Patents

Literature

120results about How to "Convenient blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

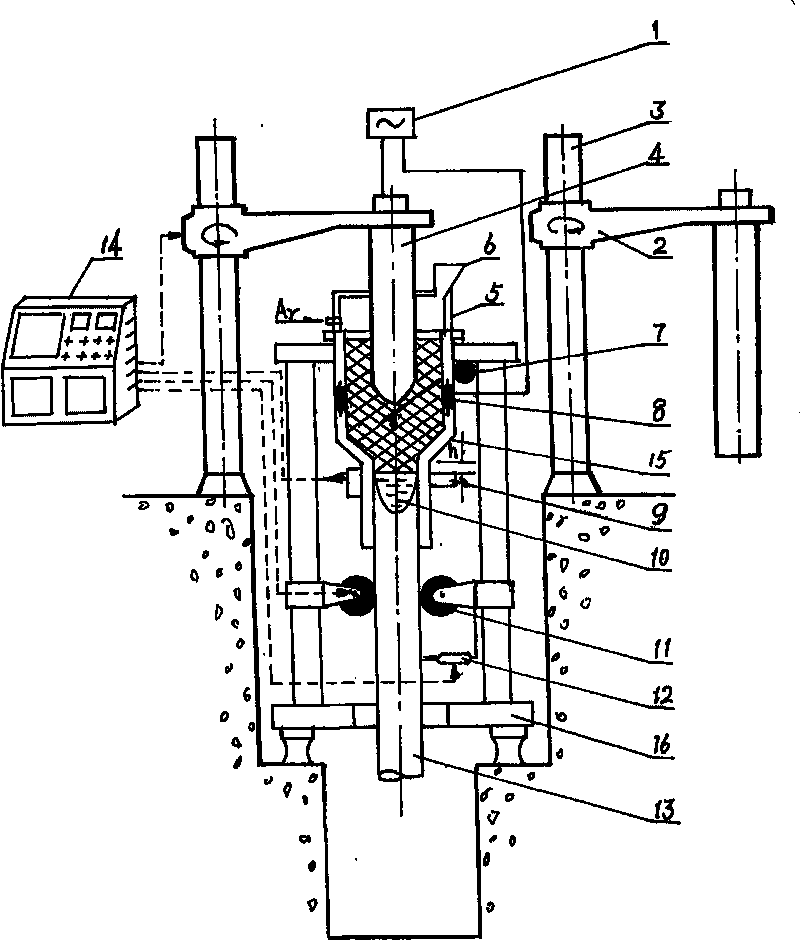

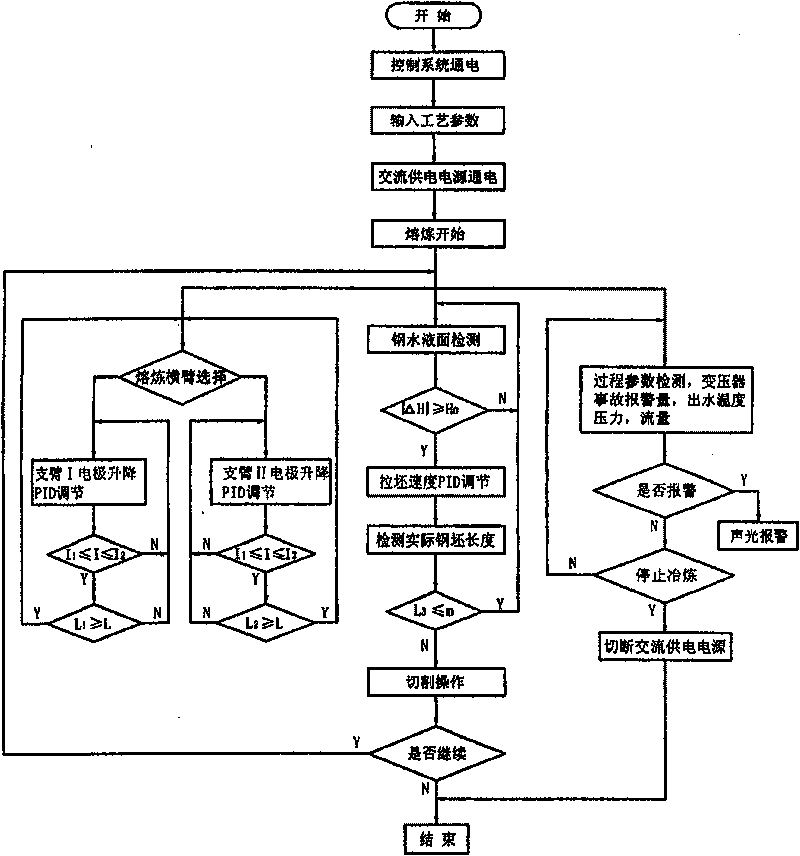

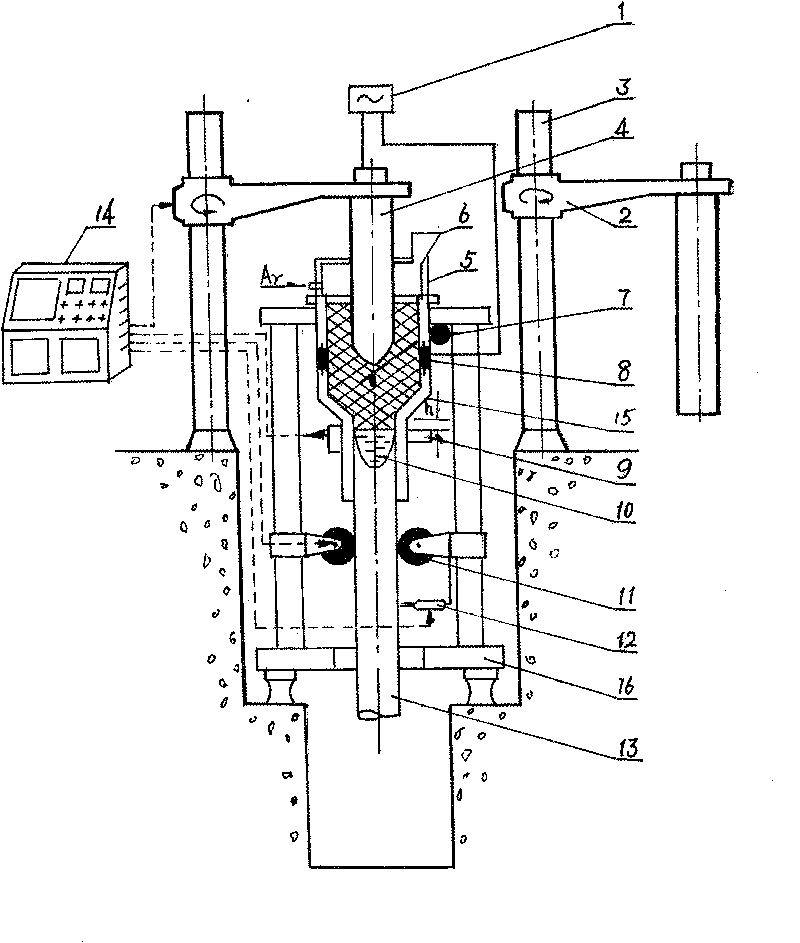

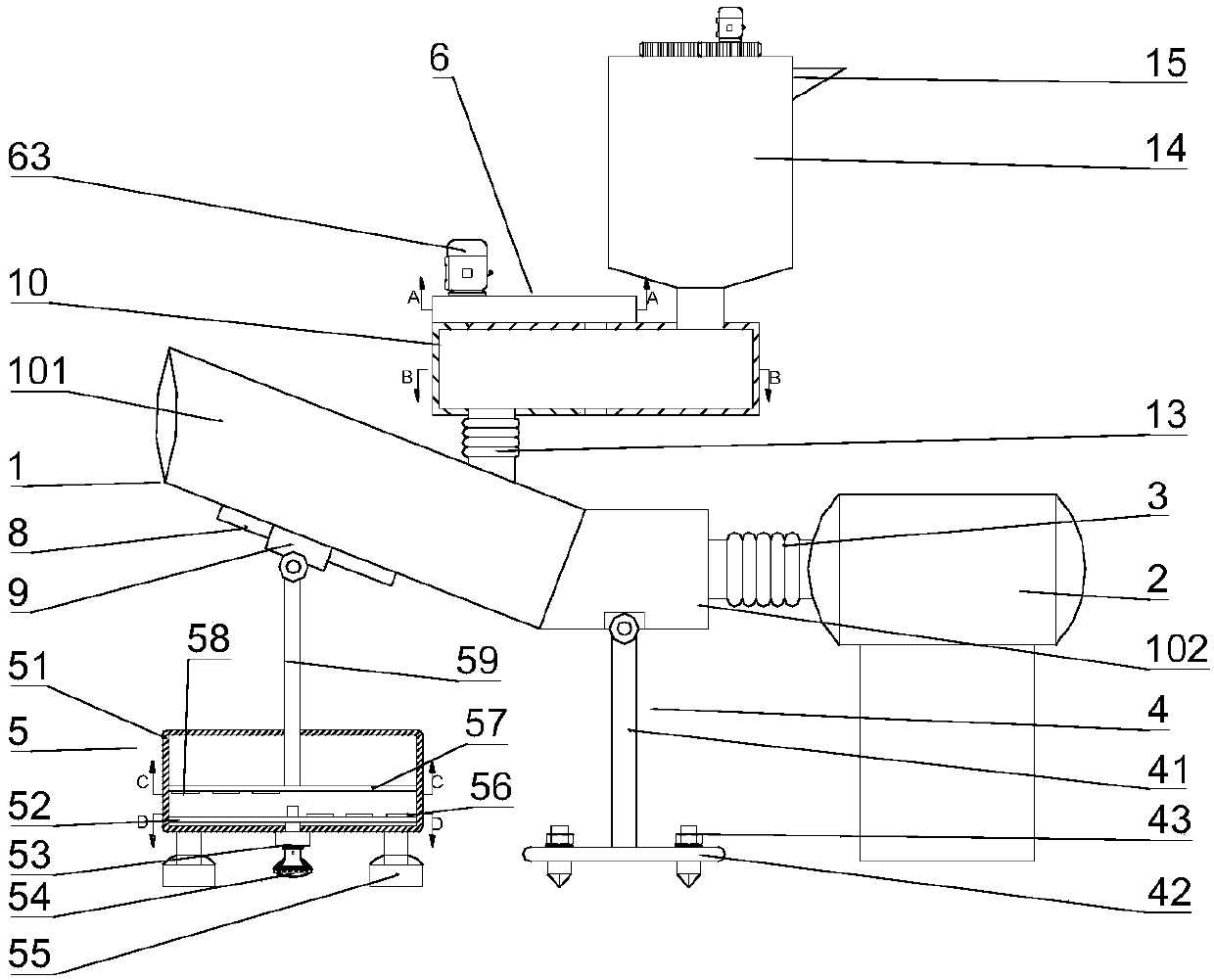

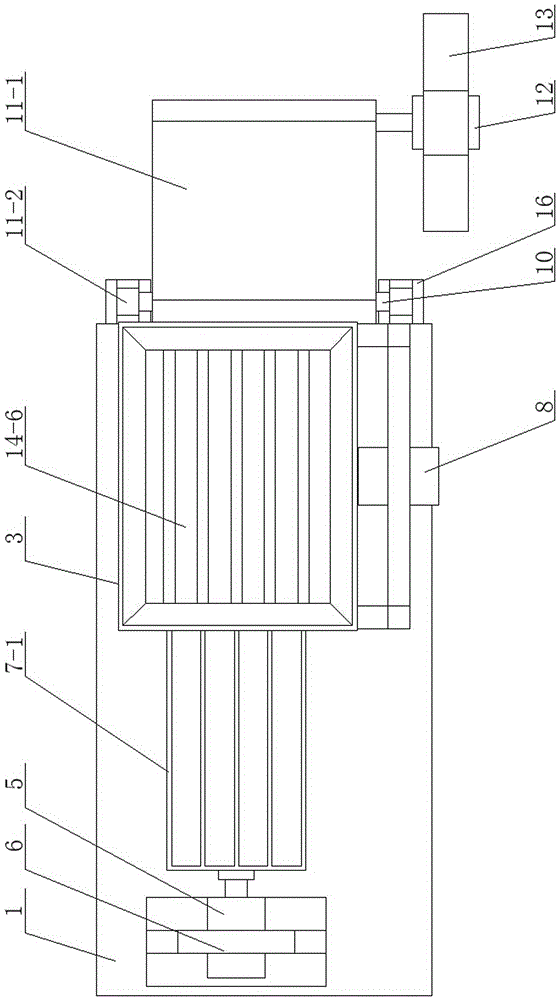

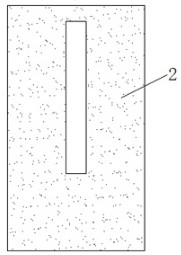

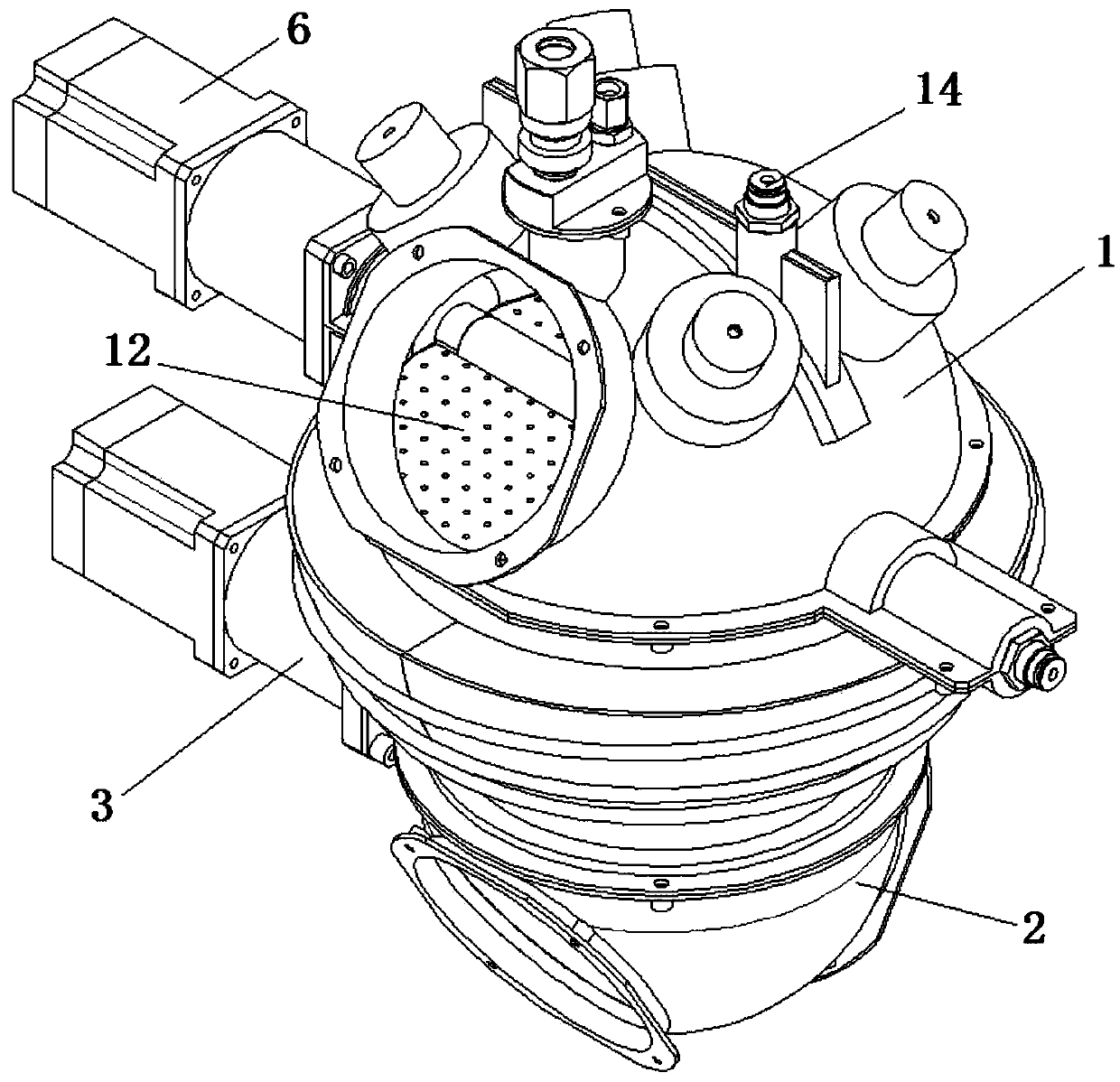

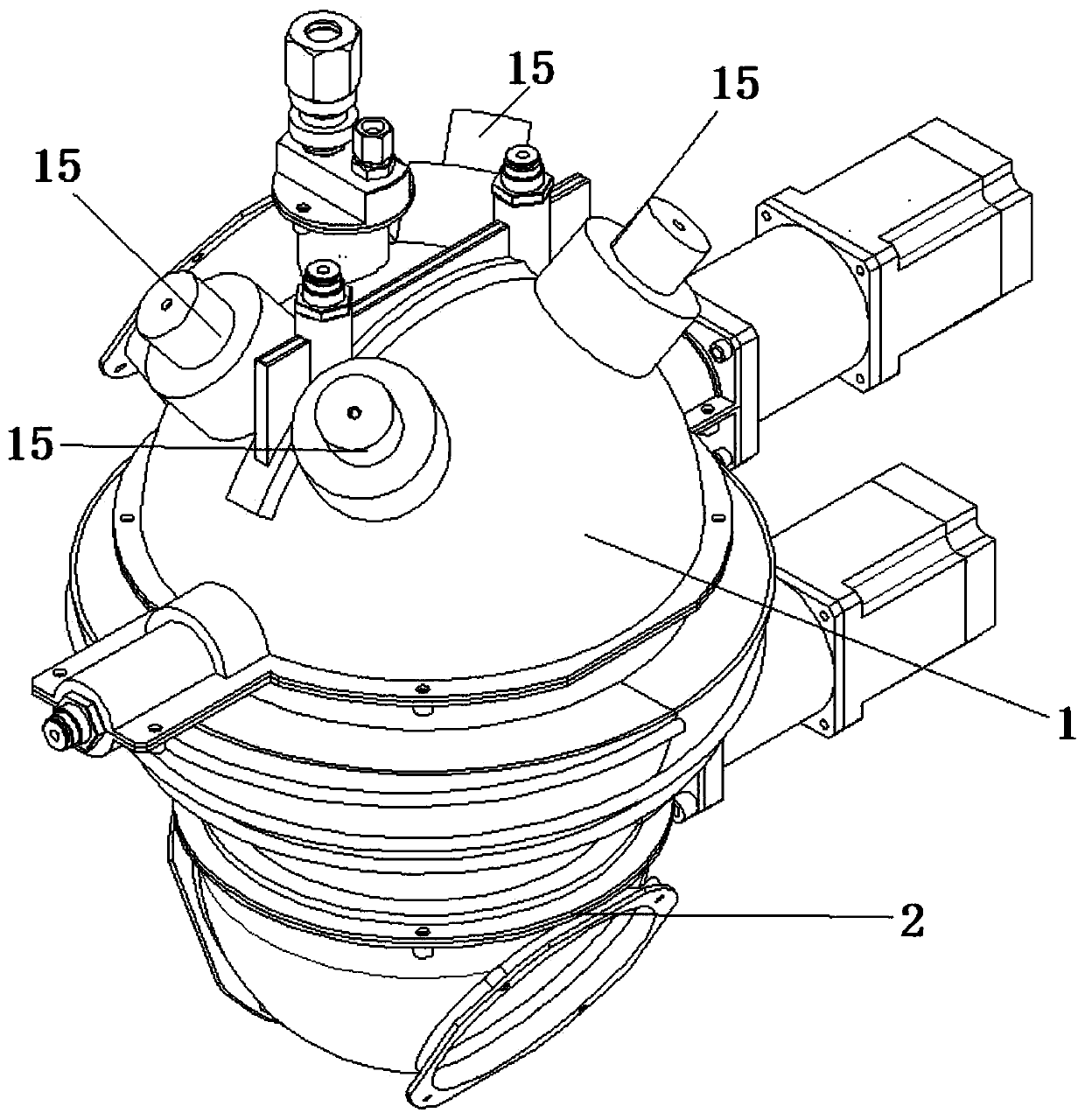

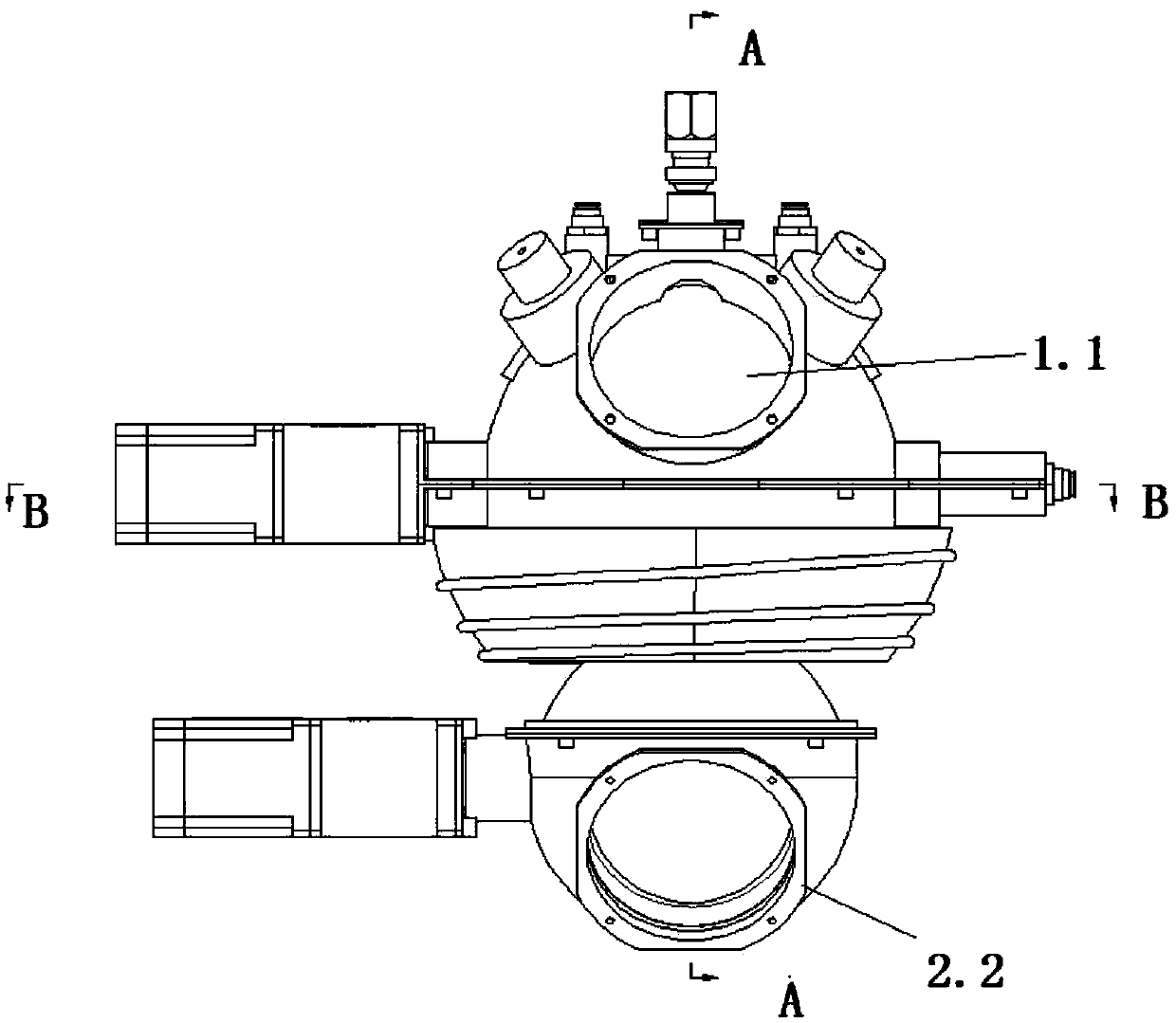

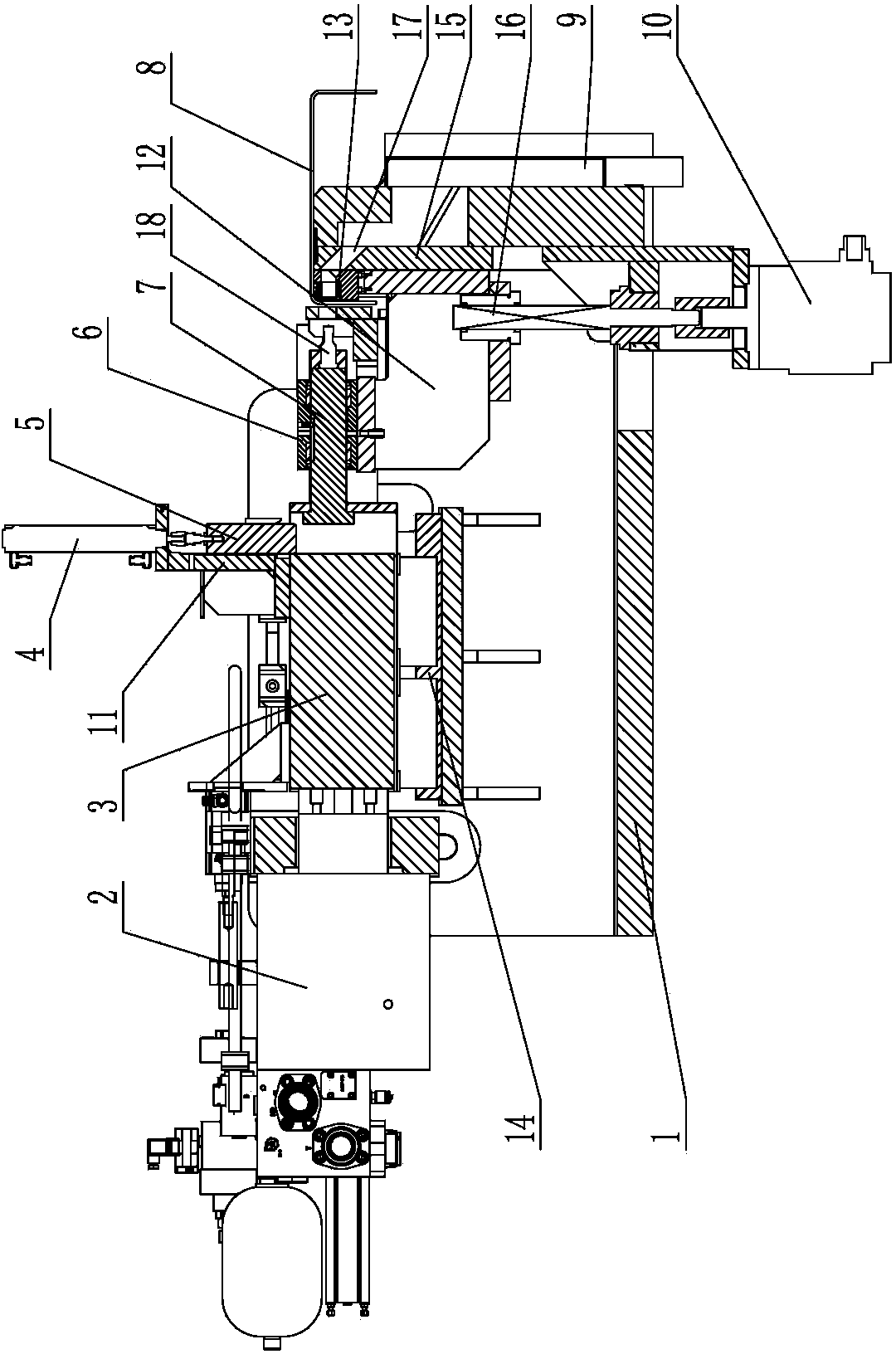

Protective atmosphere electro-slag continuous casting furnace

The invention discloses a protective atmosphere electro-slag continuous casting furnace, which belongs to metal electro-slag re-melting equipment. The furnace comprises an alternating current power supply, electrode lifting mechanisms, a consumable electrode, a conductive crystallizer, a supporting mechanism, a molten steel liquid level detection device, an argon protective cover, a vibration mechanism, a throwing mechanism, a cutting device and a control system. The electrode lifting mechanisms are fixed on two sides of the conductive crystallizer; one end of the consumable electrode is fixed on a cross arm of the electrode lifting mechanism and is connected with the alternating current power supply, while the other end passes through the argon protective cover and is placed inside the conductive crystallizer; the conductive crystallizer is a jacket type water-cooled crystallizer with combined upper and lower parts, a conductive ring is embedded at the upper wall, and the conductive ring is connected with the alternating current power supply through a cable so that a loop is formed from the alternating current power supply, the consumable electrode, furnace slag, the conductive ring to the alternating current power supply; the vibration mechanism is fixed on the supporting mechanism, and a cam of the vibration mechanism is tightly contacted with a shell of the conductive crystallizer; the joint of upper and lower cavities of the conductive crystallizer is provided with the molten steel liquid level detection device; the throwing mechanism and the cutting device are fixed under an ejection port of the conductive crystallizer in turn; and the control system is electrically connected with the cross arm of the electrode lifting mechanism, the molten steel liquid level detection device, the drawing mechanism and the cutting device respectively. The protective atmosphere electro-slag continuous casting furnace can realize electro-slag continuous casting.

