Patents

Literature

35results about How to "Realize loading operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

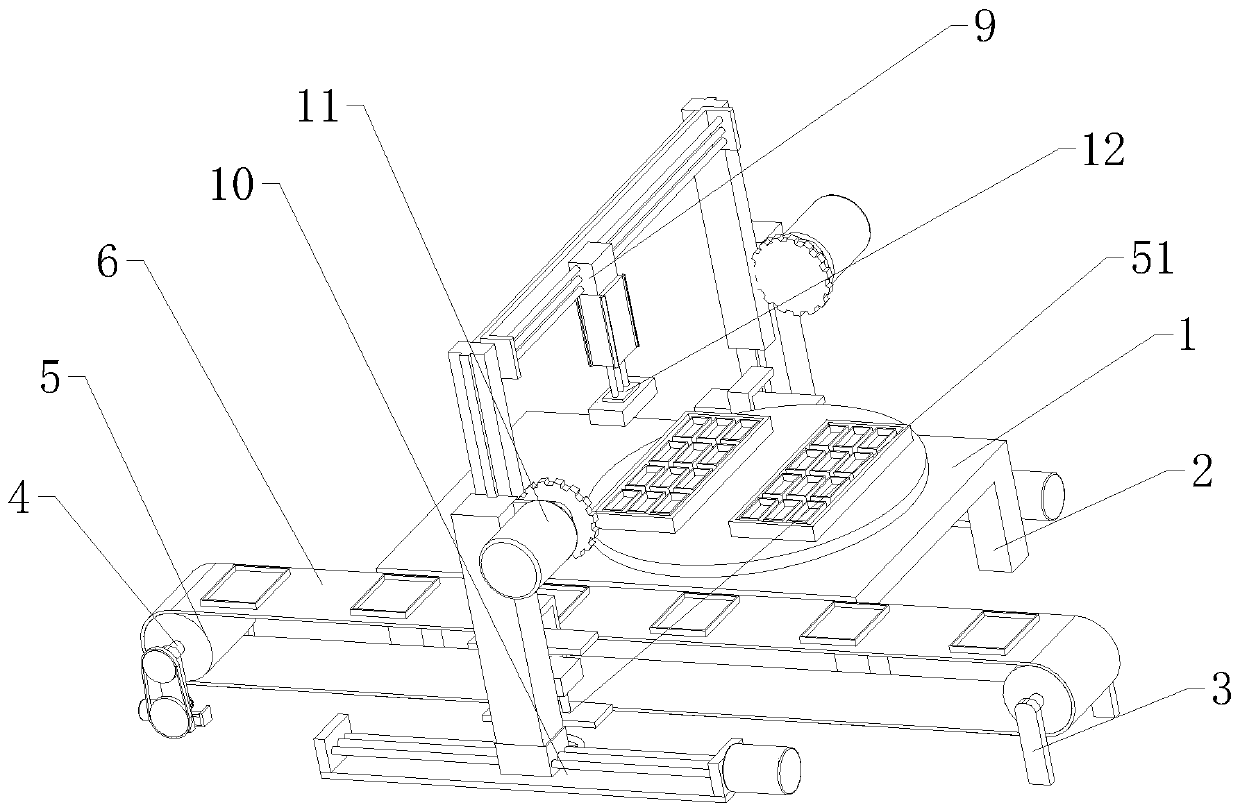

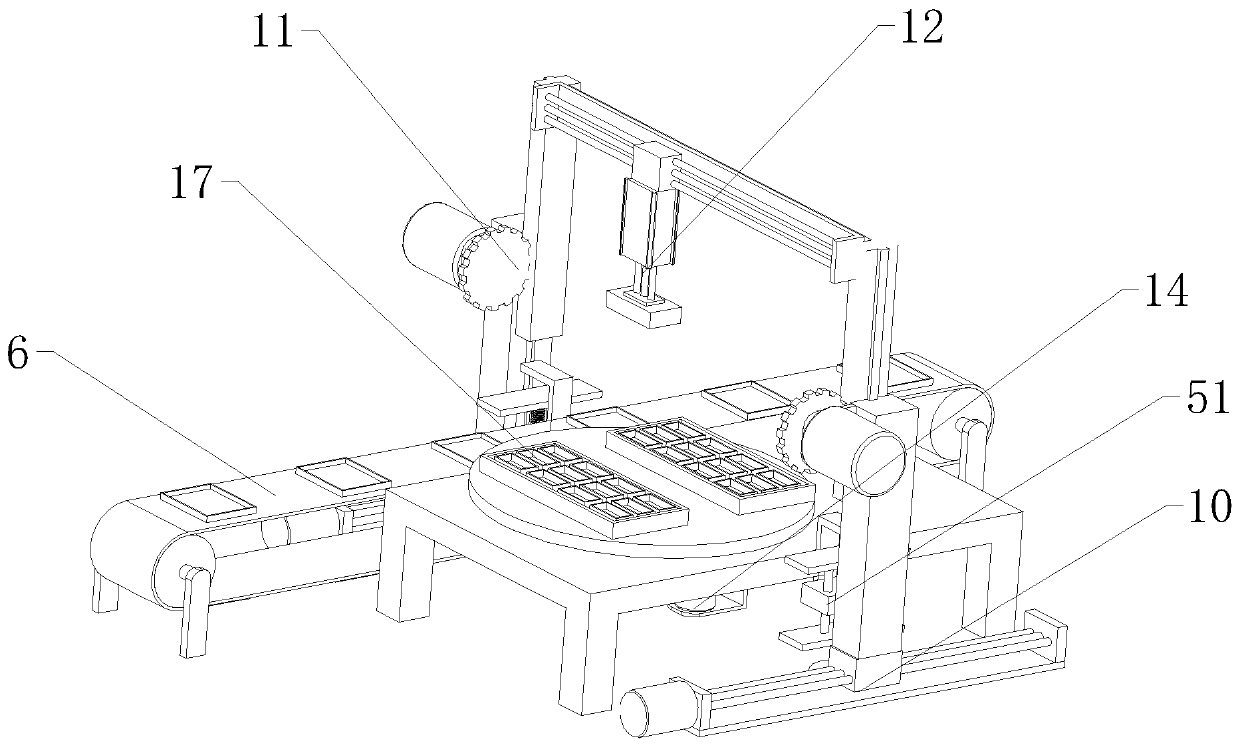

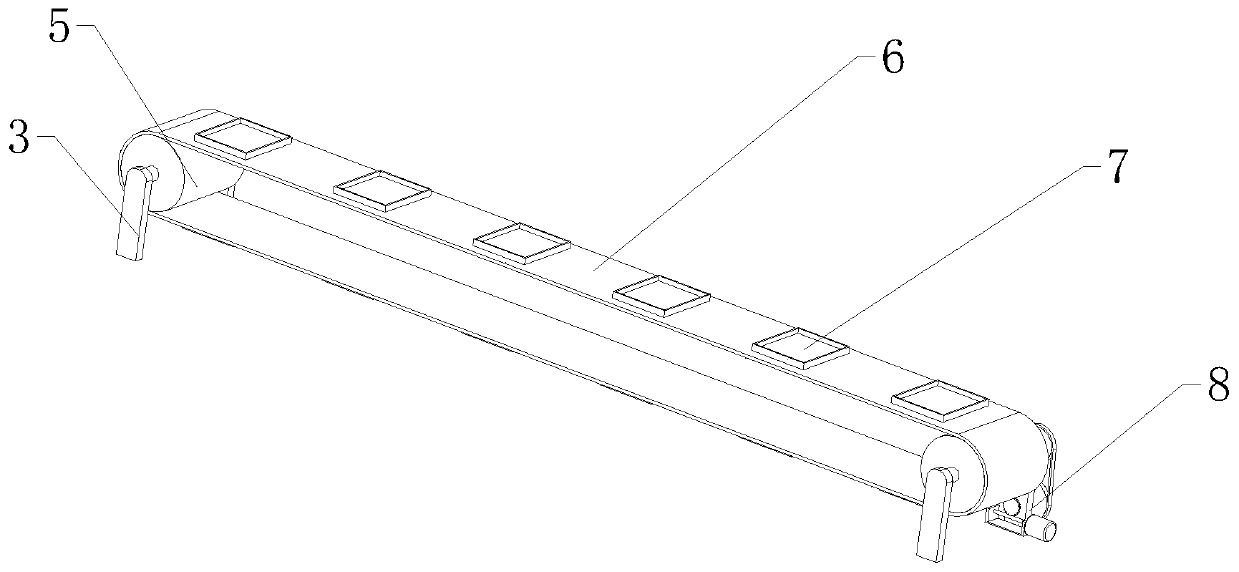

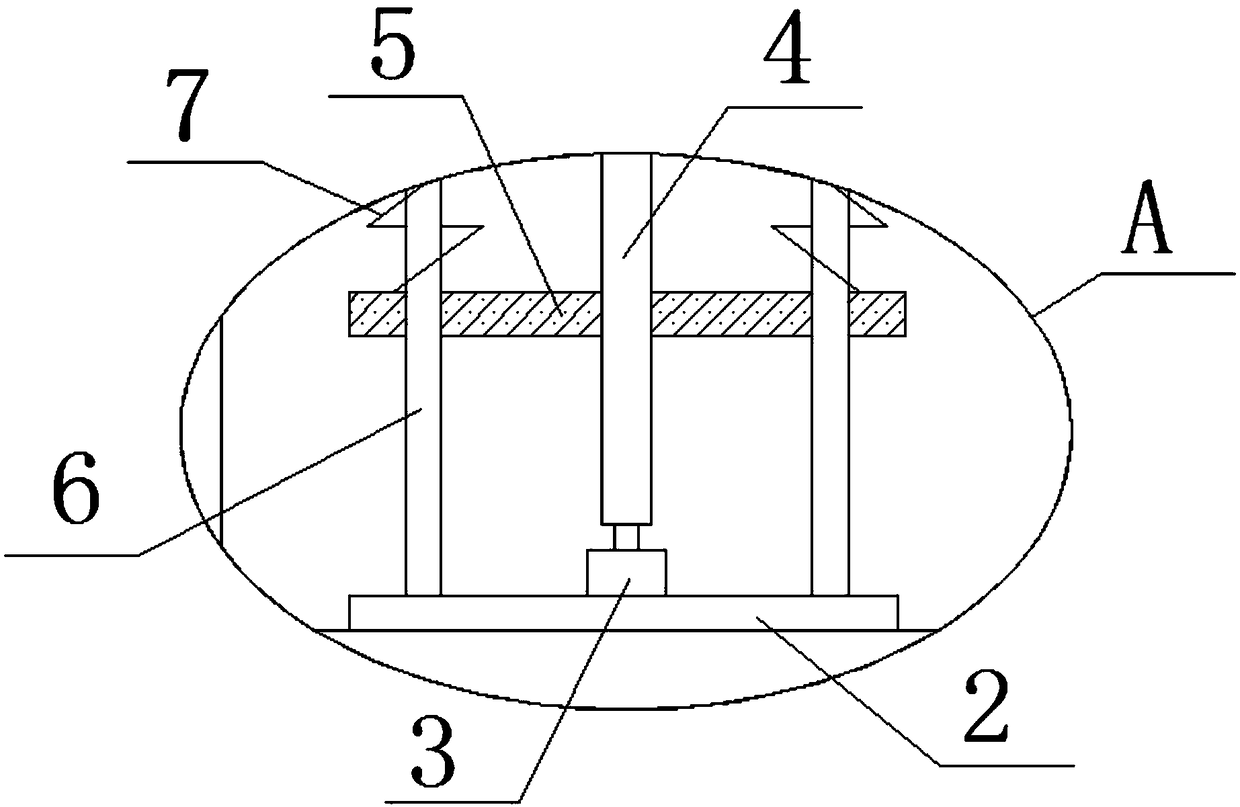

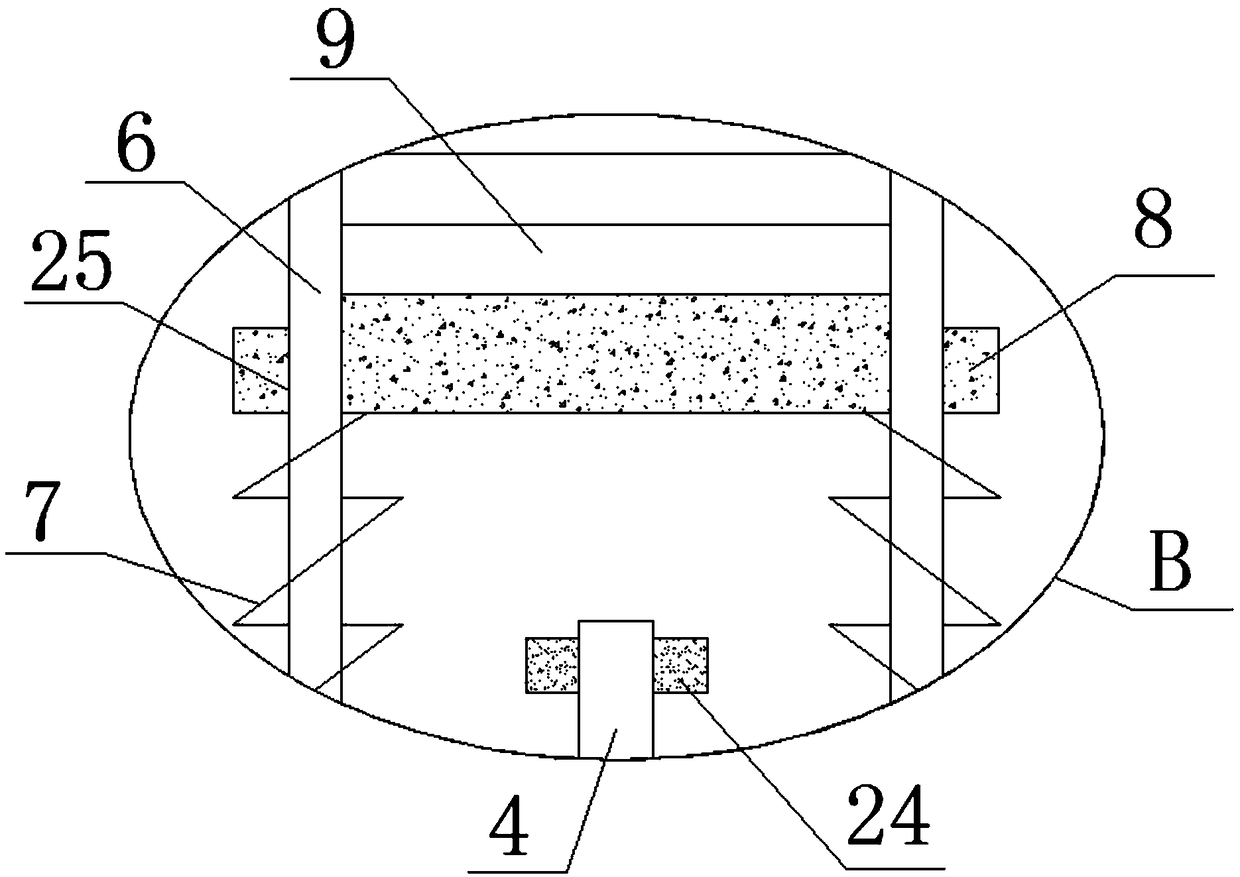

Automatic chip charging device

The invention relates to the technical field of automatic charging equipment, and specifically relates to an automatic chip charging device. The device comprises a working platform, and a conveying device which is arranged at the side part of the working platform, wherein the conveying device comprises a supporting frame, a roller, and a conveyor belt which sleeves the roller; the roller is fixedly arranged on the supporting frame; a driving assembly is arranged on the supporting frame; a picking and storing device is arranged at the upper parts of the working platform and the conveying device; the picking and storing device comprises a longitudinal moving mechanism and a lifting mechanism which are symmetrically arranged; the lifting mechanism is arranged on the output end of the longitudinal moving mechanism; a transverse moving mechanism is also connected to the output end of the lifting mechanism; a grabbing mechanism is arranged on the output end of the transverse moving mechanism; a jig device is arranged on the working platform; the jig device comprises a second rotating shaft which is shafted to the working platform; a rotating mechanism for driving the second rotating shaft to rotate is arranged at the bottom side of the working platform; and a turntable is fixedly mounted on the second rotating shaft. With the adoption of the device, the chip charging efficiency is improved.

Owner:夏安祥

Automatic book core feeding device for perfect binding book-in-cover mechanism

The invention discloses an automatic book core feeding device for a perfect binding book-in-cover mechanism. The book core feeding device comprises a rack, a supporting plate is welded to one side ofthe rack, a first motor is fixedly installed at the top of the supporting plate, a lead screw is fixedly installed on an output shaft of the first motor, the outer side of the lead screw is sleeved with a sliding plate in a threaded manner, guide rods are welded to the two sides of the top of the supporting plate, the sliding plate is installed on the two guide rods in a sliding and sleeving manner, the outer sides of the two guide rods are sleeved with one material containing plate in a sliding manner, two symmetrically-arranged springs are welded to the bottom of the material containing plate, the springs are movably installed on the outer sides of the corresponding guide rods in a sleeving manner, and the bottom ends of the springs and the top of the sliding plate are welded. Accordingto the automatic book core feeding device, the sliding plate is driven to upwards extrude the springs to enable the springs to absorb energy, electricity of the springs can drive remaining book coresto move upwards when book cores on the material containing plate are reduced, a rotary disc drives a plurality of rubber columns to rotate in a circulated manner, the rubber columns can push the bookcores to a discharging plate one by one, and the discharging operation is relatively convenient and quick.

Owner:陈慧慧

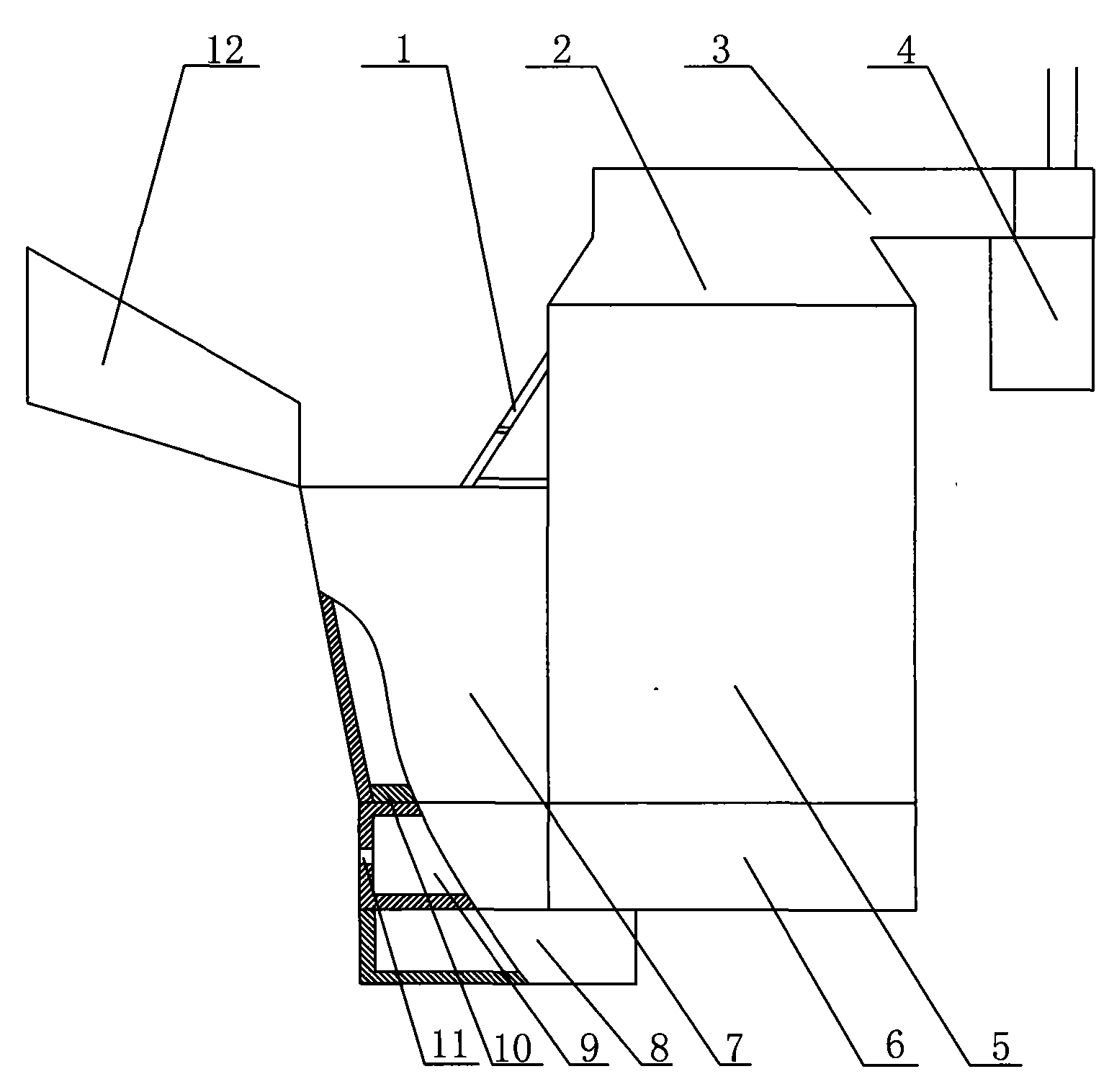

Firewood straw direct-combustion boiler and combustion process thereof

InactiveCN101556075ALow running costLow costSolid fuel combustionWater heatersCombustion chamberAtmospheric air

The invention belongs to the technical field of boilers and boiler burning and in particular discloses a firewood straw direct-combustion boiler and a combustion process thereof, wherein the boiler comprises a boiler body, a dust collecting chamber, and a thermolysis combustion chamber with a water jacket, a water cooling grate is arranged at the lower end of the thermolysis combustion chamber, a reinforcing combustion chamber is arranged below the water cooling grate and communicated with a boiler gas distributing chamber which is communicated with a boiler heat exchange chamber, the top end of the boiler heat exchange chamber is connected with a chimney communicated with the atmosphere, and the water jacket and the water cooling grate are respectively communicated with a water tank of the boiler heat exchange chamber at one side of the thermolysis combustion chamber. In such technical proposal, the combustion process of the boiler is combined with the structure thereof, thereby realizing the direct combustion of firewood straws, solving the problems of low heat value of the firewood straws and low heat intensity, providing a practical and feasible approach capable of leading to the full use of the firewood straw energy for the firewood straw treatment during the agricultural production and also reducing the environment pollution caused by burning the firewood straws.

Owner:王惠生 +1

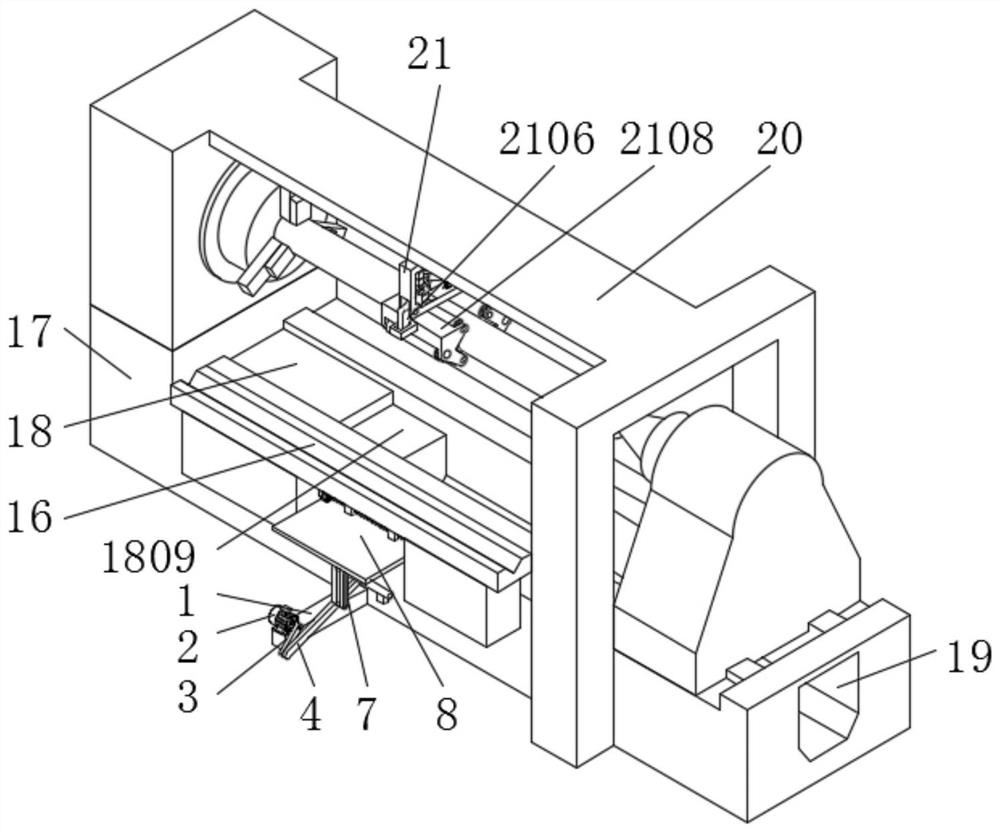

Outer surface finish machining equipment for honeycomb ceramic carrier and use method

ActiveCN113070798ARealize loading operationRealize lifting operationEdge grinding machinesPolishing machinesSurface finishStructural engineering

