Crawler-type automatic feeding loader facilitating centralized stacking in harbor district

An automatic feeding and crawler-type technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient loading and unloading materials, tight storage space, large operating labor force, etc., and achieve the effect of flexible opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

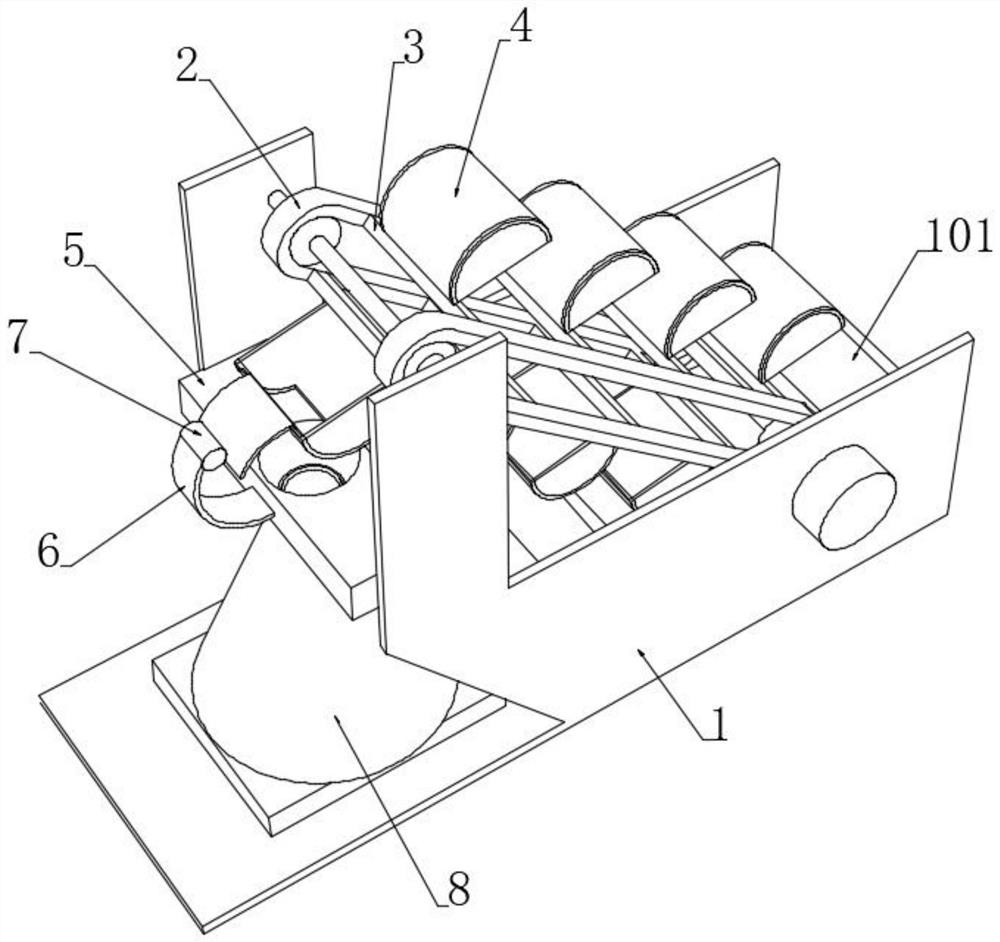

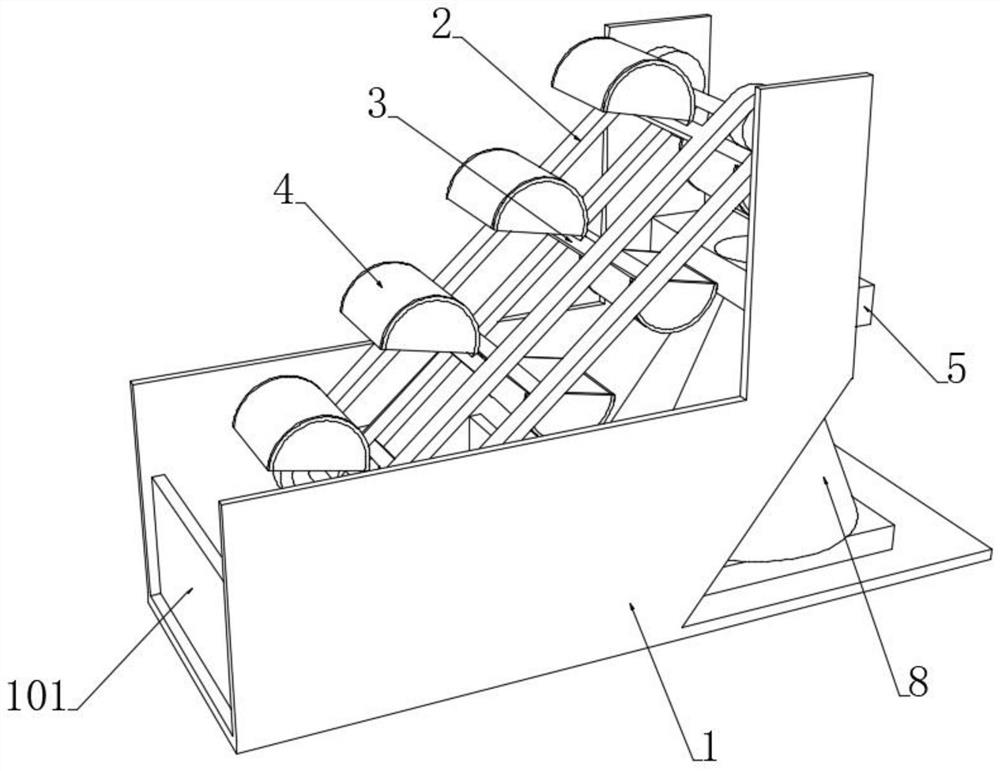

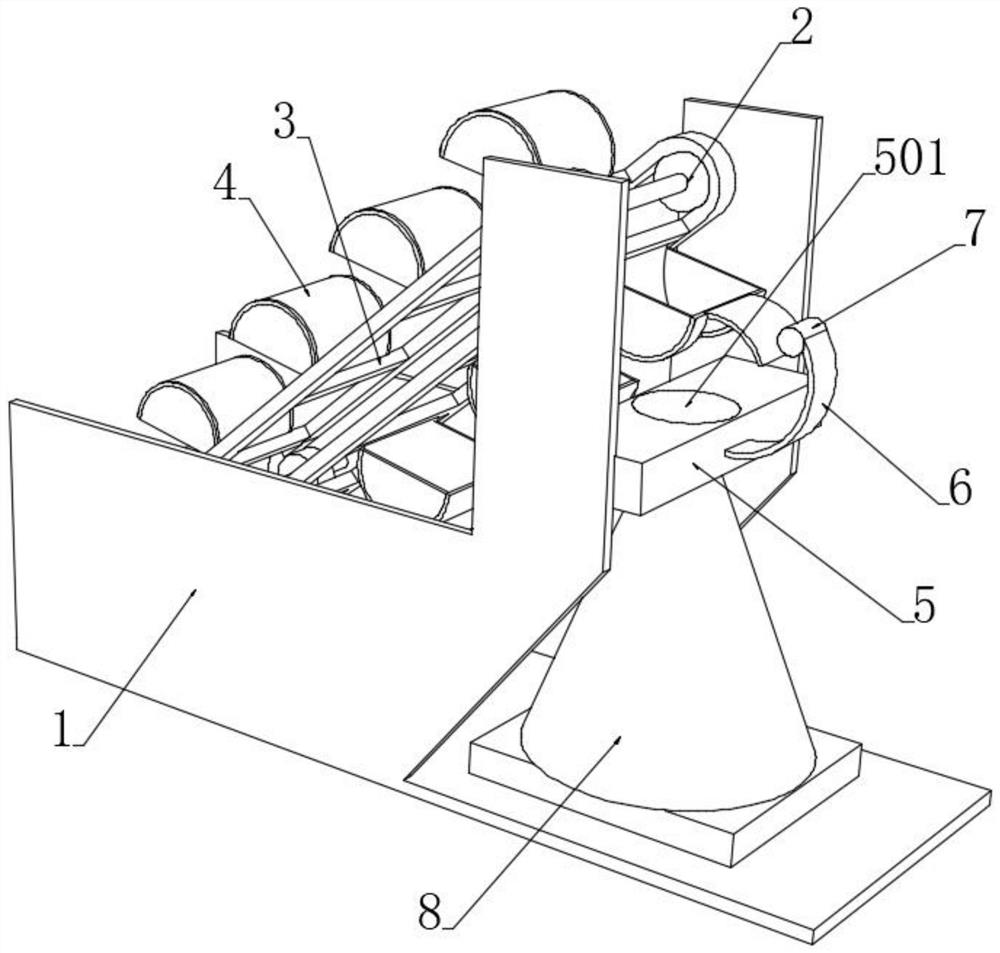

[0039] see Figure 1-4 , a crawler-type automatic loading loader that is convenient for centralized stockpiling in the port area, including a loading platform 1 and a crawler conveyor assembly 2 fixedly installed on the loading platform 1, and the outer end wall of the crawler conveyor assembly 2 is evenly A plurality of connecting beams 3 are distributed and connected, and the outer ends of the multiple connecting beams 3 are fixedly connected with a loading hopper 4. The loading table 1 includes a bottom plate at the bottom and side plates fixedly connected to both sides of the top of the bottom plate. The assembly 2 is installed obliquely upwards between the two side plates. The crawler conveyor assembly 2 includes a pair of rotating rollers rotatably installed on the two side plates. The two pairs of rotating rollers are equipped with crawler chains. The rollers are fixedly connected by a linkage shaft. A driving motor for driving one of the rotating rollers is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com