Owner:SHENYANG HUASHENG METALLURGICAL TECH & INSTALLATION

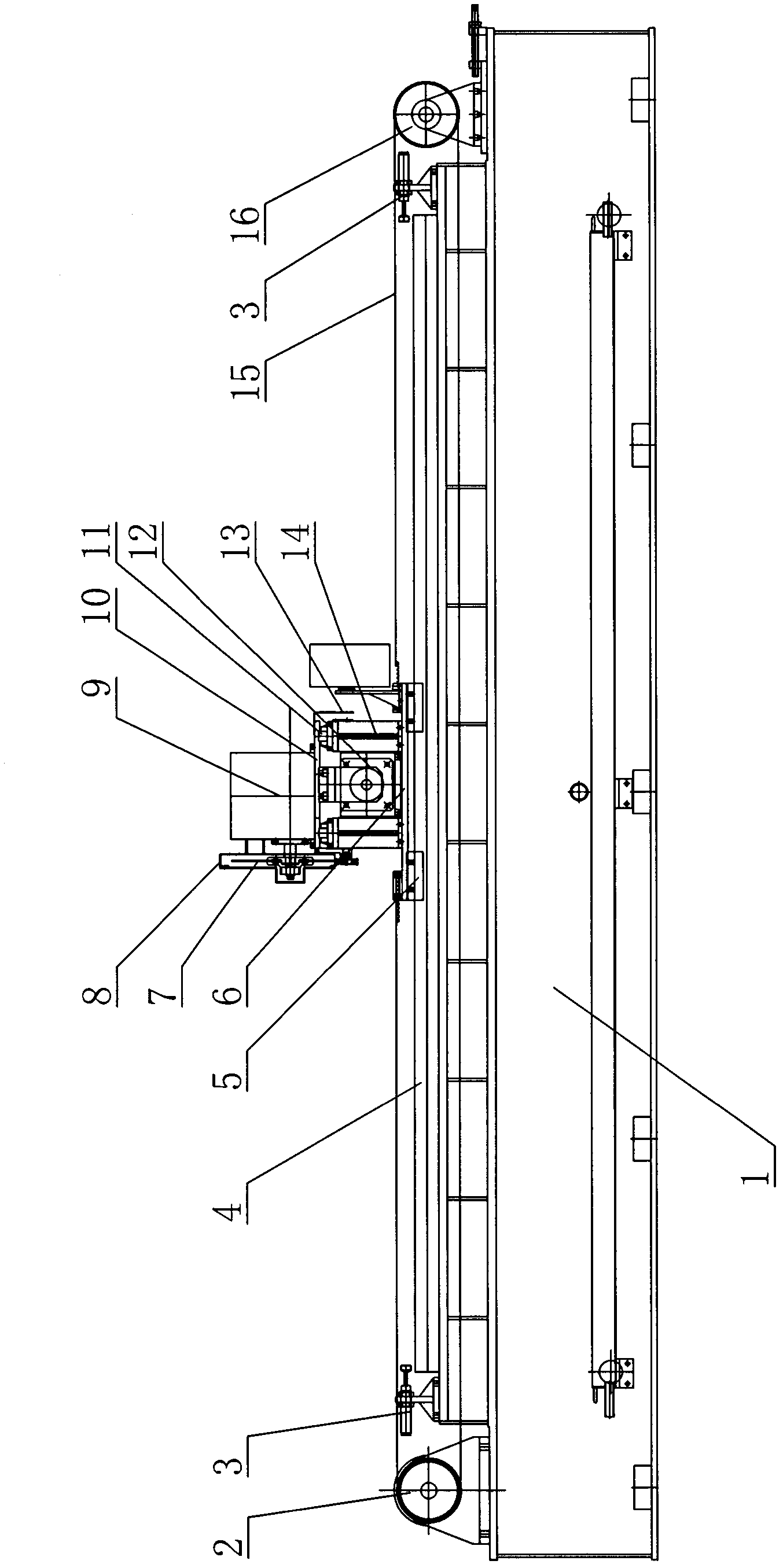

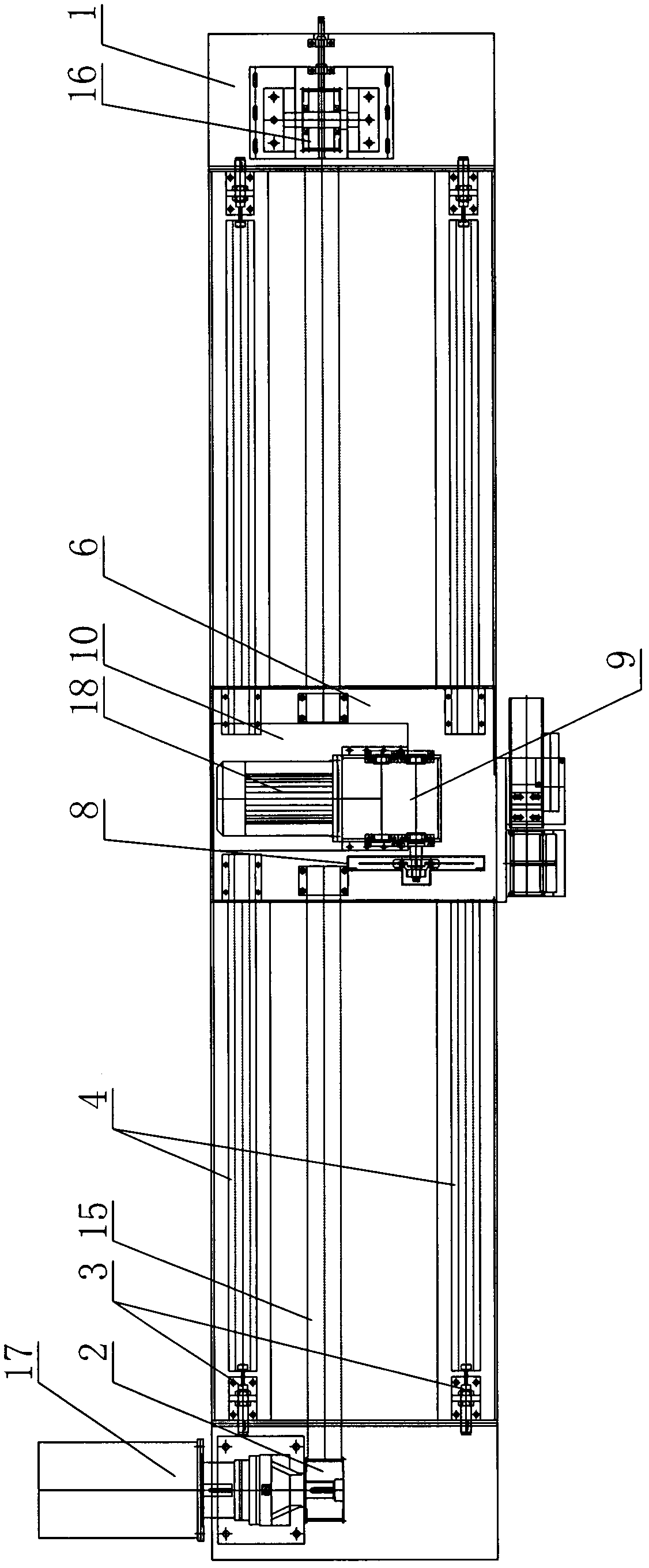

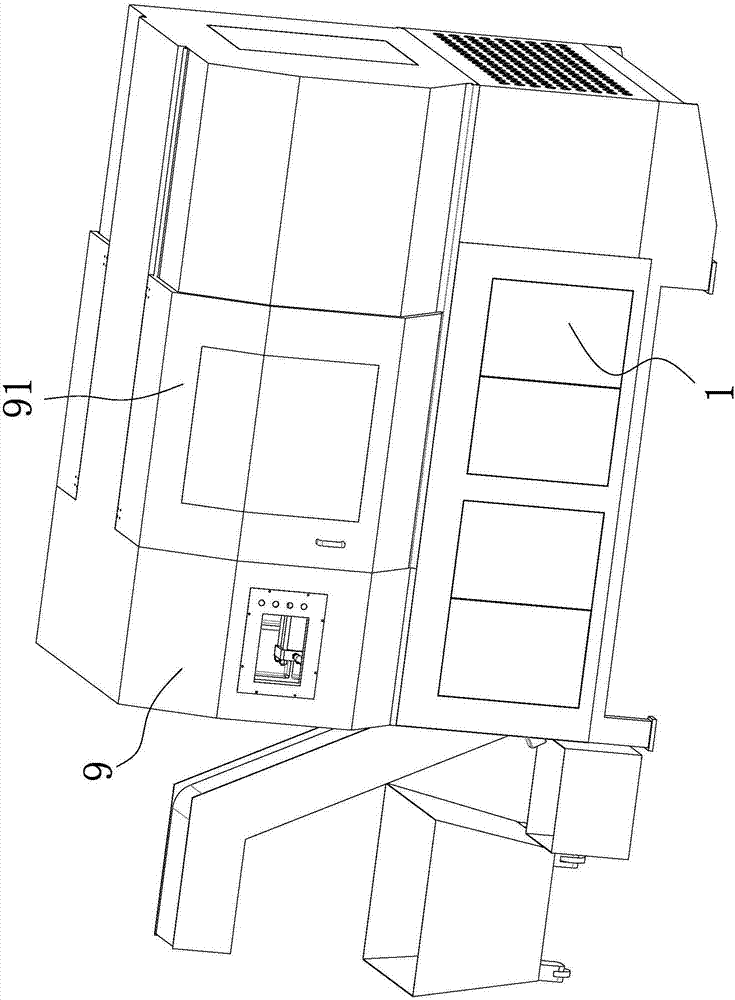

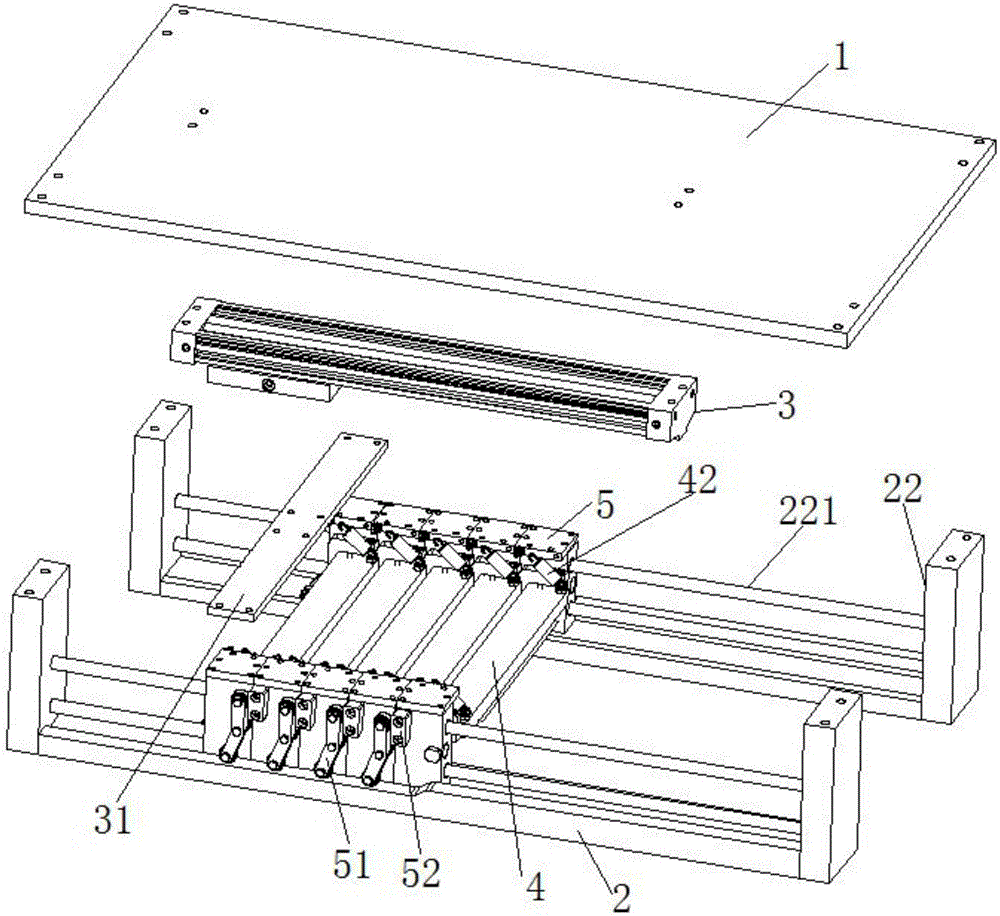

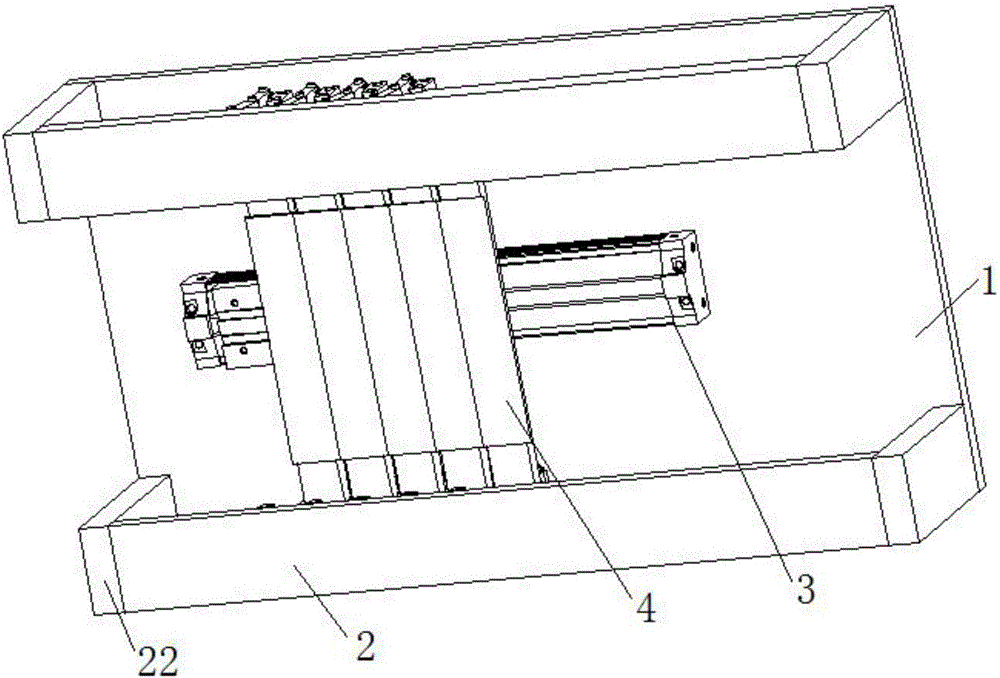

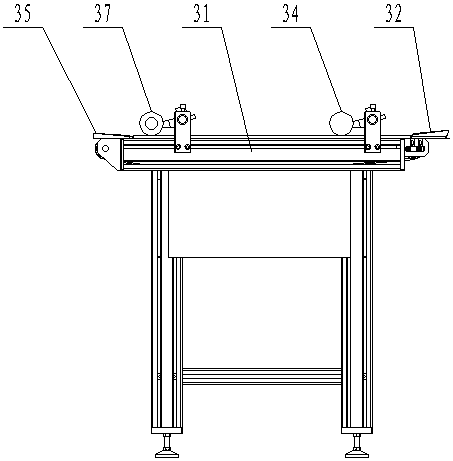

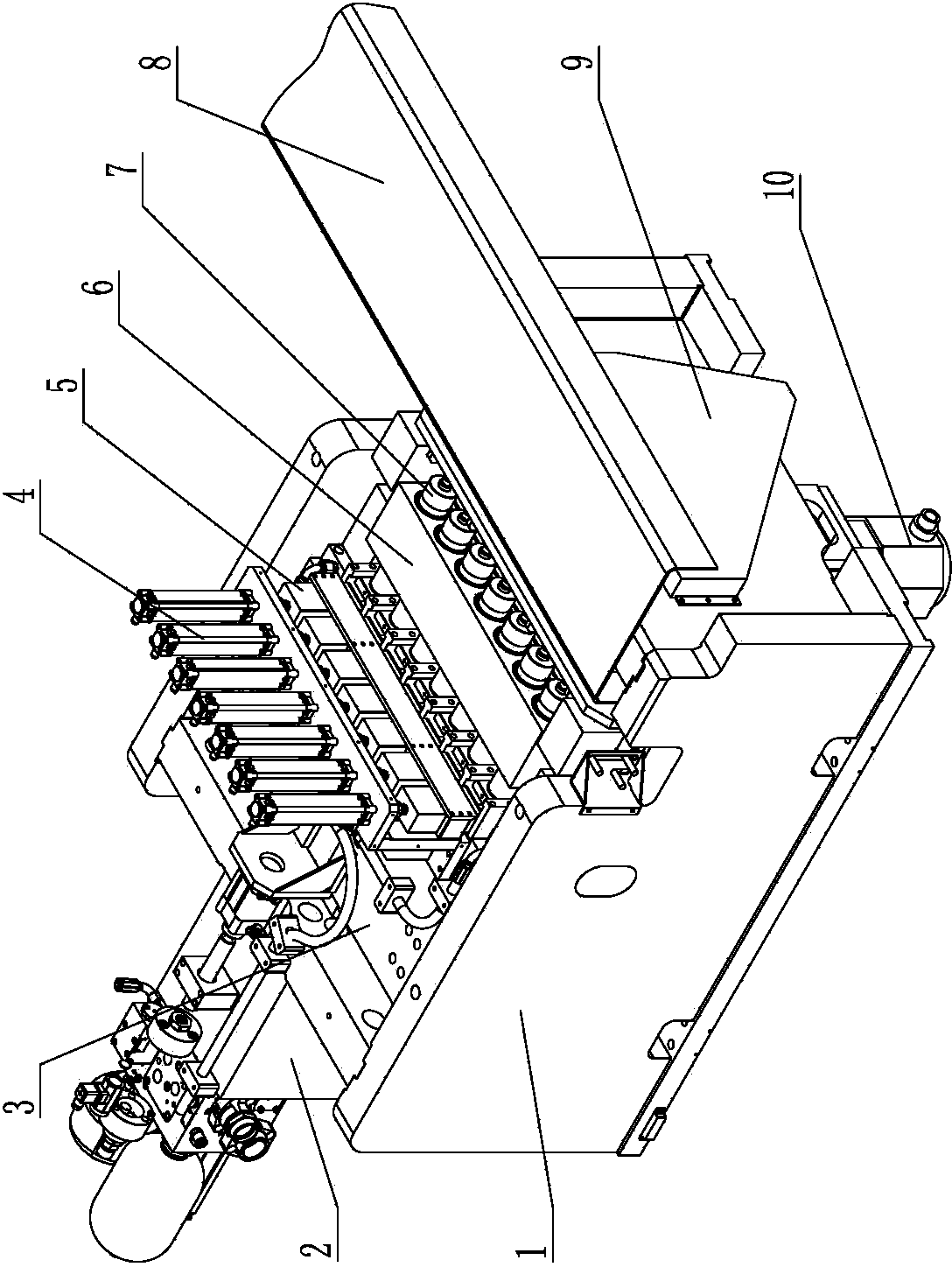

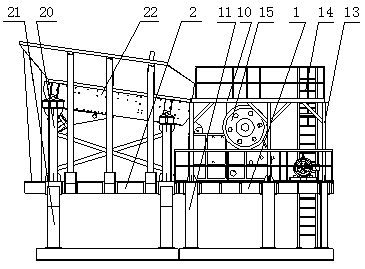

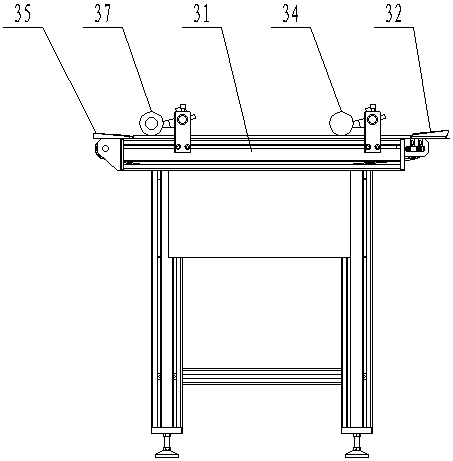

Synchronous cold saw cutting machine

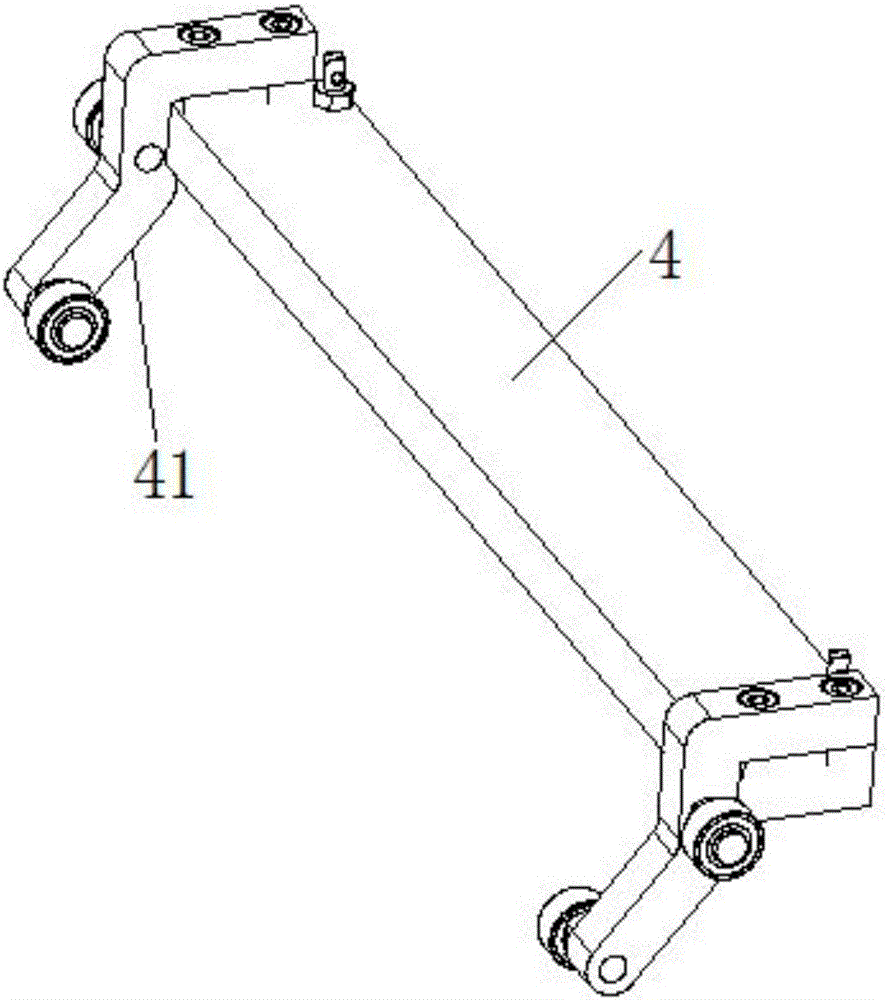

ActiveCN102059486AConvenient blankingAvoid stockpilingMetal sawing devicesMetal sawing accessoriesLinear motionBall screw

The invention relates to a synchronous cold saw cutting machine in the field of welding pipe automatic production equipment. In the synchronous cold saw cutting machine, a saw cutting motor is connected with a milling saw blade through a transmission box; two parallel main guide rails are horizontally arranged on a machine frame; main sliding blocks are arranged on the main guide rails in a matching way and fixedly arranged on the lower side of a main workbench; a driving mechanism for driving the main workbench to do linear motion is arranged on the machine frame and is in synchronous transmission connection with a main servo motor; an upright column is arranged on the main workbench and is connected with a secondary workbench through a secondary guide rail sliding block mechanism; the transmission box is fixedly arranged on the upper side of the secondary workbench; the lower side of the secondary workbench is in transmission connection with a feed motor through a ball screw mechanism; a screw nut of the ball screw mechanism is fixed with the lower side of the secondary workbench; the two ends of a screw rod of the ball screw mechanism are arranged on the upper side of the main workbench through a screw rod base; and a pipe fixture is arranged on the side of the main workbench. The synchronous cold saw cutting machine can cut off a metal pipe during the linear motion of the metal pipe, does not generate burrs on the cut, and can obviously increase the production speed of a welding pipe production line.

Owner:江苏省南扬机械制造有限公司

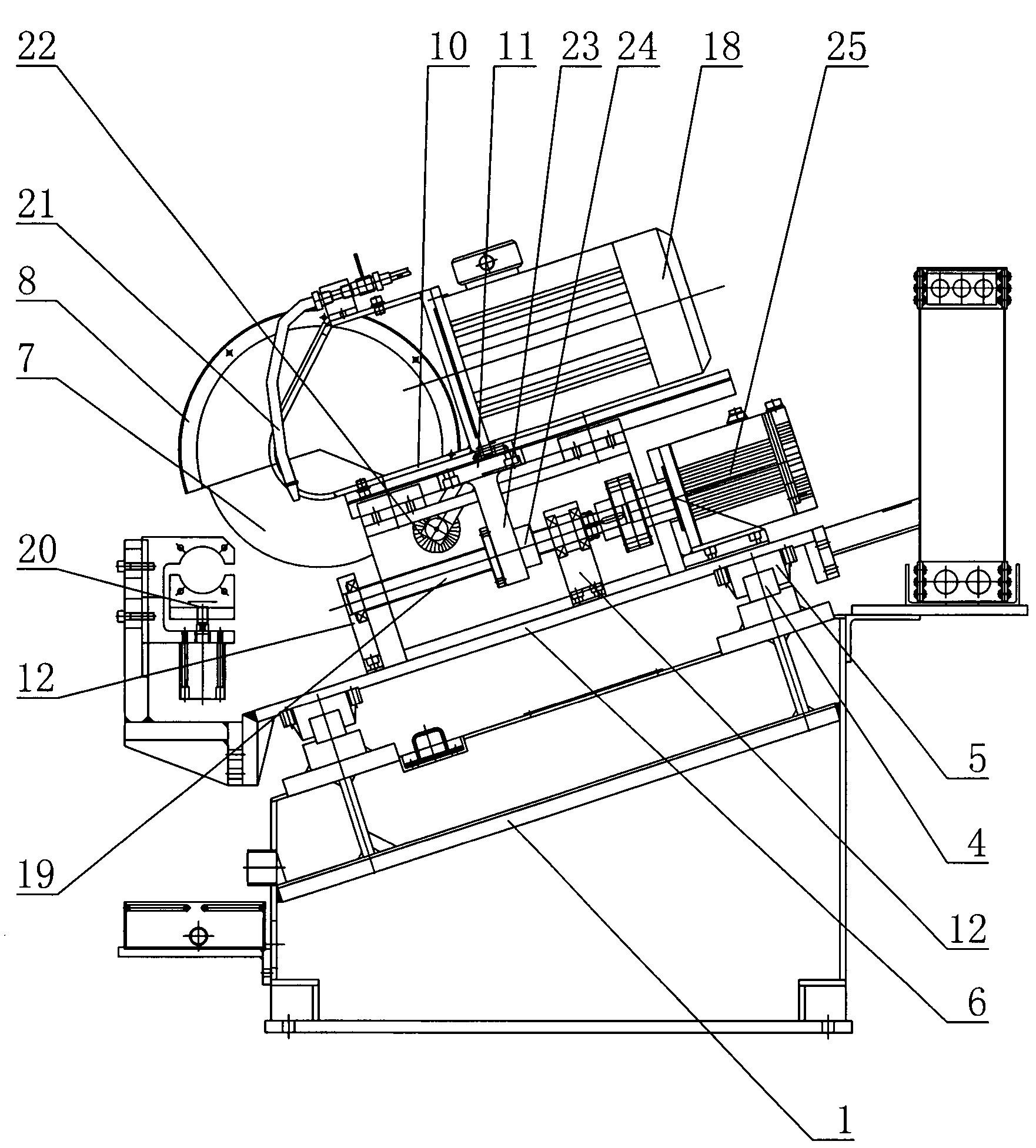

Improved bamboo cutting machine

ActiveCN106042077AAdjust the tilt angleReduce manufacturing costProfiling/shaping machinesReciprocating motionEngineering

The invention relates to an improved bamboo cutting machine. The improved bamboo cutting machine is characterized in that a bamboo placement table is arranged on a base and directly faces a conveying mechanism arranged on one side of the improved bamboo cutting machine; a cutting mechanism is arranged on the base, and comprises a plurality of cutters which perform reciprocating motion up and down; according to the specifications of to-be-machined bamboo, the cutters can be switched over at