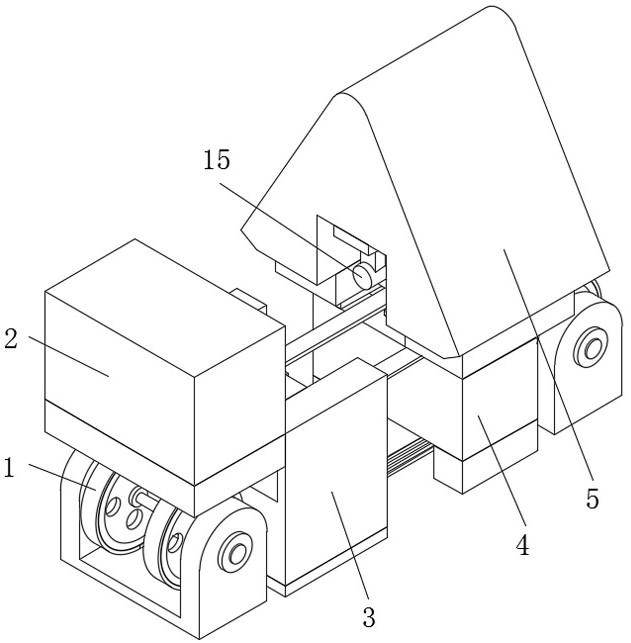

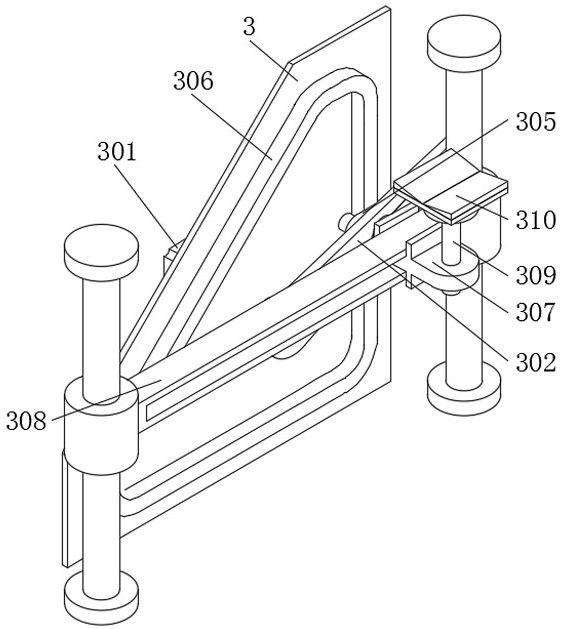

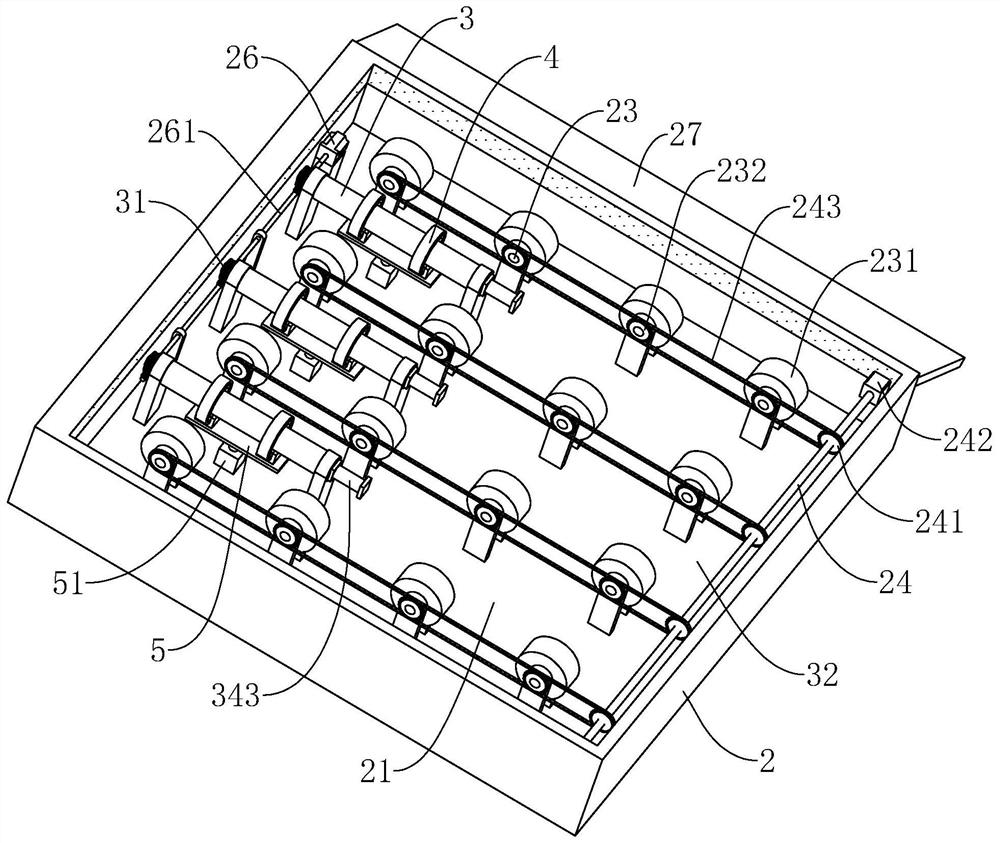

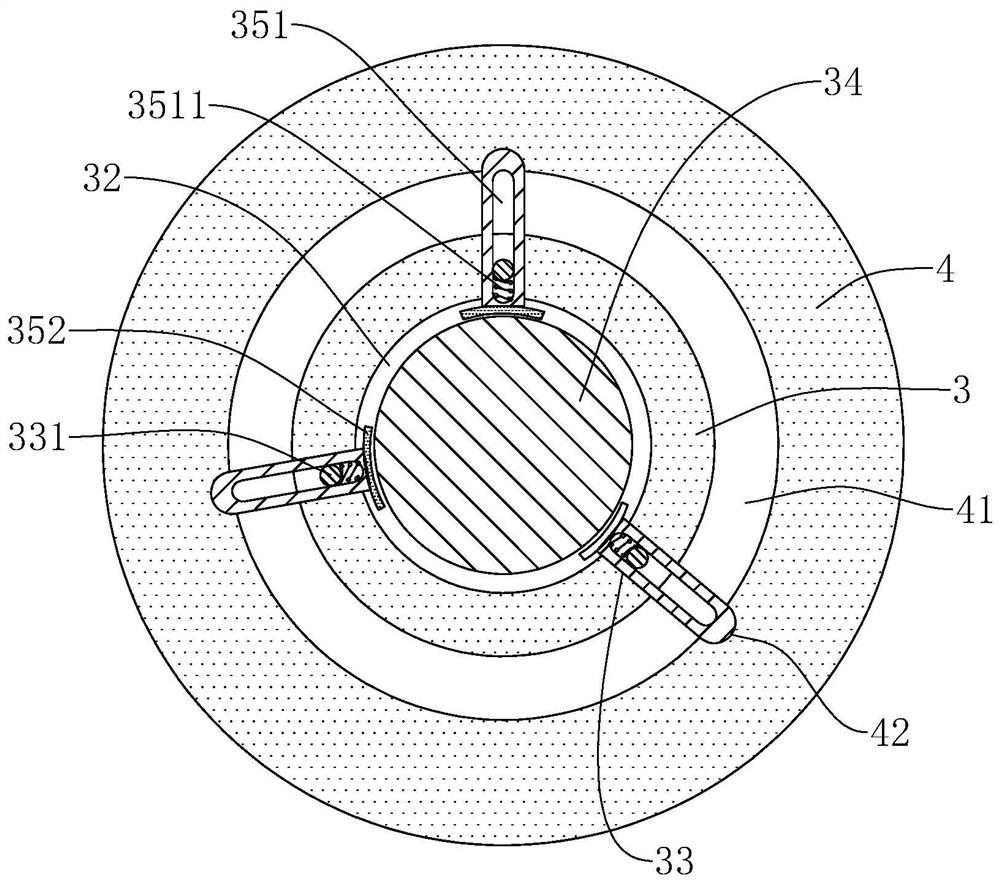

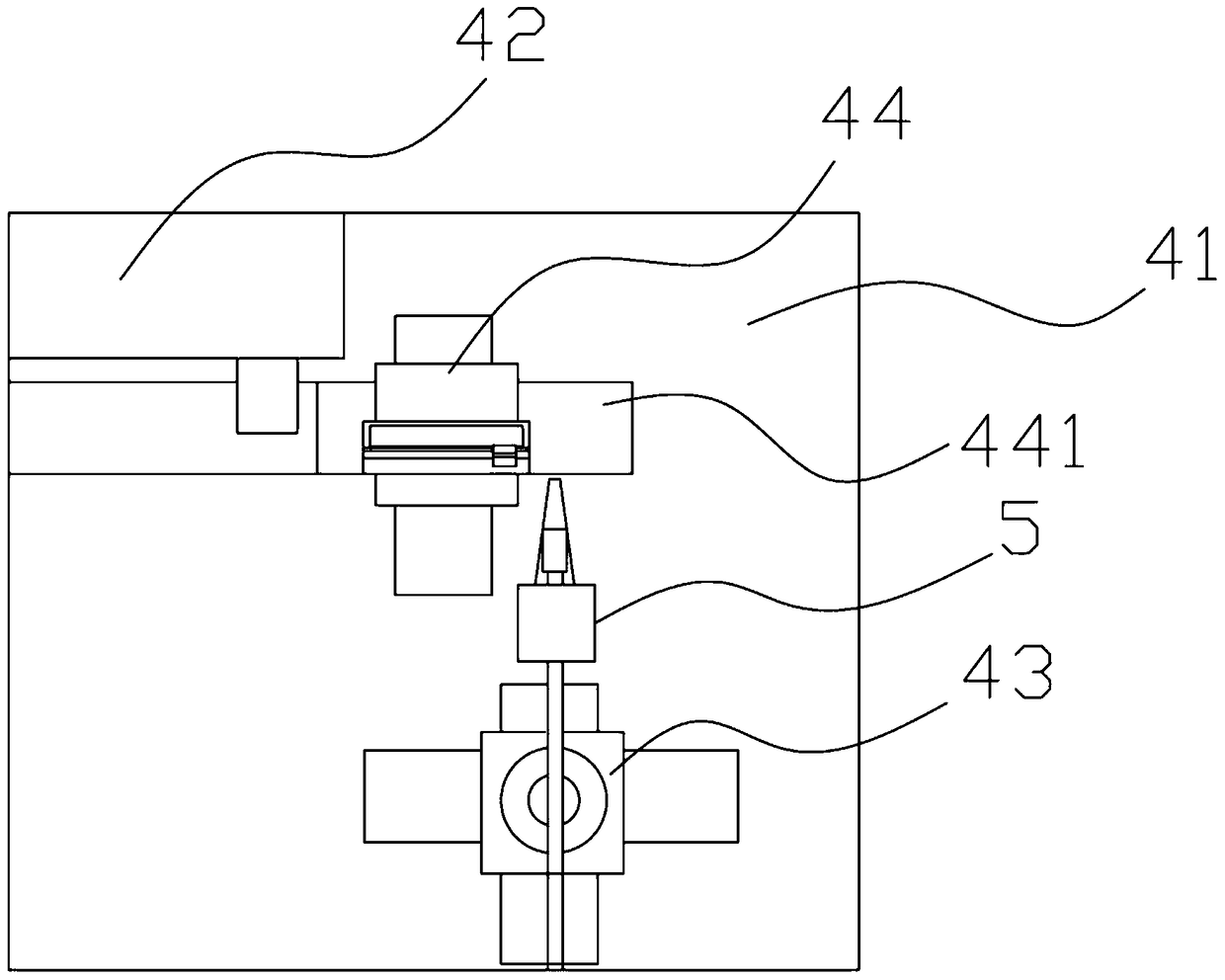

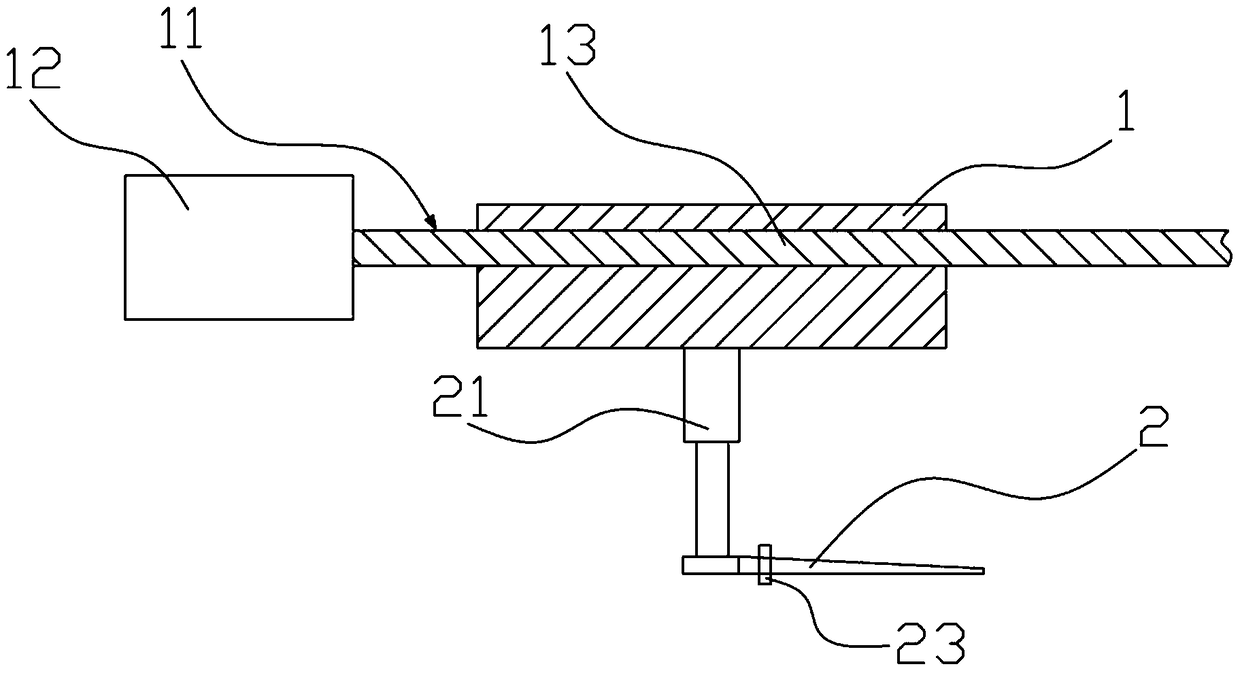

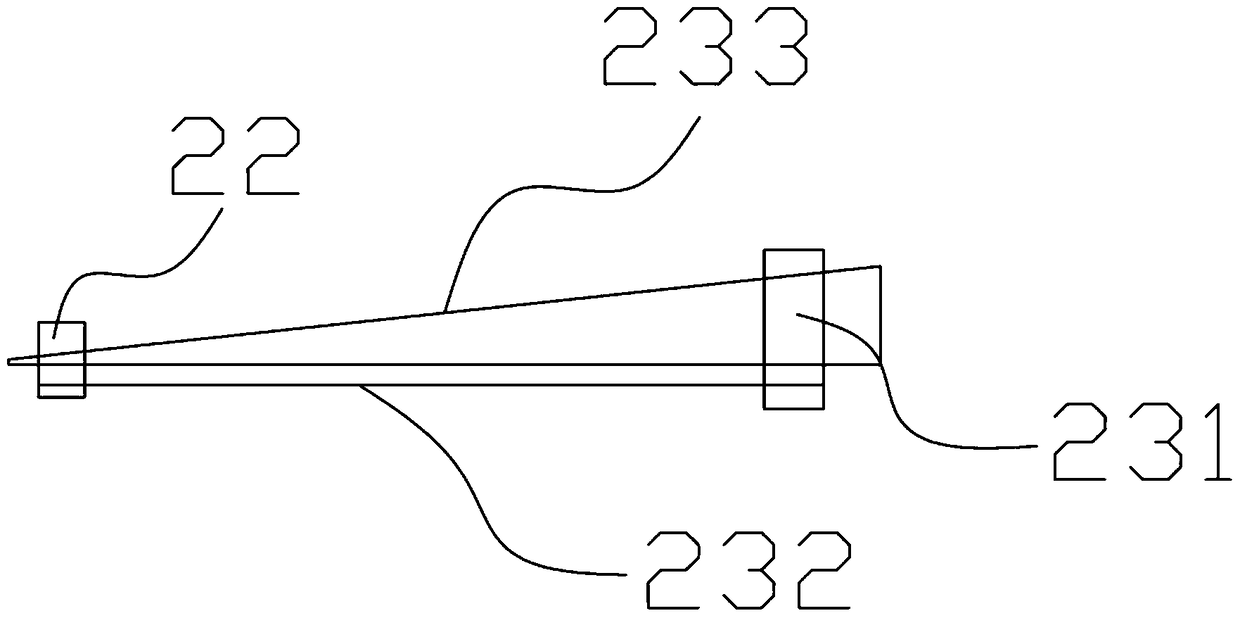

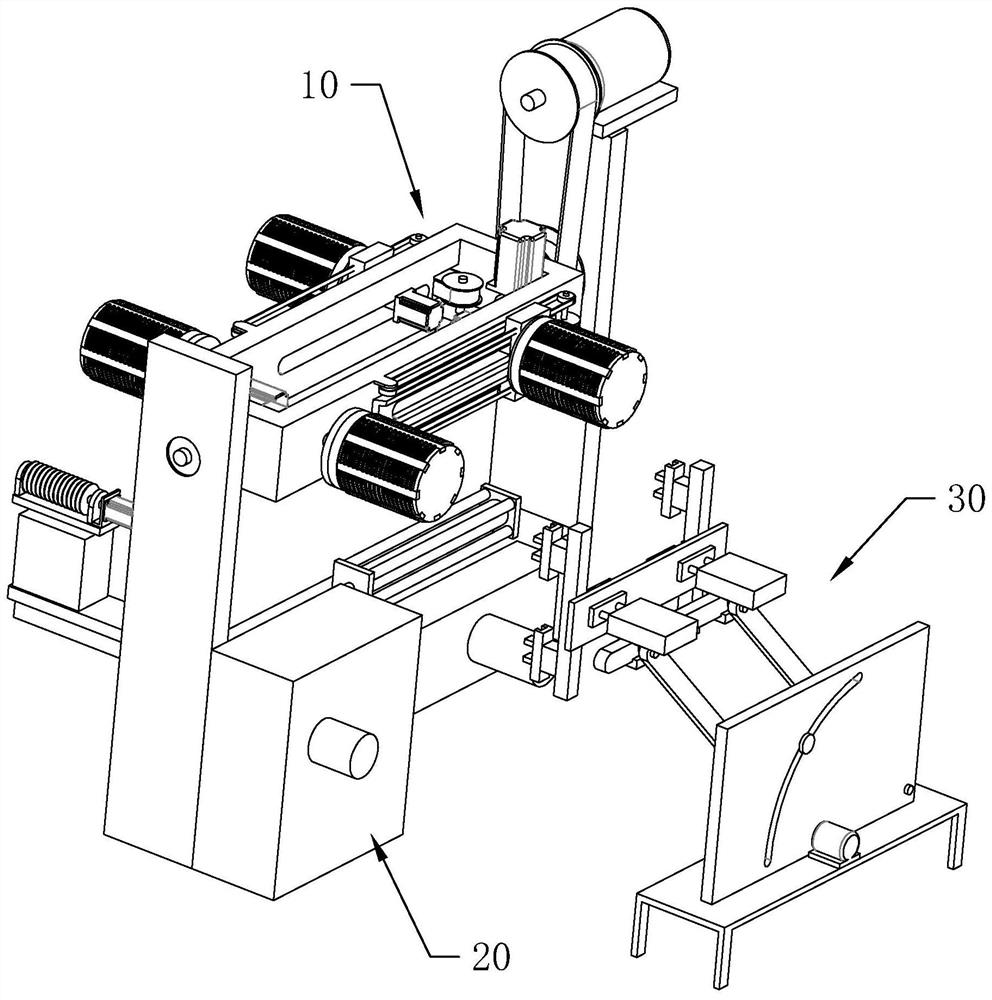

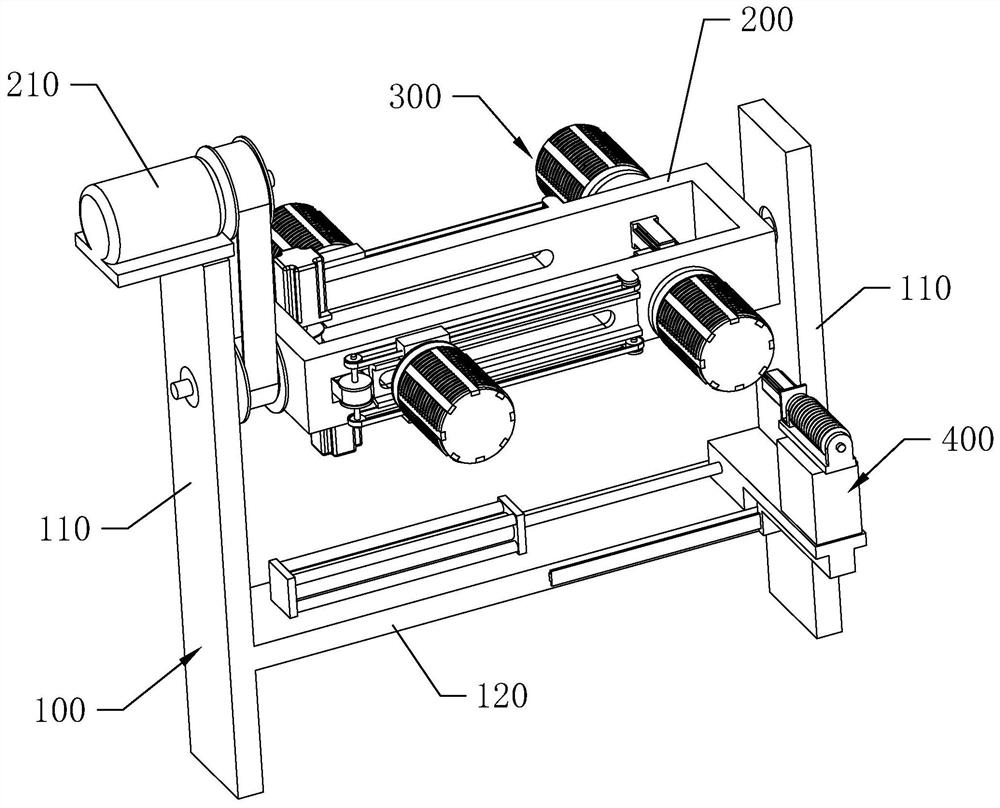

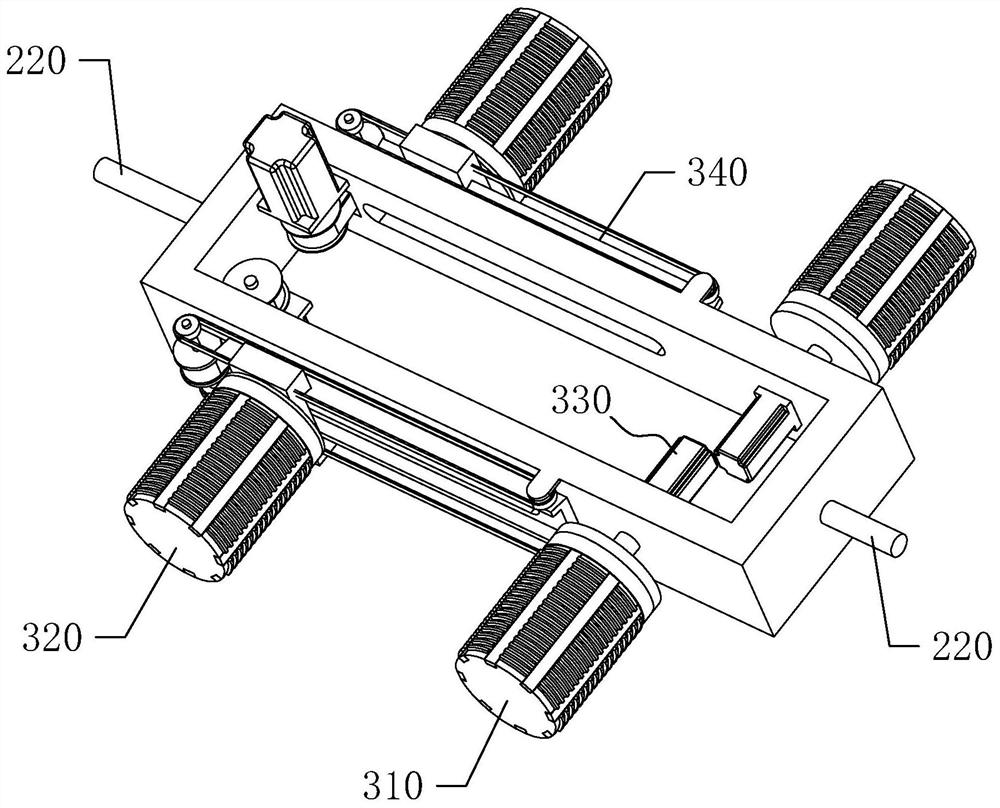

The invention discloses outer surface finish machining equipment for a honeycomb ceramic carrier and a use method, and belongs to the technical field of honeycomb ceramic carrier machining. The outer surface finish machining equipment for the honeycomb ceramic carrier comprises a conveying belt, a feeding bin is arranged above one end of the conveying belt, and a feeding mechanism is fixedly connected to the end, located on the outer side of the conveying belt, of the feeding bin. According to the outer surface finish machining equipment for the honeycomb ceramic carrier and the use method, a guide sliding column is arranged, in a feeding mechanism, a swing pore plate rotates to drive the guide sliding column to move through a movable sliding groove, the guide sliding column drives a movable sliding column to slide along a guide rail, so that the motion trail of a feeding plate connected with the guide sliding column is the same as the shape of the guide rail, the guide sliding column drives a movable sliding block to slide along the inner wall of a lifting pore plate and drives the lifting pore plate to slide along the inner wall of the feeding mechanism, the feeding plate is always in a horizontal state, and the feeding operation of the honeycomb ceramic carrier is realized through the direction-unchanged movement of the feeding plate.

