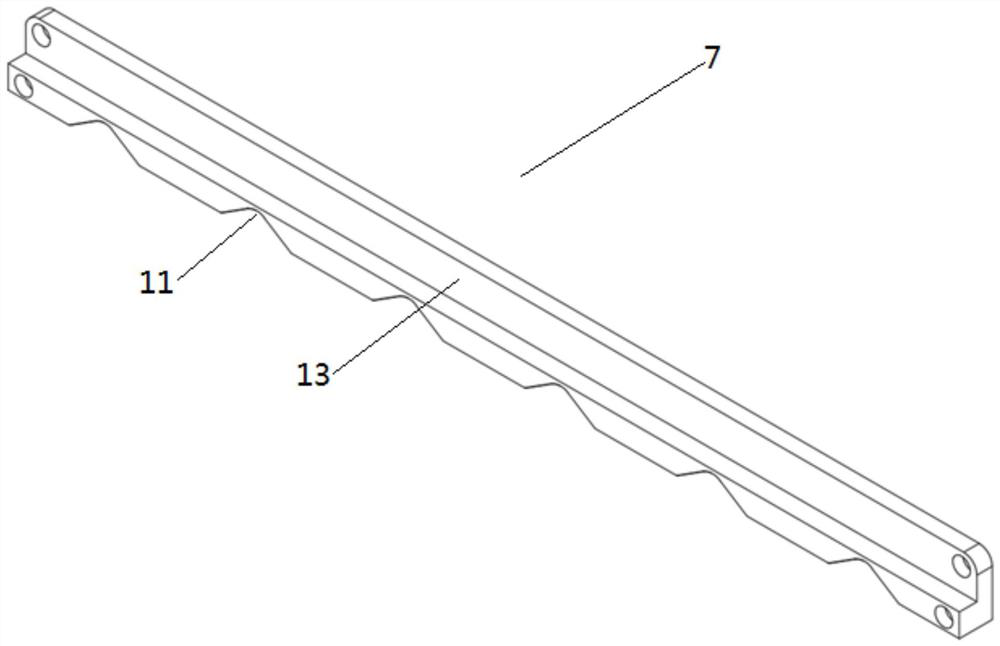

[0032] Such as figure 1 and 2 As shown, the device includes a square material platform 1 and two sliding mechanisms 2, and the two sliding mechanisms 2 are respectively located on one side of the material platform 1; the sliding mechanism 2 includes an inner slide bar 3, an outer Slide bar 4, inner slide block 5, outer slide block 6, two synchronous wheels 15, two synchronous belts 14 and guide rail 9, the two ends of inner slide bar 3 and outer slide bar 4 pass through the synchronous belt that bypasses synchronous wheel 15 14 connections; the inner slider 3 is connected to the inner slider 5, and the outer slider 4 is connected to the outer slider 6, so that the inner slider 5 and the outer slider 5 drive the inner slider 3 and the outer slider 4 to slide along the guide rail 9; The material platform 1 includes several pairs of clamping plates arranged in parallel, each pair of clamping plates is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com