any time; a plurality of dividing strips are arranged on the placement table in a spaced manner; the placement table is divided by the dividing strips into a plurality of conveying tracks; a material guiding mechanism is arranged at the discharging port of the placement table; a plurality of loading and transporting tables are arranged at the outlet of the material guiding mechanism; the material guiding mechanism comprises a horizontal conveyor belt and a group of transmission rolls; a weighing sensor is arranged in the group of transmission rolls and connected with a controller; a motor of the group of transmission rolls is also connected with the controller; when a set value of the weighing sensor is reached, the motor is controlled by the controller to start up the group of transmission rolls, and then the transmission operation is initiated; a lifting table is arranged at the lower part of the material guiding mechanism and comprises a plurality of lifting columns; and the height of each lifting column can be adjusted independently. The improved bamboo cutting machine provided by the invention is equipped with the lifting platform, so that the inclination angle of the material guiding mechanism can be adjusted, the discharging can be facilitated, and products can be protected from damage.

Owner:安吉天友机械科技有限公司

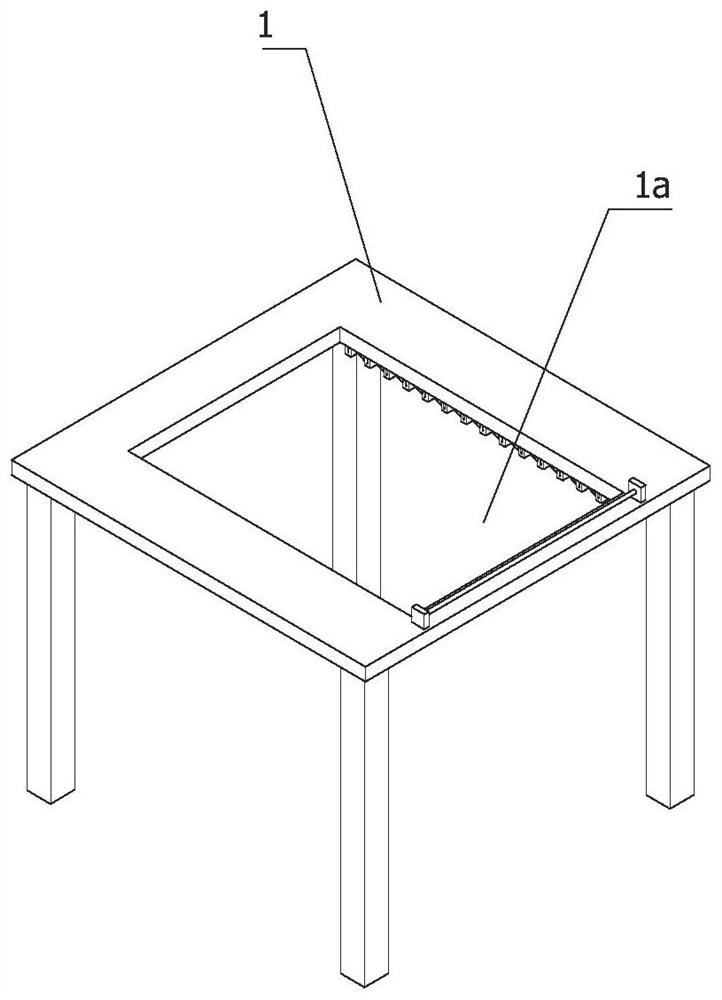

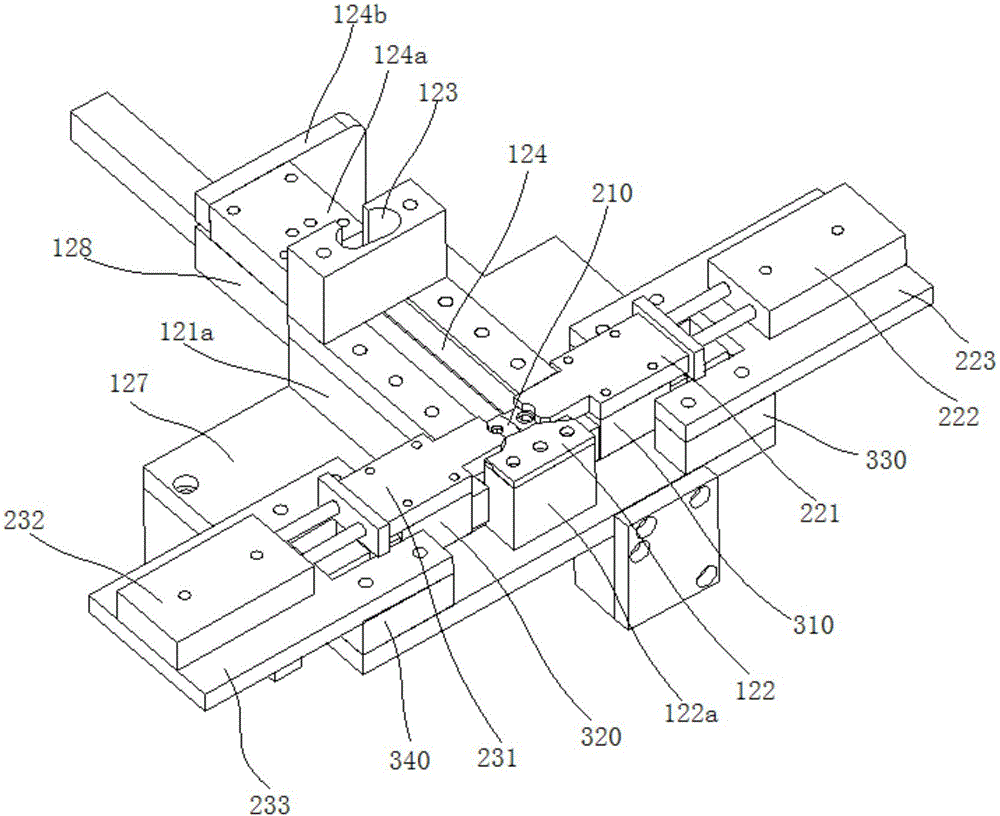

Flat bed type automatic forming device for machining winding shaft sleeve

InactiveCN107322308AConvenient blankingEasy to cleanOther manufacturing equipments/toolsLarge fixed membersEngineeringConductor Coil

The invention relates to a flat-bed type automatic forming equipment for processing rolled shaft sleeves. It solves the technical problems such as the unreasonable design of the prior art. The flat-bed type automatic forming equipment for processing rolled bushings includes a bed, a plane is arranged on the top of the bed, and a feeding mechanism, a bending and rounding mechanism, a shaping mechanism and a double bed are arranged on the plane in sequence. A head chamfering mechanism, the double-head chamfering mechanism includes a base fixed on a plane, and two cantilever sliding seats that can move in the horizontal direction are arranged on the rear surface of the base, and each cantilever sliding seat is respectively connected with the horizontal driving device Connected, a chamfering cutter head is provided at the opposite ends of the two cantilever sliding seats, and a waste chute located under the cantilever sliding seats and a waste conveying mechanism arranged in the waste chute are also provided on the bed, and the waste conveying mechanism Able to transport cutting waste from the waste chute to the outside of the waste chute. The advantages of the present invention lie in that the waste cleaning efficiency can be improved.