Owner:YIXING SILK DRAGON POTTERY

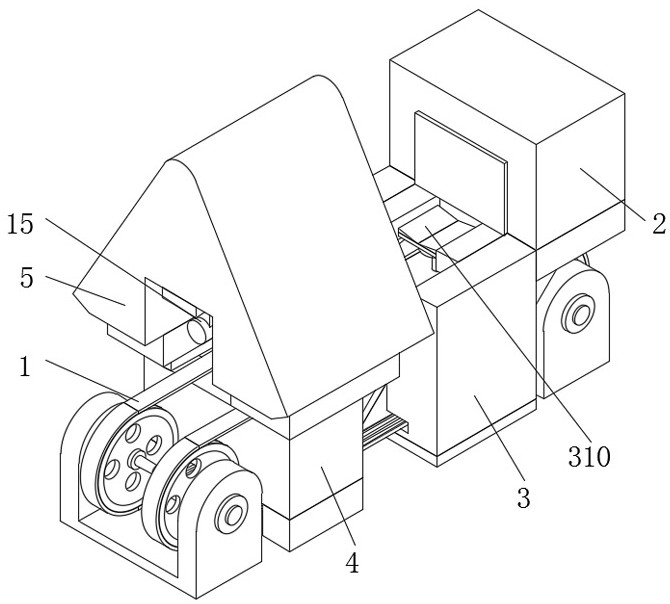

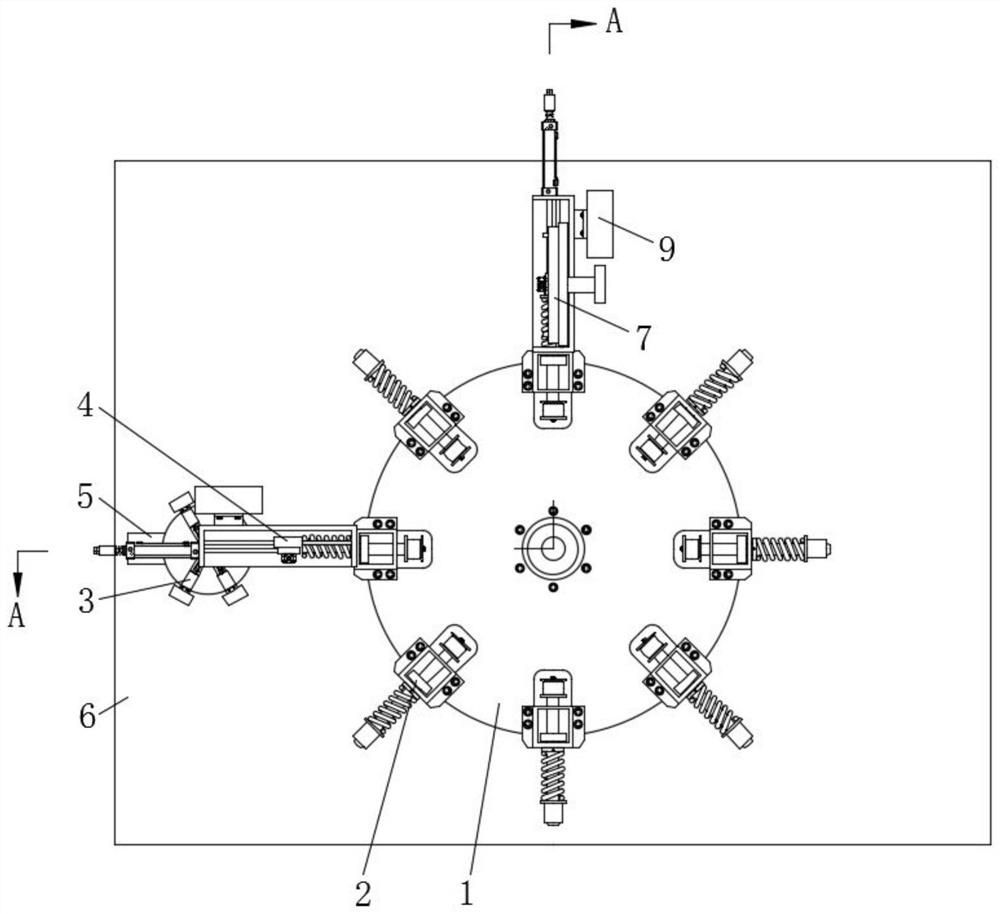

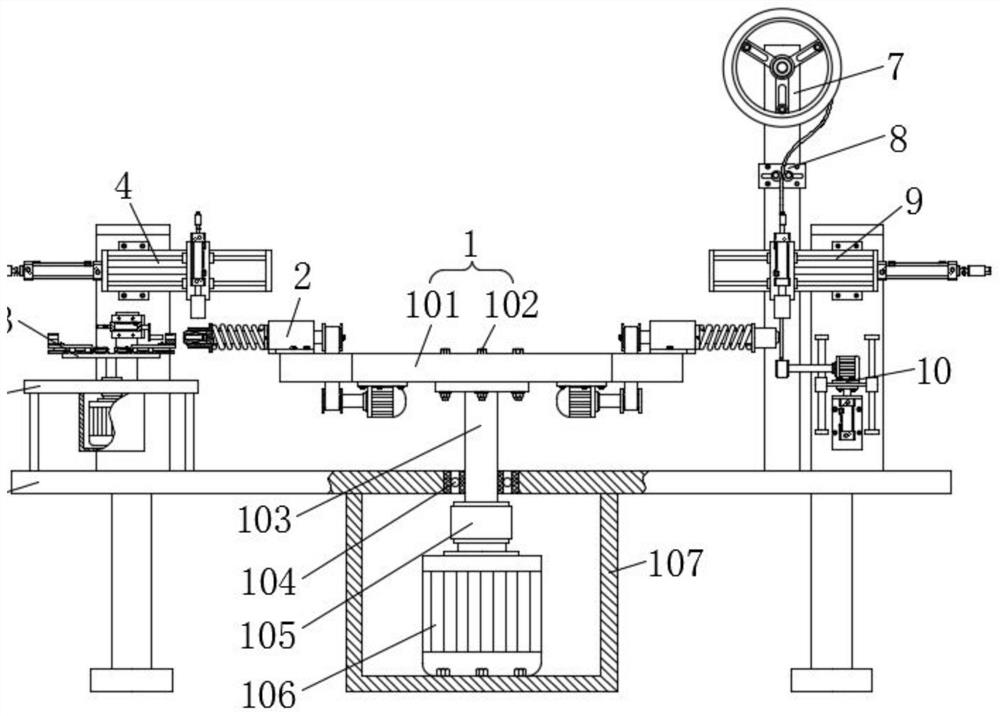

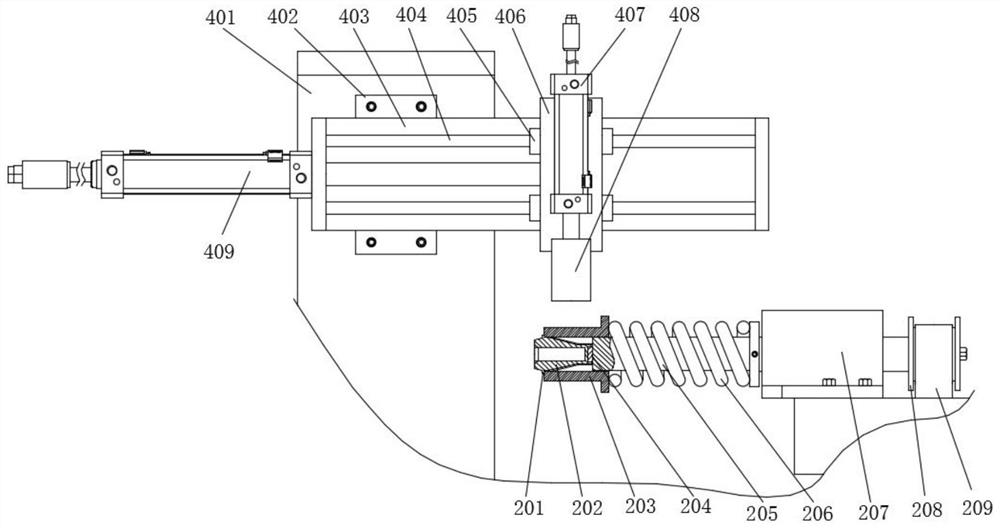

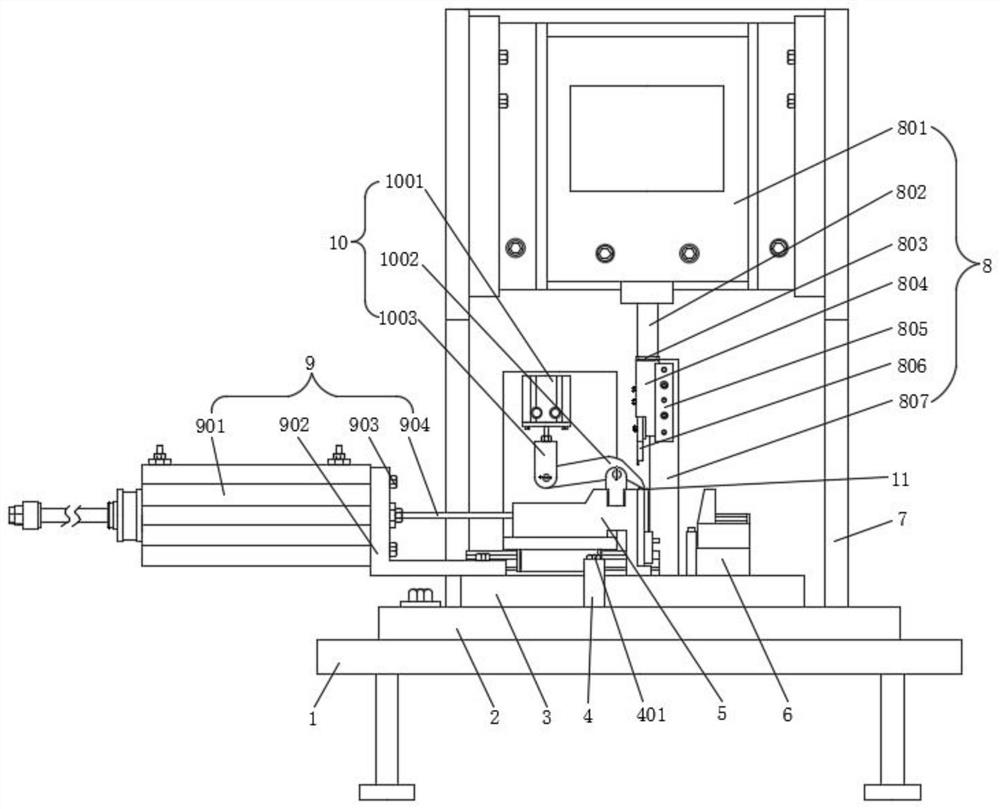

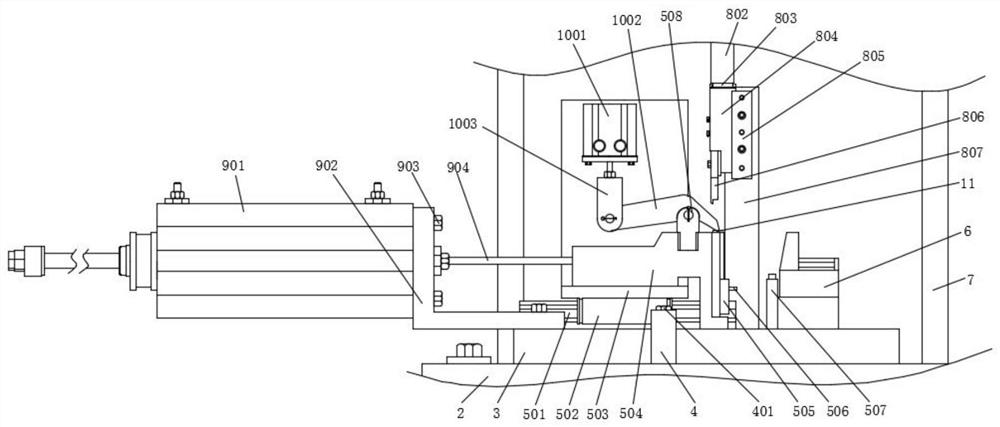

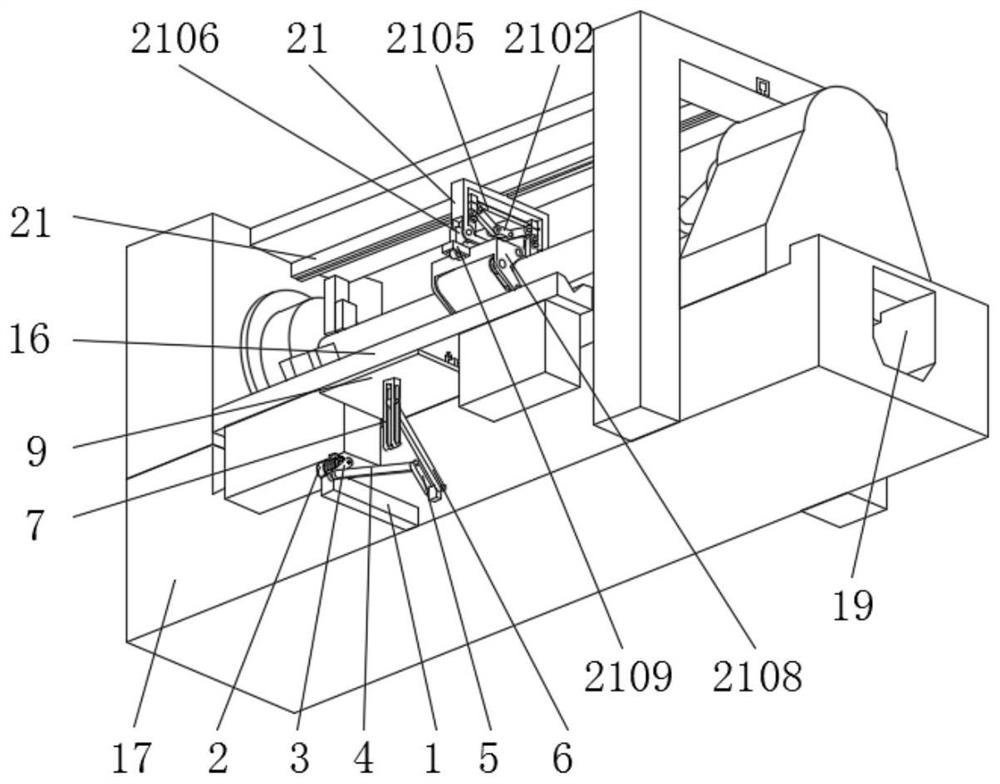

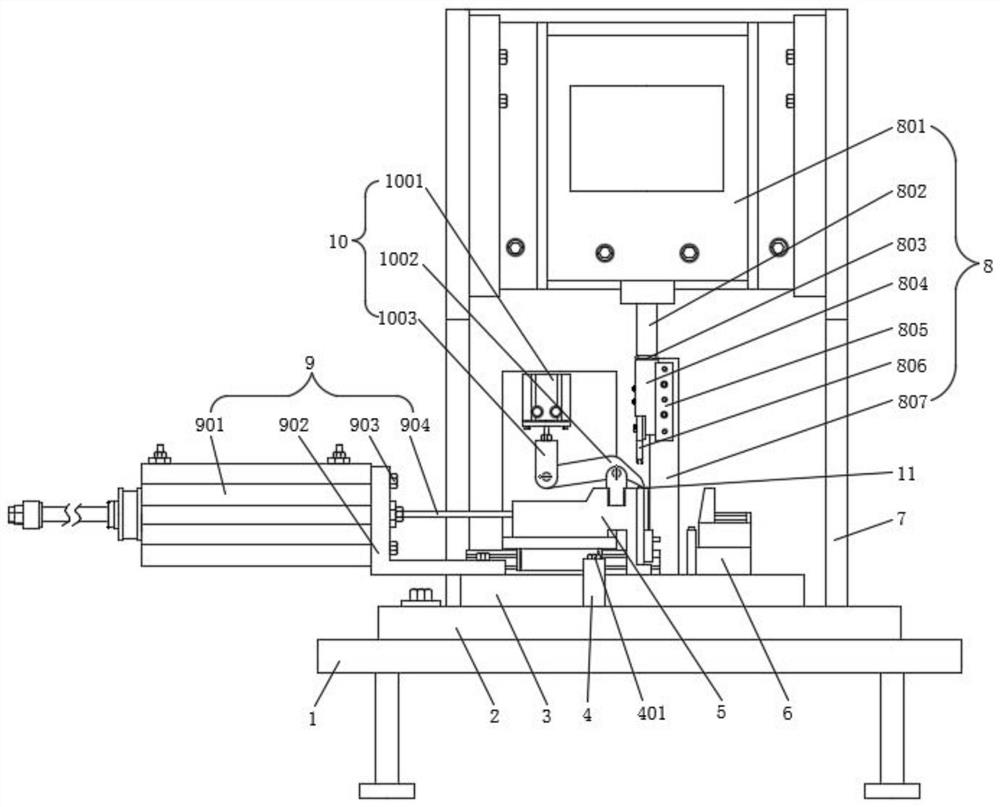

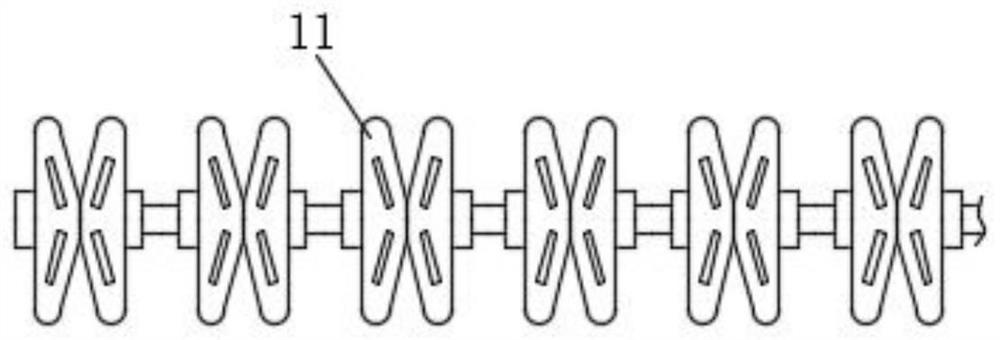

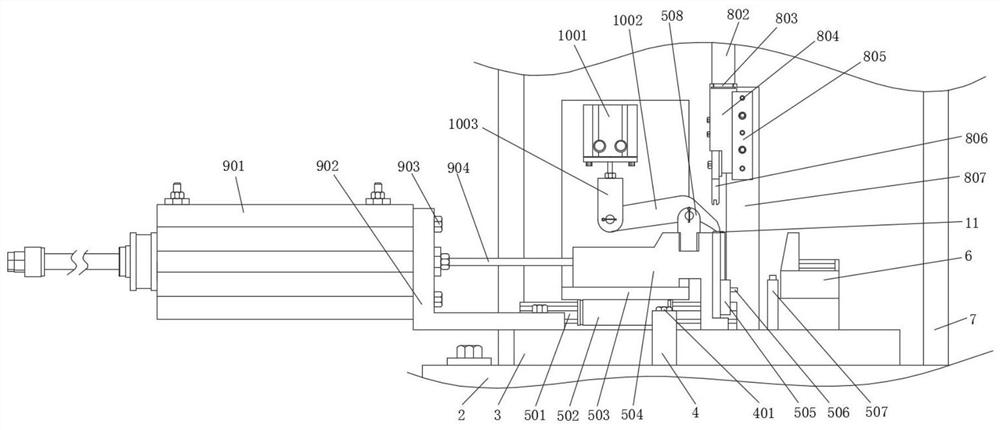

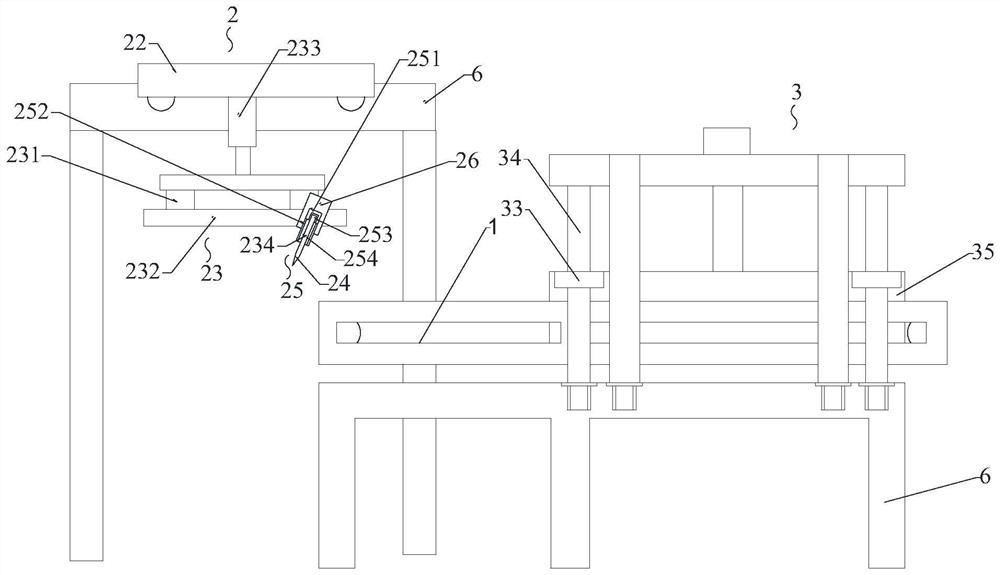

Once-forming valve grinding machine

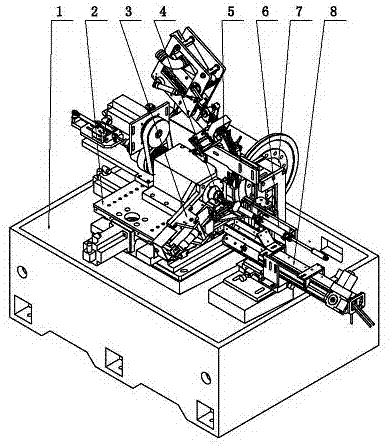

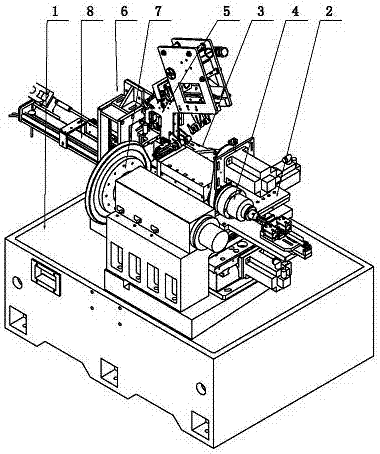

PendingCN107471097ASports reliableAvoid displacementGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

The invention discloses a once-forming valve grinding machine. The once-forming valve grinding machine comprises a lathe as well as a workpiece main shaft and a grinding main shaft which are rotatably supported on the lathe and are parallel to each other, wherein the workpiece main shaft is rotatably supported on the lathe through a workpiece main shaft base and a feeding workbench; a spring chuck is arranged in an inner hole of the workpiece main shaft; the spring chuck is connected with a pulling tube drive device through a pulling tube; a positioning rod is spiced in a pulling tube; the rear end of the positioning rod is connected with a discharge air cylinder; a positioning air cylinder is further arranged on the workbench; the positioning air cylinder is in one-way driving connection with the positioning rod; a valve centering supporting mechanism is arranged on the workbench; a centering block on the valve centering supporting mechanism and the grinding wheel main shaft are oppositely arranged at the two sides of the workpiece main shaft; an automatic feeding device, an automatic loading device and a discharge conveying device are further arranged on the lathe. The once-forming valve grinding machine can be suitable for requirements of valve once-forming grinding processing, is high in degree of automation, and can guarantee positioning precision; and a processed valve has a determined position state in a conveying process.