Owner:浙江飞宇自动化科技股份有限公司

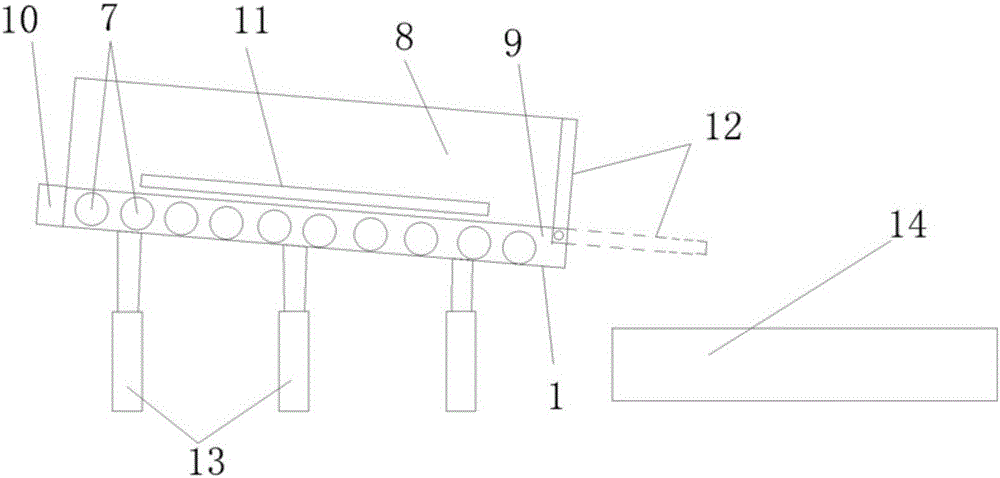

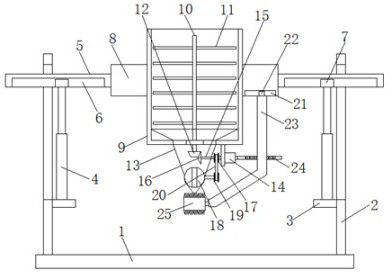

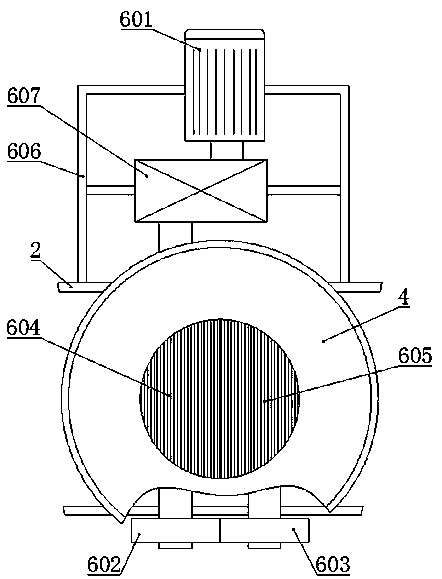

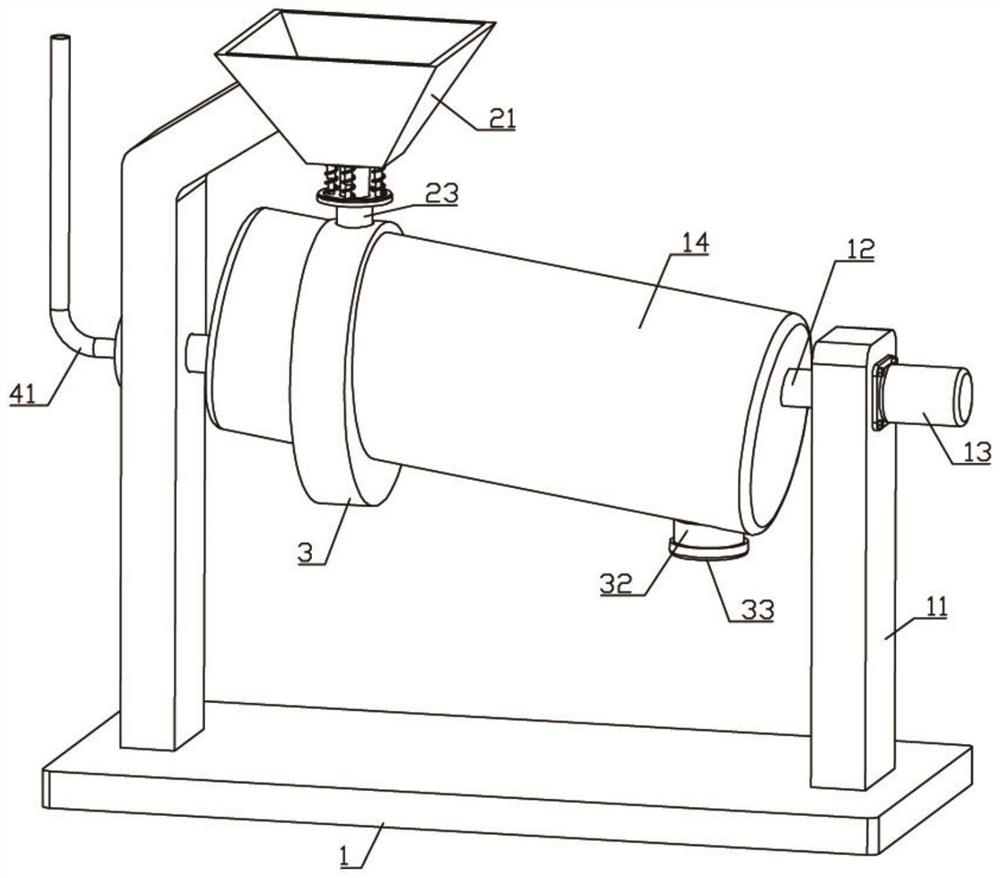

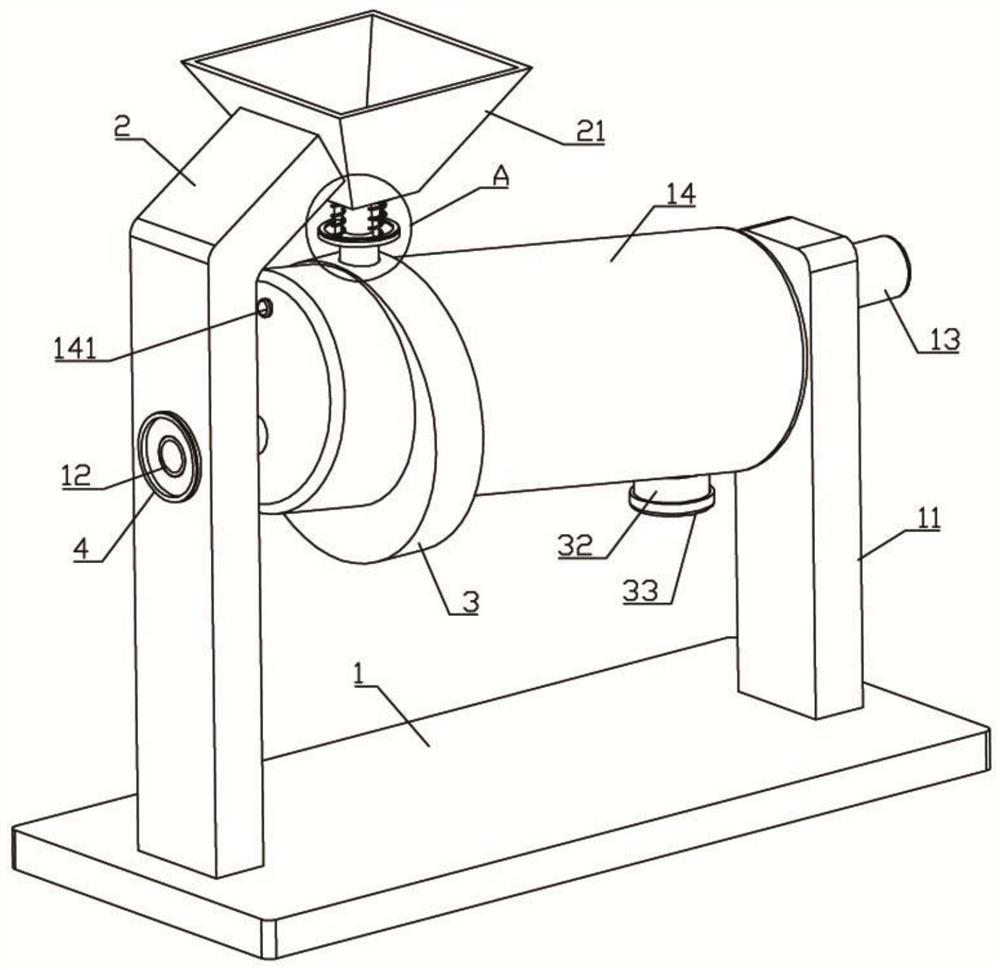

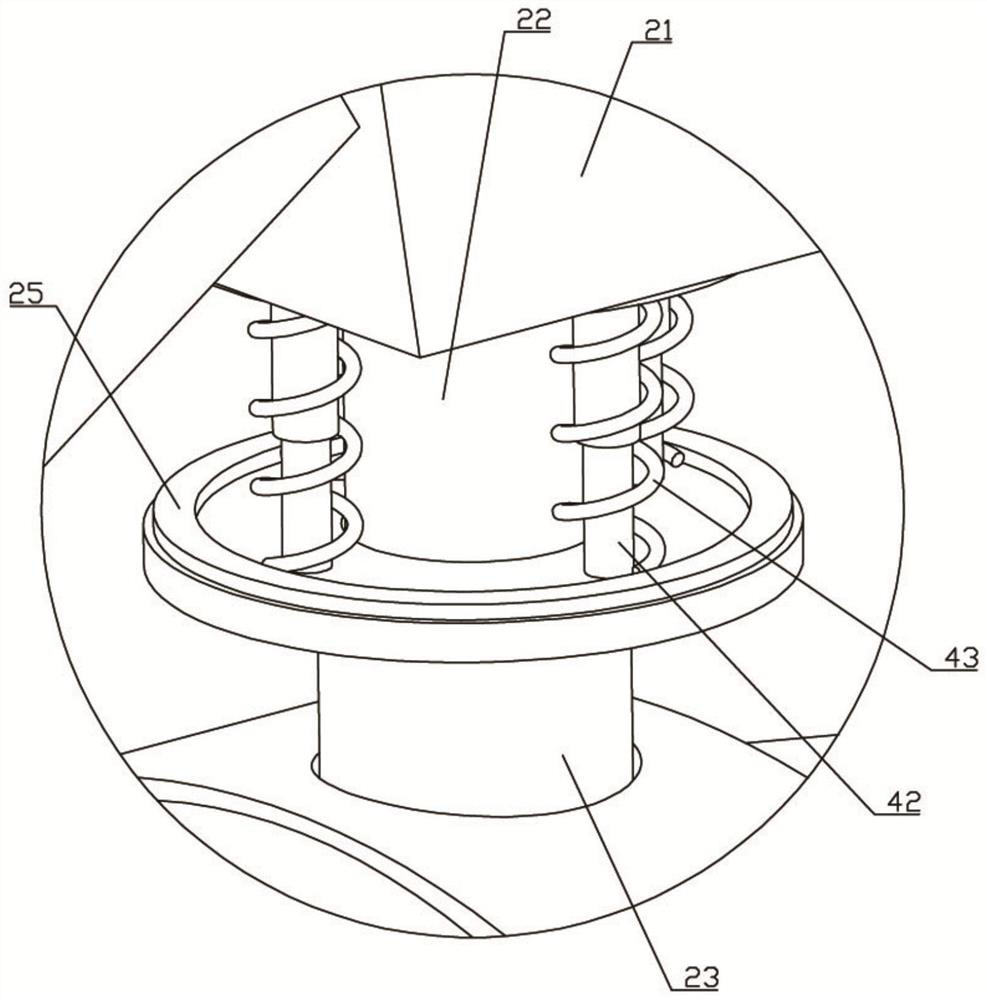

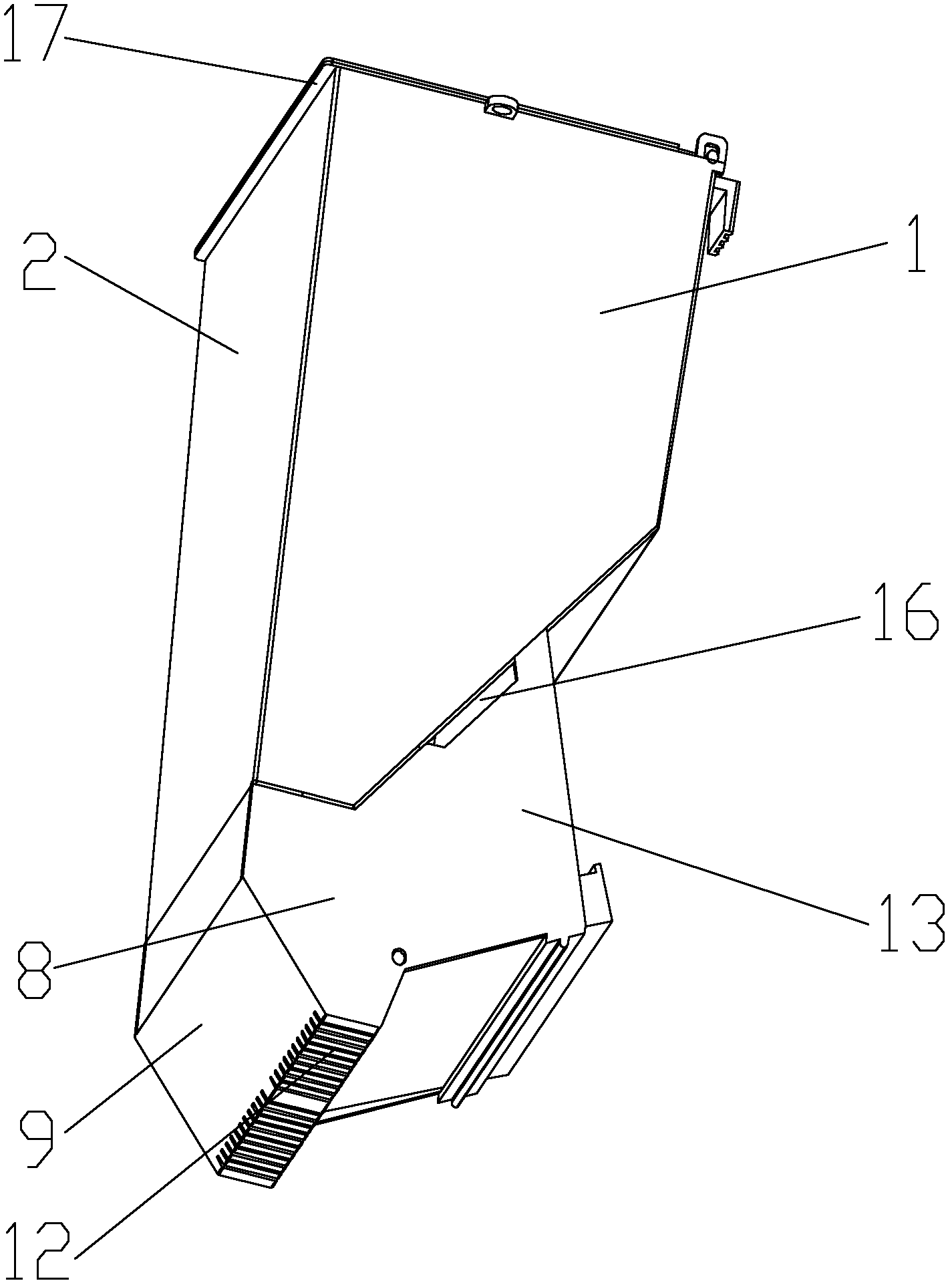

Fish feed throwing equipment for saline-alkali soil fish pond

InactiveCN107897085AEasy to adjust the tilt angleConvenient blankingClimate change adaptationPisciculture and aquariaAlkali soilSpiral blade

The invention discloses fish feed throwing equipment for a saline-alkali soil fish pond. The fish feed throwing equipment comprises an air blower and a throwing cylinder, wherein the throwing cylinderis composed of a tail pipe and a head pipe which are communicated with each other; the tail pipe is transversely arranged; the spiral directions of a first spiral blade and a second spiral blade areopposite, so that raw materials located in a feeding tank form circulation flow, feeding is facilitated, and the situation that a discharge port is blocked is avoided; feed is thrown into the fish pond through the action of the air blower, and the amount of the feed falling into the head pipe can be conveniently controlled by controlling the number of intermittent rotation of a rotating wheel; a supporting plate can be stably fixed to the ground through foundation bolts, so that the position of the throwing cylinder is fixed, and shaking is not likely to occur; a rotating handle is rotated bymanpower, when the overlapping number of first magnets and second magnets is different, lifting positions of a moving plate are different, and the inclination angles of the head pipe are also different so that the inclination angles of the head pipe can be conveniently adjusted, and throwing is facilitated.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

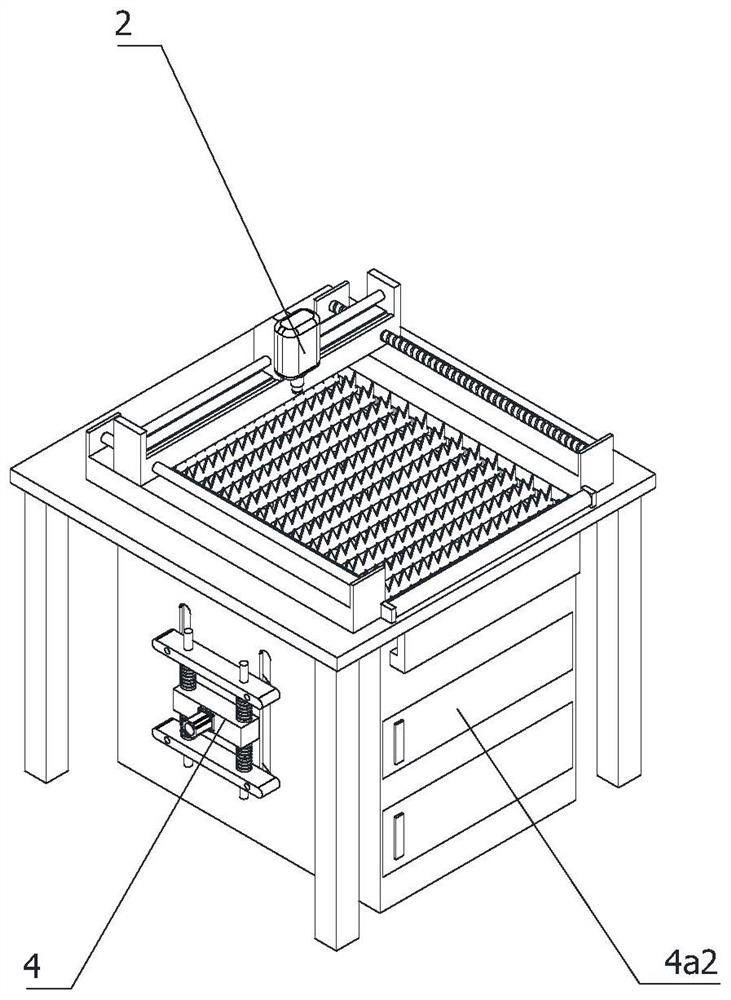

Full-automatic cell separation device based on cell machining

ActiveCN106653938ASimple structureEasy to useFinal product manufactureSemiconductor devicesEngineeringHeight difference

The invention relates to a full-automatic cell separation device based on cell machining. Two linear guide rails are arranged in parallel; a plurality of cell separation sucking discs are distributed in parallel between the two linear guide rails, two ends of each cell separation sucking disc are respectively installed on the linear guide rails in a sliding manner via sliding blocks connected with the cell separation sucking disc, the two adjacent sliding blocks are connected with each other, and rebound components are arranged between the two ends of each cell separation sucking disc and the corresponding sliding blocks; sliding pieces are arranged at two ends of the cell separation sucking discs, each linear guide rail is provided with a first guide rail surface corresponding to the sliding pieces, the first guide rail surface is formed by two first sub guide rail surfaces arranged continuously and having a horizontal height difference, and the lower ends of the sliding pieces can move along the corresponding first guide rail surfaces; the driving end of a linear driving device drives the corresponding cell separation sucking discs to move from the front end of the rail travel to the rear end, and the cell separation sucking discs passing through the joint of the first sub guide rail surfaces rotate to separate cells in sequence in the moving process. The device has the advantages that cells can be automatically separated during moving, and the efficiency is high.

Owner:WUHAN DR LASER TECH CORP LTD

Injection mould with pushing needle for pushing out

The invention discloses an injection mould with a pushing needle for pushing out. The injection mould includes a bottom plate, a back mould plate and a surface plate. The surface plate is provided with a front mould plate. The front mould plate and the back mould plate are movably connected to each other through a guide column. A back mould insert is arranged in the back mould plate and a front mould insert is arranged in the front mould plate. A flow pass is disposed between the front mould insert and the back mould insert. The bottom plate is provided with a pushing needle bottom plate. The pushing needle bottom plate is provided with the pushing needle, a first water opening pushing needle, a second water opening pushing needle and a third water opening pushing needle, wherein heads of the pushing needle, the first water opening pushing needle, the second water opening pushing needle and the third water opening pushing needle are disposed in the flow pass. The head of the second water opening pushing needle is fan-shaped and the heads of the first water opening pushing needle and the third water opening pushing needle are ball-shaped. The injection mould is simple in structure and is convenient to use. A material is convenient to push out. The injection mould is large in material-pushing strength and a plastic workpiece can be pushed out more conveniently during a demoulding process.

Owner:上海伟阳纸业有限公司

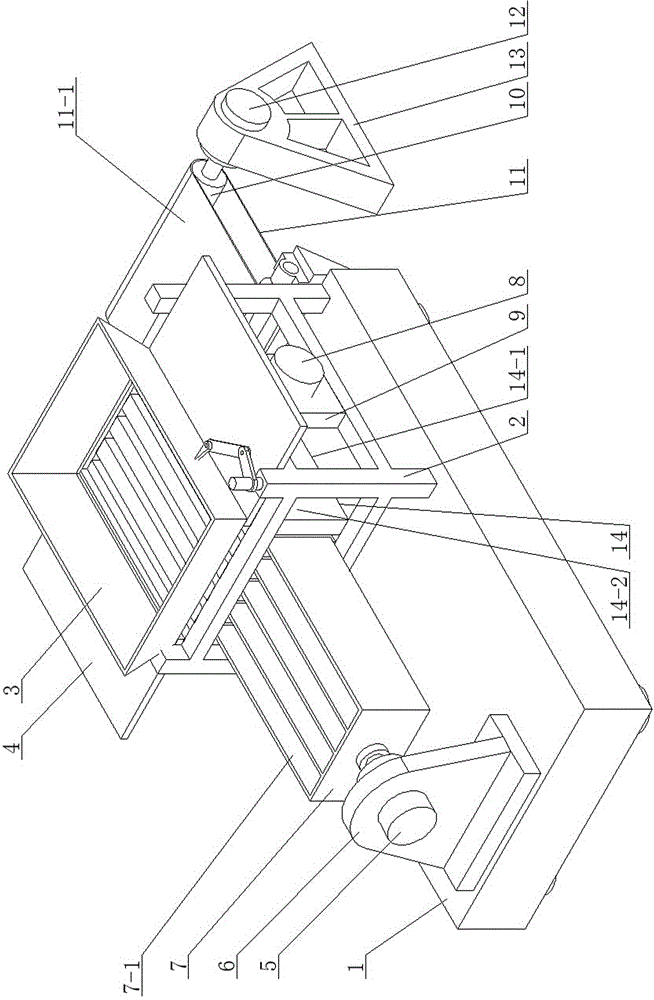

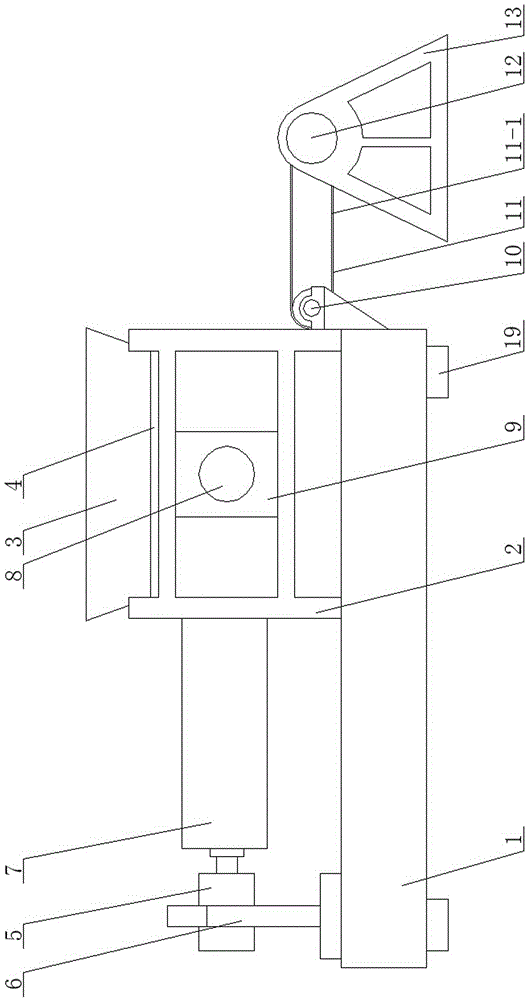

Precision-shaping straw extruder and extruding production method of seedling substrate straw board

InactiveCN105666932AImprove structural stabilityEasy loadingShaping pressHydraulic cylinderAgricultural engineering

A precision-shaping straw extruder and an extruding production method of a seedling substrate straw board belong to the technical field of agricultural machinery. Straw is used as raw materials to realize extrusion shaping of a seedling substrate straw board. A cylinder rod of a cylinder is fixedly connected with a push-out rod. A seal baffle is arranged at the abutting joint of a feeding hole of a housing and a discharge hole of a feeding hopper. Two first guide rails are fixed at a bottom end within the housing, and bottom ends of a pressing plate and a plurality of mold plates are connected in a sliding manner with the first guide rails by means of first sliders. Springs are fixed on front side surfaces of the mold plates and a front side surface of a rear sidewall of the housing. A piston rod of a hydraulic cylinder is arranged corresponding to a through hole in a front sidewall of the housing. Left and right sidewalls of the housing both are movable sidewalls. A plurality of push-out teeth of the push-out rod are arranged in a one-to-one corresponding relation with a plurality of mold cavities. Bearings are mounted at two ends of a rotating shaft, and fixedly connected with a base and a support frame by means of bearing blocks. An output shaft of a motor is in transmission connection with the rotating shaft by means of a belt transmission mechanism. Heating devices are fixed on the mold plates. The precision-shaping straw extruder and the extruding production method of the seedling substrate straw board are used for producing the seedling substrate straw board from straw in the extrusion shaping way.

Owner:孙涛

Chinese medicinal material slicing device

The invention relates to a Chinese medicinal material slicing device which comprises a transverse pushing path and is characterized in that a driving push plate is arranged at one end of the path and grating blades are arranged at the other end of the path; upper ends and lower ends of the grating blades are respectively articulated with a machine body through hinge pin shafts; and torsional springs which are sleeved on the hinge pin shafts to reset the blades are arranged on the machine body. By the addition of the offset torsional springs on the blades, the Chinese medicinal material slicing device can prolong the service life of the cutting blades and effectively solve the problem of difficulty of material falling and side bending of the blades as slices of Chinese medicinal materials and melon and fruit are clamped between two blades in the cutting process. Moreover, the device has the advantages of simple structure, convenience for operation, safety and sanitation in production as well as wide practical significance and market value.

Owner:福建康源中药材种植有限公司

Gluing device for kraft box paperboard production

InactiveCN111992415ASolve manual glue brushingPrevent solidificationLiquid surface applicatorsRotary stirring mixersPaperboardAdhesive glue

The invention discloses a gluing device for kraft box paperboard production, and relates to the technical field of kraft box paperboard production. The gluing device aims at solving the problems thatmanual glue brushing is low in efficiency and cannot ensure the uniformity of glue brushing during existing paperboard gluing, and the viscosity of glue is influenced due to the fact that the bottom of the glue is easy to solidify after standing for a long time. According to the gluing device disclosed by the scheme, the gluing device comprises a bottom plate, supporting plates are fixedly connected to the two sides of the top of the bottom plate, lifting mechanisms are arranged on the sides, close to each other, of the two supporting plates, a glue box is arranged on the sides, close to eachother, of the two lifting mechanisms, a stirring mechanism is rotationally connected to the interior of the glue box, an intermittent discharging mechanism is fixedly connected to the bottom of the glue box, and a movable wiping mechanism is arranged below the intermittent discharging mechanism. According to the gluing device, the position of a brush roller can be conveniently adjusted, moreover,uniform blanking on the surface of the brush roller is facilitated, uniform smearing of the glue is facilitated, moreover, the glue can be synchronously stirred, and the glue is prevented from being solidified.

Owner:濉溪县国光纸业有限责任公司

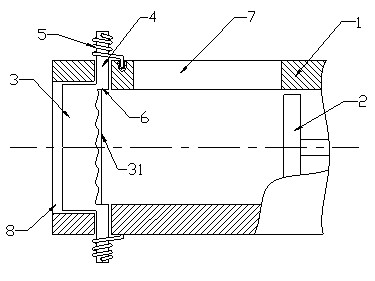

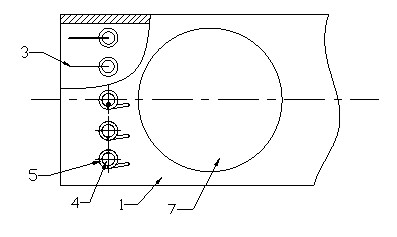

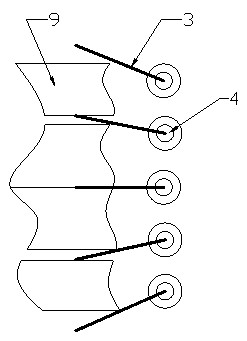

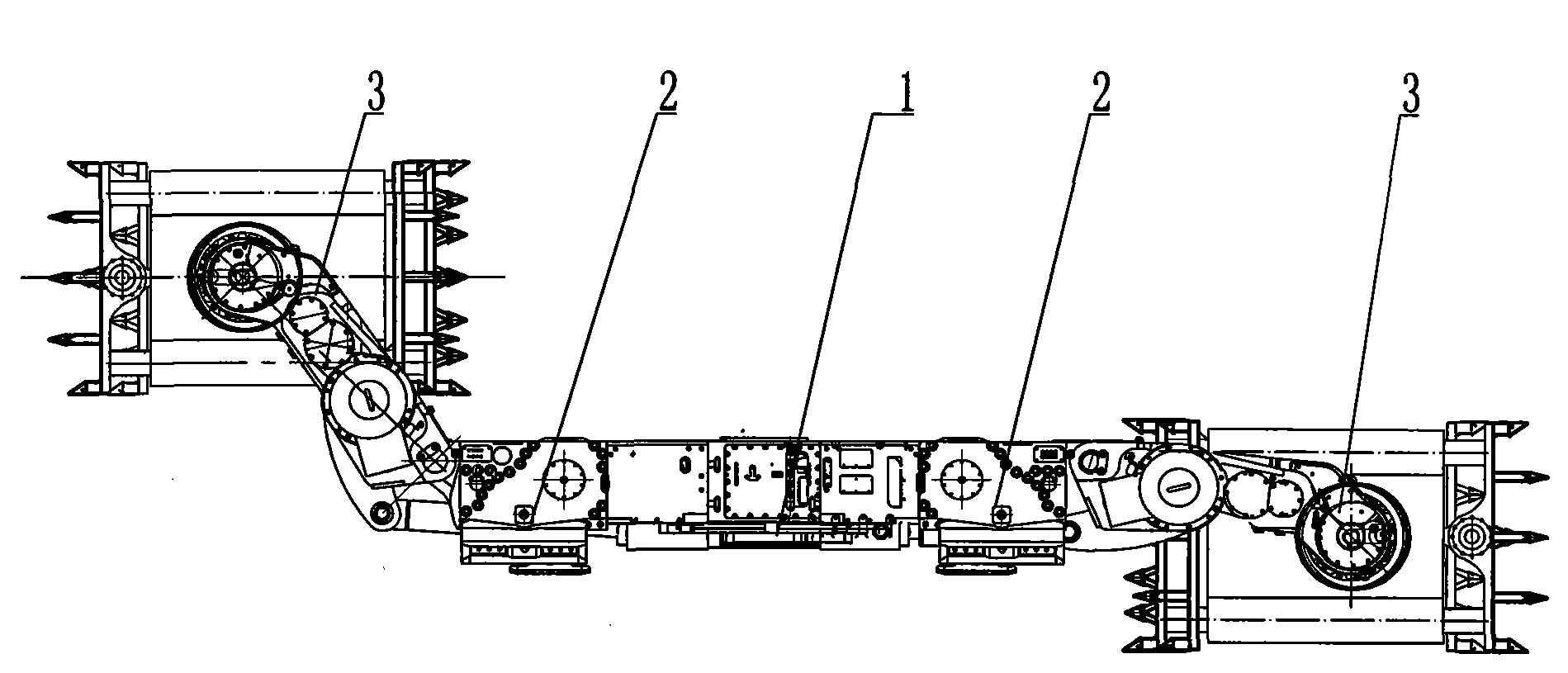

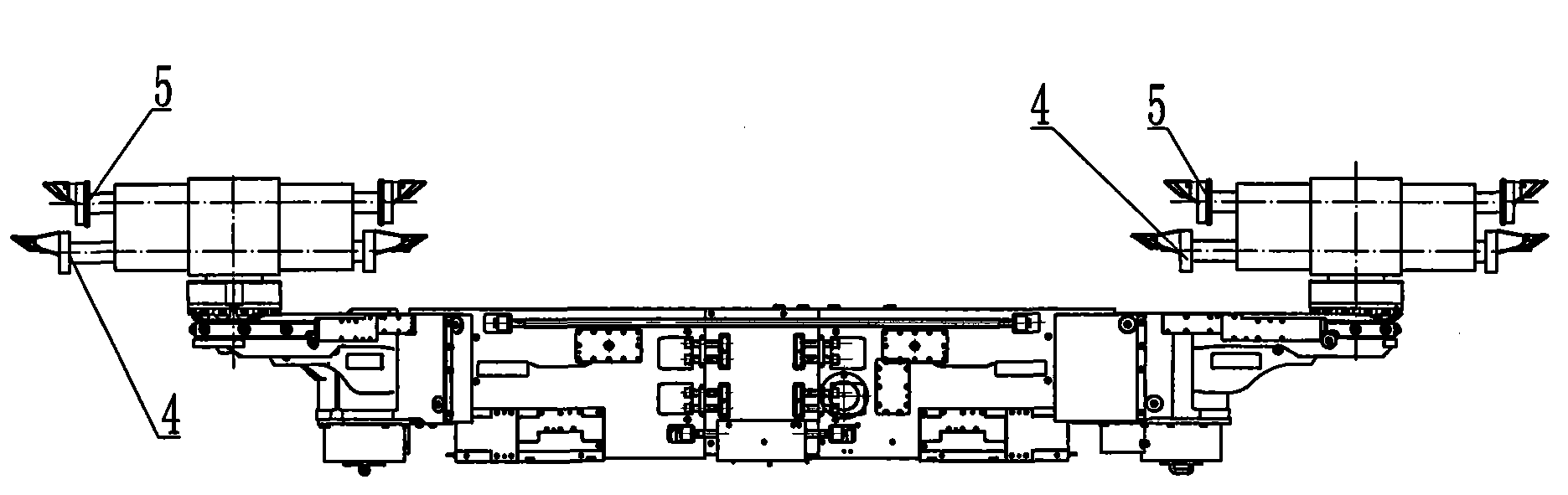

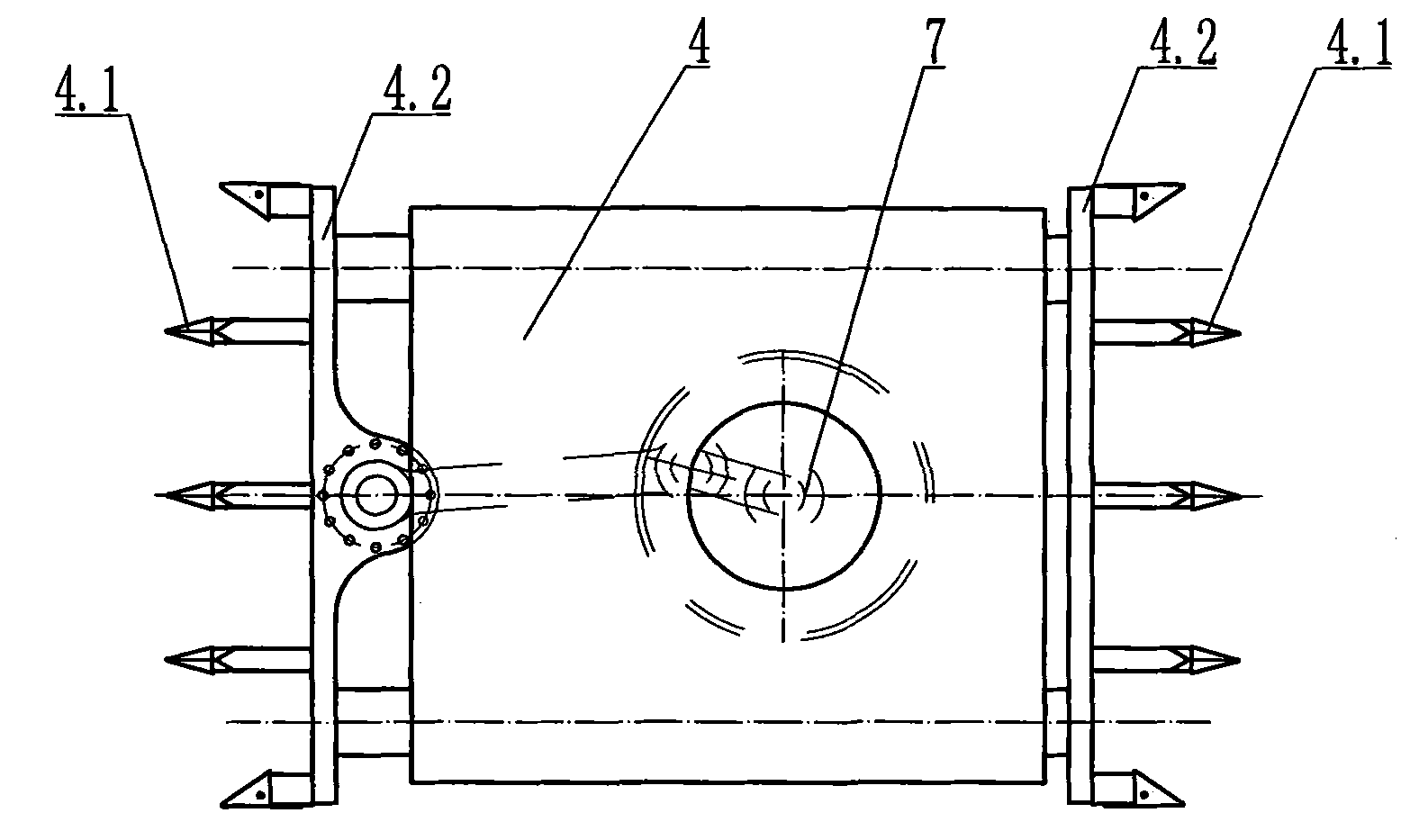

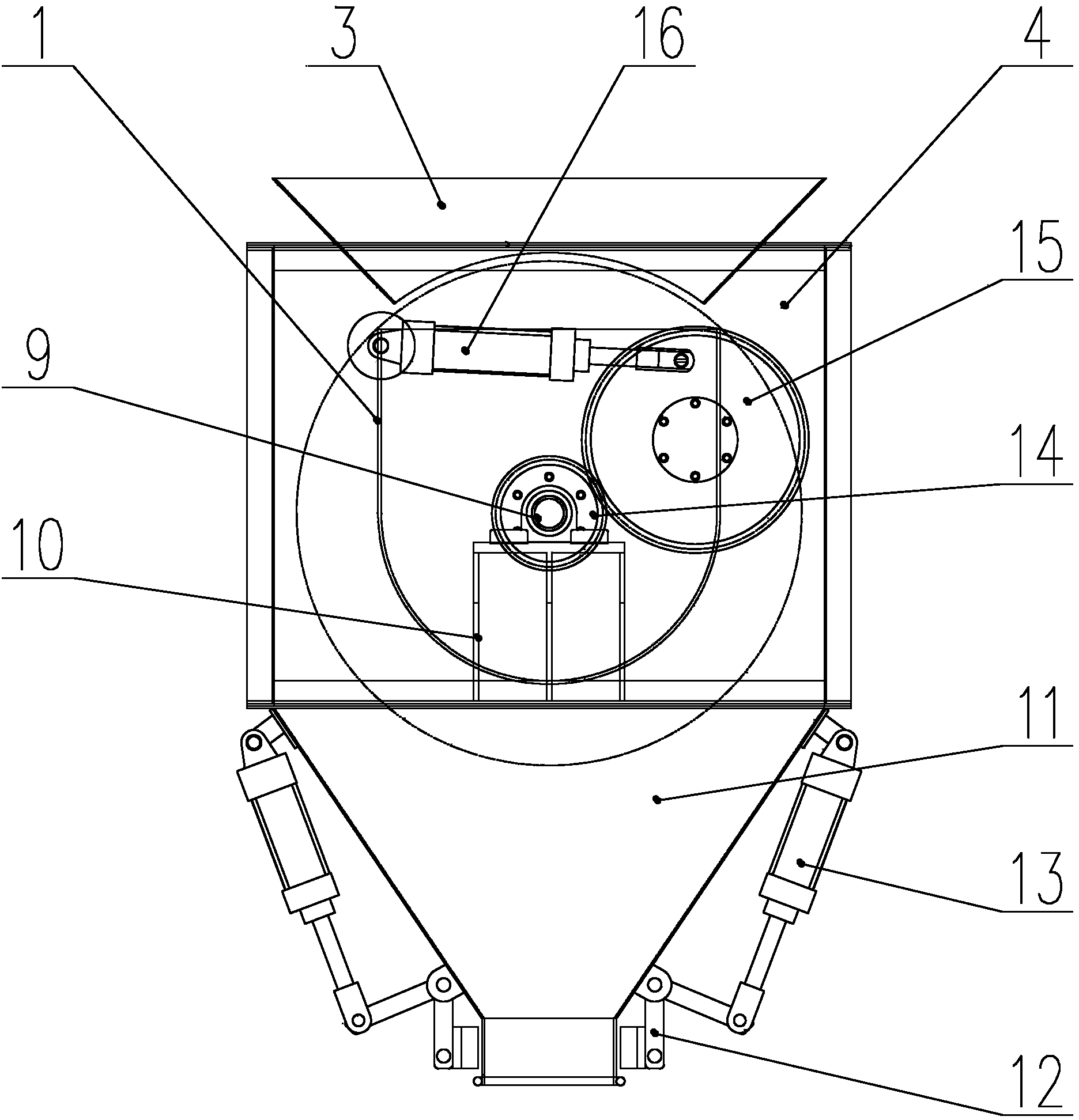

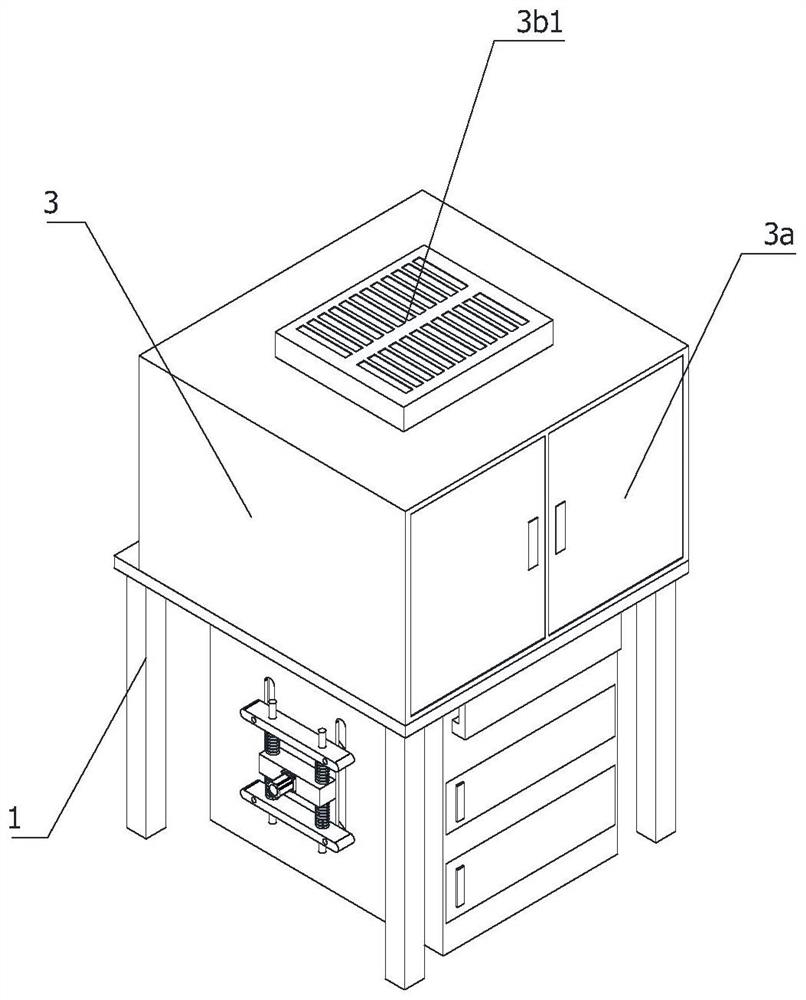

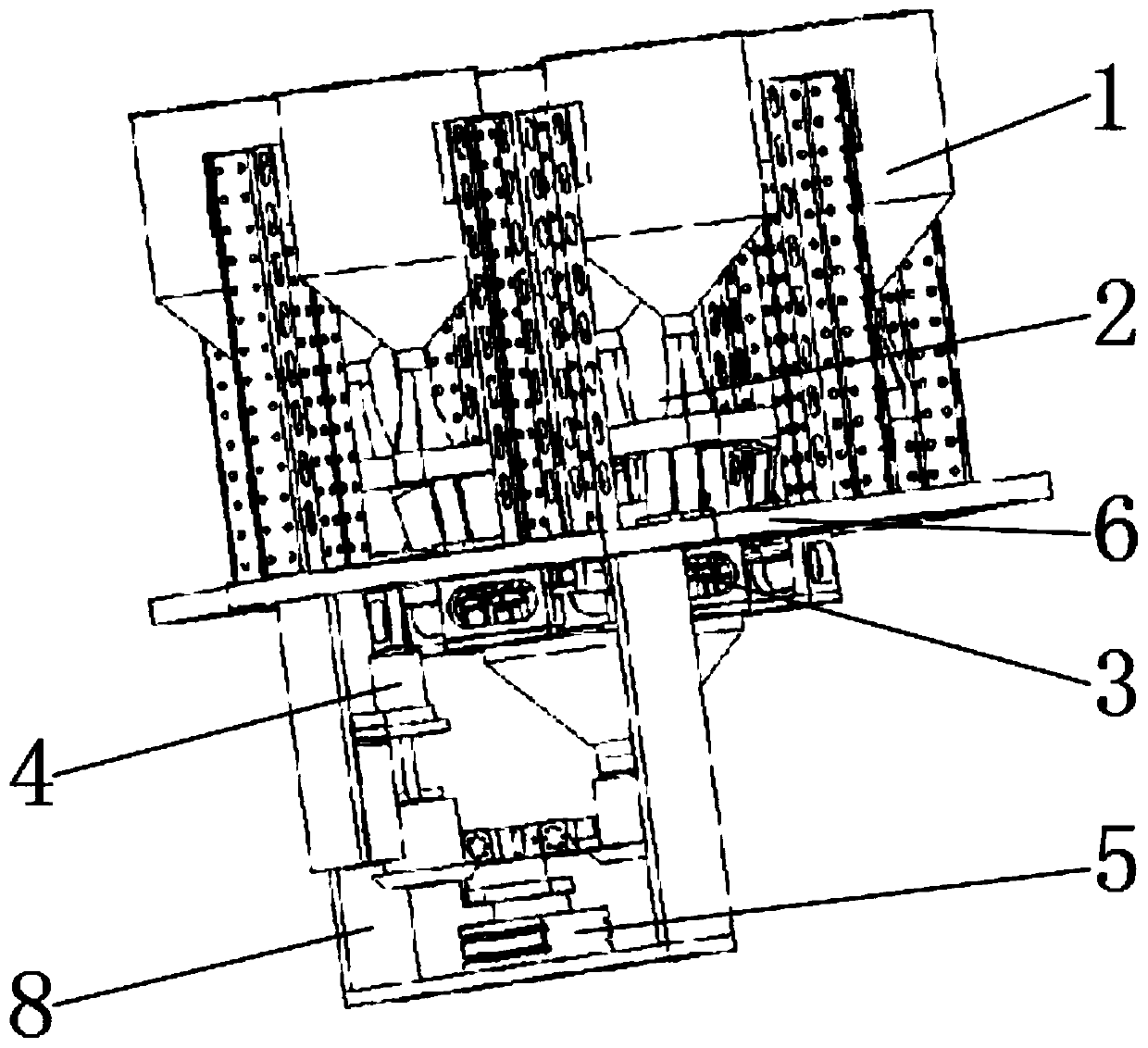

High-efficiency non-clamping impact-blanking digging method and high-efficiency non-clamping impact-blanking digger

ActiveCN103388474ASolve the problem of not being able to continuously collect materialsBlanking smoothlySlitting machinesCutting machinesEngineeringMechanical engineering

A high-efficiency mining machine for percussing falling-materials without trapping materials. A machine body of the mining machine is provided with a falling-material percussion mechanism (3). The falling-material percussion mechanism (3) comprises an outer-layer-material percussion mechanism (4) and an inner-layer-material percussion mechanism (5). The outer-layer-material percussion mechanism (4) comprises outer-layer-material percussion teeth (4.1). The outer-layer-material percussion teeth are disposed so that materials percussed down by the inner-layer-material percussion mechanism flow out through gaps between the outer-layer-material percussion teeth and / or a discharge hole (8) is reserved in the outer-layer-material percussion mechanism so that materials percussed down by the inner-layer-material percussion mechanism flow out through the discharge hole (8) of the outer-layer-material percussion mechanism. The inner-layer-material percussion mechanism comprises inner-layer-material percussion teeth (5.1). The inner-layer-material percussion mechanism and the outer-layer-material percussion mechanism work with each other to implement percussion and discharge of falling-materials. Also disclosed is a high-efficiency mining method for percussing falling-materials without trapping materials. The mining machine has a simple structure and works in a reliable way.