Owner:东台市伟锋机械厂

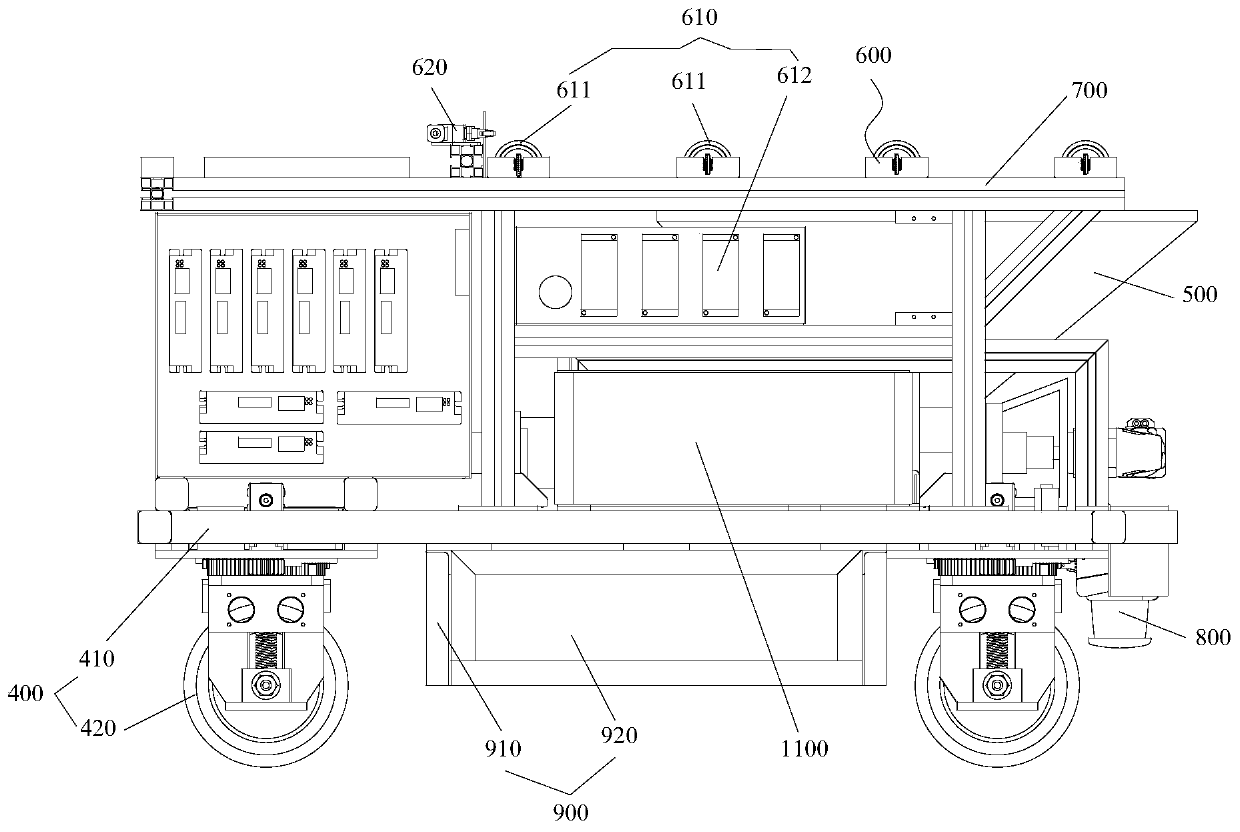

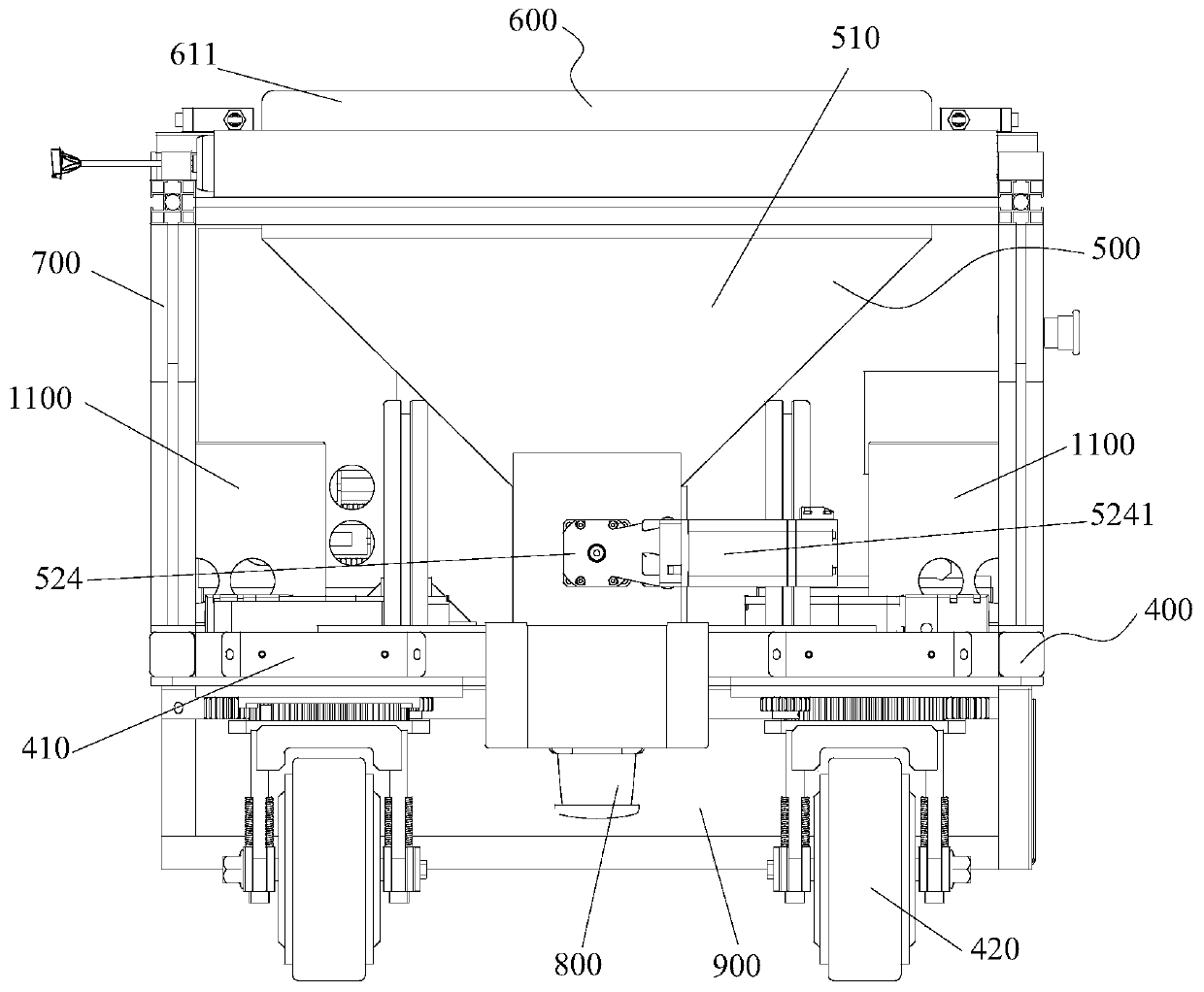

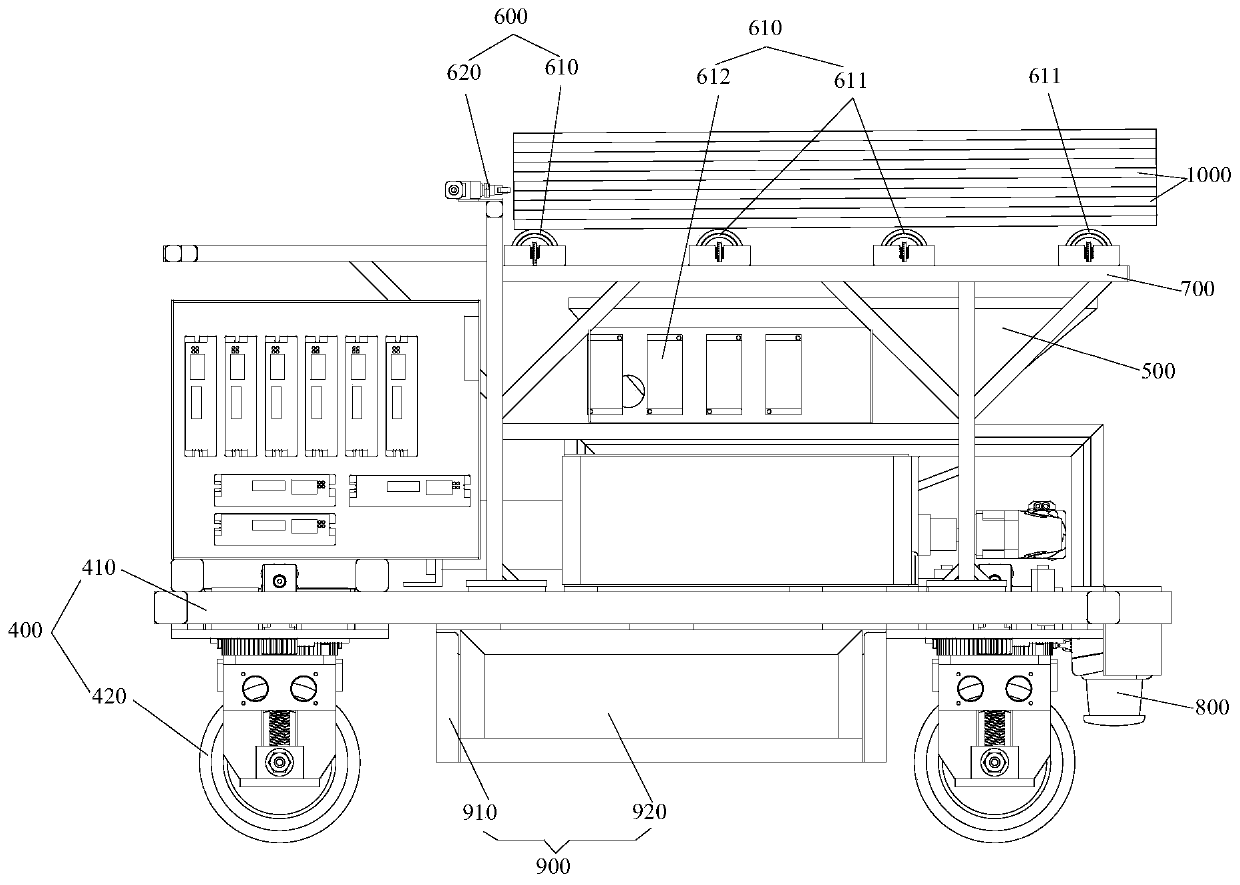

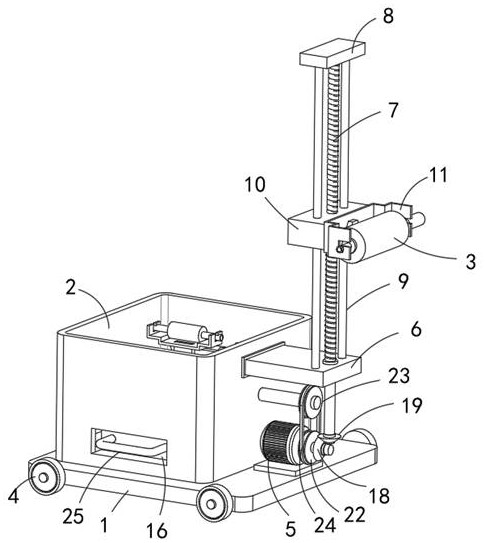

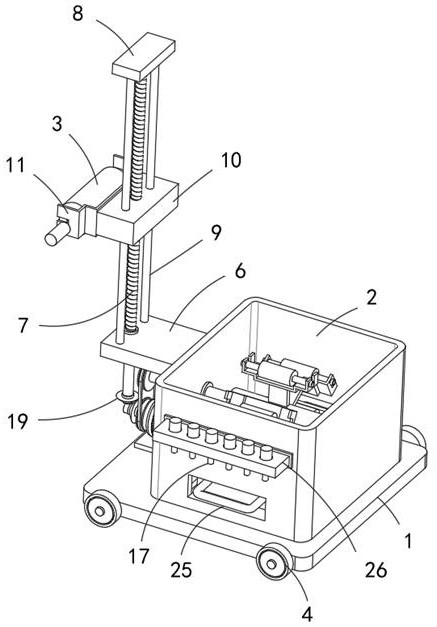

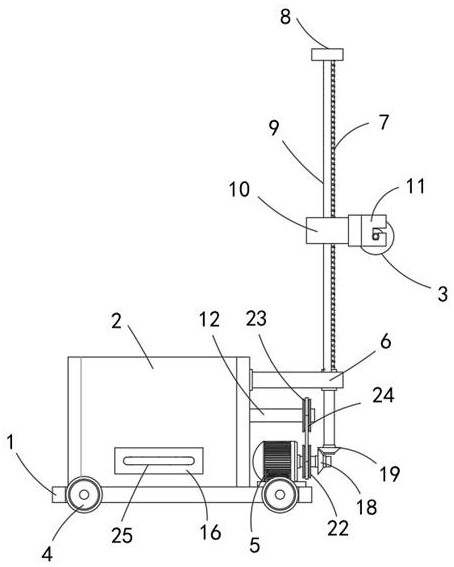

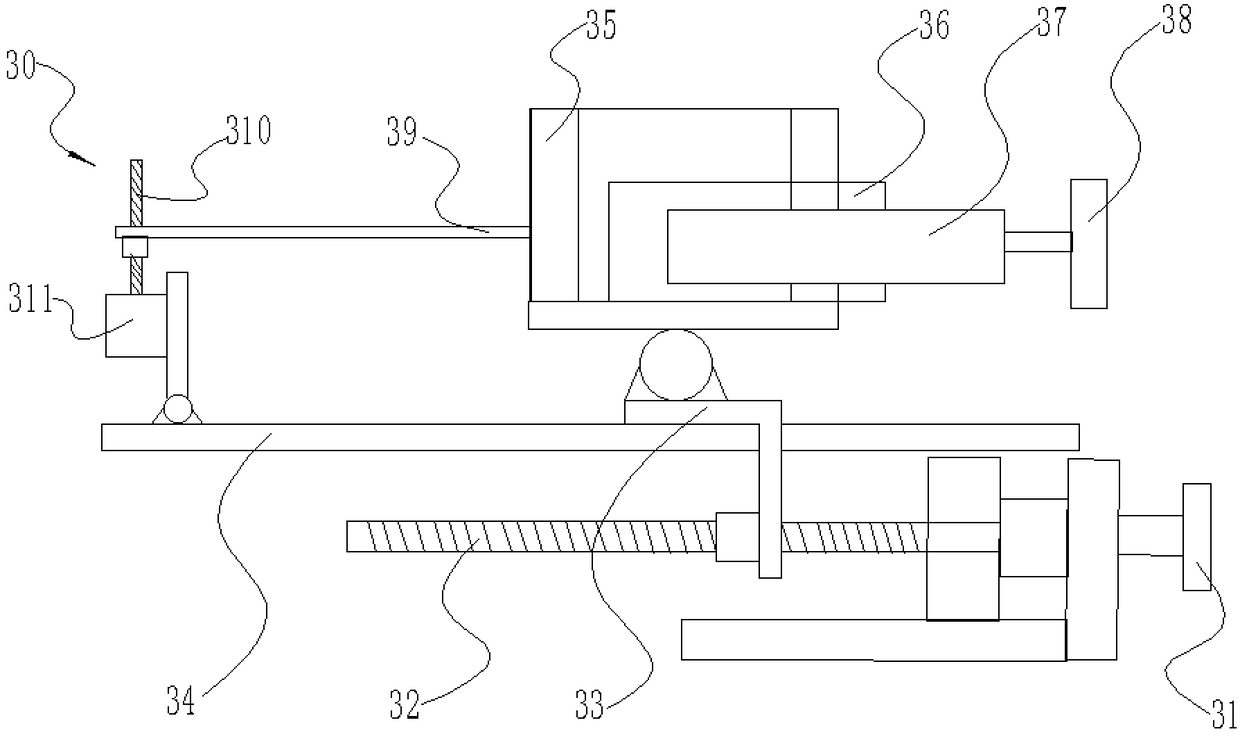

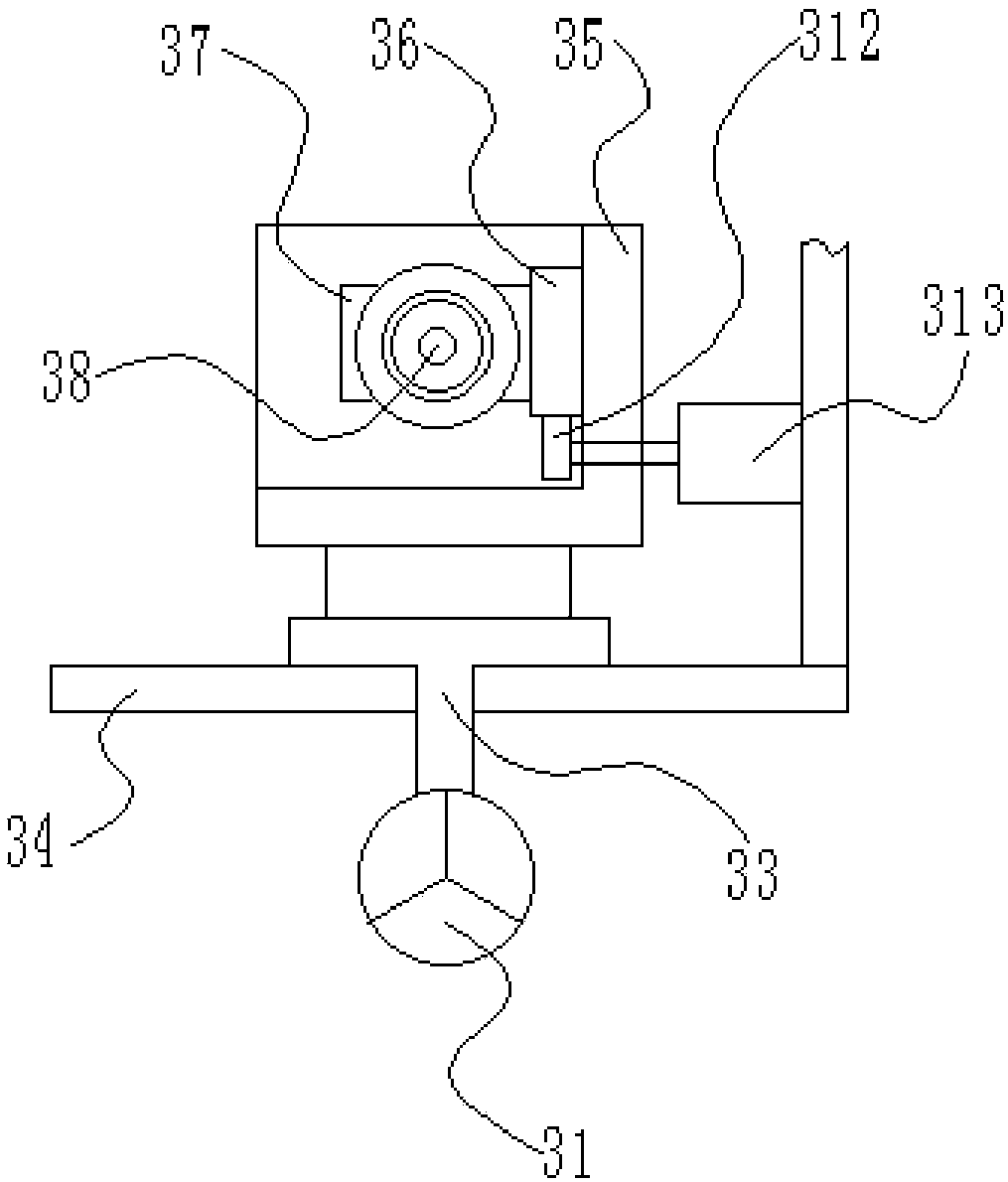

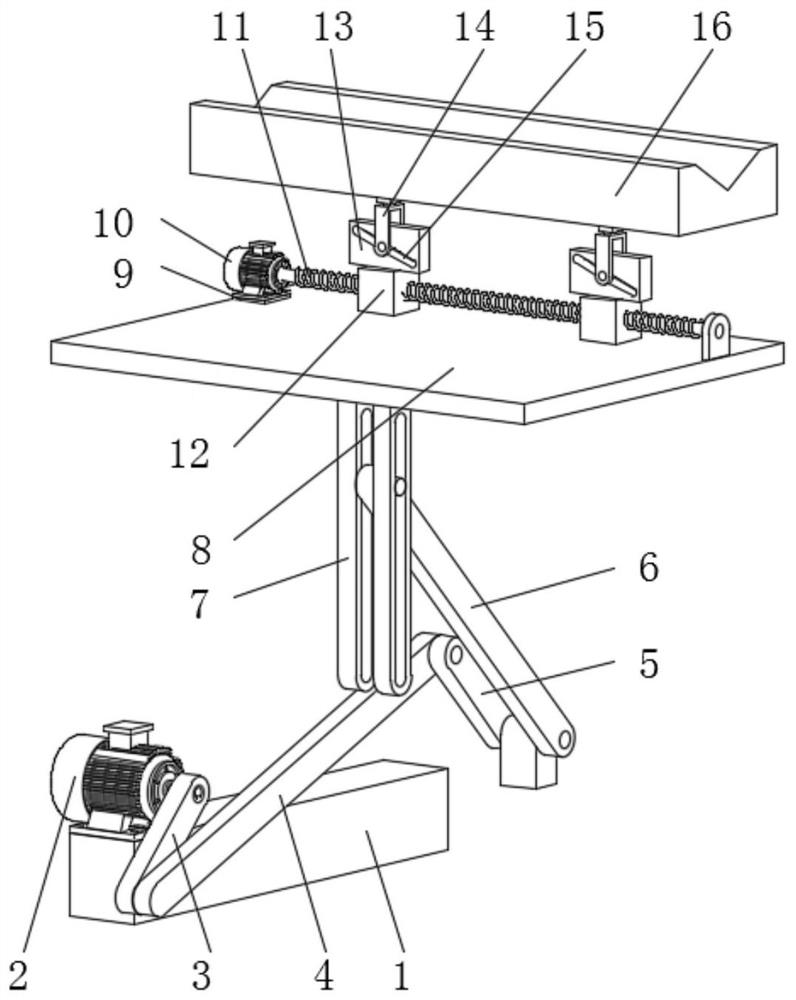

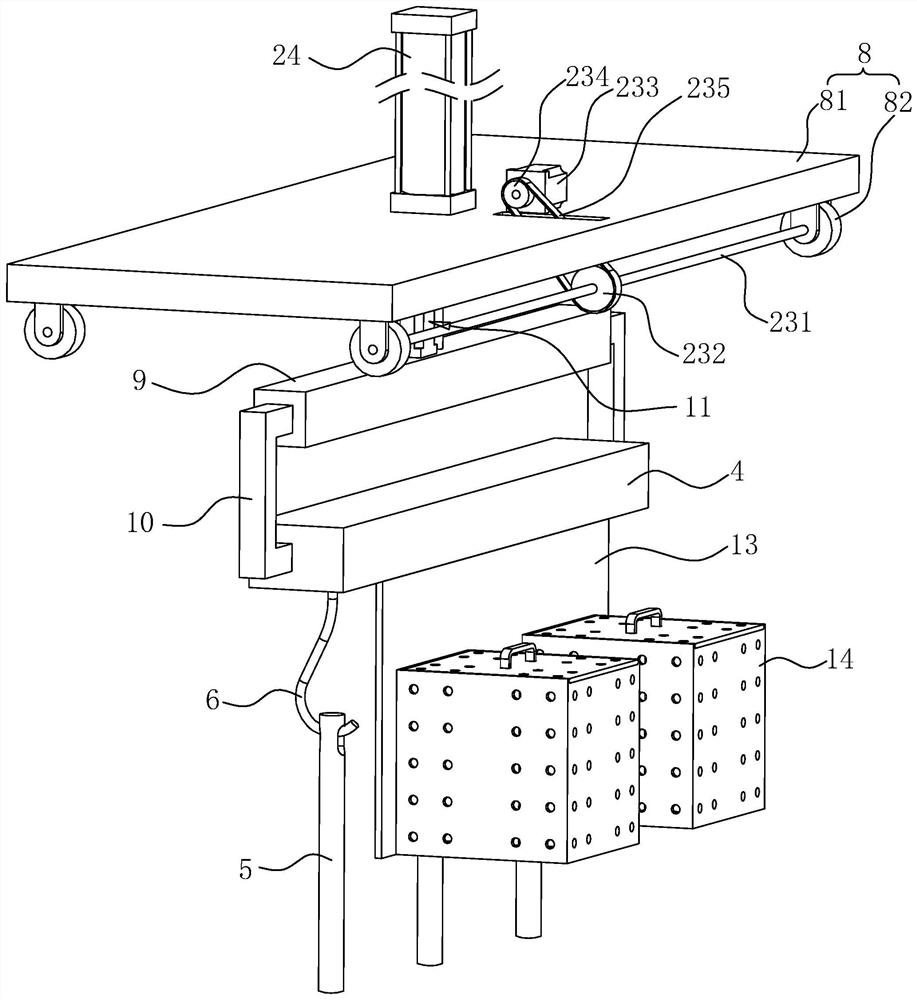

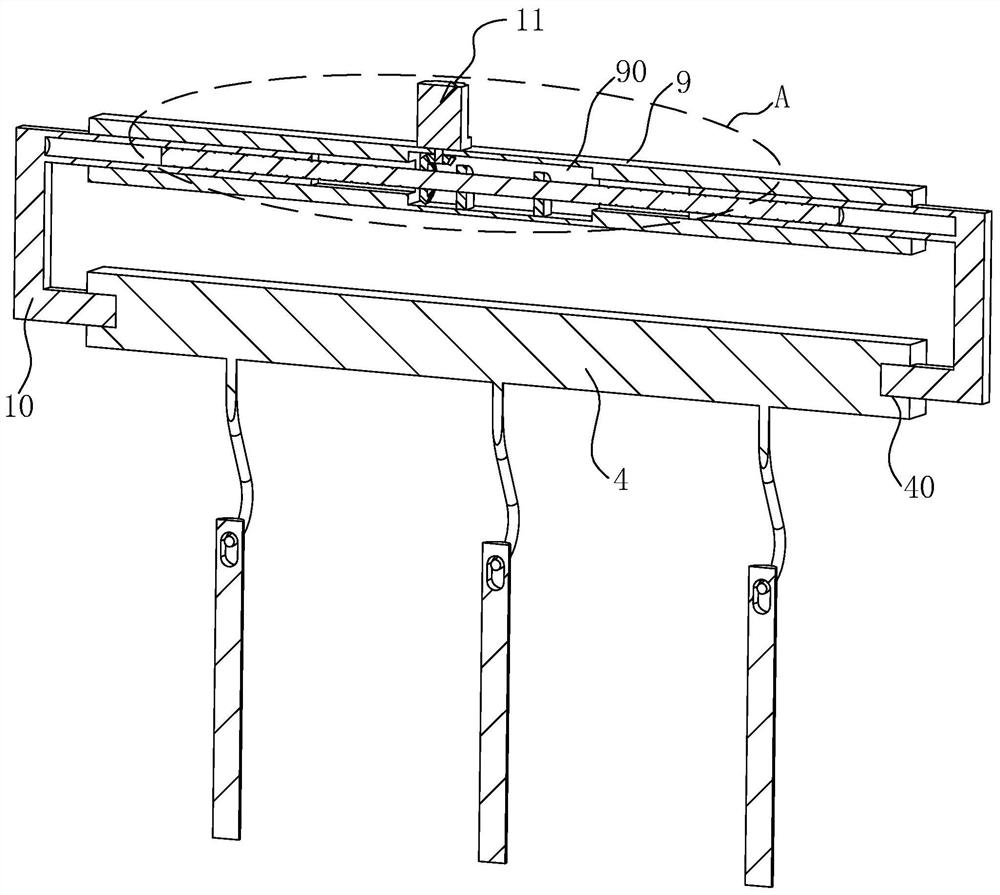

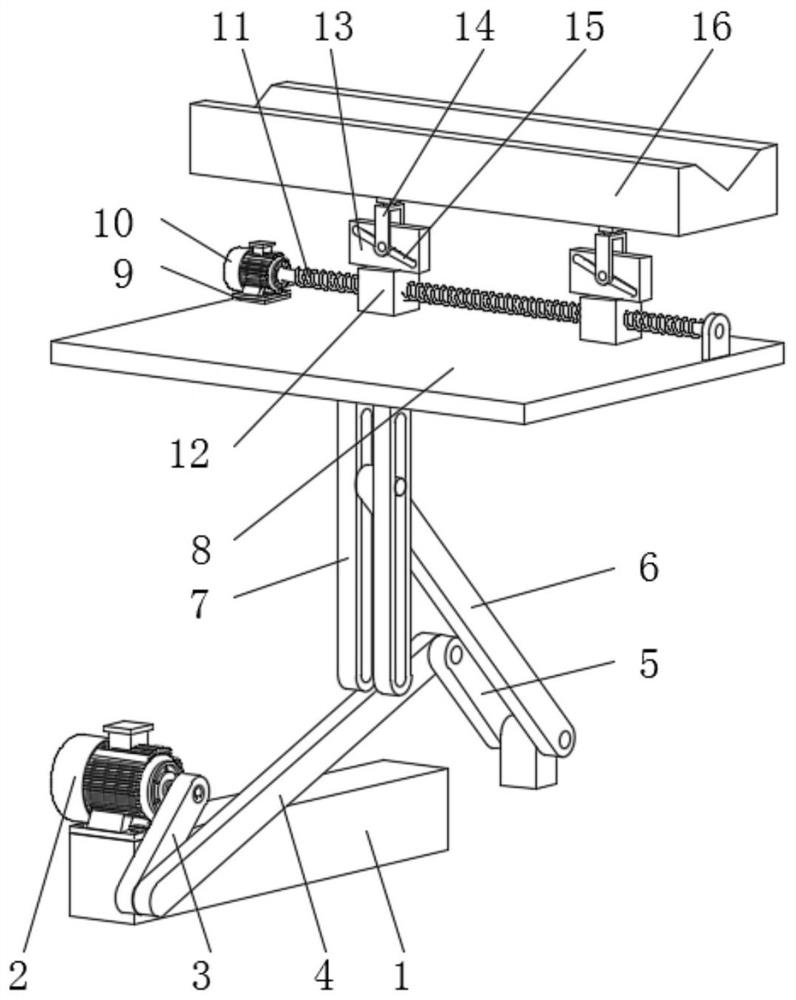

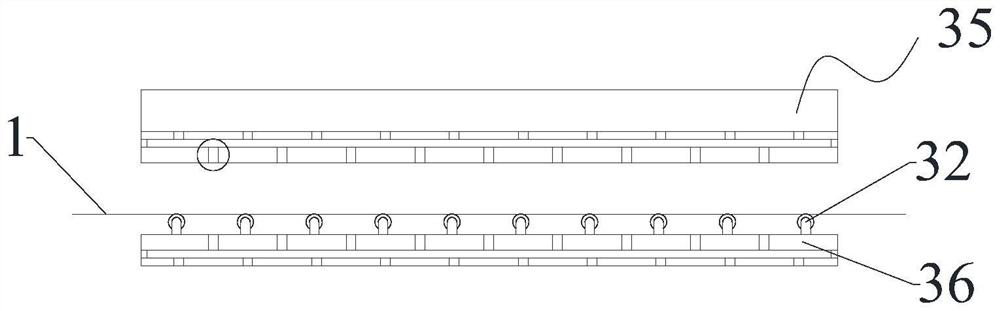

Material conveying device and floor tile paving and pasting system with device

InactiveCN110388031ARealize loading operationRealize transportationBuilding constructionsVehiclesSteering wheelUltimate tensile strength

The invention provides a material conveying device and a floor tile paving and pasting system with the device. The material conveying device comprises a vehicle body assembly, and a semi-fluid material conveying device, the vehicle body assembly comprises a vehicle body and multiple steering wheels arranged on the vehicle body, the semi-fluid material conveying device is arranged on the vehicle body and comprises a storage structure and a feeding assembly, the feeding assembly comprises a screw rod and a screw rod pump, the screw rod conveys semi-fluid material in the storage structure into the screw rod pump, and the screw rod pump outputs the semi-fluid material according to the preset output amount. The problems that in the prior art, the semi-fluid material conveying efficiency is low,and the labor intensity of workers is increased are solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Quick-to-disassemble building painting equipment for coating

InactiveCN112177291AImprove efficiencyReduce the tediousness of manual feedingBuilding constructionsElectric machineryDrive motor

The invention belongs to the technical field of building equipment, and particularly relates to quick-to-disassemble building painting equipment for coating. The equipment comprises a bottom plate, apainting box and painting rollers, rollers are rotatably connected to the front side wall and the rear side wall of the bottom plate, and the painting box is fixedly connected to the upper end of thebottom plate; and the equipment is characterized in that a driving motor is fixedly connected to the position, on the front side of the painting box, at the upper end of the bottom plate, a horizontalsupporting plate is fixedly connected to the position, on the upper side of the driving motor, of the side wall of the painting box, a vertical threaded rod is rotatably connected to the upper end ofthe supporting plate, a top plate is fixedly connected to the upper end of the threaded rod, and the lower end of the threaded rod extends to the lower side of the supporting plate. The equipment hasthe advantages that the work of the painting rollers and the feeding operation of the standby painting rollers can be achieved at the same time, so that the use efficiency is relatively improved, andthe complexity of manual feeding is reduced; and in addition, a handle can be disassembled when the painting rollers are replaced, so that the switching use between the painting rollers and the standby painting rollers is not affected.

Owner:宿州德锦建筑材料有限公司

Pneumatic ultrasonic polishing and grinding device and pneumatic ultrasonic polishing and grinding equipment

PendingCN108127488AImprove automationHigh degree of automationGrinding carriagesGrinding drivesEngineeringAutomation

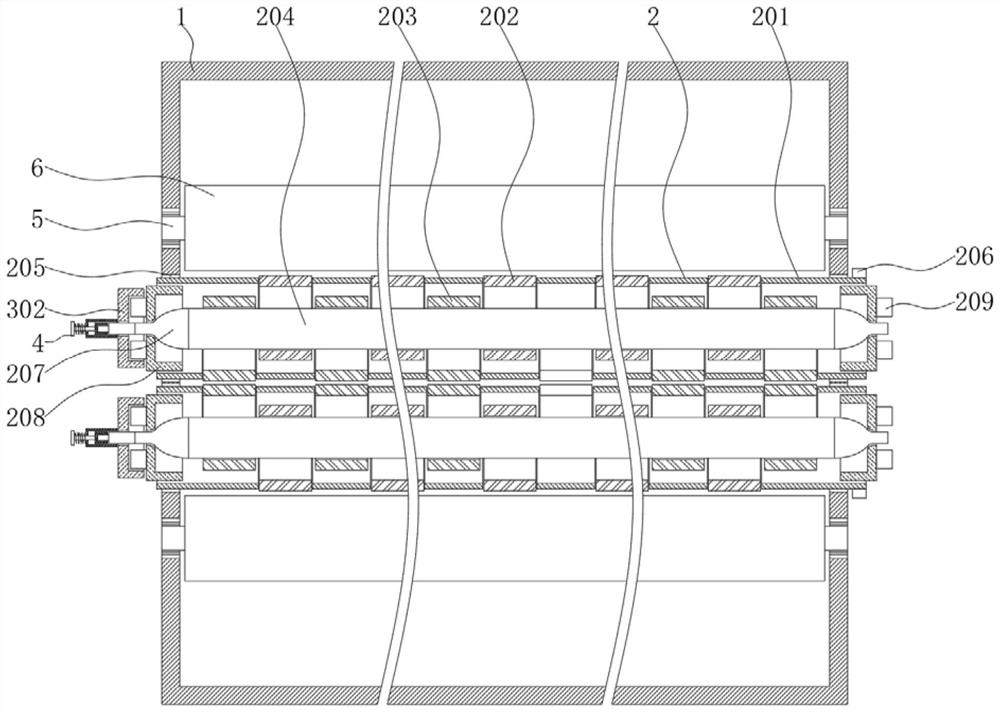

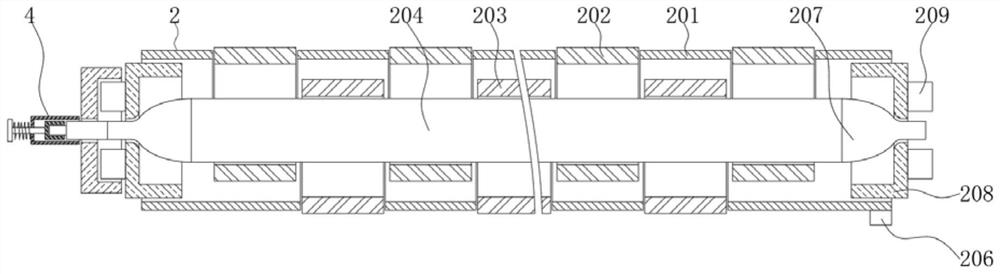

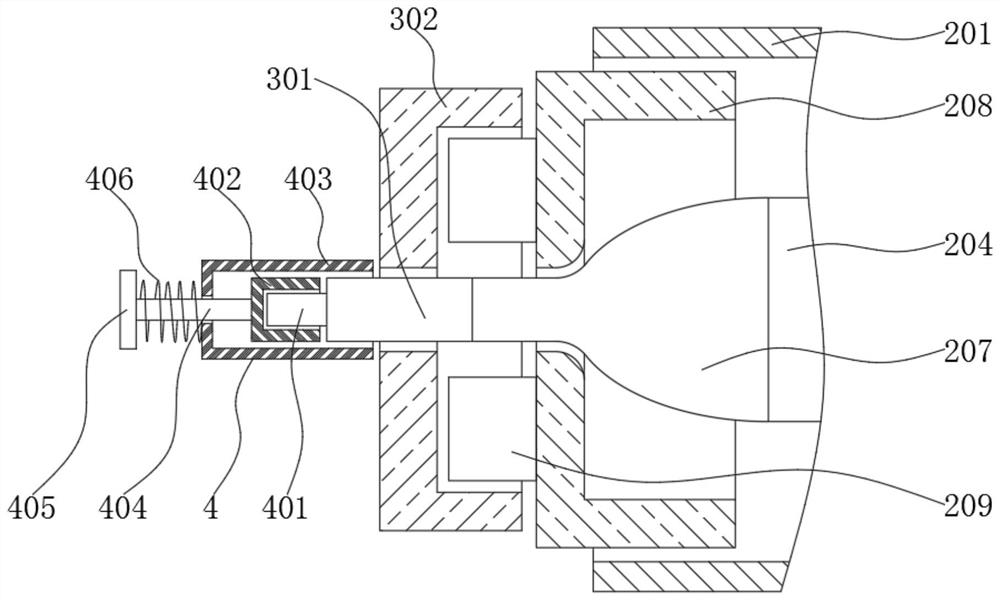

The invention discloses a pneumatic ultrasonic polishing and grinding device and pneumatic ultrasonic polishing and grinding equipment, and relates to the technical field of mechanical polishing. Thedevice and equipment are designed for solving the problems that an existing polishing method is low in polishing efficiency, large in potential safety hazards and low in automation degree. The pneumatic ultrasonic polishing and grinding device comprises a machine frame, an ultrasonic feeding module, a polishing module and a control module. The ultrasonic feeding module is installed on the machineframe, and the vertical movement and rotation of a to-be-machined piece can be achieved. The polishing module comprises a polishing piece, and the polishing piece can do horizontal movement, verticalmovement and pitching movement relative to the to-be-machined piece. The pneumatic ultrasonic polishing and grinding equipment comprises a control panel and the pneumatic ultrasonic polishing and grinding device. The pneumatic ultrasonic polishing and grinding device and the pneumatic ultrasonic polishing and grinding equipment are used for polishing and grinding a columnar metal piece.

Owner:崔红宝

Grinding process of roller surface grinding system

InactiveCN114571299ARealize loading operationRealize adjustment operationRevolution surface grinding machinesGrinding drivesElectric machineEngineering

Owner:YIXING YONGCHANG ROLL

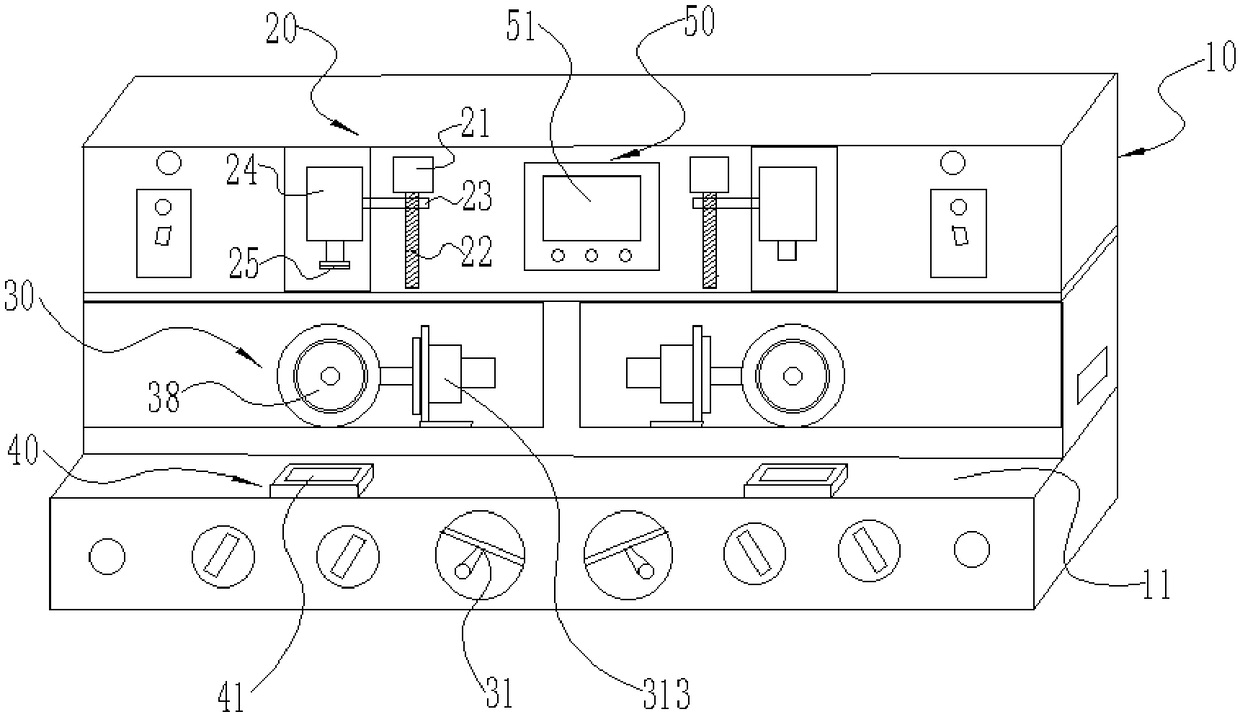

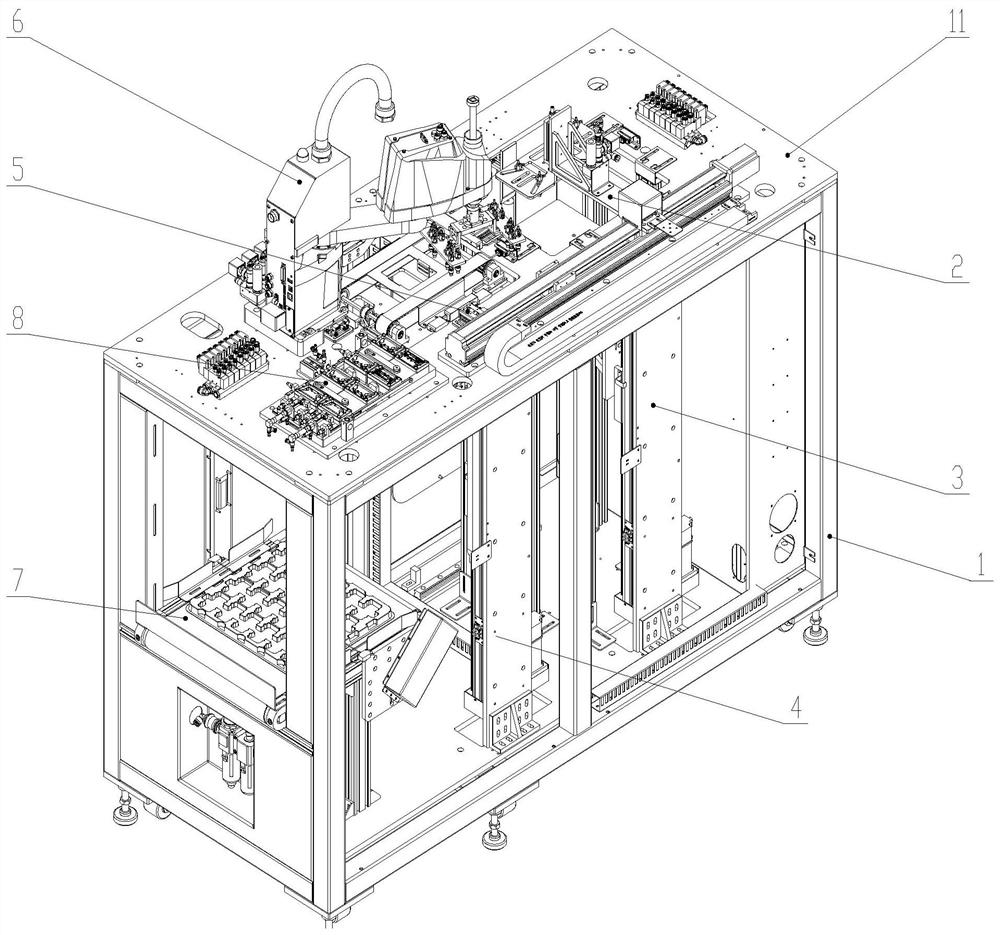

Automatic tray placing machine for battery touch panel

PendingCN114148712AFast feeding speedImprove feeding accuracyLifting devicesLoading/unloadingTouch panelWorkbench

The invention discloses an automatic tray placing machine for battery touch pads, which comprises a rack, the upper surface of the rack is a working table, a full tray output streamline, an empty tray lifting module and a working bin lifting module are arranged in the rack, the working bin lifting module is positioned on one side of the full tray output streamline, and the empty tray lifting module is positioned on the other side of the full tray output streamline. The working stock bin lifting module can output the trays to the full tray output streamline, and the working tabletop is provided with through openings extending out of the empty tray lifting module and the working stock bin lifting module. A material tray feeding and carrying mechanism, an air cylinder positioning mechanism, a product distance separating mechanism and a mechanical arm tray placing mechanism are arranged on the working table top, and through cooperation of all the mechanisms, a plurality of battery touch pads can be synchronously placed in a material tray after being separated to designated positions; furthermore, the feeding operation of a plurality of battery touch panels can be realized at one time, so that the feeding speed and the feeding accuracy are improved.