Owner:刘素华

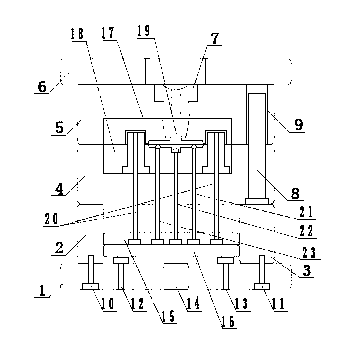

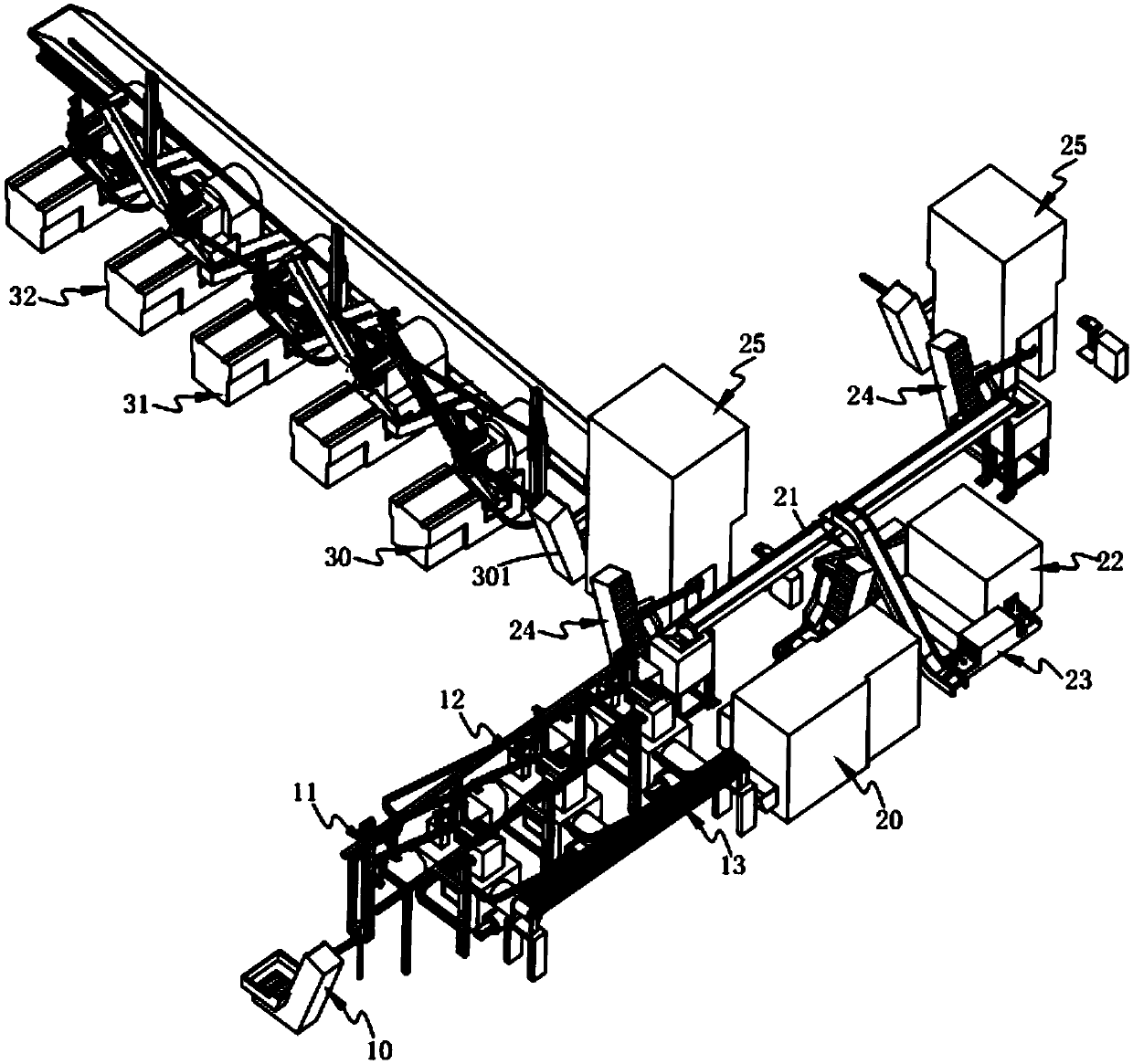

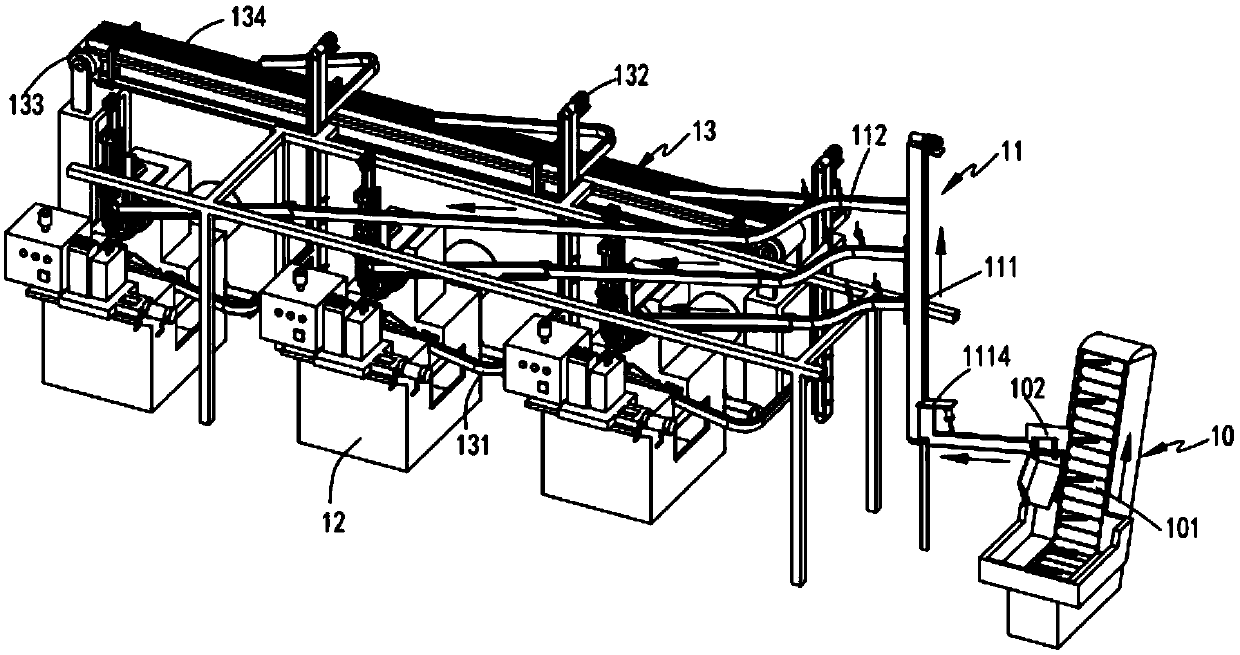

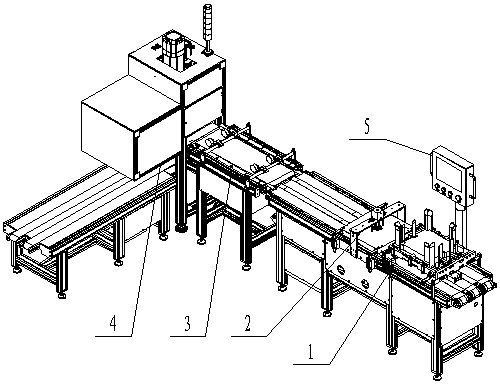

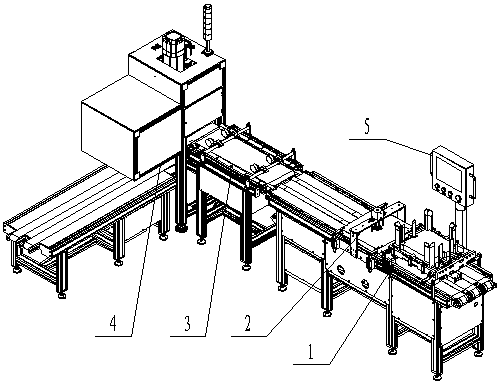

Bearing full-automatic production assembly line and technology

ActiveCN108673069ASolve the technical problems of fully automatic off-line processingAvoid cumbersomeMetal working apparatusAssembly lineMachining system

The invention provides a bearing full-automatic production assembly line and technology. The bearing full-automatic production assembly line comprises a rough machining system, a cold forging system and a finish machining system. The rough machining system, the cold forging system and the finish machining system are subjected to automatic line connection, thus annular blanks are automatically fedand machined, stations are automatically transferred, and rough turning machining, shot blasting machining, phosphorus saponification machining, cold forging machining, slitting machining and finish turning machining of bearing inner and outer sleeve rings are completed sequentially; and the technical problem of full-automatic loss line machining of inner and outer bearing sleeve ring machining equipment is solved, single machining equipment is subjected to automatic line connection to become the full-automatic production assembly line, the machining speed is increased, the tedious process ofworkpiece transferring is omitted, the labor intensity is lowered, and occupied areas of workpieces and the bearing full-automatic production assembly line are reduced.

Owner:浙江信石轴承有限公司

Packaging bag opening system and full-automatic bag opening and sealing packaging equipment

The invention relates to the field of automated packaging equipment, in particular to a packaging bag opening system. The system consists of a packaging bag folding device, a horizontal packaging bagmoving device and a packaging bag opening device. The packaging bag folding device is linked with the packaging bag opening device through the horizontal packaging bag moving device. The packaging bagopening system has the advantages that the packaging bag folding device achieves the change of each packaging bag from a horizontal state to a vertical state, one packaging bag is sucked each time, and automatic feeding is achieved; the horizontal packaging bag moving device achieves transport of the packaging bags in the vertical state; the packaging bag opening device achieves the change of each packaging bag from an initial state to an open state.

Owner:李孙

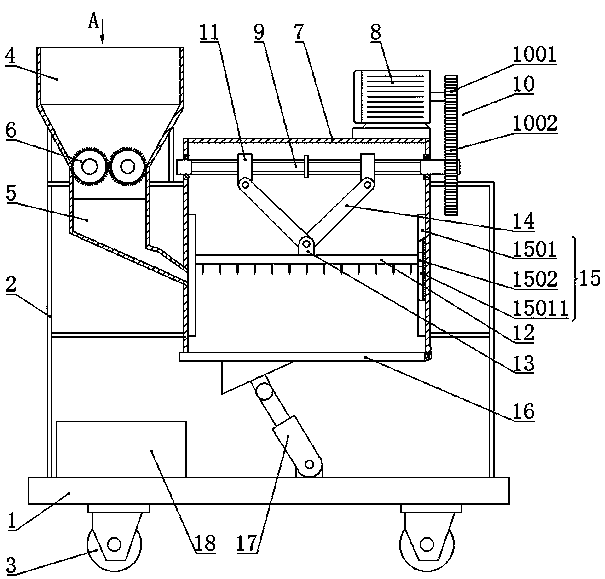

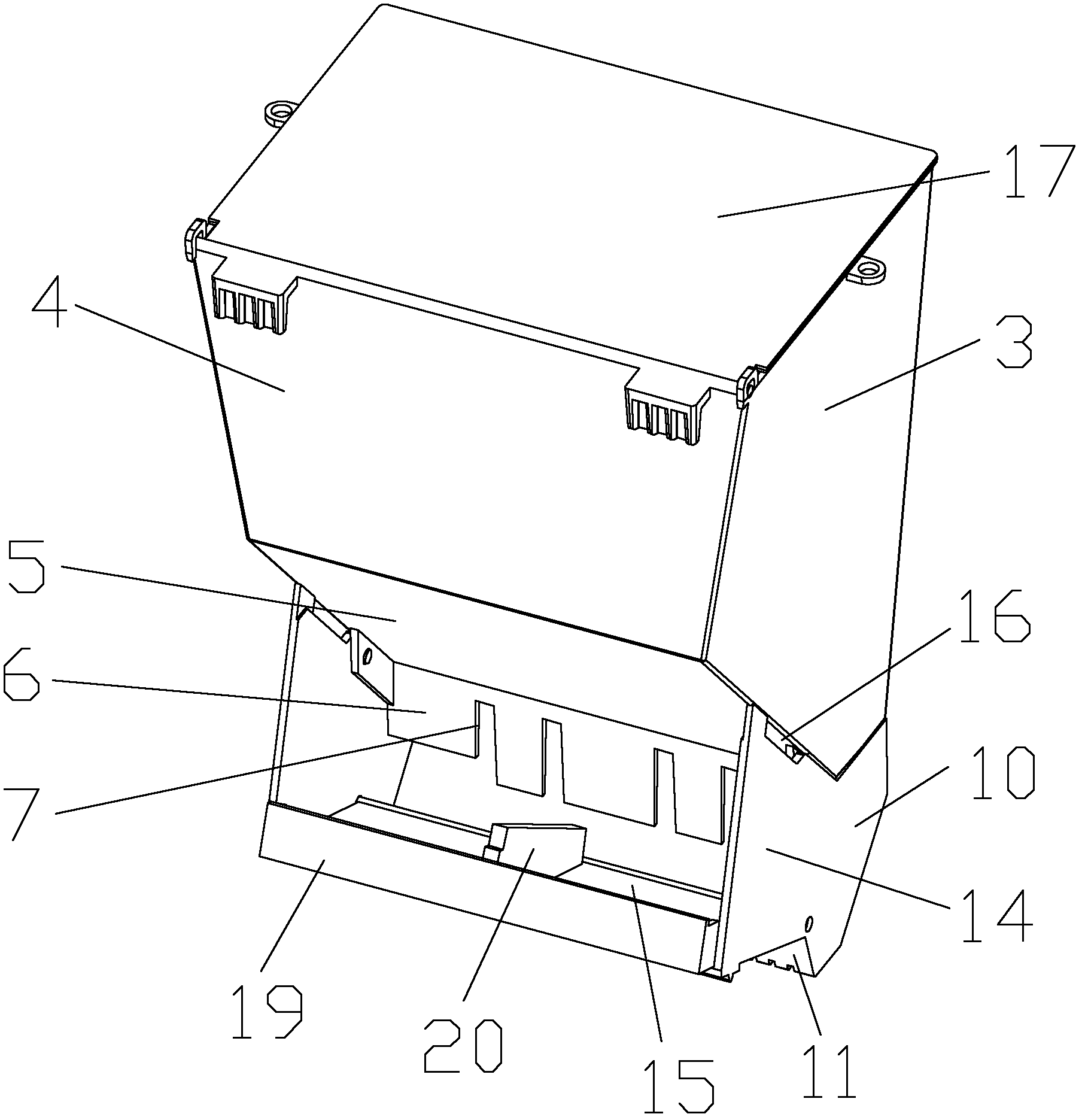

Disposable chopstick compacting and recovering device

InactiveCN109228484AImprove compactionConvenient blankingGrain treatmentsPressesEngineeringMechanical engineering

The invention discloses a disposable chopstick compacting and recovering device. The problems that disposable chopsticks cannot be smashed and are not convenient to move in the prior art are solved. The disposable chopstick compacting and recovering device comprises a base and a machine frame. Movable wheels are arranged at the bottom of the base. A feed hopper is fixed to the upper portion of oneside of the machine frame. A material receiving hopper is fixed to a discharge port of the feed hopper. A smashing mechanism is arranged on the discharge port of the feed hopper. A compacting box isfixed to one side of the machine frame. A discharge port of the material receiving hopper is communicated with the compacting box. A bidirectional lead screw driven by a compacting motor is arranged in the compacting box. Two driving blocks are symmetrically screwed to the bidirectional lead screw. A compacting plate is arranged at the portion, below the bidirectional lead screw, in the compactingbox. A driving rod is hinged between the compacting plate and the driving block. A bottom plate is movably arranged at the bottom of the compacting box. An electric push rod is hinged between the compacting plate and the machine frame. The disposable chopstick compacting and recovering device has the advantages of being easy and convenient to operate, reliable in disposable chopstick smashing andconvenient to move.