Owner:扬州京柏自动化科技有限公司

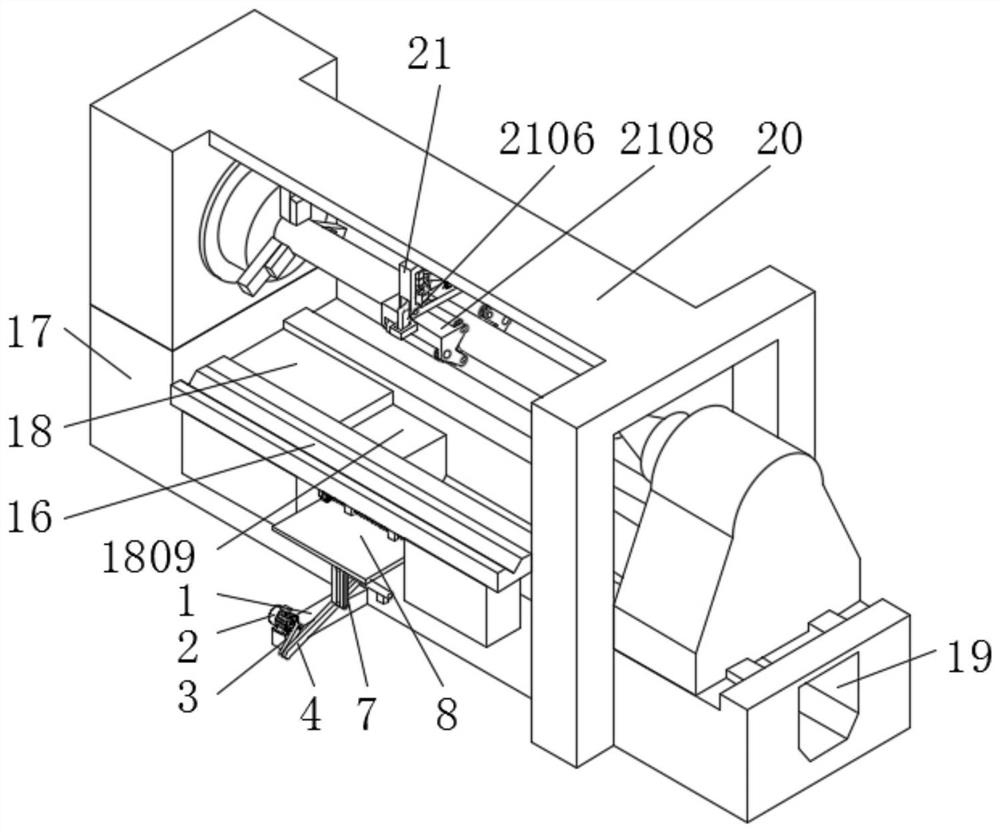

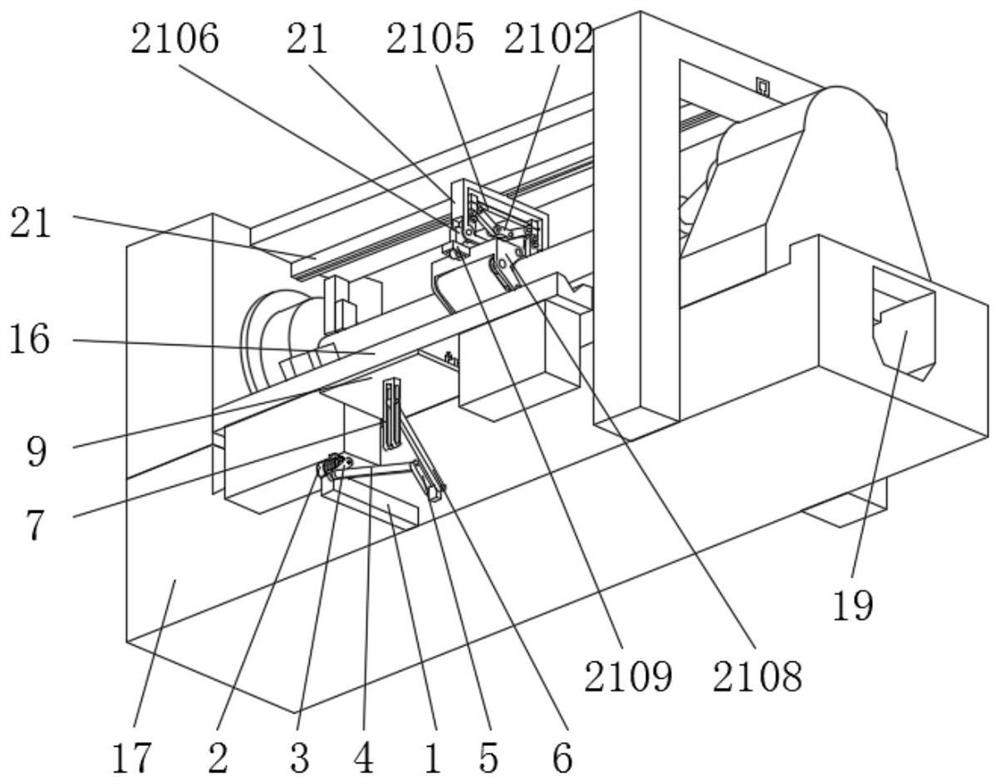

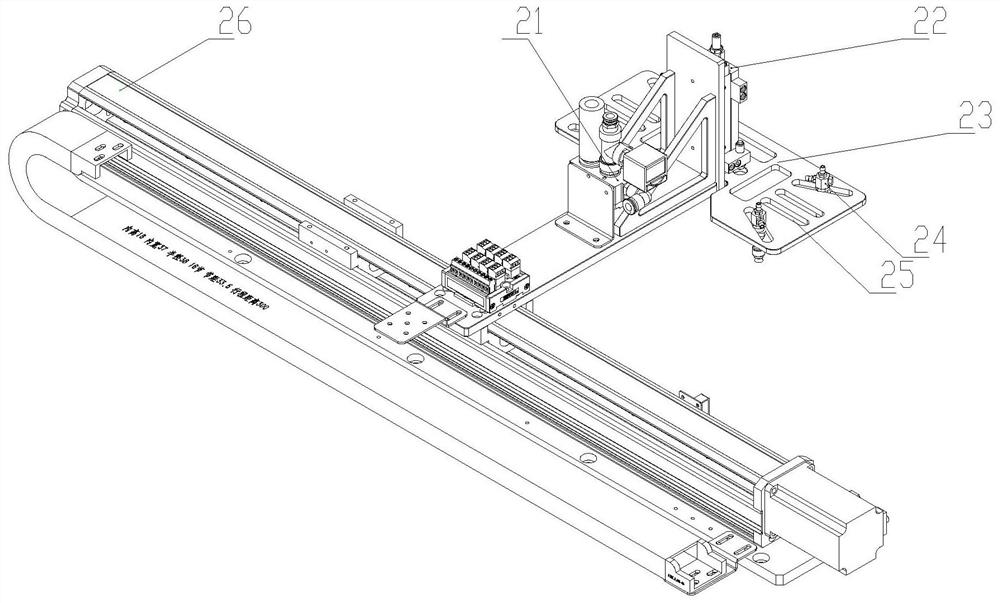

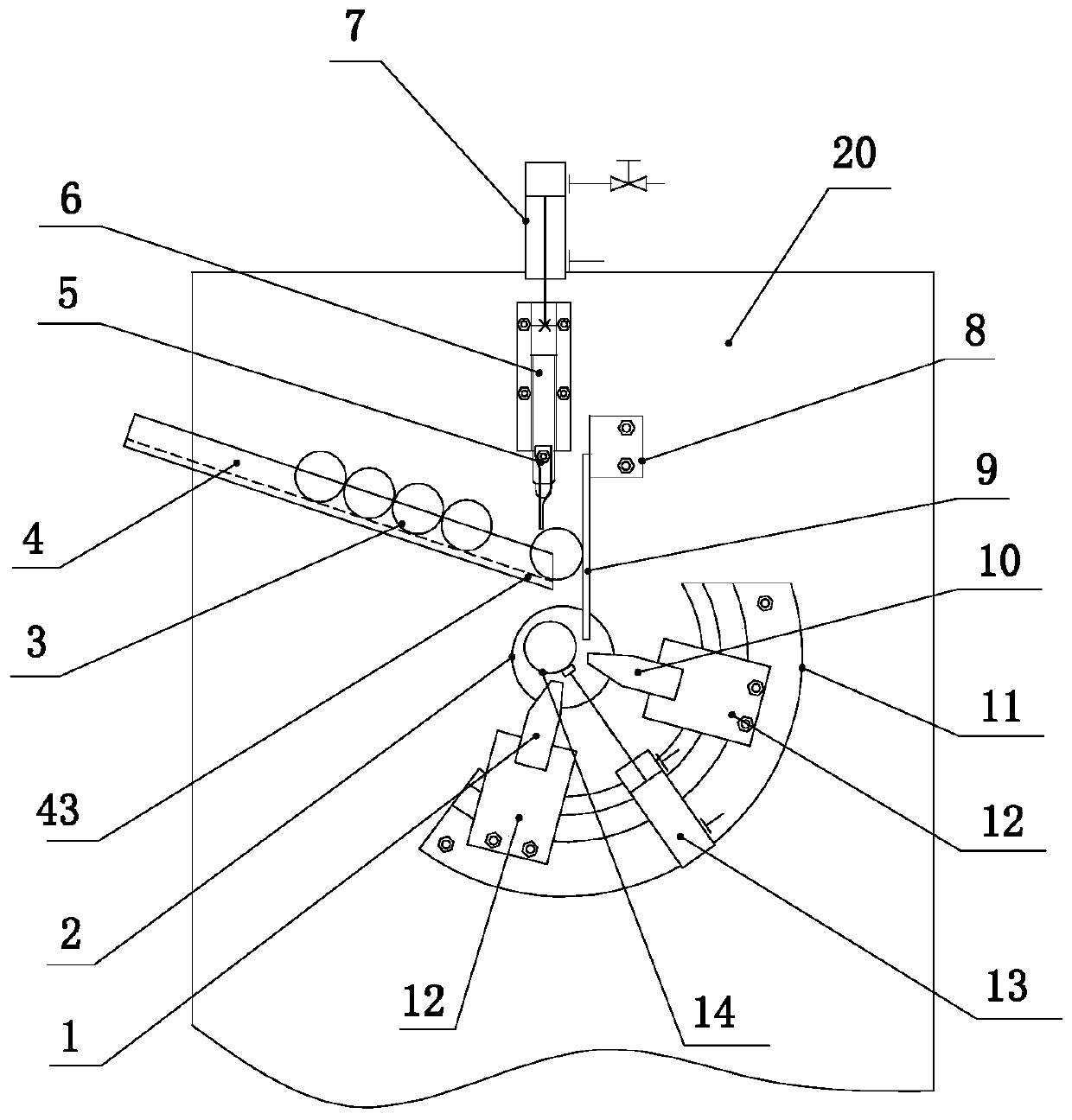

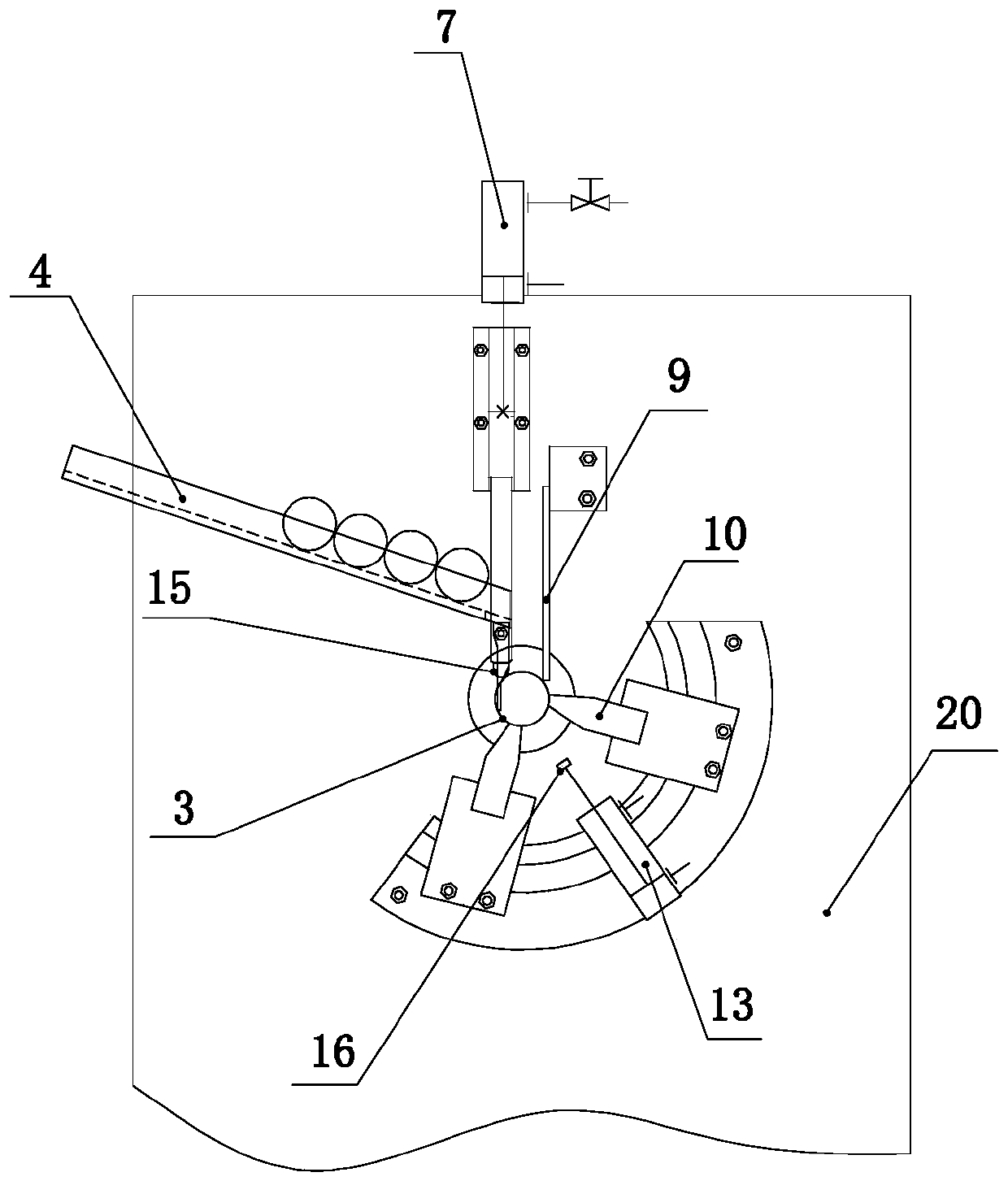

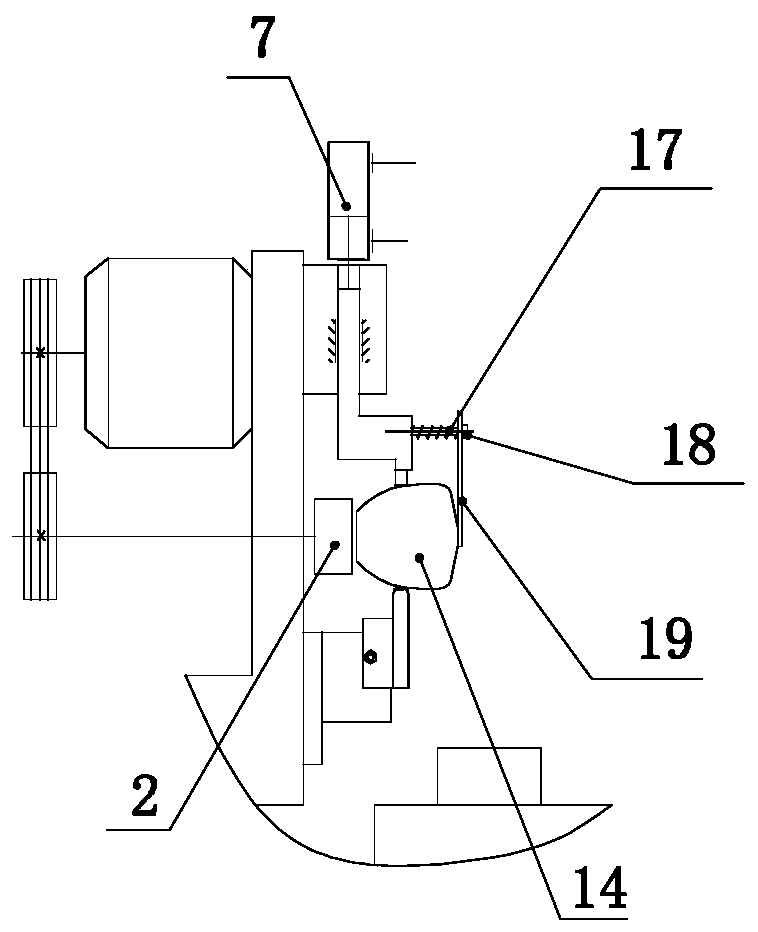

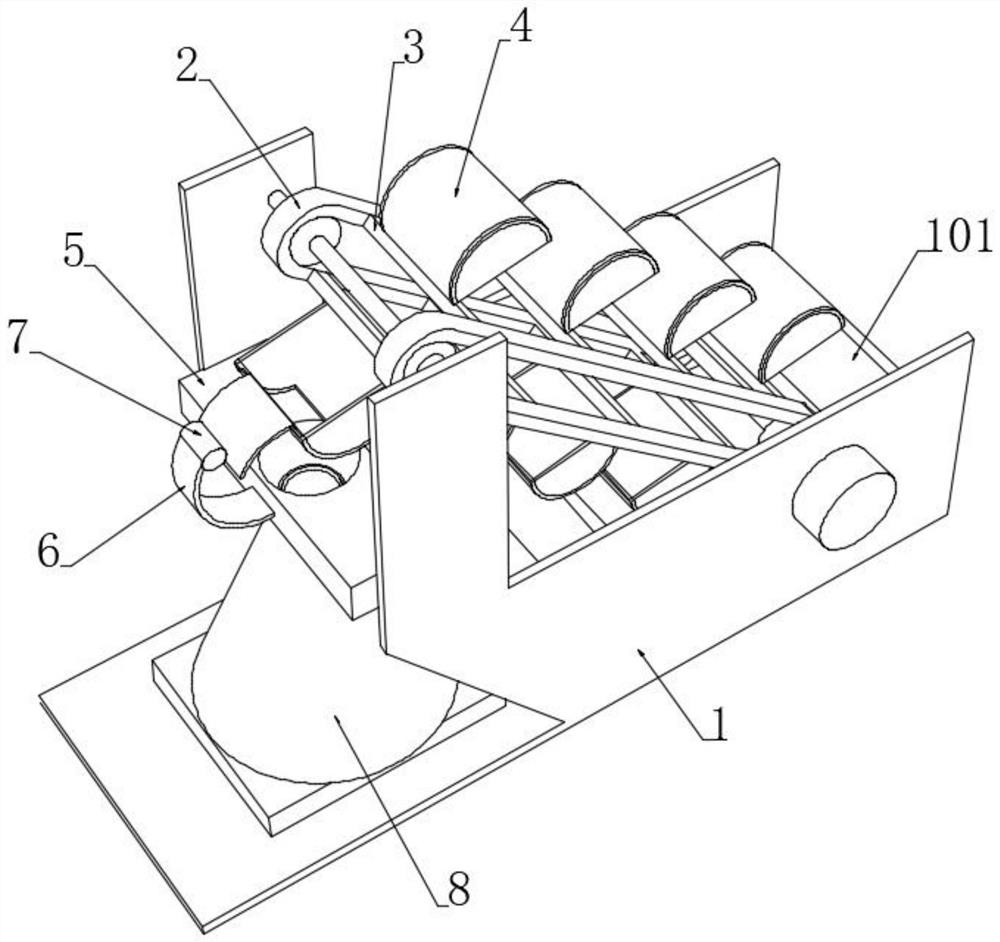

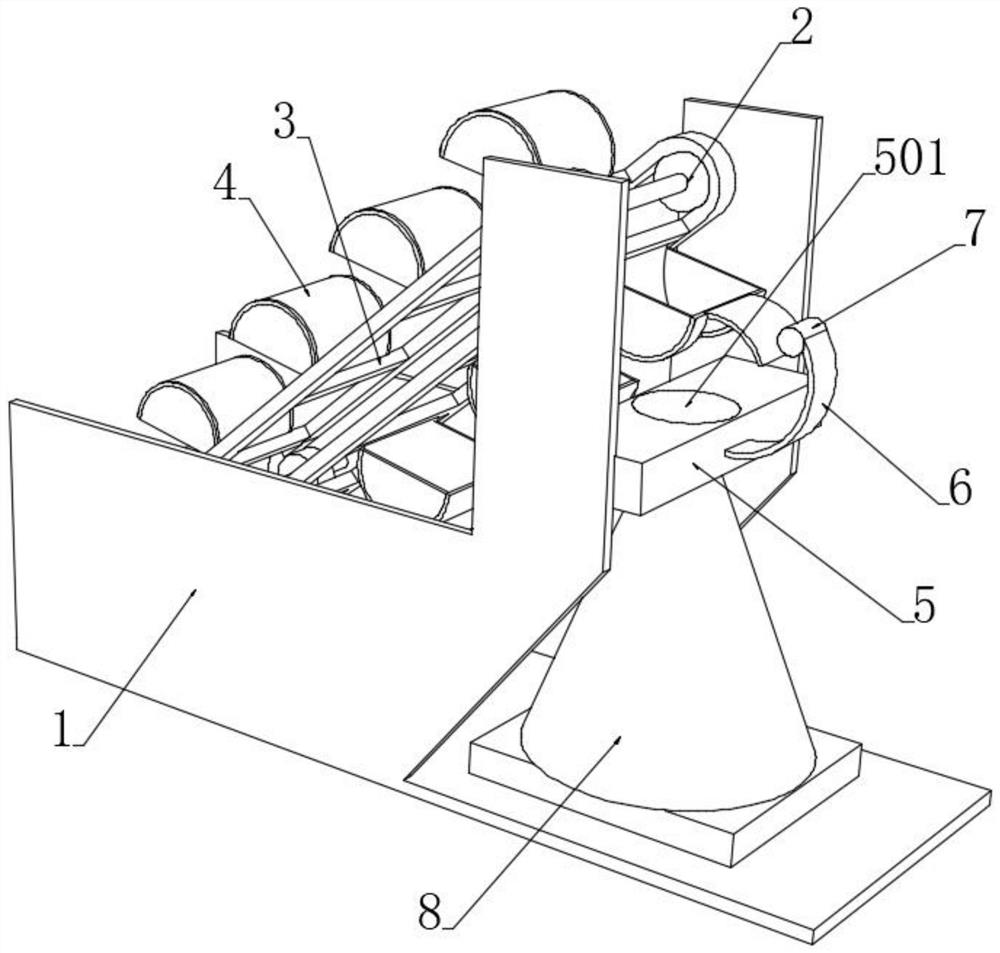

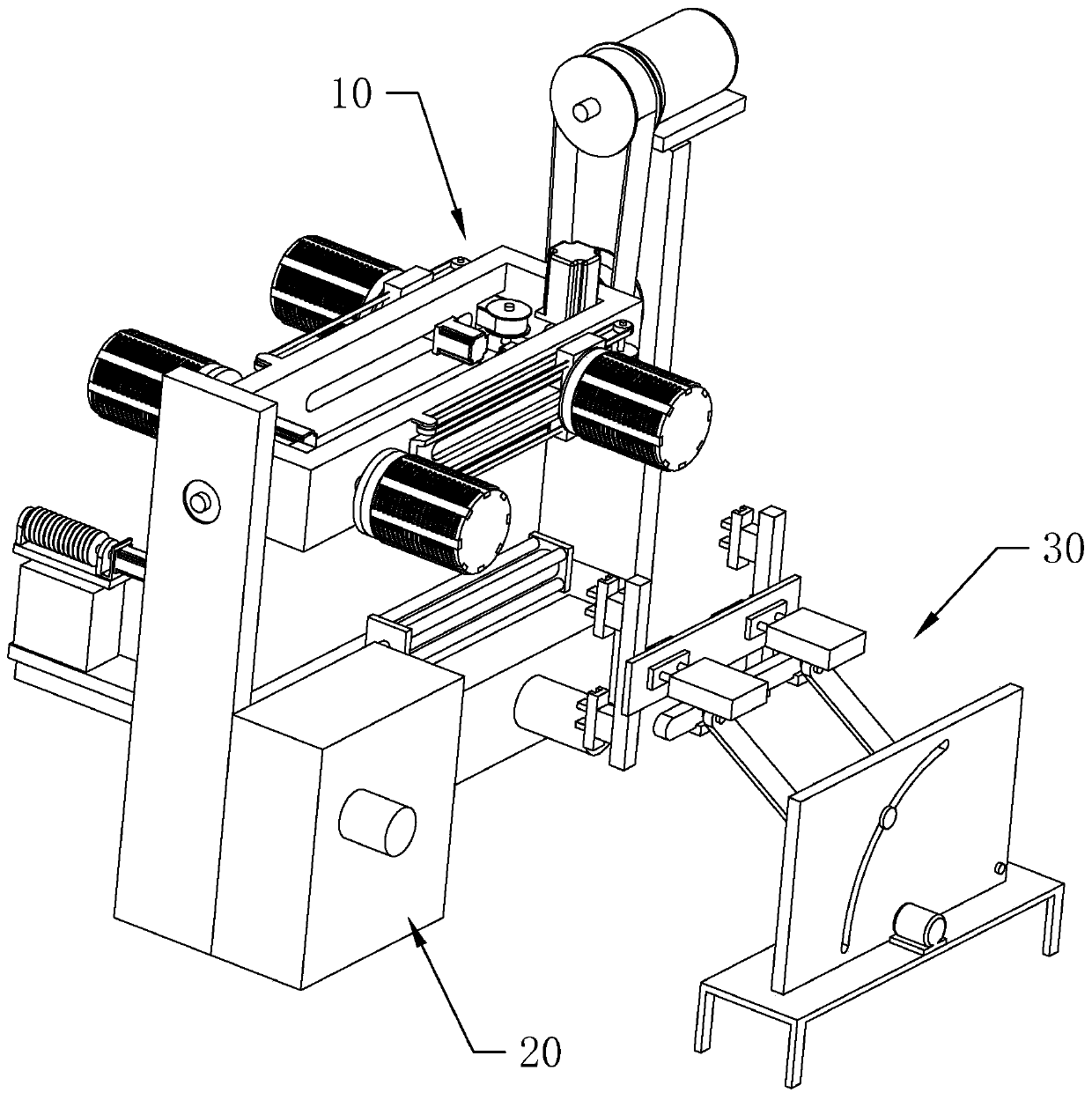

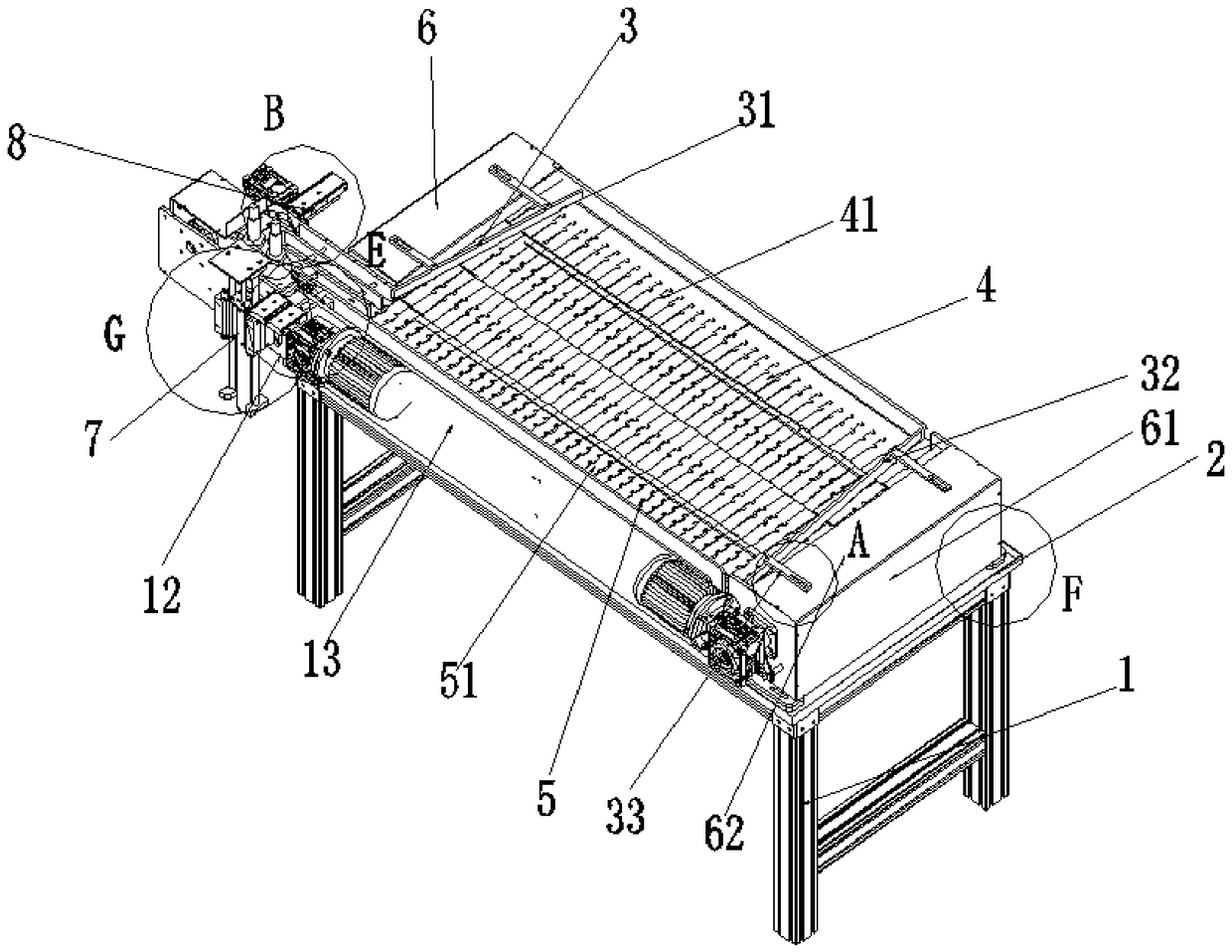

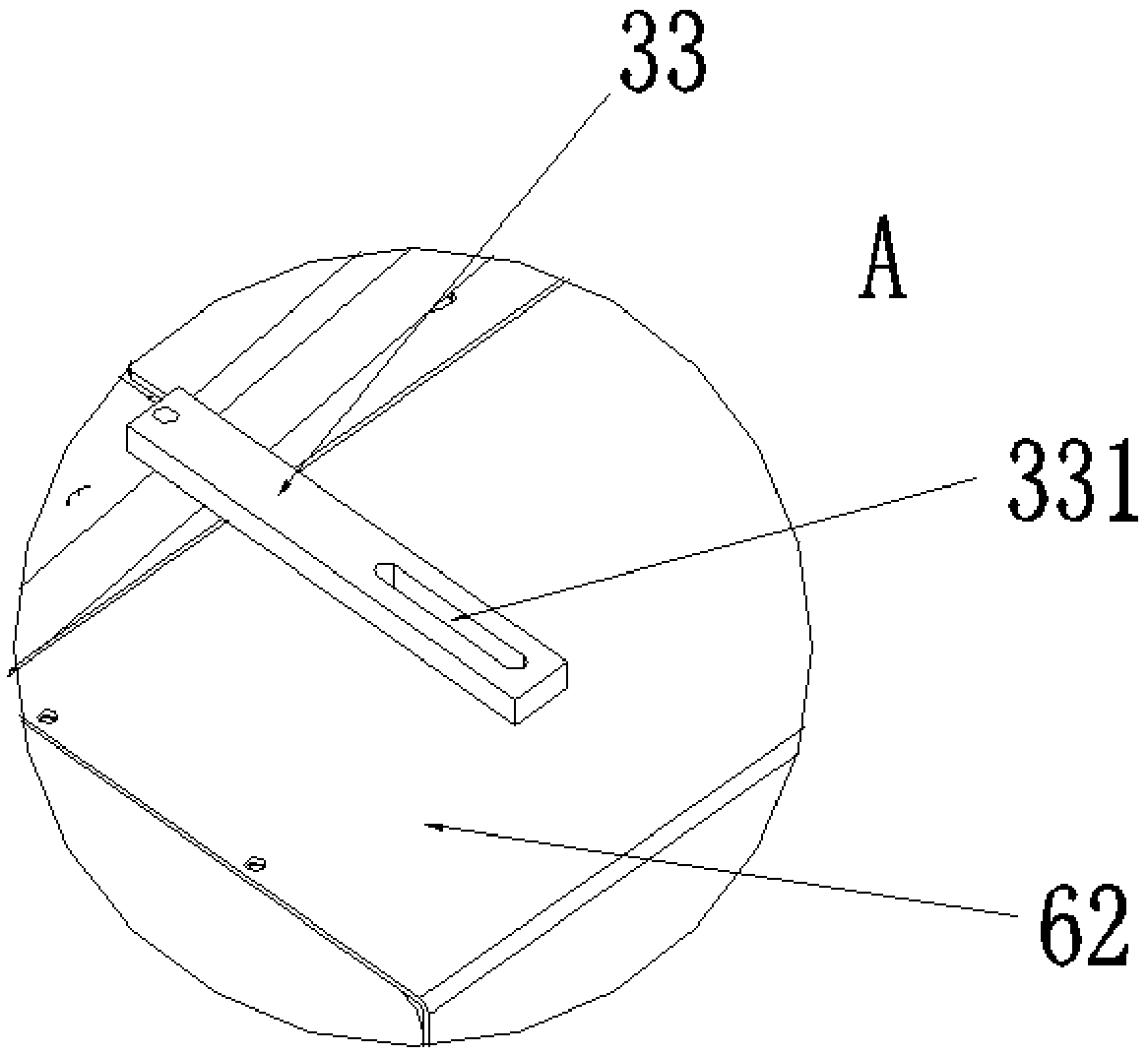

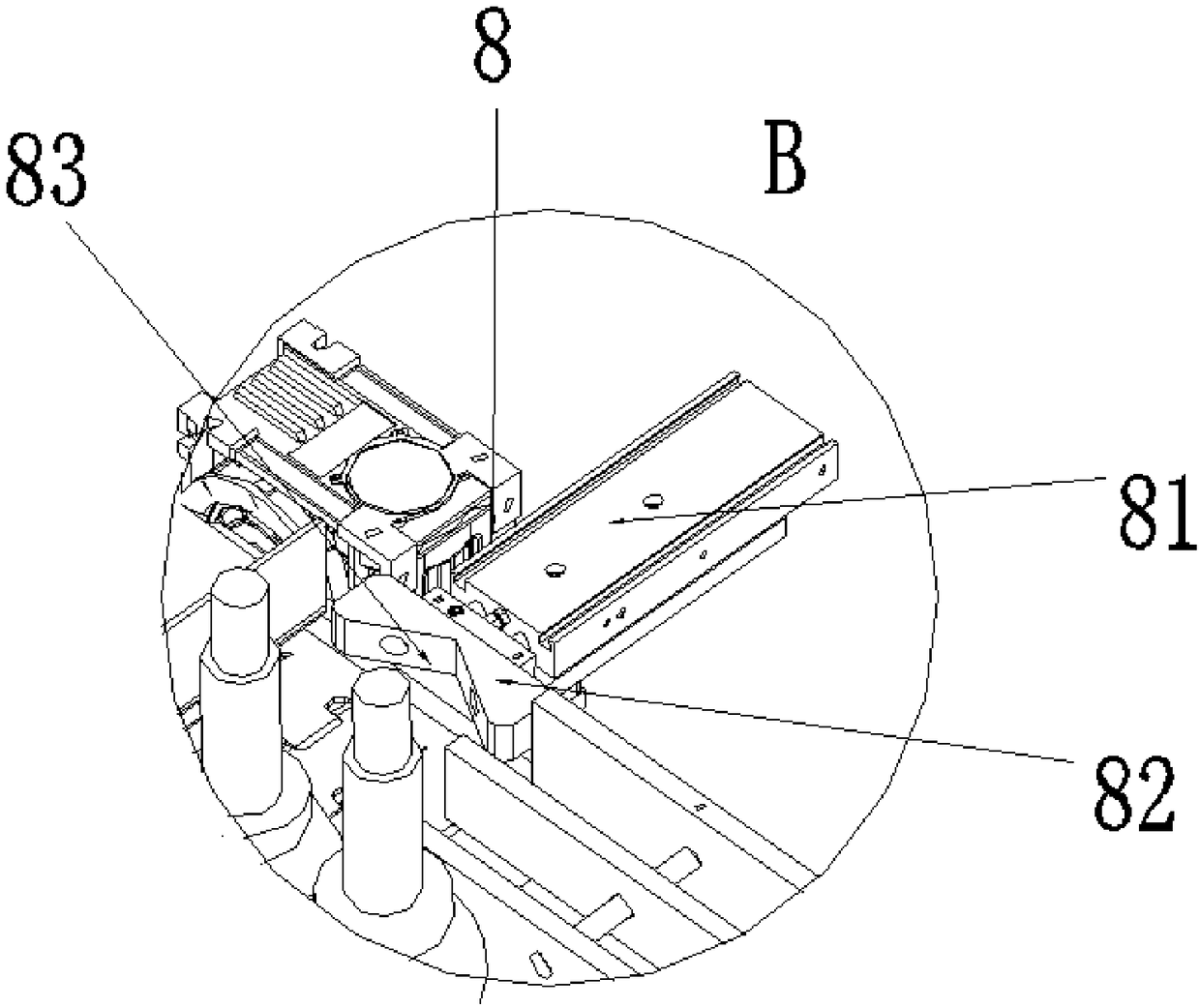

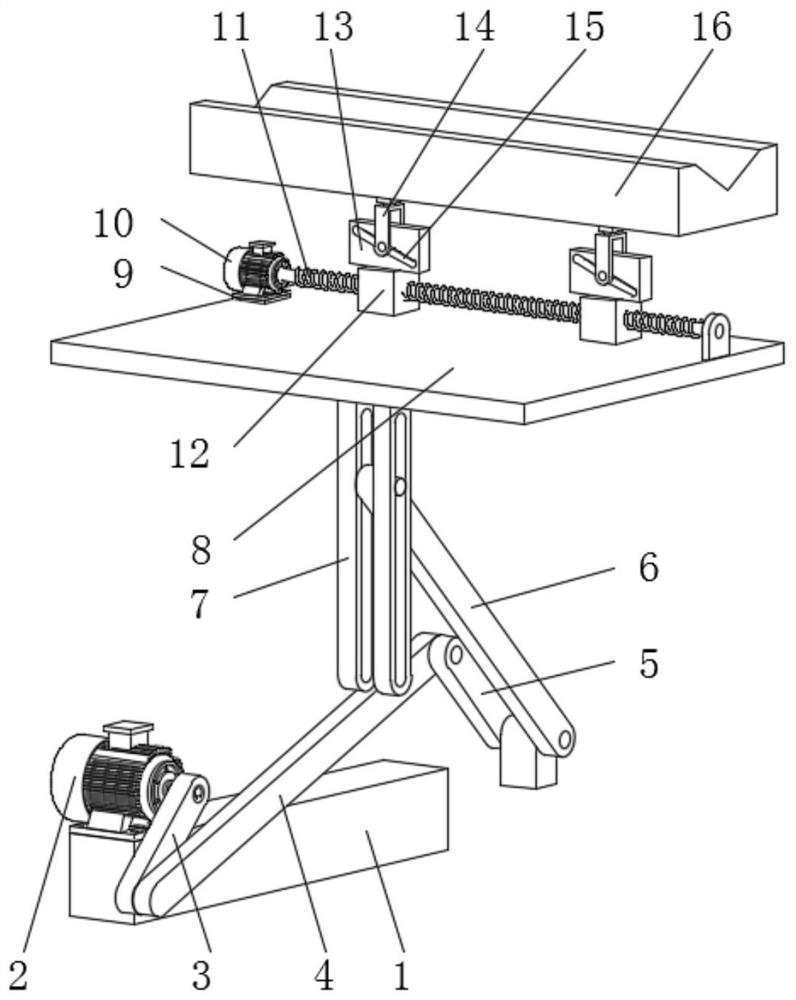

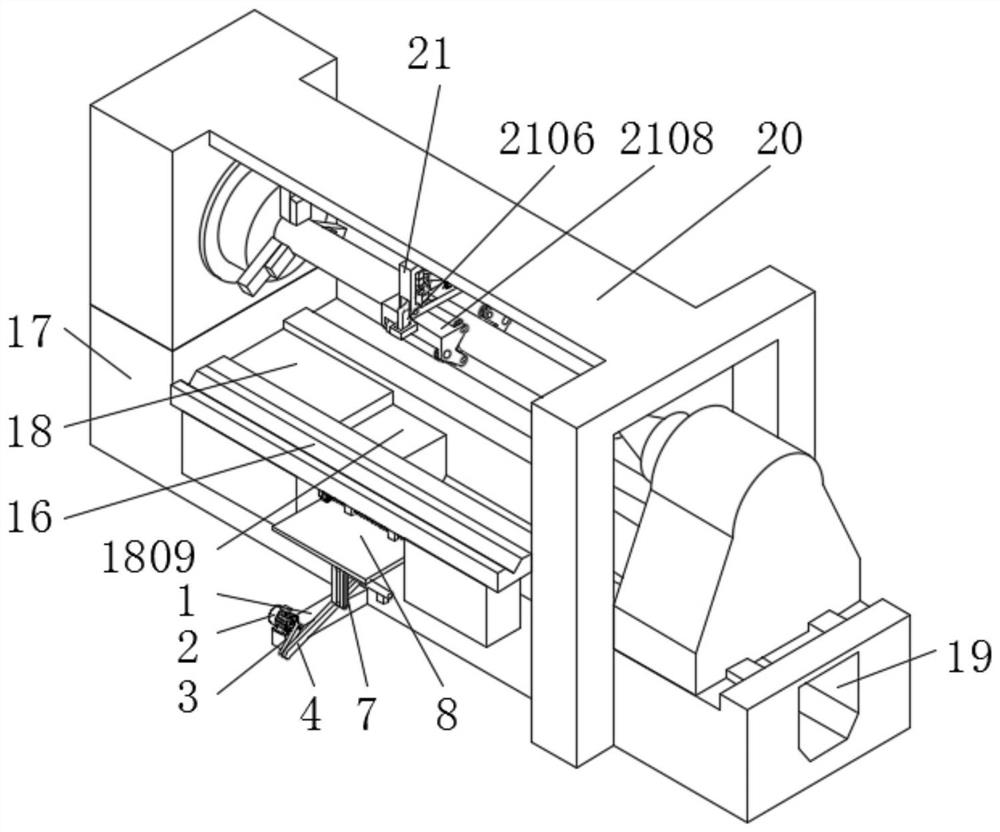

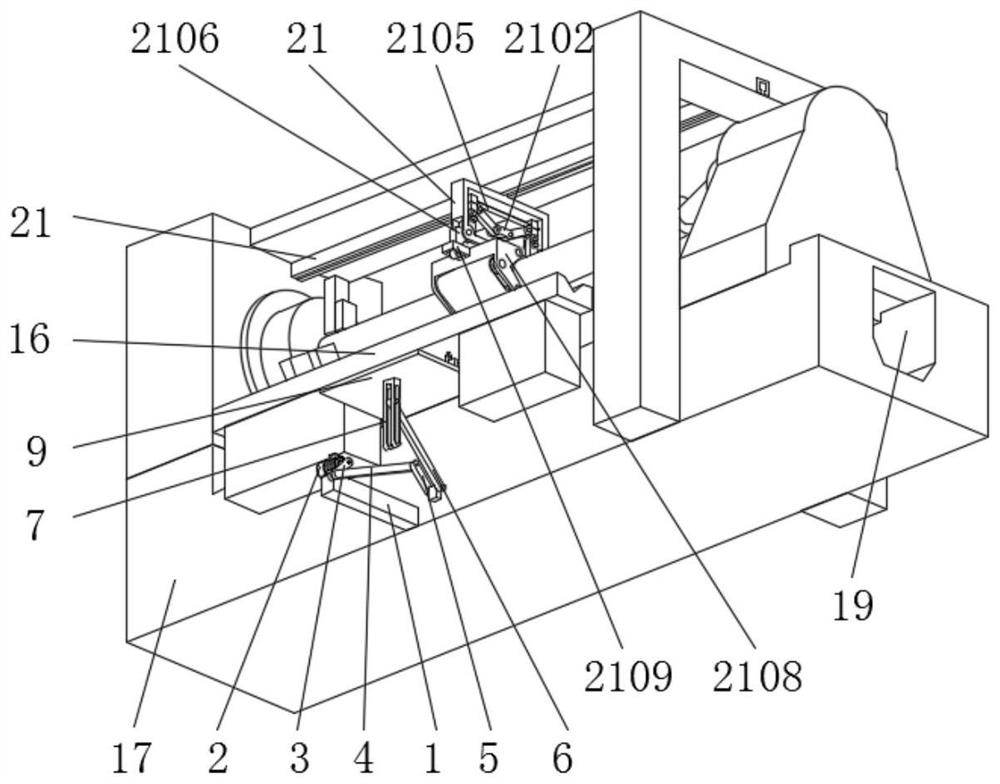

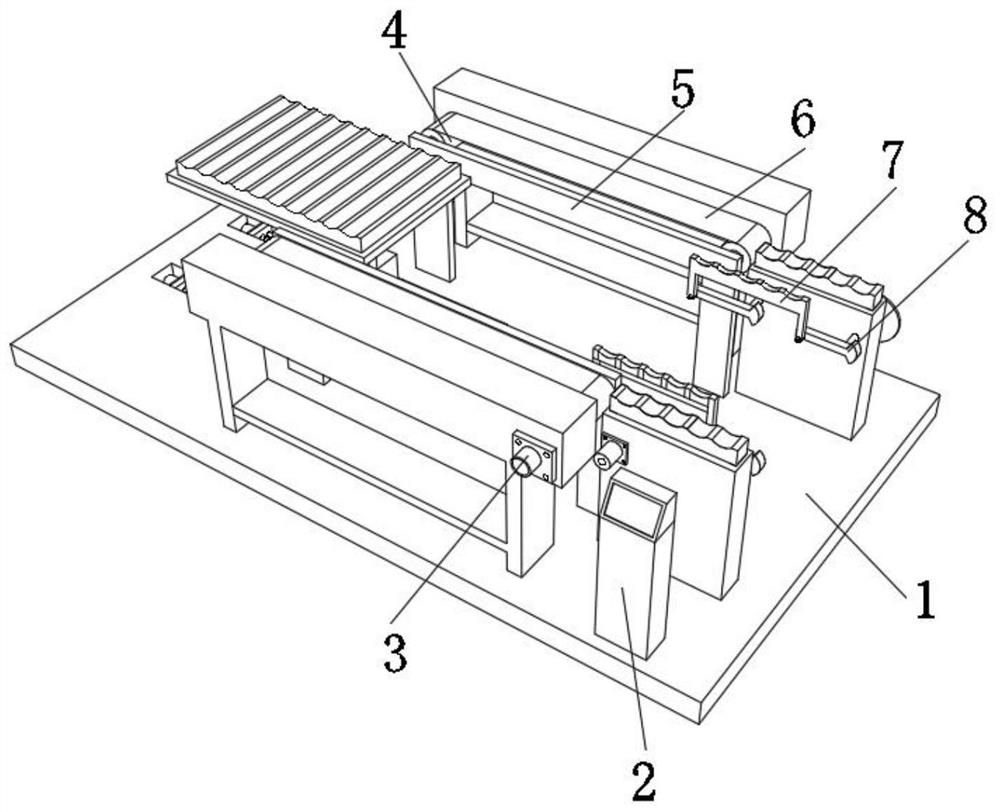

Automatic feeding and discharging system for spherical roller spherical base surface specialized grinding machine

InactiveCN110465860ARealize loading operationRealize unloading operationGrinding machinesGrinding feedersReciprocating motionEngineering

The invention discloses an automatic feeding and discharging system for a spherical roller spherical base surface specialized grinding machine. The automatic feeding and discharging system for the spherical roller spherical base surface specialized grinding machine is used for achieving feeding and discharging of spherical rollers and comprises a rack, a crescent-moon-shaped plate, an electromagnetic chuck, a discharging channel, a conveying spring plate, a conveying movable plate and a material beating head; two support bases are slidably installed on the crescent-moon-shaped plate, locking structures are arranged between the support bases and the crescent-moon-shaped plate, a first support is fixed to the first support base, and a second support is fixed to the other support base; the electromagnetic chuck is arranged over the crescent-moon-shaped plate; the discharging channel is obliquely arranged, and roller blanks are arranged on the discharging channel; the upper end of the conveying spring plate is fixedly connected with the rack; the conveying movable plate is arranged on the left side of the conveying spring plate and arranged on the upper side of the lower end of the discharging channel, and a conveying driving mechanism used for driving the conveying movable plate to do vertical reciprocating motion is arranged on the rack; and the material beating head is movably arranged on the crescent-moon-shaped plate, and a material beating driving mechanism used for driving the material beating head is arranged on the crescent-moon-shaped plate. According to the system, feeding and discharging of the spherical rollers can be conveniently achieved.

Owner:临清市海滨轴承制造有限公司

Die pressing production line

The invention belongs to the technical field of sound-absorbing cotton, and provides a die pressing production line. The die pressing production line comprises a rack. The rack is provided with a feeding device, a baking box and a die pressing machine, all of which are sequentially distributed and connected through a conveying belt. The feeding device comprises a material taking device arranged onthe rack. The material taking device comprises transverse parts connected with the rack through a walking device. Longitudinal parts and a first grabbing device are arranged at the bottoms of the transverse parts. Second grabbing devices are arranged at the two ends of the longitudinal parts. The transverse parts are connected with the walking device through a telescopic rod. The 2-5 longitudinalparts are arranged, and the first grabbing device is arranged in the center of the area defined by the second grabbing devices. The first grabbing device is a needle type inserting rod, and the second grabbing devices are suction cups or mechanical arms. A conical inserting head is arranged at one end of the first grabbing device, and a connecting part is arranged at the other end of the first grabbing device, wherein the connecting part is connected with the transverse parts through an installing base. The die pressing production line solves the technical problems that in the prior art, a sound-absorbing cotton production line is simple in structure, and usage is not convenient.