Owner:李思颖

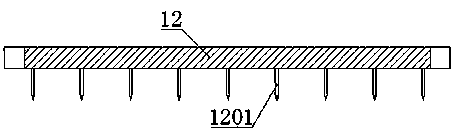

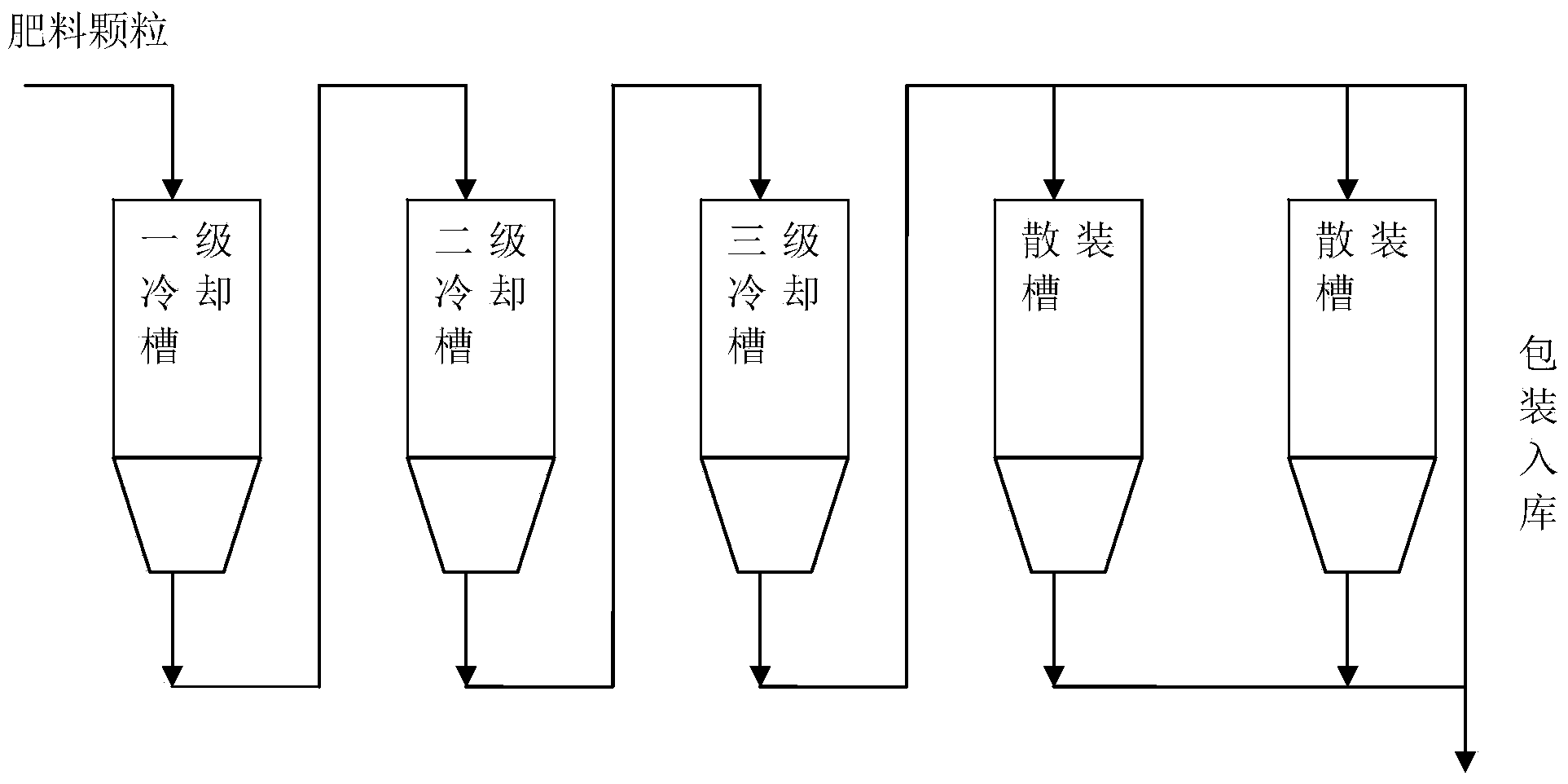

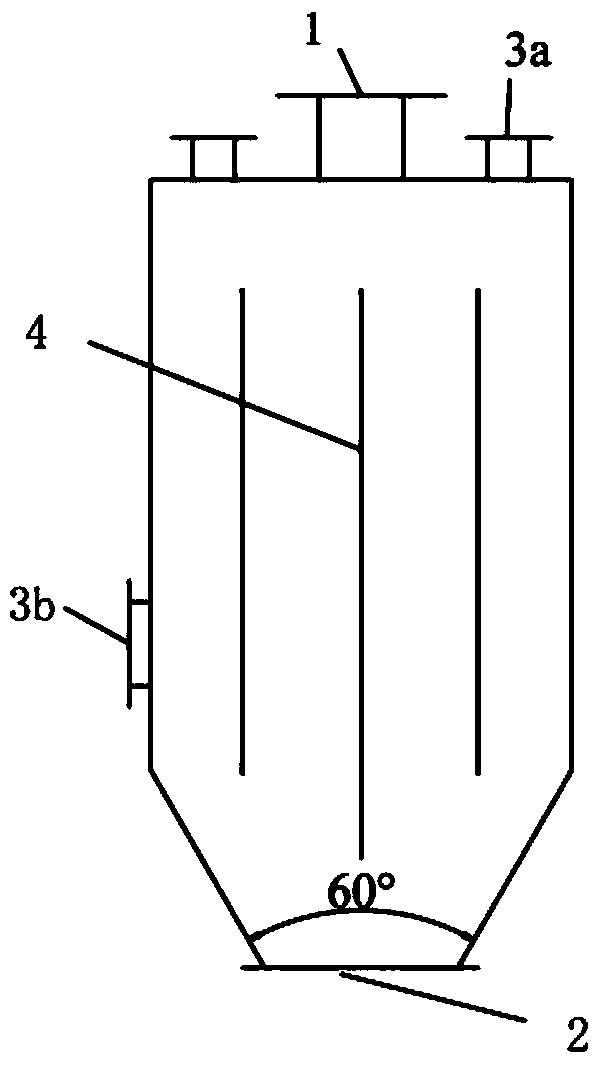

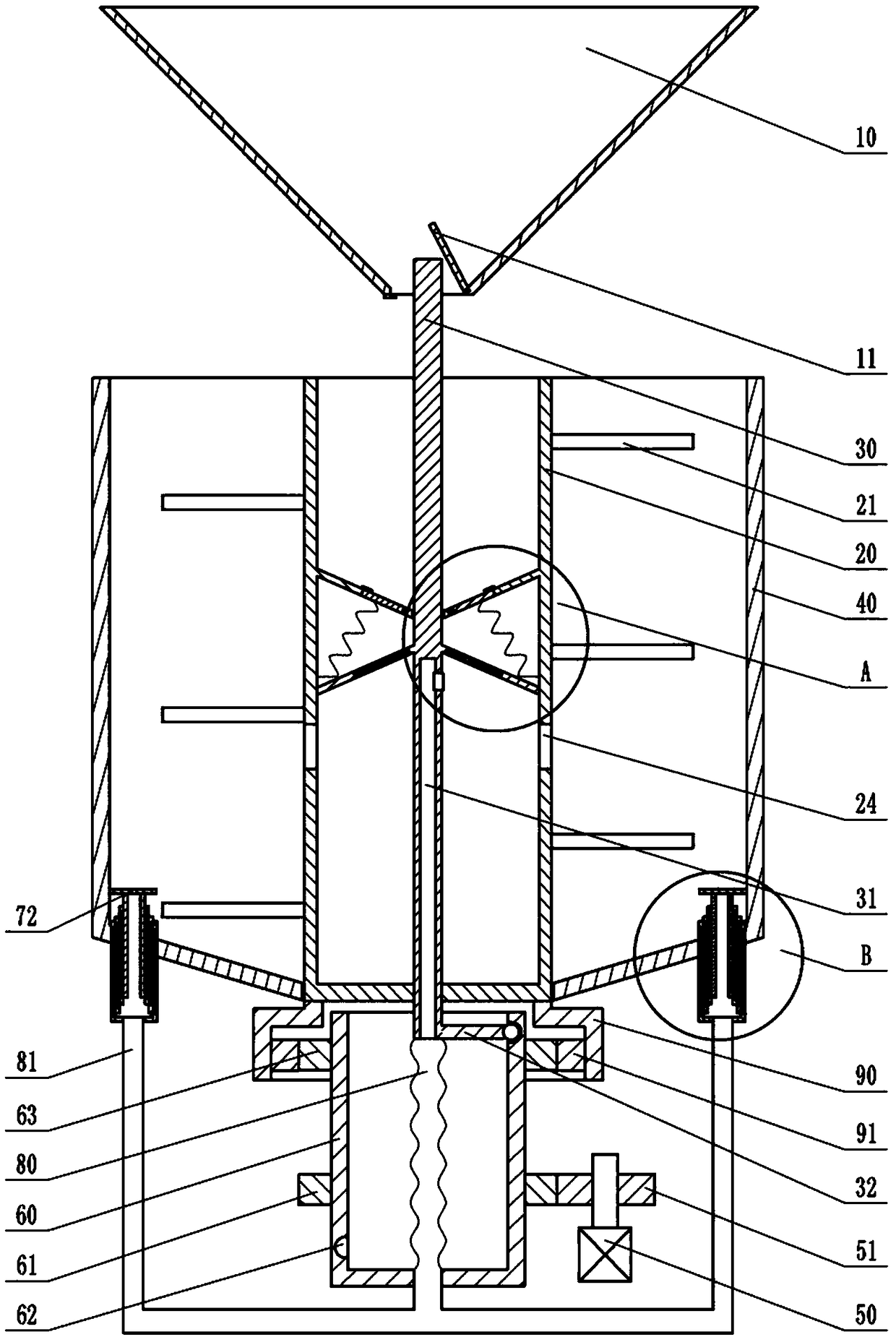

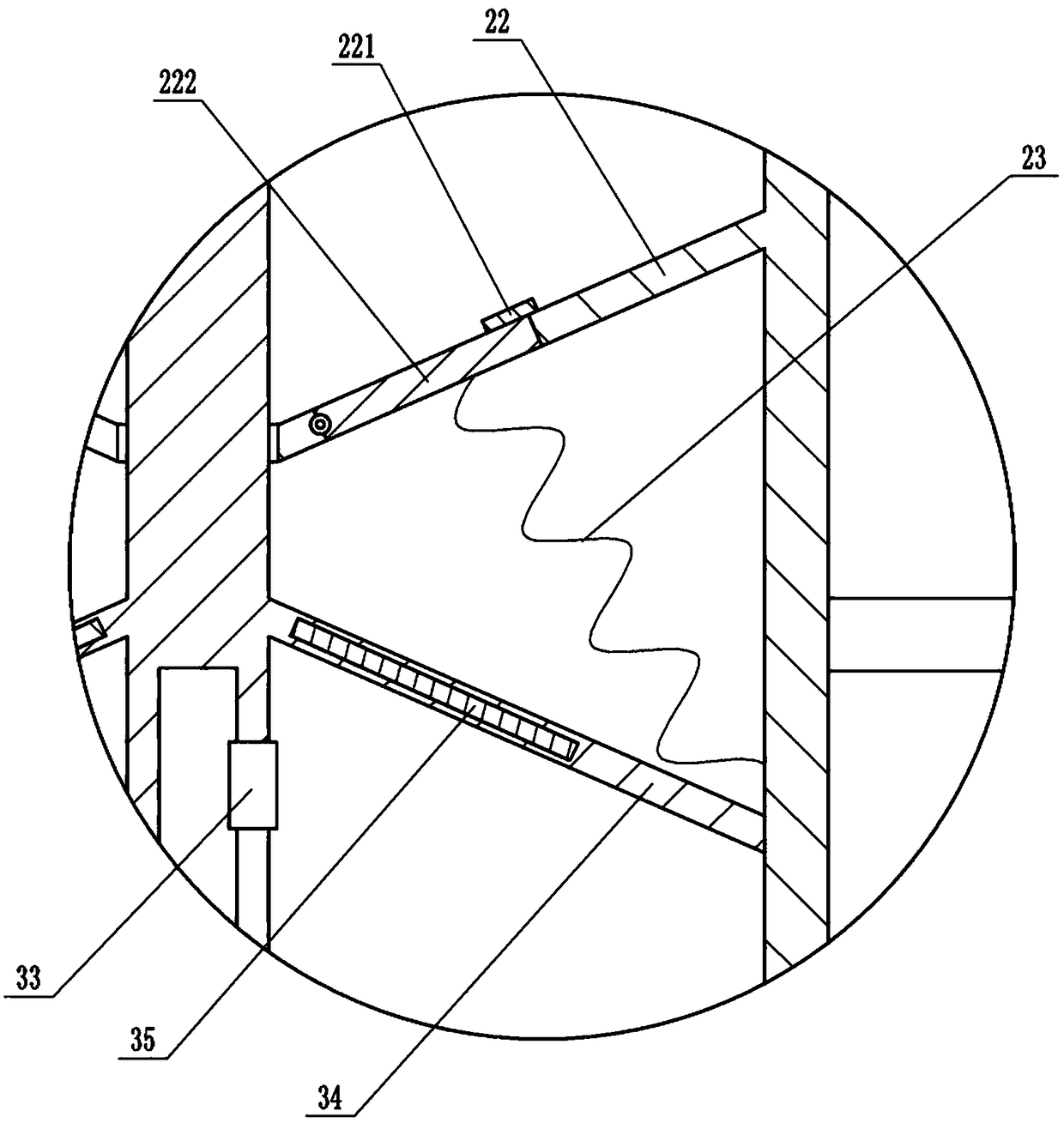

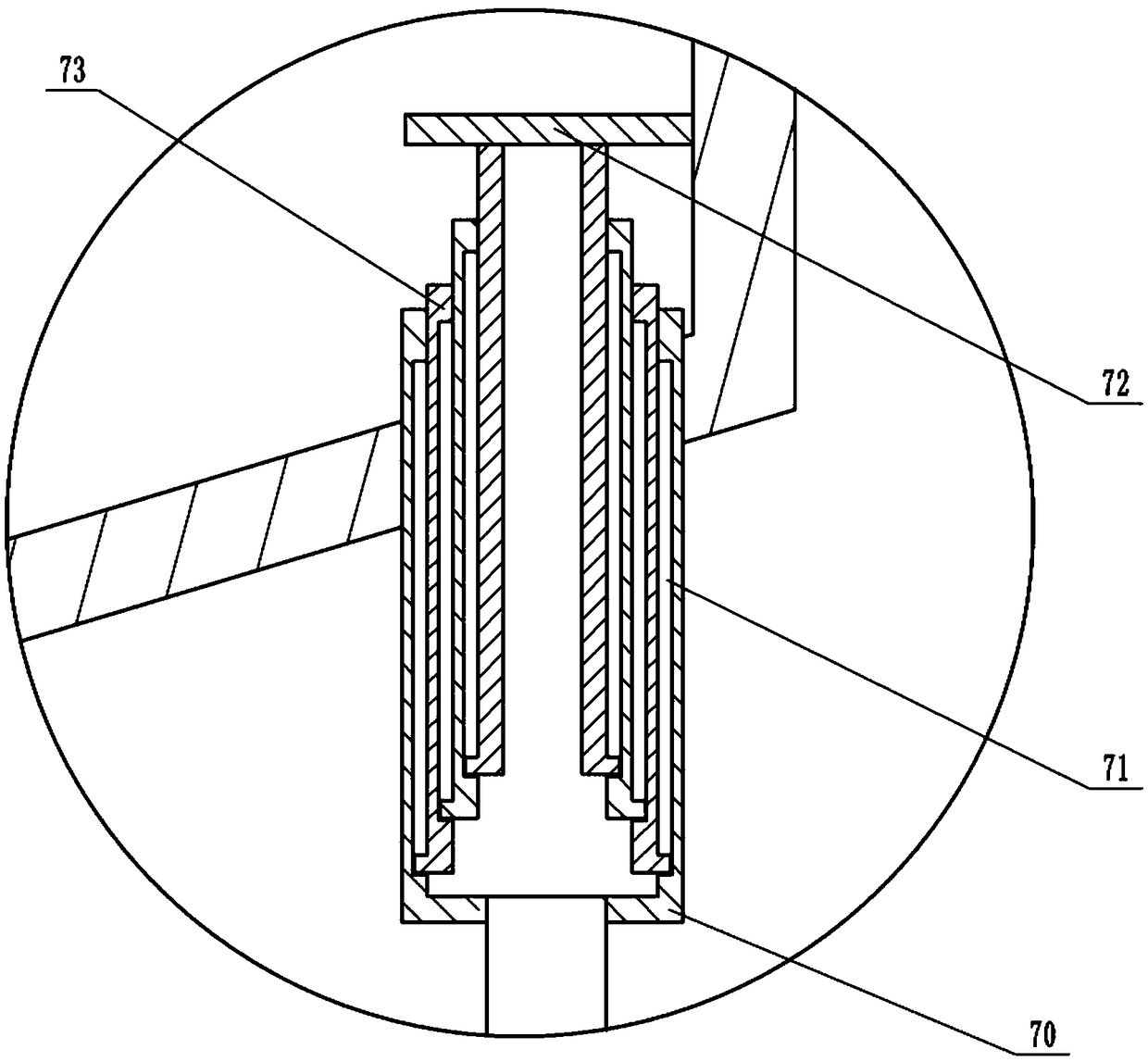

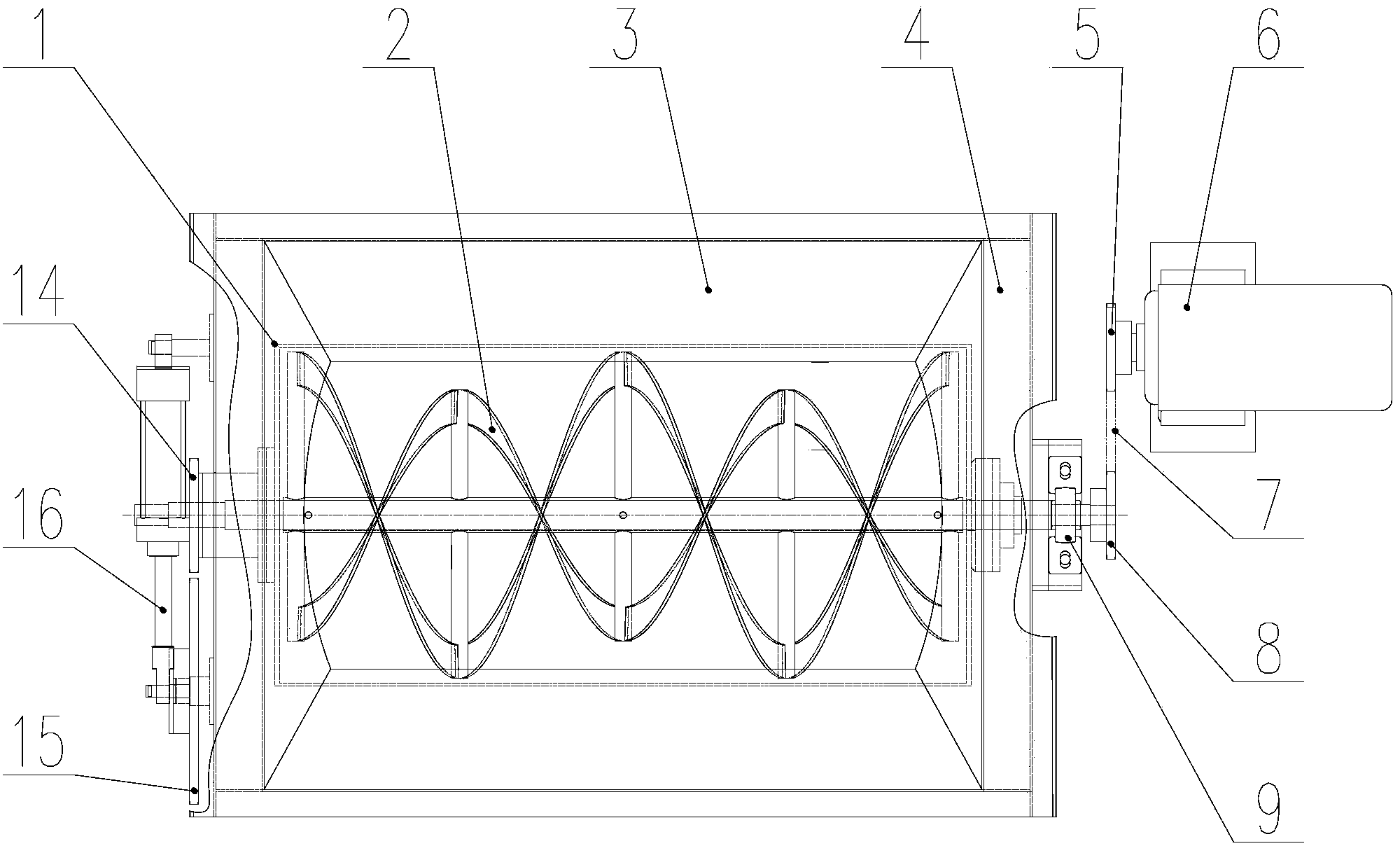

Fertilizer cooling method and device

ActiveCN103411363ASpeed up heat dissipationReduce or eliminate cakingDomestic cooling apparatusLighting and heating apparatusAgricultural engineeringEnergy consumption

The invention provides a fertilizer cooling method. The fertilizer cooling method comprises cooling granular fertilizer through more than one cooling tank, conveying the cooled granular fertilizer to bulk tanks for storage or packing storage, during the cooling process, taking the granular fertilizer out of storage for sunning, and during the sunning process, the granular fertilizer is insulated from outside air. The fertilizer cooling method reduces energy consumption, saves the costs, improves the quality of the fertilizer and avoids generating waste gas. The invention also provides a fertilizer cooling device. The fertilizer cooling device comprises the cooling tanks, the top of every cooling tank is provided with a feeding port, the bottom of the cooling tank is provided with a discharge port and is of a cone shape, and the inside of every cooling tank is provided with more than one isolation board which horizontally divides the inside of the cooling tank into a plurality of blanking channels. The fertilizer cooling device enlarges the contact area between the granular fertilizer and the cooling tanks and can effectively avoid 'arches' formed by the granular fertilizer.

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

Multifunctional veterinary herbal medicine superfine crushing equipment

The invention discloses a multifunctional veterinary herbal medicine superfine crushing equipment. The superfine crushing equipment comprises a shell, wherein the shell is fixed on a machine frame, agrinding device is arranged in the shell, the grinding device comprises an upper grinding body and a lower grinding body, the upper grinding body and the lower grinding body are of conical umbrella-shaped structures, a rotating shaft I is fixedly connected to the upper end of the upper grinding body, the rotating shaft I is in a tubular shape with openings at two ends, the upper end of the rotating shaft I penetrates through the shell and then is in driving connection with an upper grinding body driving motor arranged on the machine frame, the lower end of the lower grinding body is fixedly connected with a rotating shaft II, and the lower end of the rotating shaft II penetrates through the shell and is in driving connection with a lower grinding body driving motor arranged on the machineframe. The superfine crushing equipment has the characteristics that grinding and superfine crushing are synchronous, multi-stage crushing is achieved, and automatic liquid generation is achieved.

Owner:QINGDAO AGRI UNIV

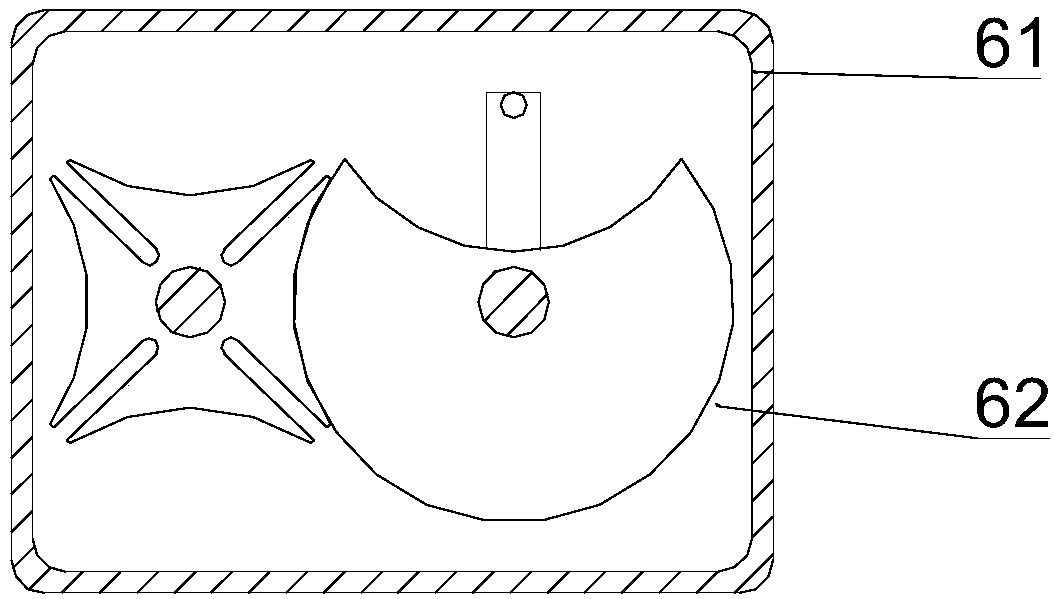

Composite fertilizer production device

PendingCN108686565ASimple structureLow costTransportation and packagingMixer accessoriesAgricultural engineeringFertilizer

The invention belongs to the technical field of fertilizer processing, and particularly discloses a composite fertilizer production device. The composite fertilizer production device comprises a powerunit, a stirring unit, a cleaning unit and a discharging unit, wherein the discharging unit comprises a hopper and an ejector rod; the hopper is hinged to a door; the stirring unit comprises an outerbarrel and an inner barrel; a stirring rod is fixed on a side wall of the inner barrel; the power unit comprises a transmission mechanism, a rotating barrel and a motor; the transmission mechanism isused for driving the rotating barrel and the inner barrel to rotate simultaneously; a closed curved groove is formed in the inner wall of the rotating barrel; a connecting rod of which one end is clamped in the curved groove is fixed on the ejector rod; the cleaning unit comprises an annular scraper blade and a telescopic mechanism; a cavity is formed in the lower portion of the ejector rod; a through opening is formed in the ejector rod; a universal joint is arranged at a connection position of a rotating center on the bottom of the rotating barrel; a corrugated tube is connected between theuniversal joint and the lower portion of the ejector rod; and an air tube is connected between the universal joint and the telescopic mechanism. By the device, the problem that excrement is attachedto the inner wall of the device and is difficult to clean can be solved.