Owner:保定棉金汽车饰件制造有限公司

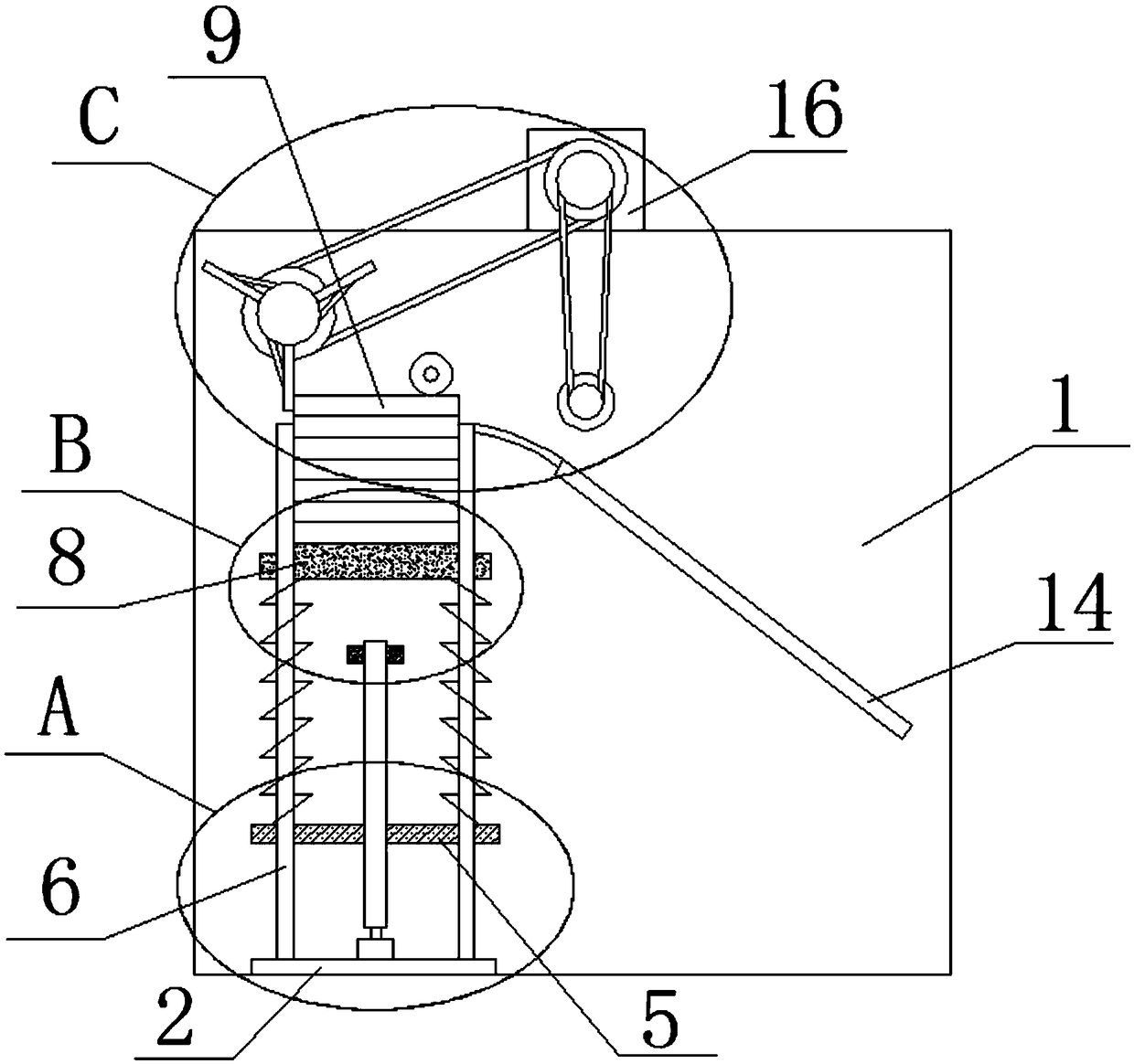

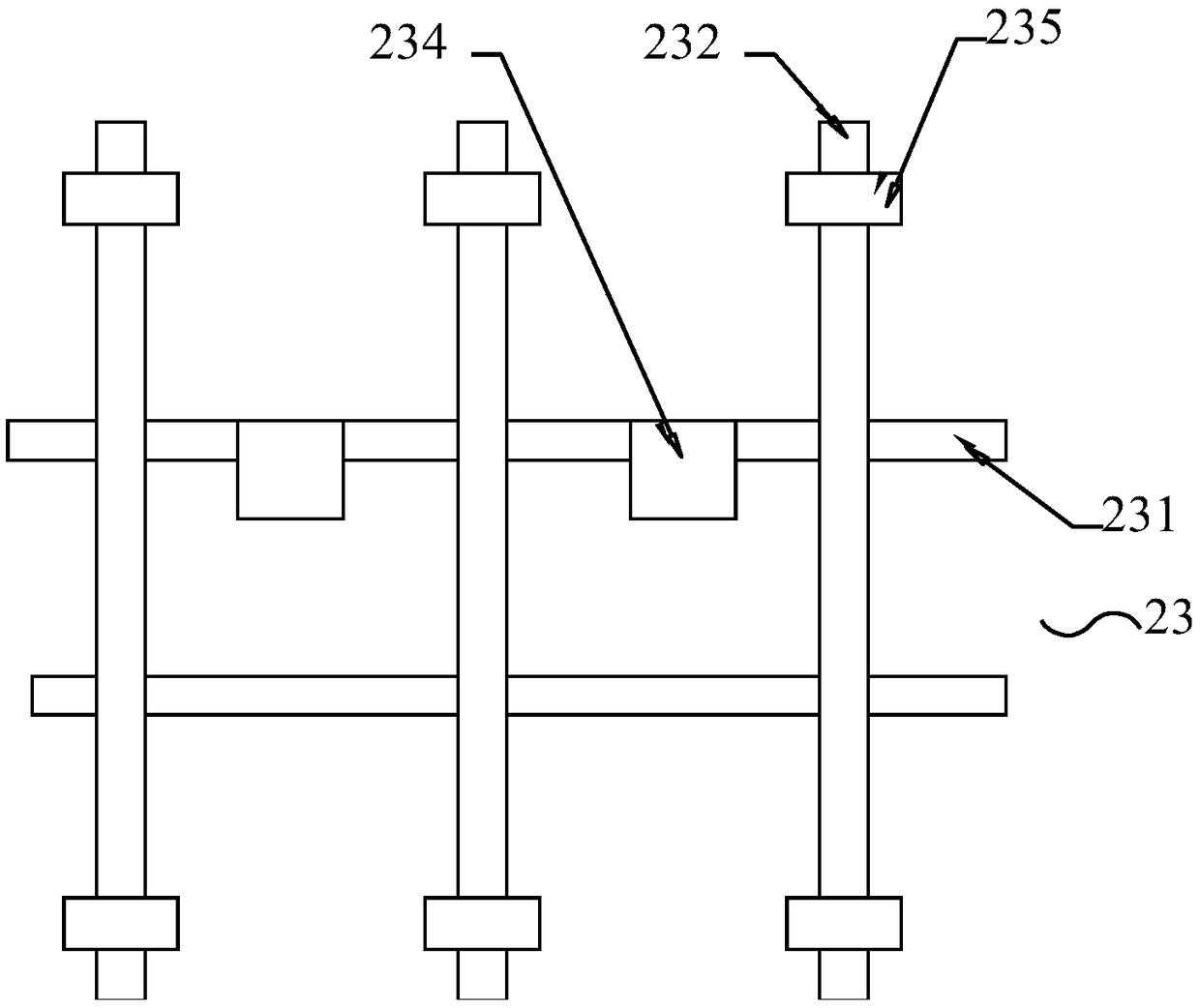

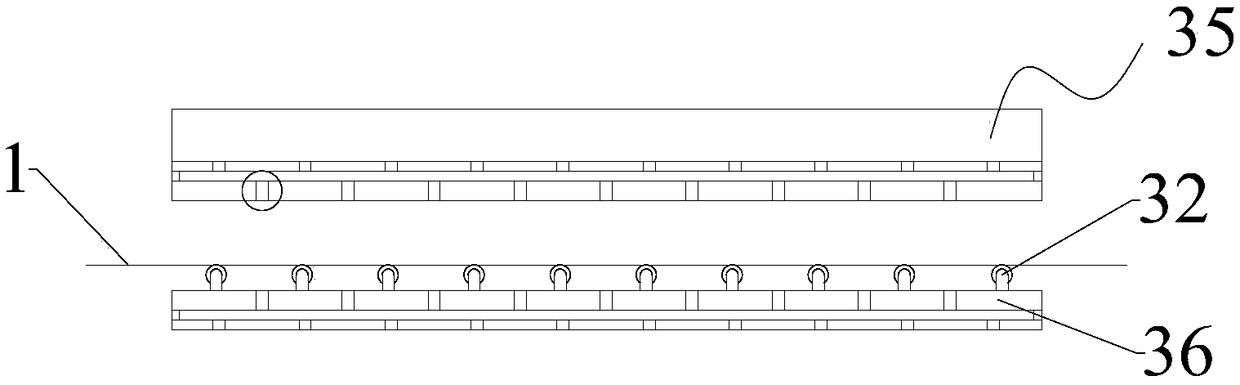

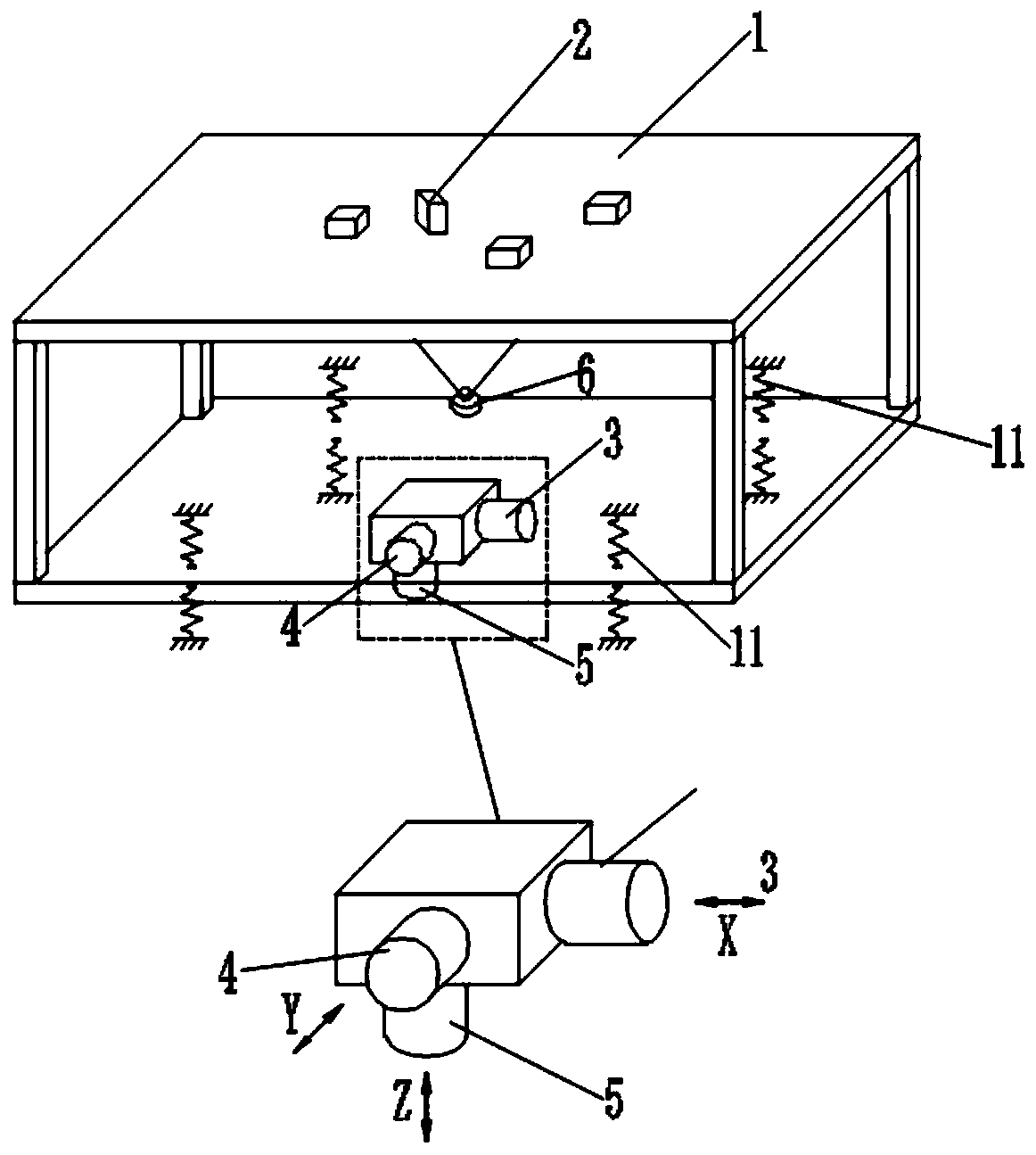

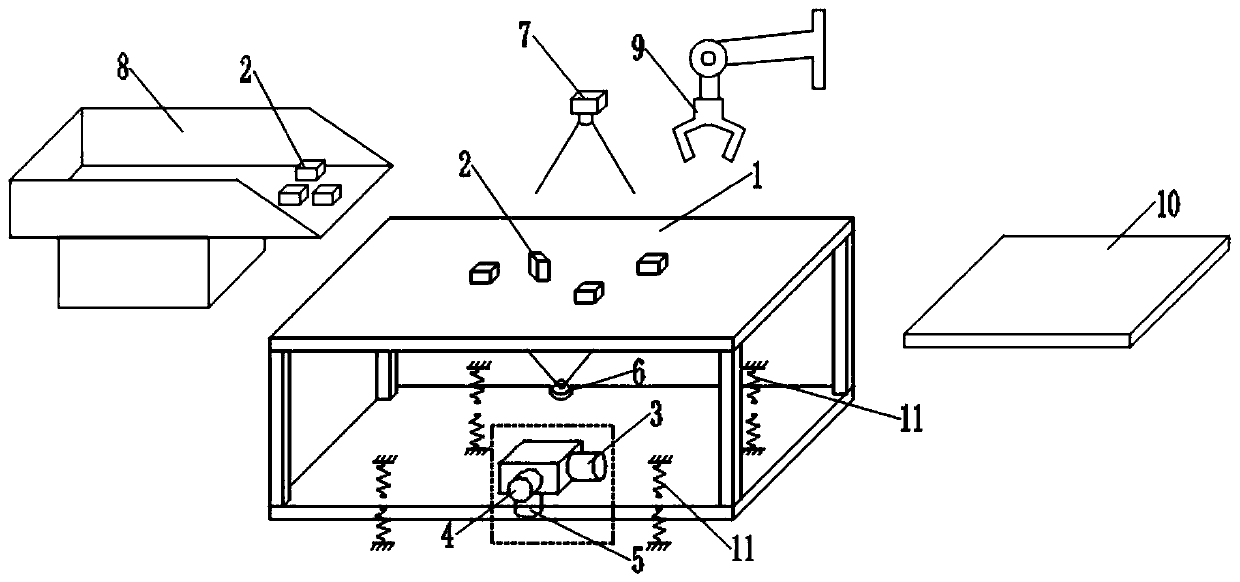

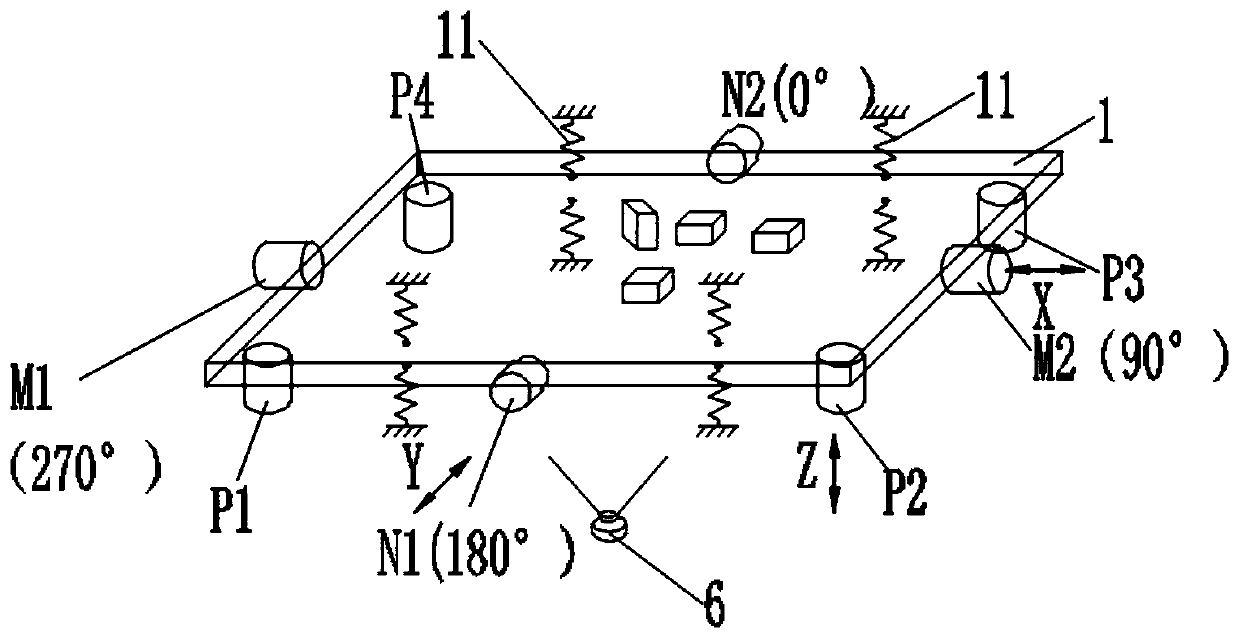

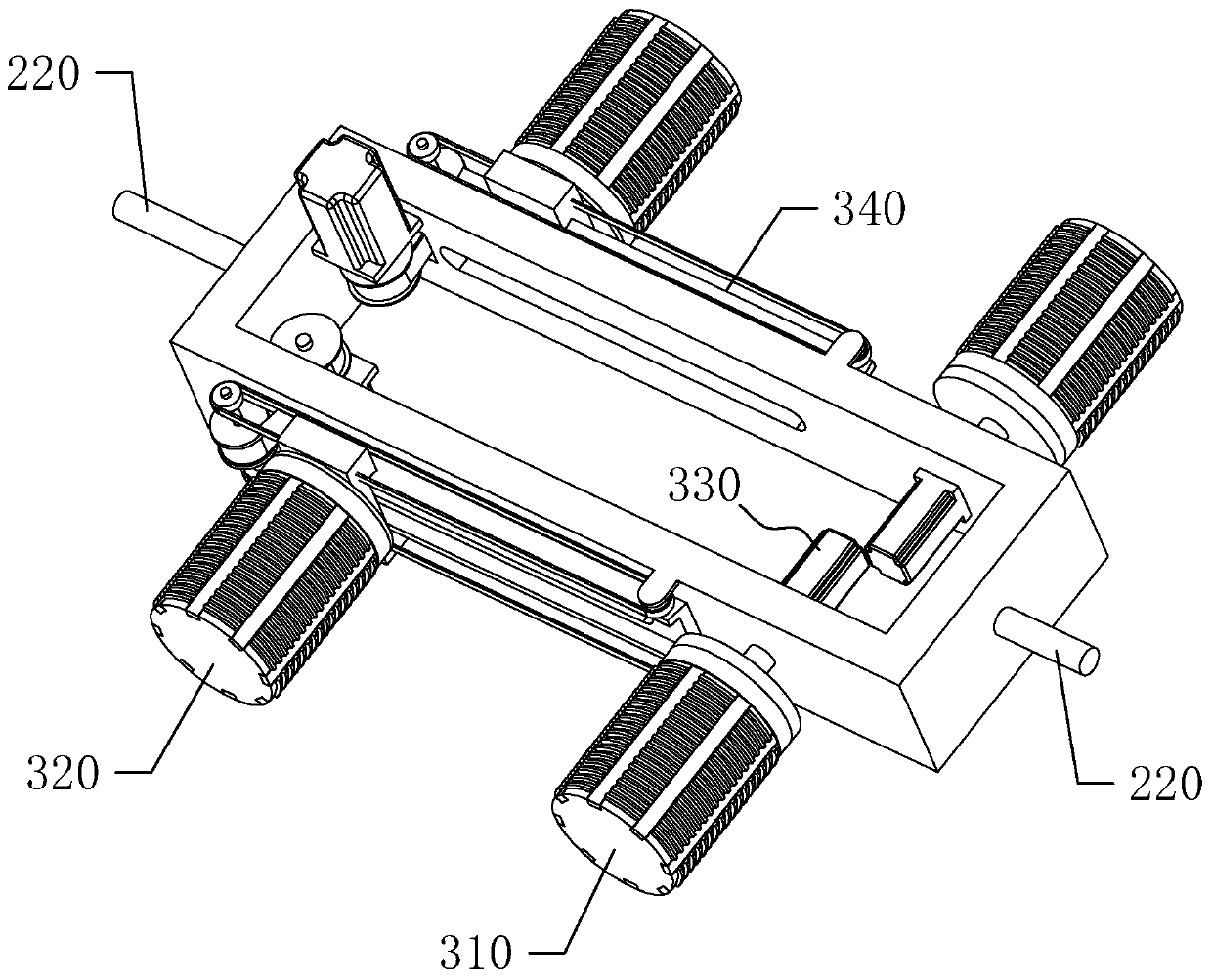

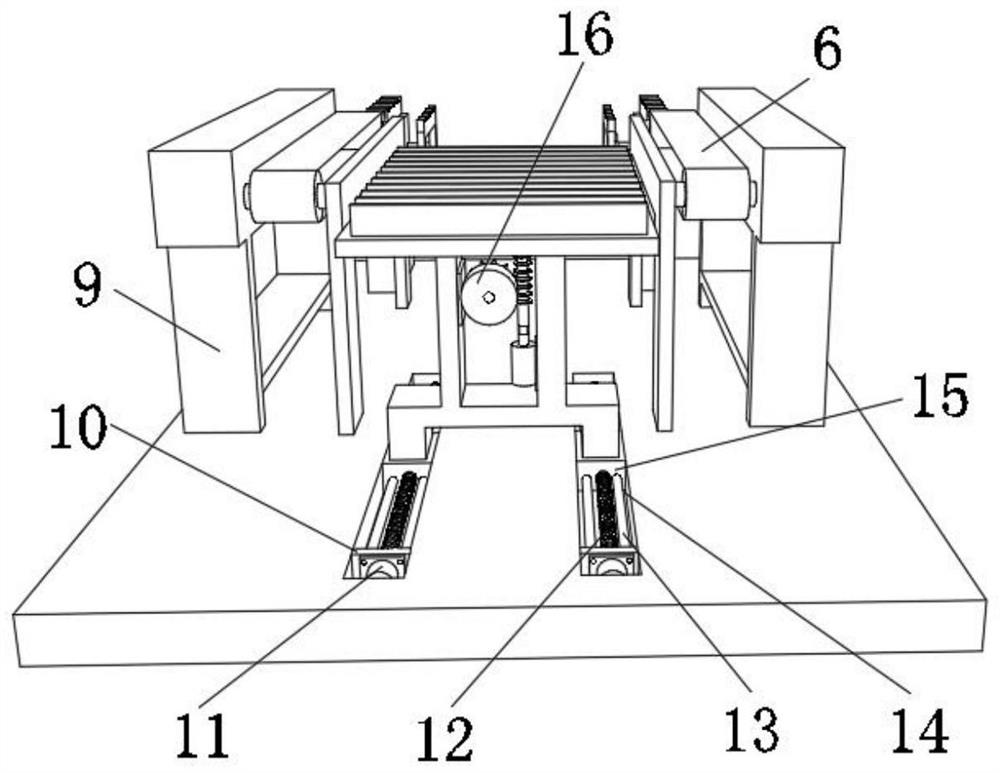

Batched bulk parts separating device, loading system and loading method

PendingCN110480294AFlexibleOvercome various defects of manual assemblyMetal working apparatusControl systemManipulator

The invention discloses a batched bulk parts separating device, a loading system and a loading method. The device comprises a base, a supporting part and a tray. The supporting part is connected to the base, the tray is arranged on the supporting part, a tray stressing part is arranged on the base, the tray stressing part is connected to a control part, the action direction of the tray stressing part is one or more of X axis, Y axis and Z axis, and the tray responses to action of the tray stressing part; and the loading system comprises the separating device, a stock bin, a CCD photographic system, a manipulator, a material platform and a control system. The separating device has the advantages that the separating device separates batched bulk parts and makes the parts in expected gestureswithin a given time; by defining the direction, the parts can be conveyed to any areas; matched with the loading system, the parts are loaded automatically and flexibly; the same device can be suitable for parts of different specifications; when products are replaced, control parameters are only regulated according to the parts, so that the production efficiency is improved and the production cost is lowered.

Owner:无锡丹尼克尔自动化科技有限公司

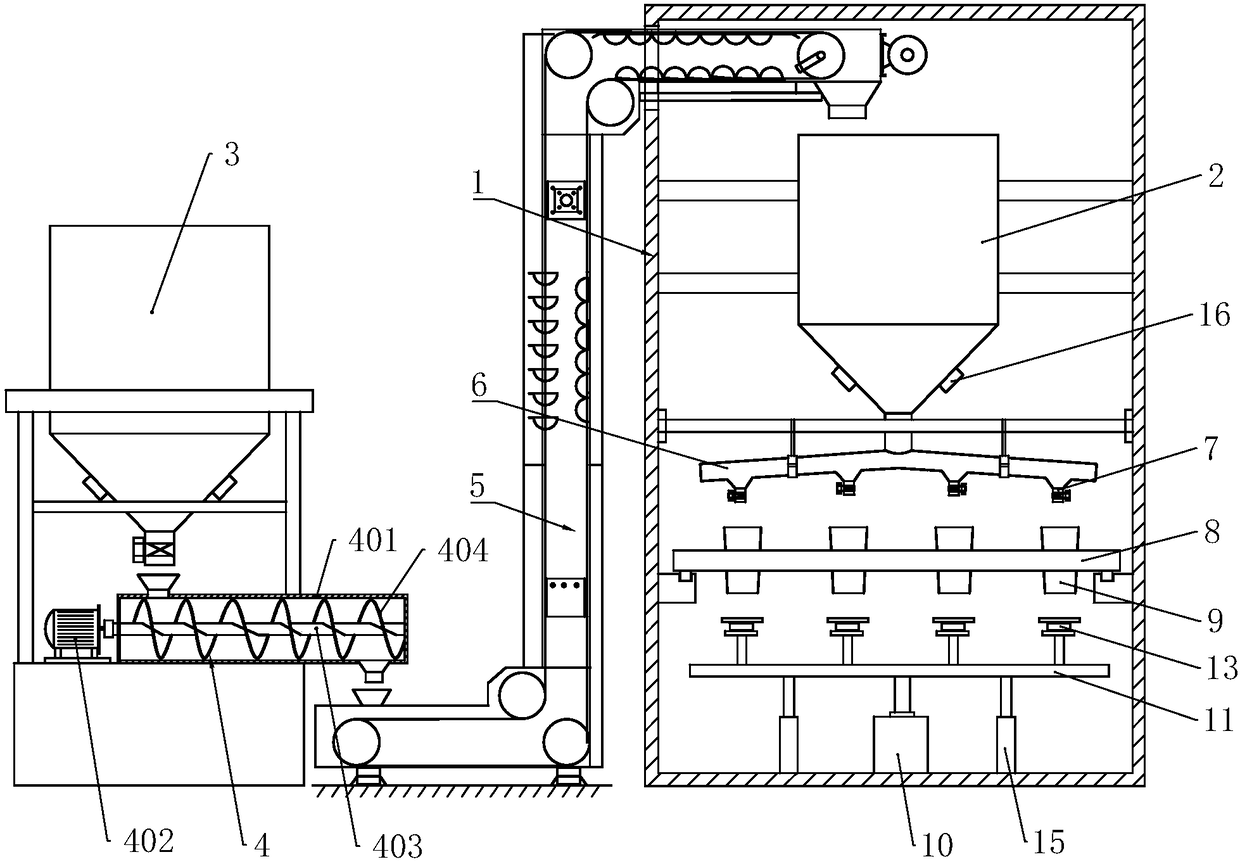

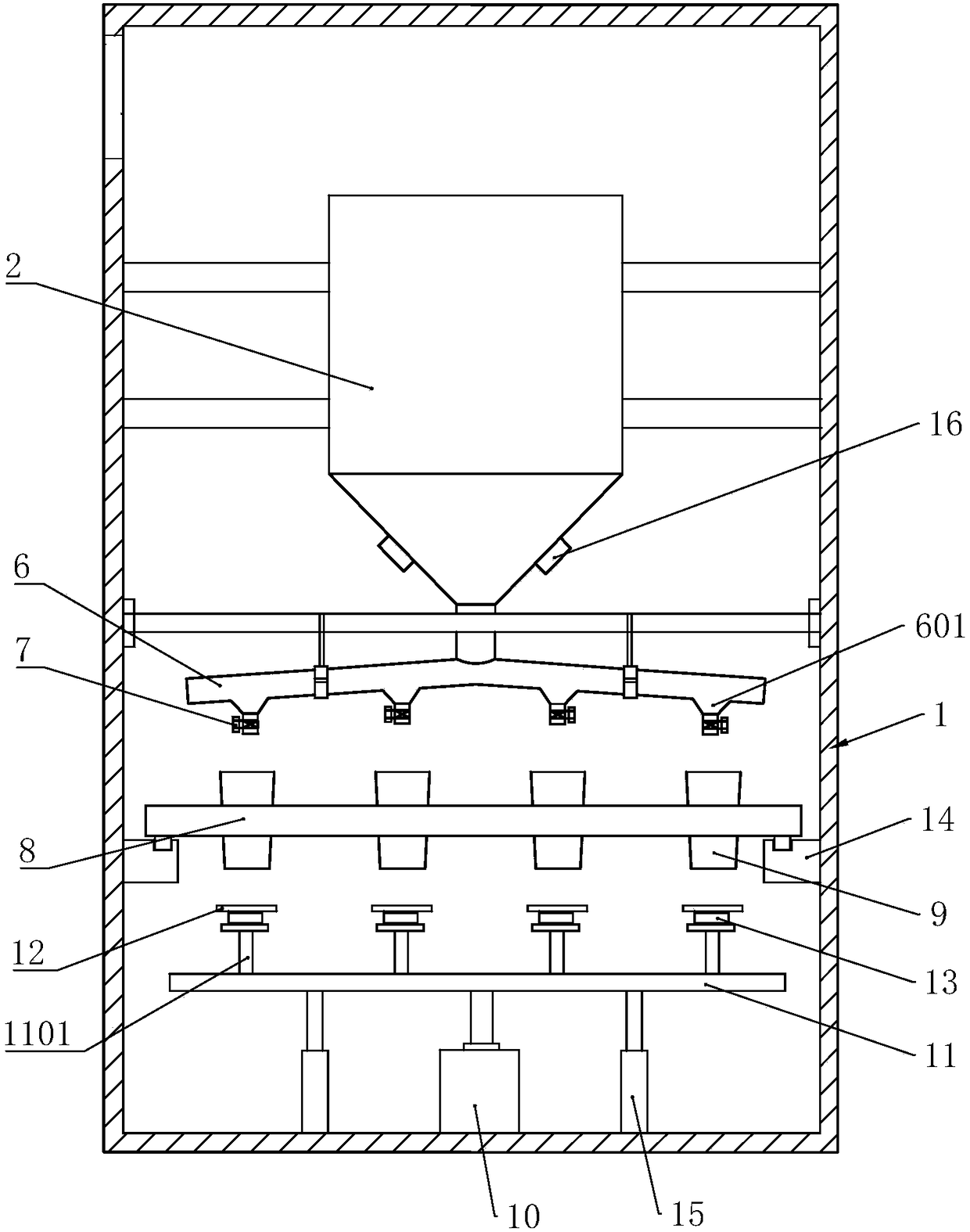

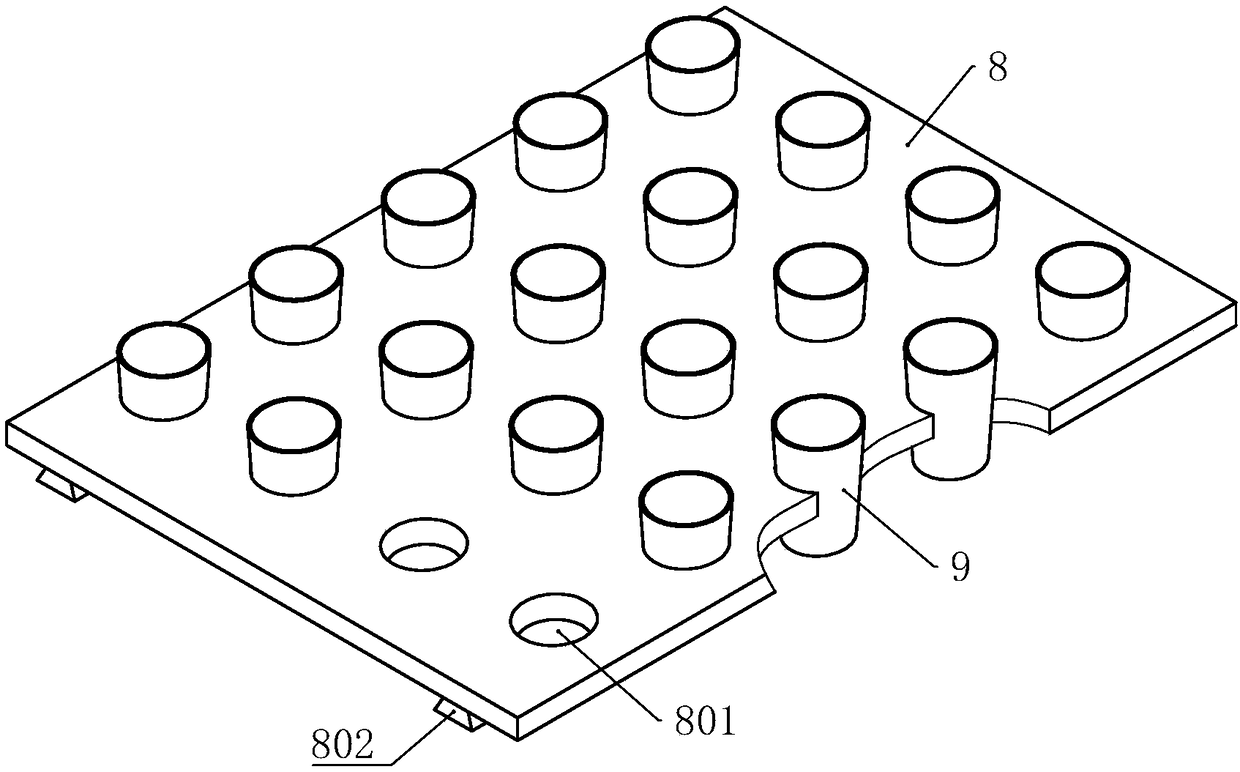

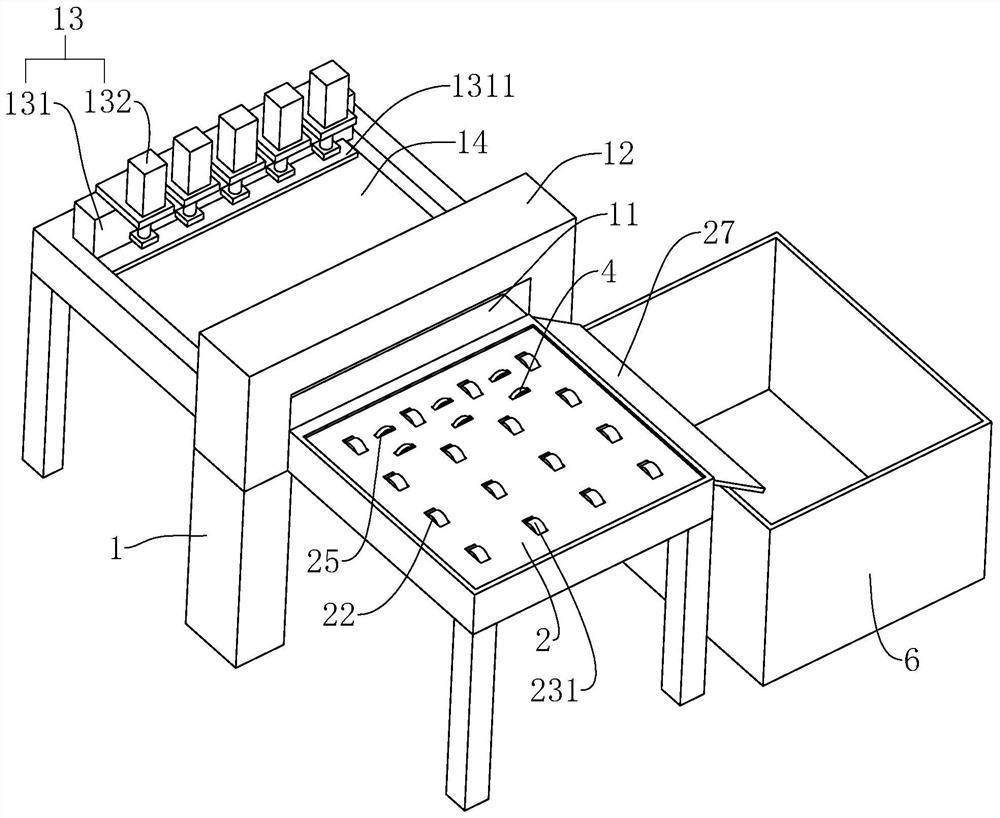

Automatic weighting and distributing device and application thereof in aspect of processing raw materials of brake pads and medicine

PendingCN108298333AImprove distribution efficiencyExtended service lifeLoading/unloadingMechanical conveyorsElectricityEngineering

The invention relates to an automatic weighting and distributing device and an application thereof in the aspect of processing raw materials of brake pads and medicine. The invention belongs to the technical field of weighing and distribution, and provides an automatic weighting and distributing device. The automatic weighting and distributing device comprises a distributing box body, a feeding mechanism, a distributing mechanism, a bearing mechanism and a weighing mechanism, wherein a storage hopper is fixedly installed in the distributing box body; the feeding mechanism comprises a batch hopper, a mixing conveyor and a rotary bucket lifting machine; the distributing mechanism comprises a distributing pipe which communicates with the storage hopper, and a plurality of distributing openings on which electromagnetic valves are respectively installed are formed in the distributing pipe; the bearing mechanism comprises a sliding plate, a plurality of through holes are formed in the sliding plate, and material cups are put in the through holes; and the weighing mechanism comprises an air cylinder, cup ejection rods, trays and weighing sensors, a piston rod of the air cylinder is fixedly connected with the cup ejection rods, the trays are installed on the cup ejection rods by virtue of the weighing sensors and correspond to the through holes, and the weighing sensors are electrically connected with the electromagnetic valves which are vertically and correspondingly arranged respectively. The automatic weighting and distributing device has the advantages of simple structure and low cost, simultaneous precise distribution of multiple material cups is realized, and the distributing efficiency of raw materials of products is improved.

Owner:青岛创高世纪信息科技有限公司

Automatic winding machine for inductance coil

The invention discloses an automatic winding machine for an inductance coil. The automatic winding machine comprises a rotating disc assembly, the rotating disc assembly comprises a rotating disc, material clamping assemblies used for clamping materials are arranged on the rotating disc in an annular array mode, a first pushing sleeve assembly matched with the material clamping assemblies is arranged on the portion, on a workbench, of one side of each material clamping assembly, a feeding assembly used for pushing materials is arranged above the portion, on one side of the workbench, of a support base, a tape output assembly is arranged at one side of the clamping assembly, a guiding assembly is arranged under a tape output assembly, a second pushing sleeve assembly matched with the clamping assembly is arranged in the portion, on the workbench, below the guiding assembly, and an auxiliary winding assembly used for being matched with the material clamping assembly to wind an adhesive tape material strip is arranged below the second pushing sleeve assembly. According to the automatic winding machine, automatic feeding and clamping of large-batch inductance coil materials is achieved, rapid adhesive tape wrapping and winding operation can be achieved, and the labor intensity and the labor efficiency of enterprise employees can be reduced.

Owner:YAXIN (HUAIHUA) ELECTRONICS CO LTD

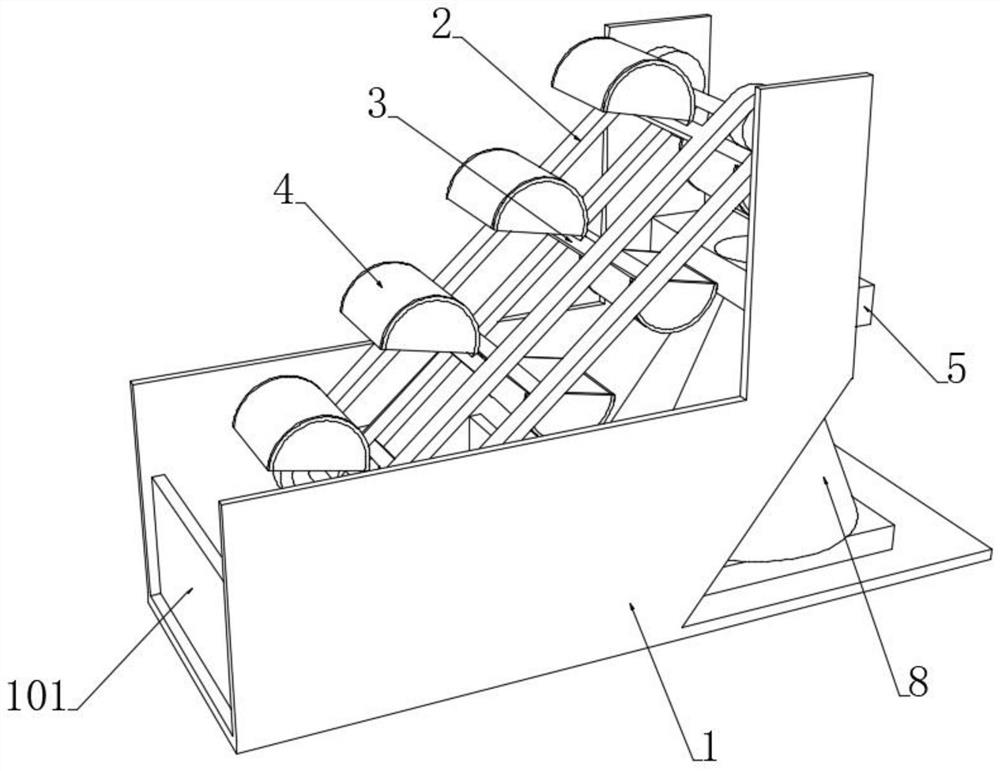

Crawler-type automatic feeding loader facilitating centralized stacking in harbor district

InactiveCN112623627AFlexible opening and closingRealize loading operationConveyorsConveyor partsMarine engineeringStructural engineering

The invention discloses a crawler-type automatic feeding loader facilitating centralized stacking in a harbor district, and belongs to the technical field of feeders. A plurality of feeding hoppers are uniformly distributed on a crawler conveying assembly, sequentially and circularly move from the bottom of the crawler conveying assembly to the top of the crawler conveying assembly, and upwards drive materials when moving to a stacking cavity; when the feeding hoppers move to the top end of the crawler conveying assembly, the magnetic attraction effect of a magnetic attraction starting mechanism on an arc-shaped turning cover plate is utilized, at the moment, after the arc-shaped turning cover plate is turned over through magnetic attraction, materials in the feeding hoppers fall down through a discharging cavity, and feeding and collecting operation is completed; after the feeding hoppers are away from the magnetic attraction starting mechanism, the arc-shaped turning cover plate turns over and resets towards the position of the discharging cavity so as to achieve subsequent feeding operation, materials do not need to be loaded manually, materials conveyed upwards do not need to be manually discharged, no material blocking device is needed, the arc-shaped turning cover plate is flexibly opened and closed during material loading and unloading, and loading and unloading operation is not affected.

Owner:倪小华

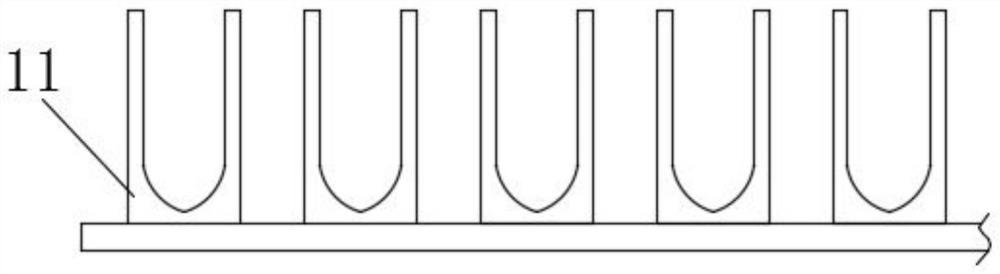

Terminal cutting-off and press-fitting device with L-shaped stamping head

PendingCN113369560AImprove cutting efficiencyImprove pressing efficiencyContact member manufacturingShearing machinesBusiness enterpriseEngineering

The invention discloses a terminal cutting-off and press-fitting device with an L-shaped stamping head, and relates to the technical field of terminal cutting-off and press-fitting. The terminal cutting-off and press-fitting device comprises a workbench, a bottom plate and a supporting frame, wherein the bottom plate is connected with a lower supporting plate through a clamping block and a clamping bolt, the upper end of the lower supporting plate is sequentially provided with a pushing assembly, a sliding block assembly and a workpiece limiting seat, the sliding block assembly is matched with a clamping assembly above to clamp terminals, each terminal is of a U-shaped linear array sheet structure, a cutting-off assembly is arranged at the side end of the clamping assembly and comprises the stamping head, and the lower end of the stamping head is of an L-shaped protruding structure and can be matched with the terminal. With the terminal cutting-off and press-fitting device with the L-shaped stamping head, the processing requirements of enterprises on large-batch terminal feeding, cutting and press-fitting are met, unqualified terminal cutting-off and press-fitting caused by misoperation of employees of the enterprises are avoided, then the rejection rate of the enterprises is reduced, the cutting-off and press-fitting efficiencies of the terminals are improved, and the phenomena of bending and unevenness of the terminals due to overlarge feeding thrust are effectively avoided.

Owner:YAXIN (HUAIHUA) ELECTRONICS CO LTD

Automatic cloth wrapping machine

ActiveCN110171151ARealize loading operationUninterrupted continuous supplyBeltsThree-dimensional spaceEngineering

The invention discloses an automatic cloth wrapping machine. The machine comprises a cloth wrapping machine body, a feeding device and a clamping device, wherein a V-belt is continuously supplied to the cloth wrapping machine through the feeding device, and then the clamping device is used for controlling a clamping jaw air cylinder to do the inherent path movement in the three-dimensional space so as to realize the feeding operation of the V-belt, thus achieving the full-automatic feeding and feeding operation.

Owner:ZHEJIANG SANLISHI INTELLIGENT EQUIP MFG CO LTD

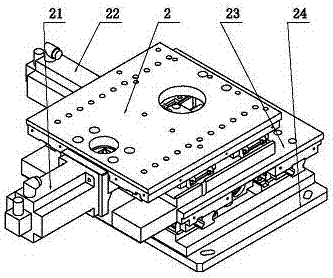

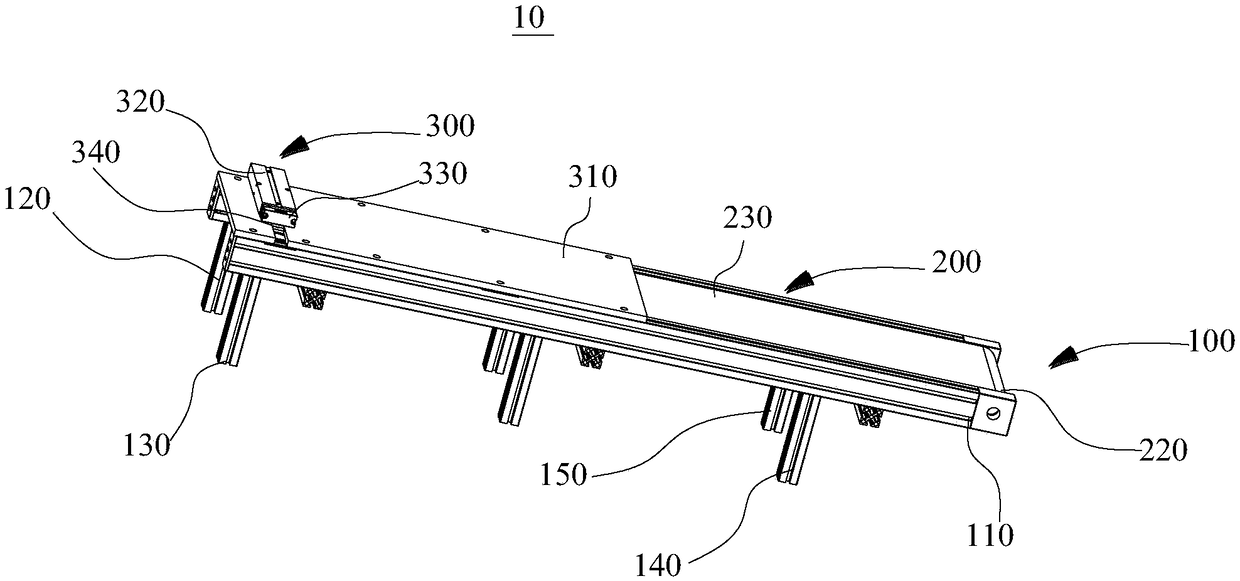

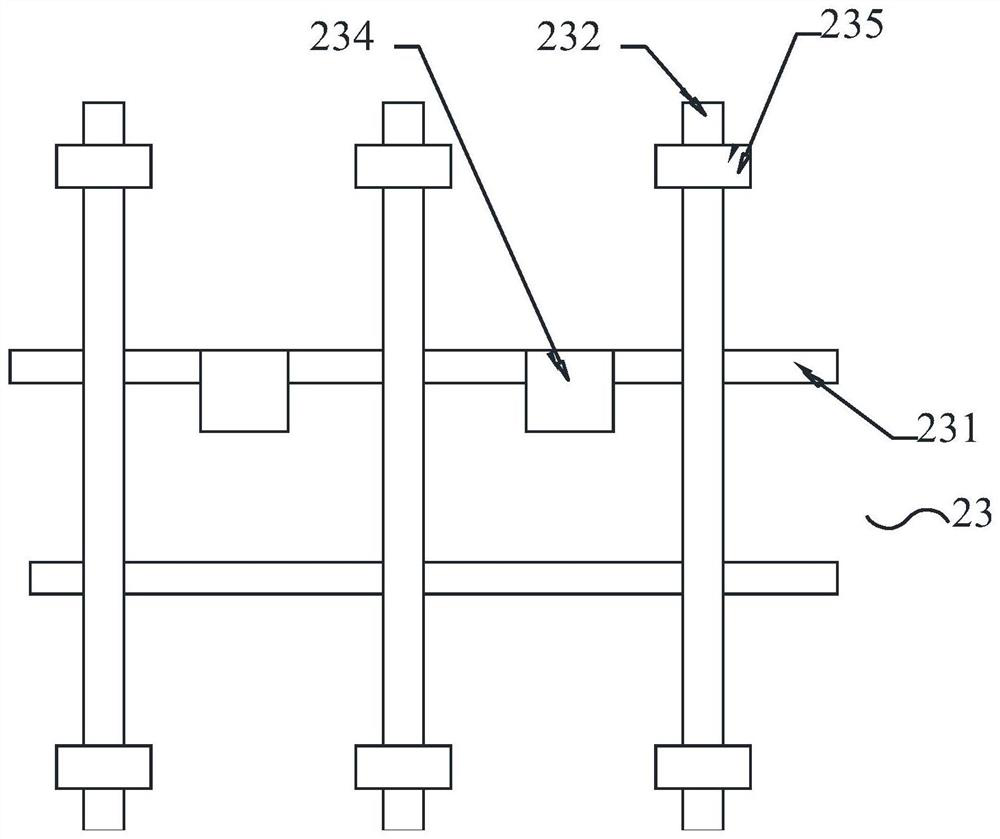

Loading device used for SD memory card

The invention discloses a loading device used for an SD memory card. The loading device comprises a supporting assembly, a transmission assembly and a pushing assembly, wherein the transmission assembly is arranged on the supporting assembly; the pushing assembly is arranged on the transmission assembly; the supporting assembly comprises a transmission mounting framework, a first supporting frame,a second supporting frame, a third supporting frame and a fourth supporting frame; and the first supporting frame, the second supporting frame, the third supporting frame and the fourth supporting frame are separately arranged on four end corner positions of the transmission mounting framework. According to the loading device used for the SD memory card disclosed by the invention, the supportingassembly, the transmission assembly and the pushing assembly are arranged, the supporting assembly is used for mounting the transmission assembly and the pushing assembly, and is used for achieving the relatively good supporting effect on the transmission assembly and the pushing assembly; the transmission assembly is used for transmitting the memory card; and the pushing assembly is used for pushing materials on the transmission assembly to a next station, so that loading operation is realized; and mechanical automatic loading replaces a conventional loading mode, so that loading efficiency is improved.

Owner:惠州恒立信科技有限公司

Irregular part feeding equipment

InactiveCN108996117ARealize loading operationConvenience for subsequent loading operationConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to the field of feeding equipment, in particular to irregular part feeding equipment. The feeding equipment comprises a supporting framework. A workbench is arranged on the supporting framework. At least two transferring portions driving parts to move are arranged on the workbench. The adjacent transferring portions are opposite in moving direction. The feeding equipment further comprises an unloading portion used for transferring the parts out of the feeding equipment. The feeding equipment further comprises a guide portion used for part guiding. According to the novel feeding equipment disclosed by the invention, through cooperation among the transferring portions, the unloading portion and the guide portion, the to-be-fed parts can be fed, meanwhile, through cooperation between the transferring portions and the guide portion, the to-be-fed parts can be dispersed, and subsequent feeding operation is facilitated.

Owner:WUHU QUAN CHENG INTELLIGENT TECH

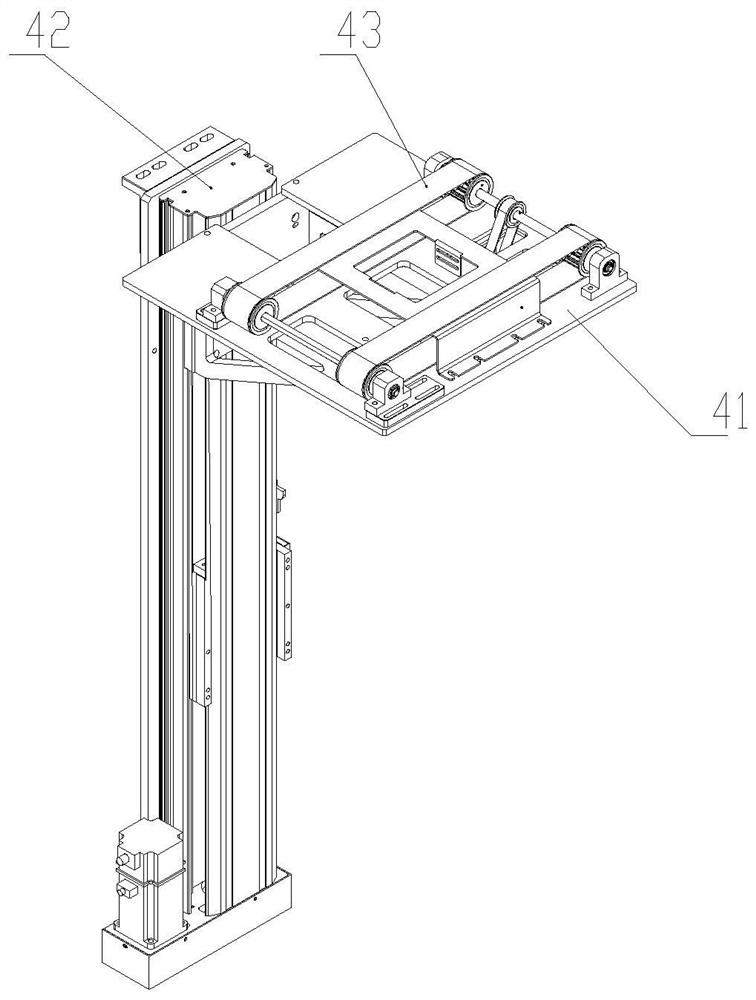

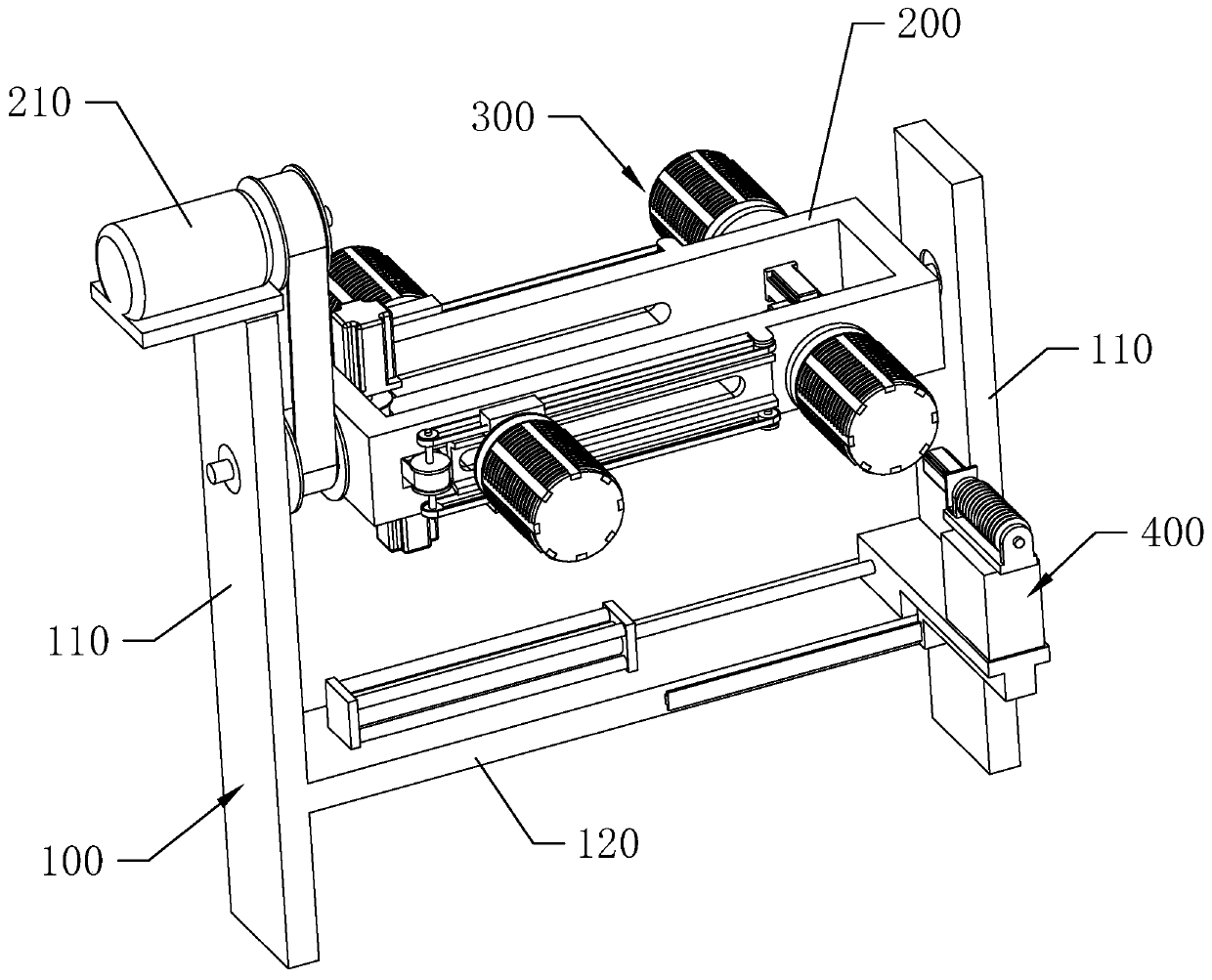

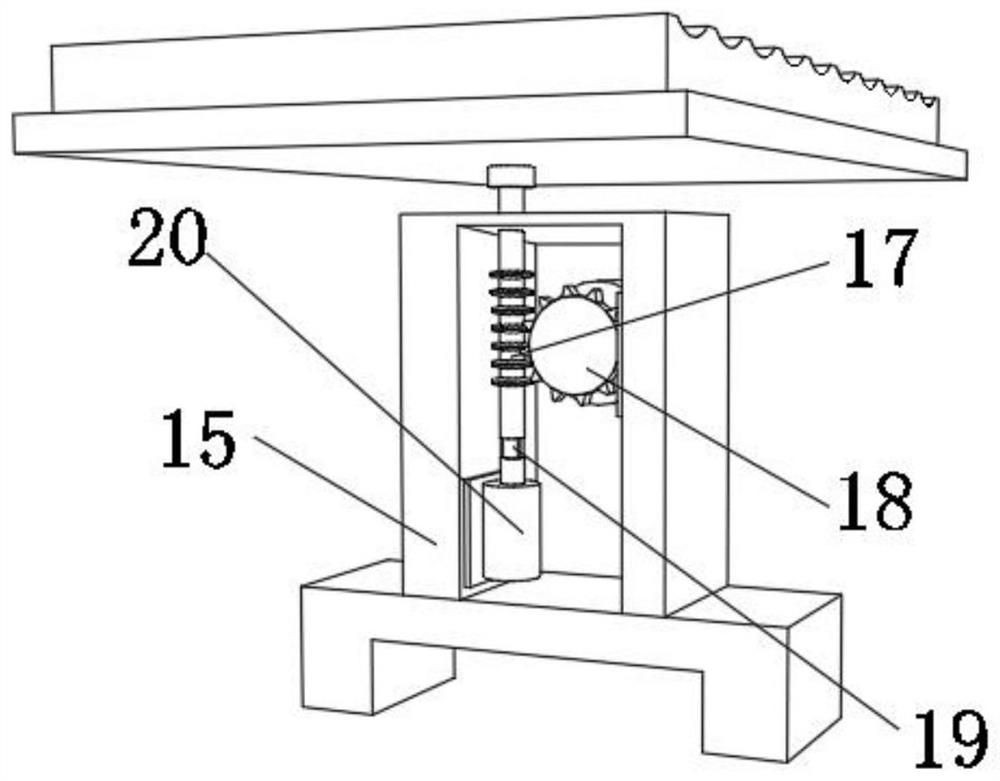

Surface grinding device for roller machining and using method

ActiveCN113579922ARealize loading operationRealize adjustment operationRevolution surface grinding machinesGrinding drivesElectric machineryMoving frame

The invention discloses a surface grinding device for roller machining and a using method, and belongs to the technical field of roller production. The surface grinding device for roller machining comprises a transfer frame; a transfer motor is fixedly connected to the inner wall of the transfer frame; furthermore, a rotating plate is mounted at the output end of the transfer motor; the end, away from the transfer motor, of the rotating plate is rotationally connected with a movable connecting rod; and the end, away from the rotating plate, of the movable connecting rod is rotationally connected with a short swinging plate rotationally connected with the inner wall of the transfer frame. According to the surface grinding device for roller machining and the using method, due to arrangement of a moving frame, in a grinding mechanism, a lifting connecting plate moves to drive two sets of guide sliding blocks to synchronously and reversely slide along limiting rods through two sets of connecting rods; the guide sliding blocks move to drive a swing bent plate to rotate through a sliding hole groove, so that the swing bent plate rotates to drive a grinding body in the moving frame to move through a moving hole groove; and through synchronous and reverse movement of the two sets of moving frames, rapid grinding operation on the roller raw materials is achieved.

Owner:YIXING YONGCHANG ROLL

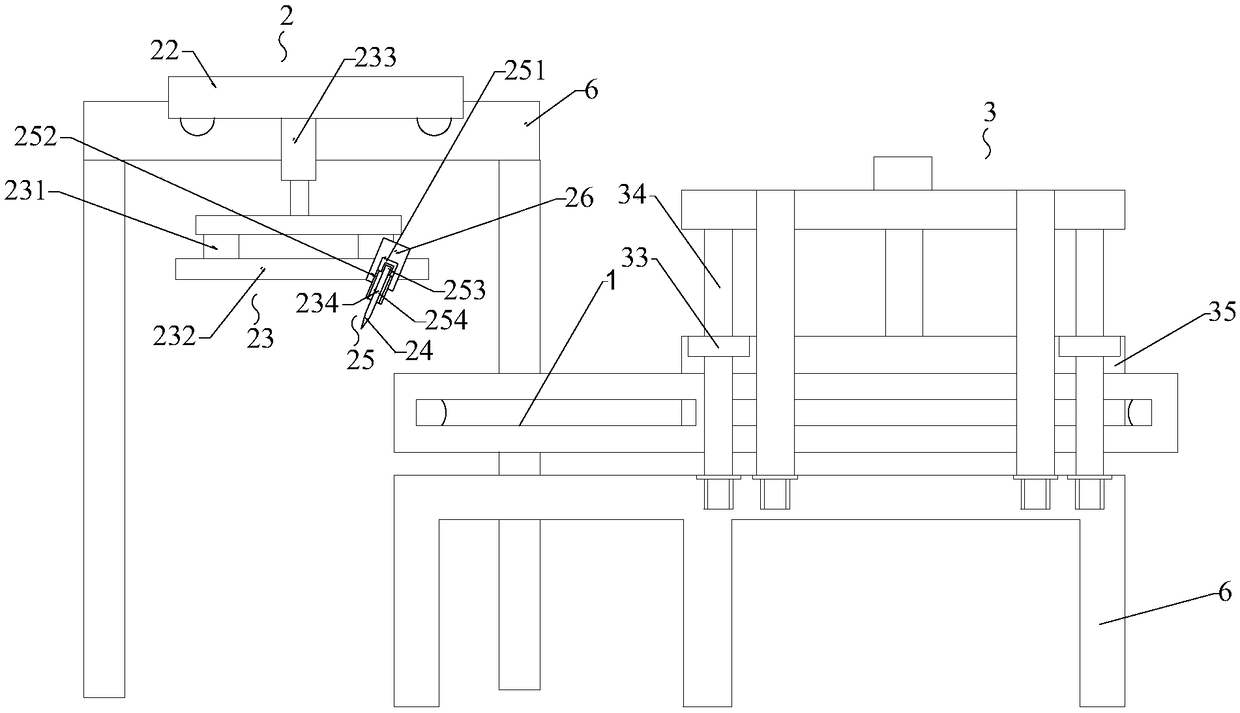

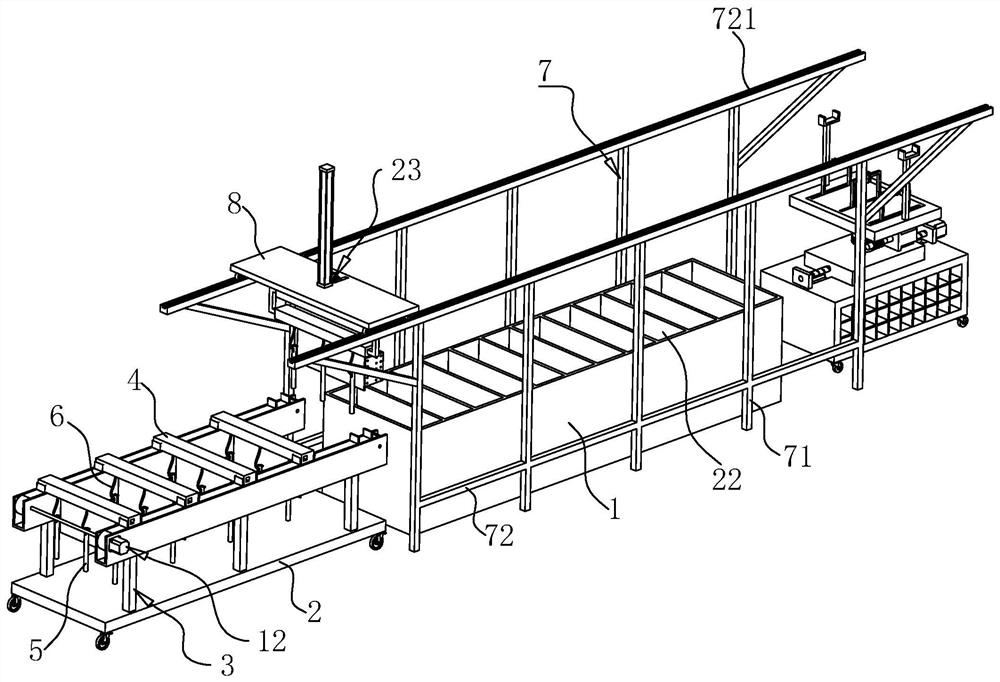

An automatic plate cutting device and cutting method for customized furniture production

ActiveCN113414837BReduce manual operationsReduce labor costsCircular sawsBand sawsIndustrial engineeringHand operations

The application relates to an automatic plate cutting device and cutting method for customized furniture production, belonging to the technical field of cutting equipment, which includes a main body and a feeding platform, a sawing mechanism, a pressing mechanism, a clamping mechanism, and a Mechanism and air flotation table, the feeding platform is equipped with a material feeding component, which is used to push the plate to be cut to move to the position of the sawing mechanism, and the feeding platform is equipped with a material discharging component, which is used to push the cut plate to move Out of the feeding platform, the feeding direction and the discharging direction of the feeding platform are perpendicular to each other, and a receiving frame is arranged on the outer side of the feeding platform and close to the discharging direction. In this application, the material-feeding component and the material-discharging component are used to replace manual operation steps of manpower, which saves manpower and cost, and improves work efficiency at the same time.

Owner:佛山市锦裕家具实业有限公司

Chip packaging equipment for 12-inch wafers

ActiveCN105261581BIncreased load rangeRealize loading operationSemiconductor/solid-state device manufacturingEngineeringPower consumption

The invention discloses chip packaging equipment suitable for a 12inch wafer. The chip packaging equipment comprises a slide mounting rack and a loading welding head, wherein the slide mounting rack is driven by a first drive unit to slide back and forth along a horizontal direction; the loading welding head is arranged on an output shaft of a second drive unit; a third drive unit is arranged on the loading welding head and drives the loading welding head to rotate at 360 degrees; the second drive unit is also fixedly arranged on the slide mounting rack; and meanwhile, a wafer supporting stage is driven by a fourth drive unit to rotate at 180 degrees. Compared with the prior art, the length of the loading welding head does not need to improve, so that the loading accuracy and speed of the loading welding head are not affected; and the welding head can carry out reciprocating drive between an unloading position and a loading position within the shortest possible time. Meanwhile, the power consumption and the service lifetime of the loading welding head are not affected; and a loading operation on the 12inch wafer can be finished under the premise of not changing the structure of the loading welding head.

Owner:SUZHOU ACCURACY ASSEMBLY AUTOMATION CO LTD

Automatic production equipment for HDPE (High Density Polyethylene) waterproof and drainage filter

PendingCN114670533ARealize loading operationClean thoroughlyLamination ancillary operationsLaminationHigh-density polyethyleneStructural engineering

The invention discloses automatic production equipment for a high-density polyethylene (HDPE) waterproof and drainage filter. The automatic production equipment comprises a rack; and the three-in-one composite assembly is rotationally arranged in the middle of the rack and used for conveying the three coiled materials at the same time, the three-in-one composite assembly comprises a mounting pipe movably arranged in the middle of the rack, and a first driving ring and a second driving ring are rotationally arranged in the middle of the mounting pipe. A worm gear rod drives a driving cover to rotate, so that a regular polygon inserting hole formed in the middle of the driving cover is matched with a regular polygon column and a fixing plate to drive a driving tooth column to rotate, and the driving tooth column drives a first driving ring and a second driving ring to rotate; and through cooperation with the driven rollers, coiled materials between the driven rollers and the second driving rings, between the driven rollers at the bottom and the second driving rings and between every two vertically adjacent first driving rings can be synchronously conveyed, and therefore feeding operation can be conducted on three kinds of coiled materials compounded into products at the same time.

Owner:合肥德旺科技有限公司

An automatic wrapping machine

ActiveCN110171151BRealize loading operationUninterrupted continuous supplyBeltsThree-dimensional spaceProcess engineering

The invention discloses an automatic cloth wrapping machine, which comprises a cloth wrapping machine body, a feeding device and a clamping device. Through the feeding device, the V-belt is continuously supplied to the cloth wrapping machine, and then through the clamping device, a control clamp is adopted. The claw cylinder makes an inherent path movement in three-dimensional space to realize the feeding operation of the V-belt, so as to realize the automatic feeding and feeding operation.

Owner:ZHEJIANG SANLISHI INTELLIGENT EQUIP MFG CO LTD

A kind of anodic oxidation production line and production process

This application relates to an anodic oxidation production line and production process, which relates to the technical field of anodic oxidation of workpieces. This application includes a loading cart arranged on the feeding side of the production pool. The loading cart is provided with a loading rack. A hanging rod is movably connected to the loading rack, and a number of hooks for hanging workpieces to be anodized are arranged on the hanging rod. Supports are set up on both sides of the production pool, and the support is located above the production pool. The crane that moves in the length direction of the bracket is provided with a clamping mechanism for clamping the hanging rod, and the crane is provided with a lifting mechanism for driving the clamping mechanism to go up and down. This application realizes the loading of workpieces to be anodized through the cooperation of hanging rods, loading racks, loading carts, clamping mechanisms, lifting mechanisms, and cranes, and at the same time helps to reduce manual loading operations, thereby saving time Labor-saving effect; and help to improve processing efficiency.

Owner:太仓夏鑫电镀有限公司

A method of using a surface grinding device for roll processing

ActiveCN113579922BRealize loading operationRealize adjustment operationRevolution surface grinding machinesGrinding drivesElectric machineEngineering

The invention discloses a surface grinding device for roll processing and a use method thereof, belonging to the technical field of roll production. A surface grinding device for roll processing includes a transfer frame, the inner wall of the transfer frame is fixedly connected with a transfer motor, and the transfer motor The output end of the rotary plate is installed with a rotating plate, and the end of the rotating plate far away from the transfer motor is screwed with a movable connecting rod, and the end of the movable connecting rod far away from the rotating plate is screwed with a swing short plate screwed with the inner wall of the transfer frame. Using the surface grinding device and the method of use, by setting the mobile frame, in the grinding mechanism, the movement of the lifting connecting plate drives the two sets of guide sliders to slide synchronously and reversely along the limit rod through two sets of connecting rods, and the guide slider moves through the sliding hole The groove drives the swing bending plate to rotate, so that the swing bending plate rotates through the movement hole groove to drive the grinding main body in the moving frame, and through the synchronous reverse movement of the two sets of moving frames, the rapid grinding operation of the roll material is realized.

Owner:YIXING YONGCHANG ROLL

A sander loading machine convenient for quantitative output

ActiveCN111922902BTo achieve the purpose of quantitative deliveryEasy to transportGrinding carriagesGrinding feed controlSanderStructural engineering

The invention discloses a sander feeding machine which is convenient for quantitative output, and relates to the technical field of sander feeding machines; in order to carry out quantitative output of materials; it specifically includes a base, and the outer wall of the top of the base is welded with two mounting plates, one of which is The outer wall of one side of the mounting plate is rotatably connected with a rotating shaft, the outer wall of the circumference of the rotating shaft is welded with a rotating disc, the outer wall of the top of the rotating disc is welded with a moving column, and the outer wall of one side of the mounting plate is rotatably connected with an intermittent motion disc through the rotating shaft. Four accommodating grooves are provided on the outer wall around the intermittent motion disc, and the outer peripheral wall of the moving column is slidably connected to the inner wall of the accommodating groove, and the outer wall of the rotating shaft of the intermittent motion disc is welded with a second transmission roller. In the present invention, two rotating rods and a placing frame are arranged on the inner wall of one side of the same mounting plate to form a transmission mechanism, and the rotation of the two rotating rods can be used to realize the effect of transferring the material on the top of the discharging frame through the placing frame.

Owner:盐城鼎恒机械有限公司

Terminal cutting and press-fitting device with H-shaped stamping head

PendingCN113843445ASimple structureEasy to useContact member manufacturingShearing machinesBackplaneEngineering

The invention discloses a terminal cutting and press-fitting device with an H-shaped stamping head, and relates to the technical field of terminal cutting and press-fitting processing. The terminal cutting and press-fitting device comprises a workbench and a bottom plate, wherein the upper surface of the bottom plate is connected with a lower supporting plate through a clamping block and a clamping bolt; a pushing assembly is arranged at one side of the lower supporting plate; one side, away from the pushing assembly, of a slide block assembly is equipped with a workpiece limiting base for placing a workpiece; the slide block assembly is matched with a clamping assembly above, and can clamp a terminal; a cutting assembly for cutting off the terminal is arranged at the side end of the clamping assembly and above the slide block assembly; the cutting assembly comprises a stamping head; and the lower end part of the stamping head is in the shape of an H-shaped bump structure, and can be matched with the terminal. The terminal cutting and press-fitting device meets processing needs, on large-batch terminal loading, cutting and press-fitting, of enterprises, avoids unqualified terminal cutting or press-fitting due to misoperation of enterprise staff, reduces a rejection rate of the enterprises, improves cutting and press-fitting efficiency of the terminal, and improves economic benefits.

Owner:YAXIN (HUAIHUA) ELECTRONICS CO LTD

A molding production line

The invention belongs to the technical field of sound-absorbing cotton, and provides a die pressing production line. The die pressing production line comprises a rack. The rack is provided with a feeding device, a baking box and a die pressing machine, all of which are sequentially distributed and connected through a conveying belt. The feeding device comprises a material taking device arranged onthe rack. The material taking device comprises transverse parts connected with the rack through a walking device. Longitudinal parts and a first grabbing device are arranged at the bottoms of the transverse parts. Second grabbing devices are arranged at the two ends of the longitudinal parts. The transverse parts are connected with the walking device through a telescopic rod. The 2-5 longitudinalparts are arranged, and the first grabbing device is arranged in the center of the area defined by the second grabbing devices. The first grabbing device is a needle type inserting rod, and the second grabbing devices are suction cups or mechanical arms. A conical inserting head is arranged at one end of the first grabbing device, and a connecting part is arranged at the other end of the first grabbing device, wherein the connecting part is connected with the transverse parts through an installing base. The die pressing production line solves the technical problems that in the prior art, a sound-absorbing cotton production line is simple in structure, and usage is not convenient.

Owner:保定棉金汽车饰件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com