Owner:遵义大兴复肥有限责任公司

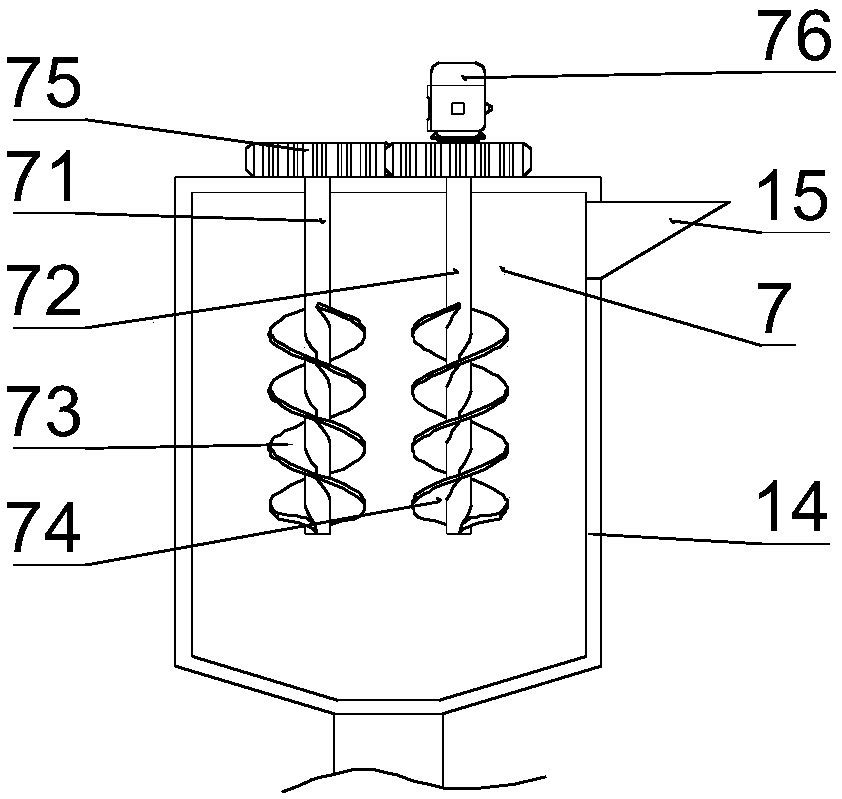

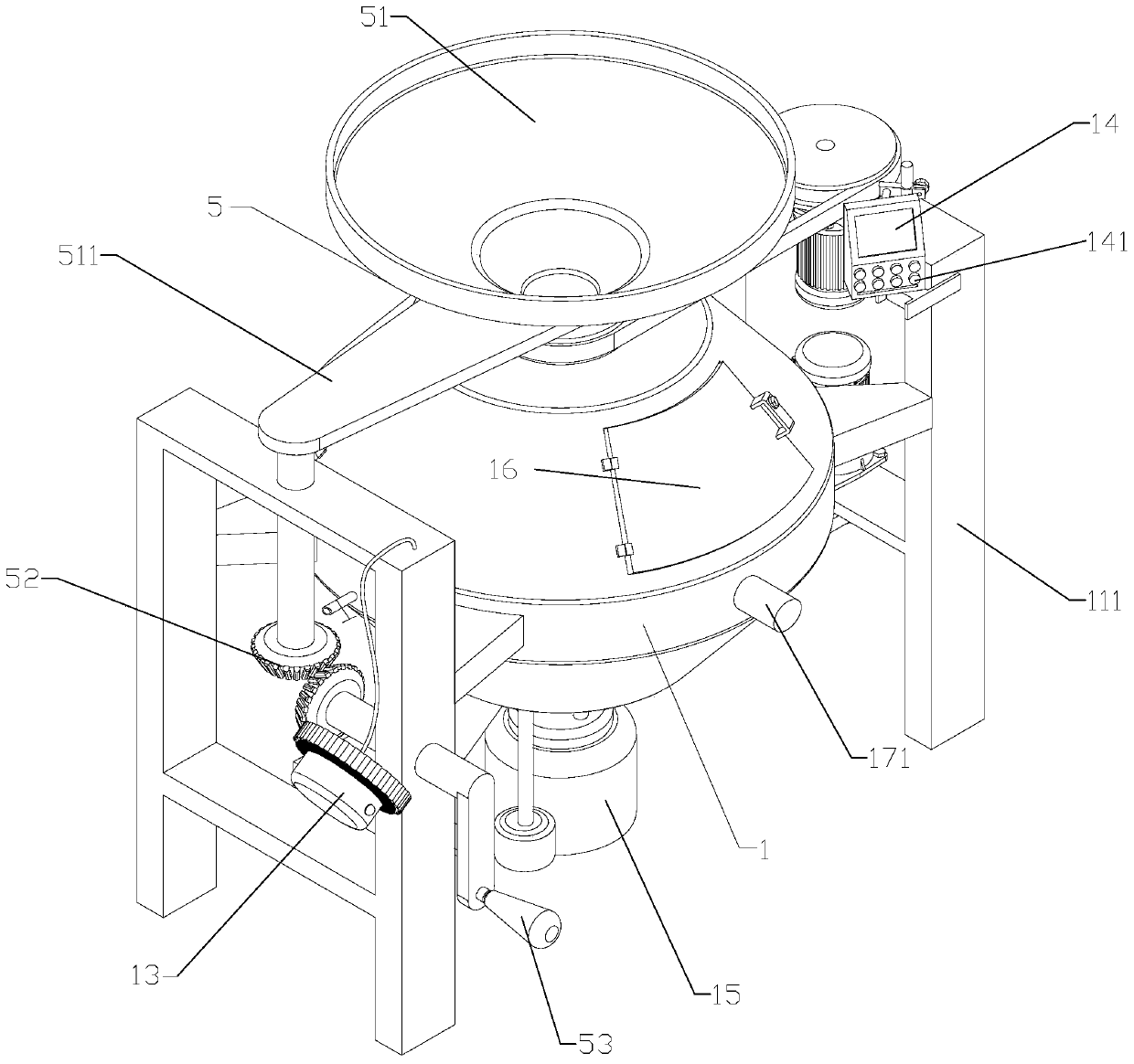

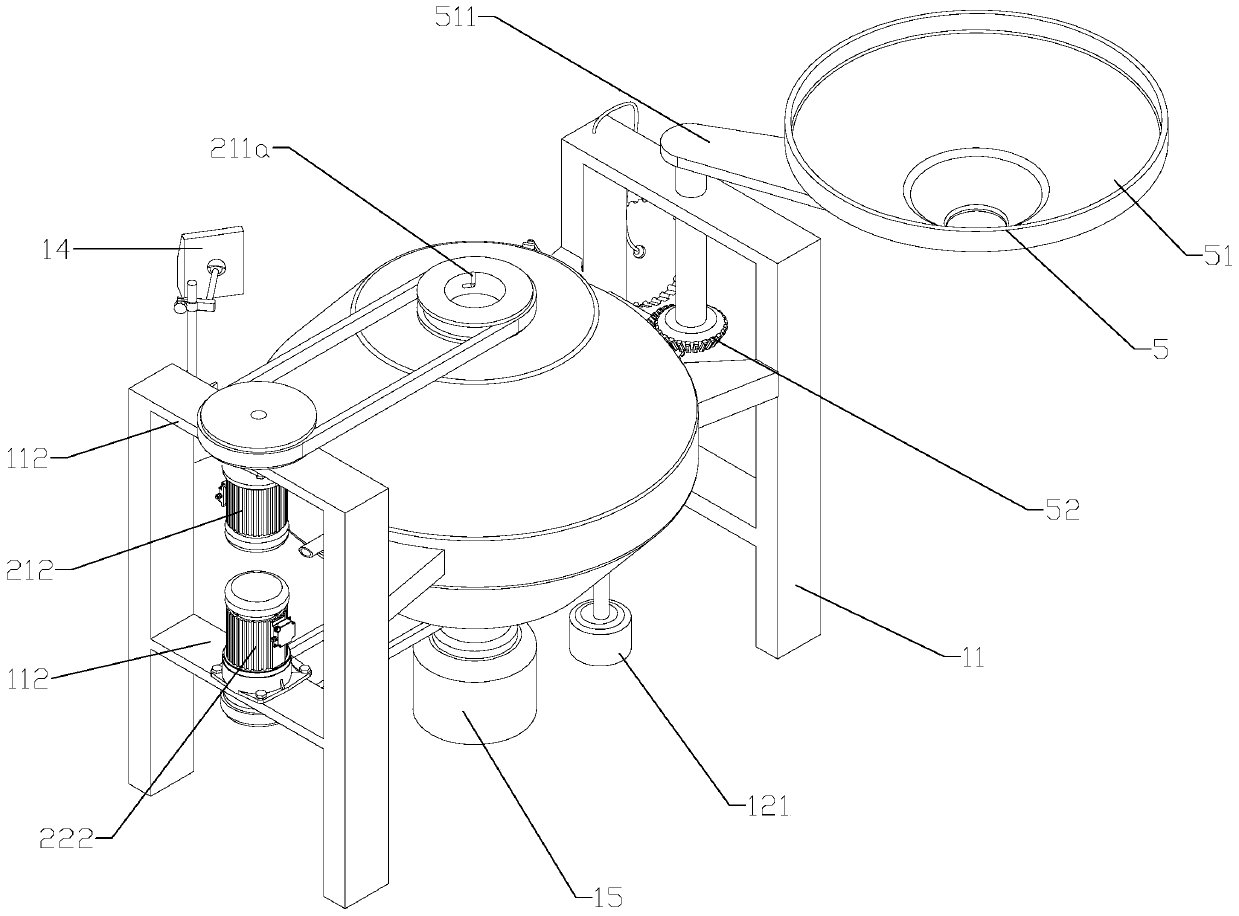

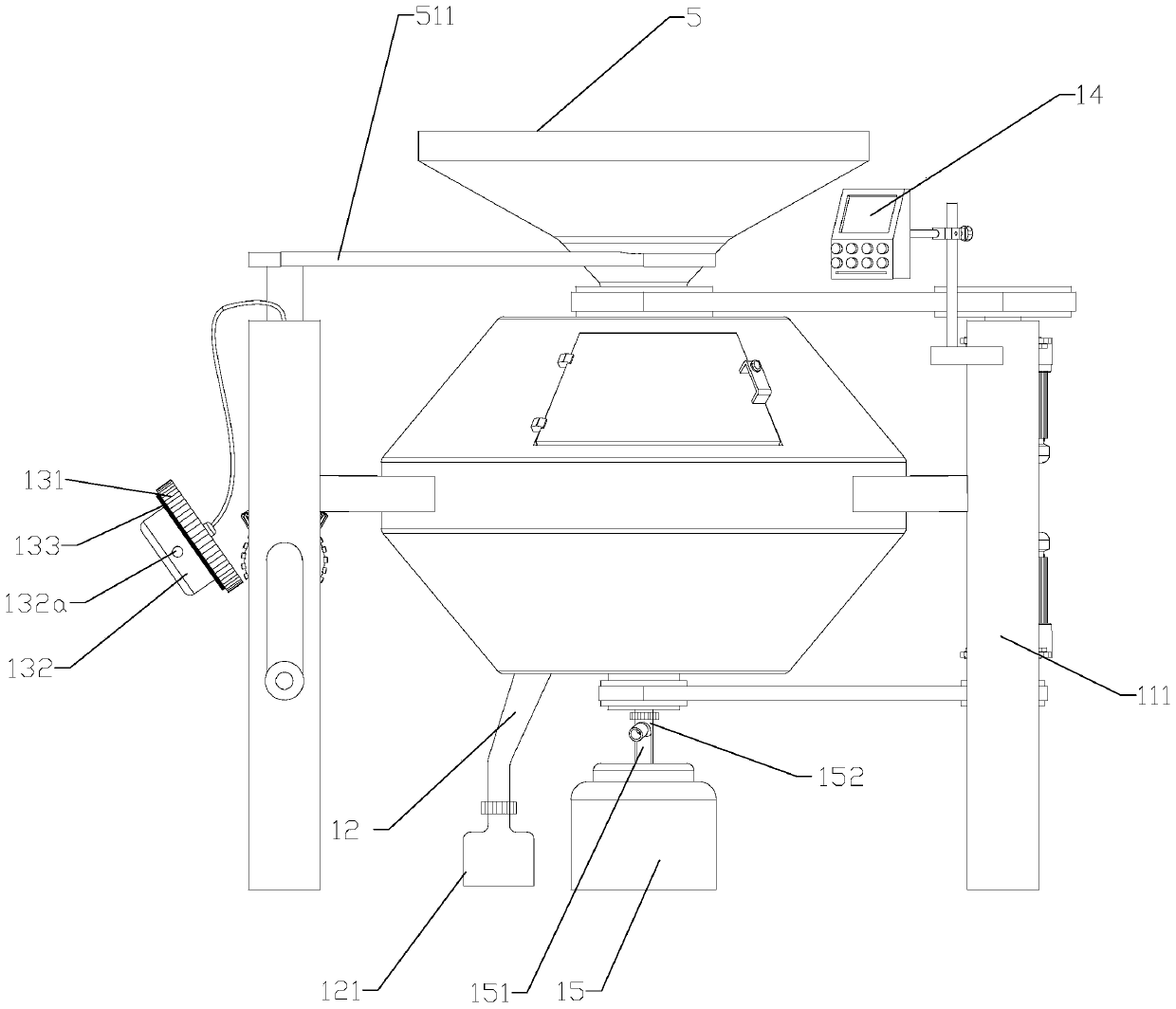

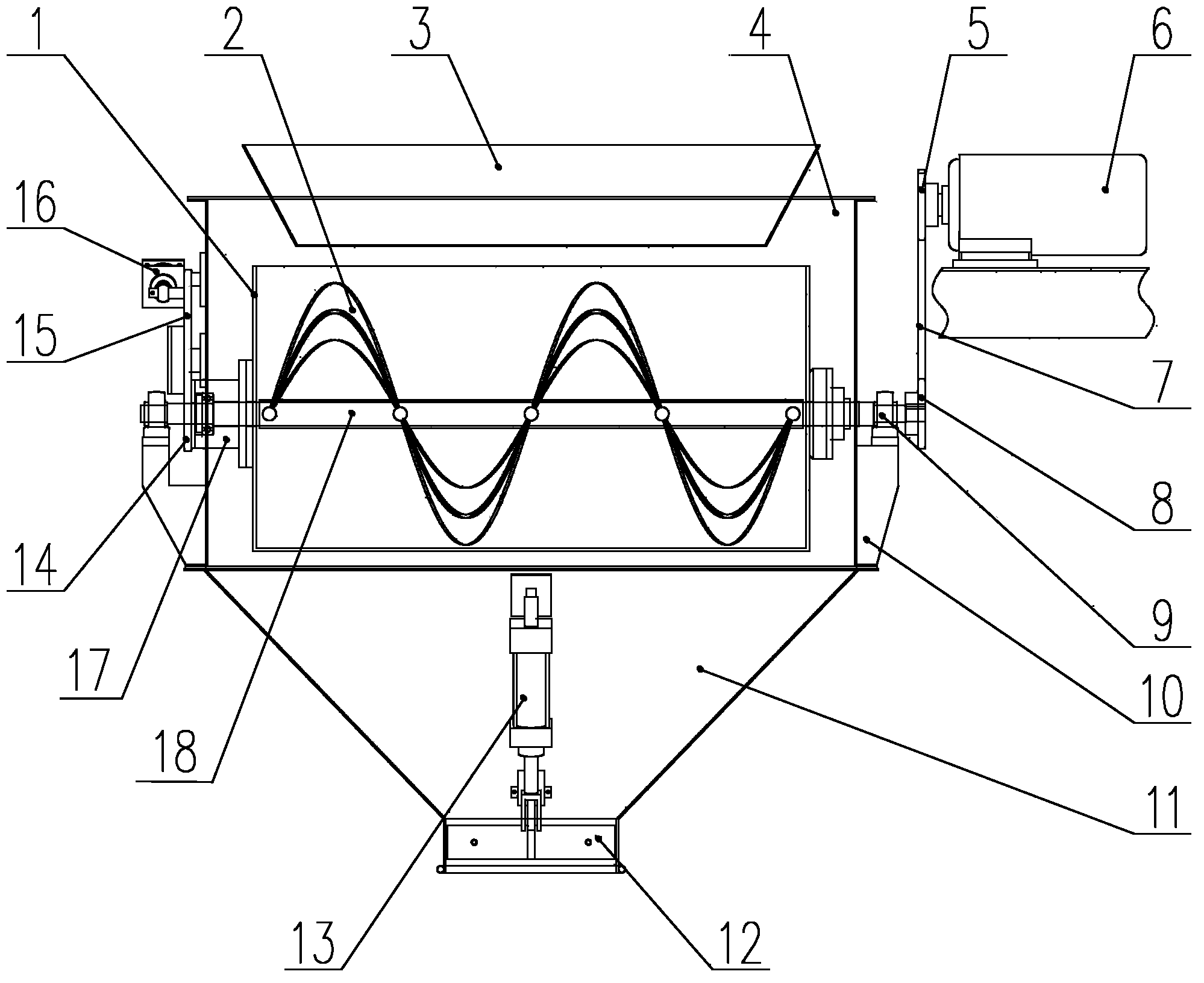

Mixer

ActiveCN103349931AEvenly mixedConvenient blankingRotary stirring mixersMixer accessoriesEngineeringMechanical engineering

The invention discloses a mixer. The mixer comprises an outer cover and a feeding hopper, wherein the packing hopper is connected below the outer cover; a mixing hopper is horizontally erected in the inner cavity of the outer cover; an stirrer is arranged in the inner cavity of the mixing hopper; the mixing hopper is provided with a hole which communicate the inside of the mixing hopper with the outside; the mixing hopper rotates around a horizontal axis. The mixer disclosed by the invention can be used for mixing materials uniformly and can discharge materials conveniently without leakage. The mixing hopper can turn over to pour out the materials. Because the mixing hopper is arranged in the inner cavity of the outer cover, the spilling of the materials can be prevented effectively, and the materials can be discharged completely.

Owner:和原生态控股股份有限公司

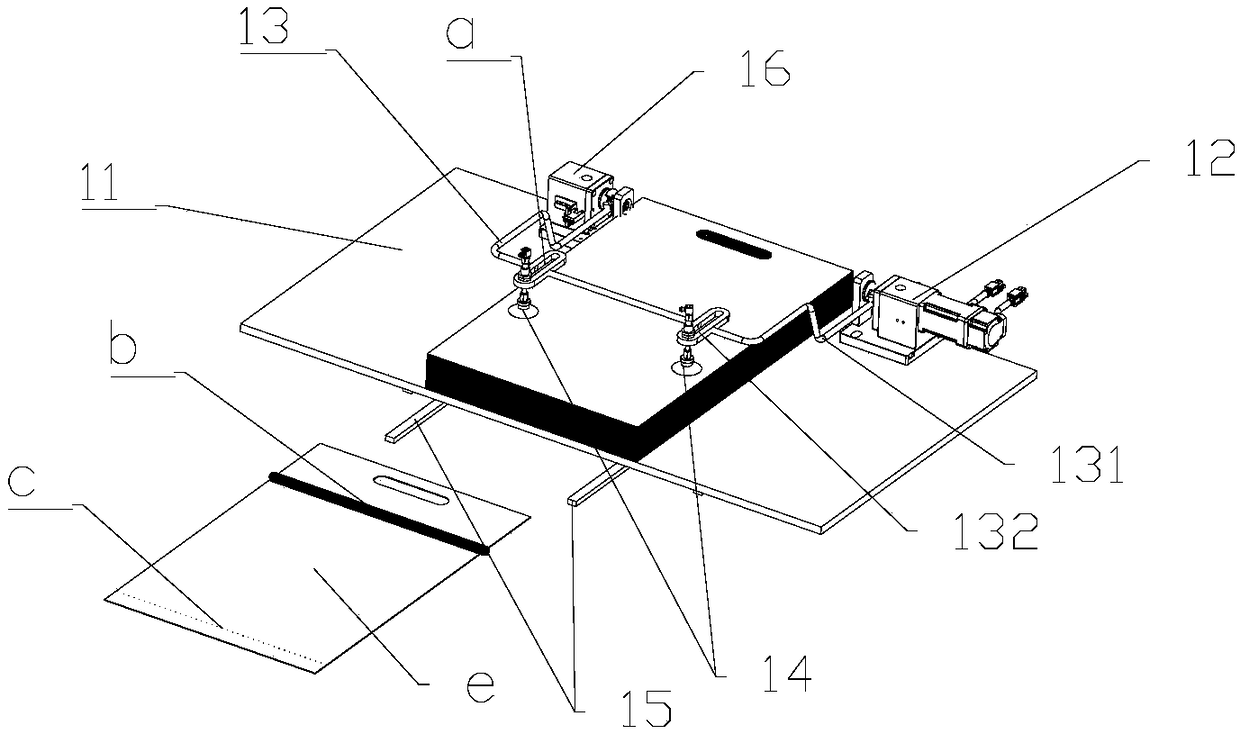

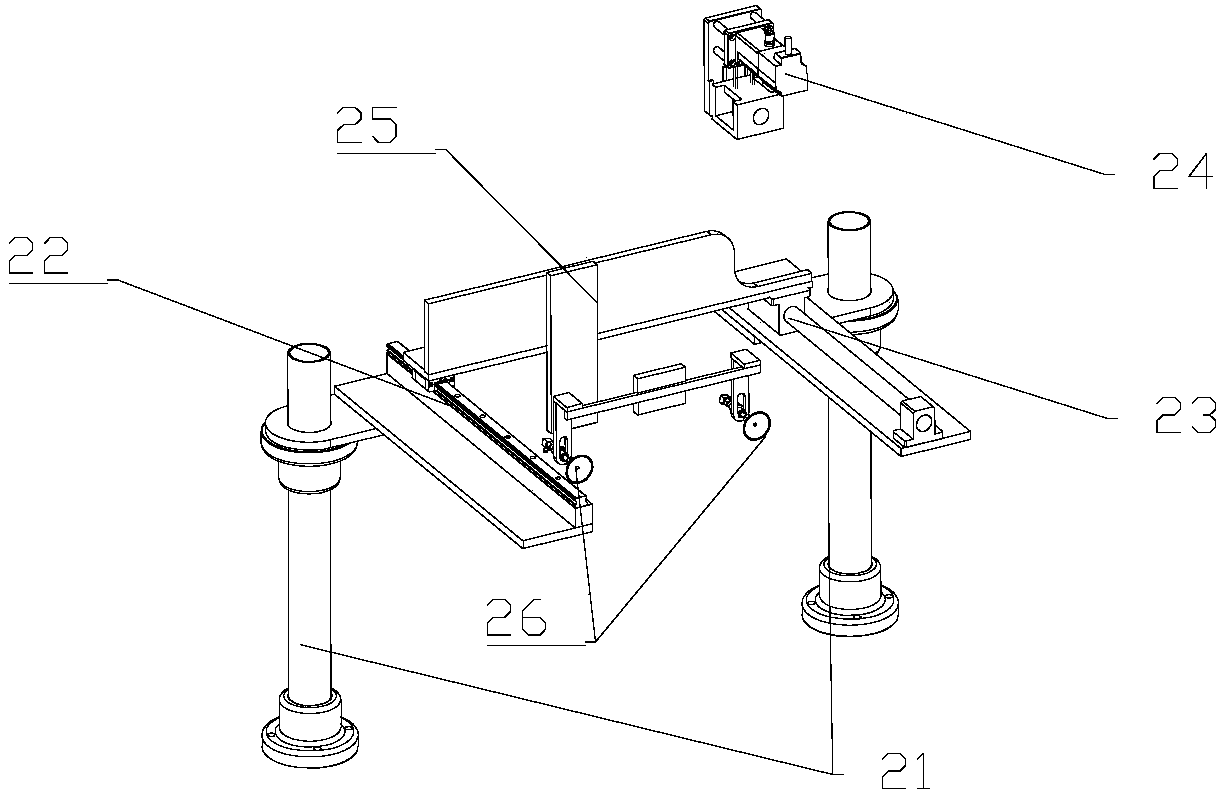

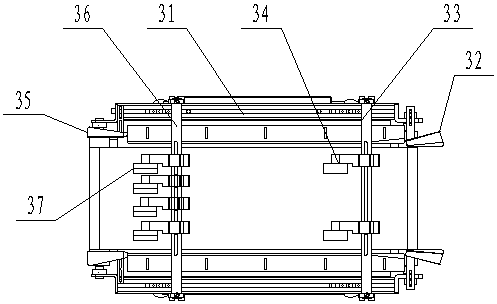

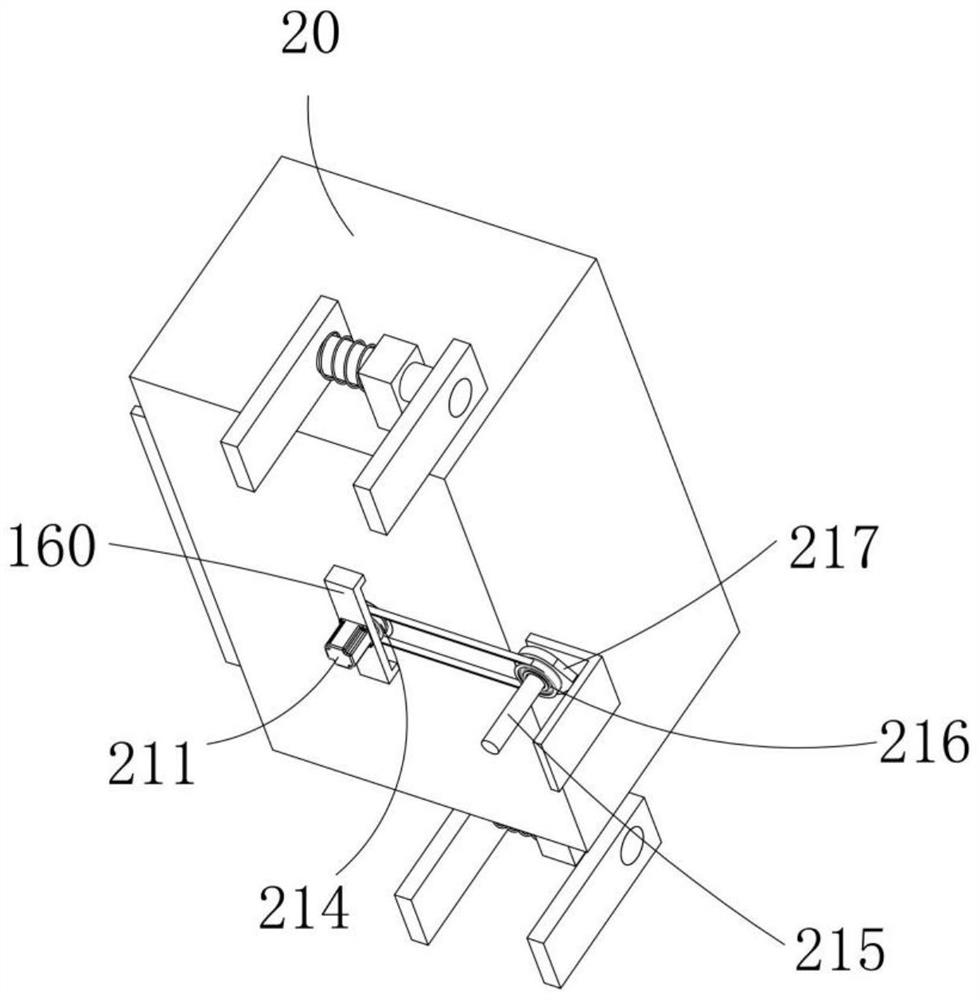

Taking device of cigarette carton cover automatic leveling, shaping and collecting system

PendingCN109160005AAvoid re-deformationEasy to follow upPackagingArticle feedersCollection systemCarton

The invention discloses a taking device of a cigarette carton cover automatic leveling, shaping and collecting system. The taking device comprises a warehouse, a conveying structure and a single taking structure; the warehouse is positioned above the conveying structure, and is used for placing carton covers to be treated; the conveying direction of the conveying structure is parallel to the longfolding line direction of carton covers in the warehouse on the upper side; the conveying structure comprises a conveying frame, and an air sucking belt arranged on the conveying frame; the air sucking belt performs stepper conveying; and the single taking structure is arranged under the warehouse, and is used for grabbing single carton covers to put on the conveying structure. The taking device can automatically take single carton covers from the warehouse according to the production takt and put onto the conveying structure to realize stepper intermittent conveying.

Owner:CHINA TOBACCO HENAN IND

Laser cutting machine facilitating waste treatment

InactiveCN114289893AEasy to collectEasy to collect separatelyLaser beam welding apparatusThermodynamicsFresh air

The invention relates to the technical field of laser cutting, in particular to a laser cutting machine convenient for waste treatment, which comprises a workbench and a cutting assembly, the cutting assembly is located above the workbench, the center of the workbench is provided with a blanking groove, and the workbench is provided with a sealing cover, a fresh air assembly, a collecting mechanism and an adjusting assembly. When a workpiece is cut through the cutting assembly, the workpiece is placed above the blanking groove, after being cut, the workpiece falls into the collecting mechanism through the blanking groove, waste and finished products are screened through the collecting mechanism, the waste cannot be scattered while the finished products are conveniently collected, and through the arrangement of a sealing cover, in the cutting process, the cutting efficiency is greatly improved. Smoke dust and molten slag do not fly up, the interior of the sealing cover is always kept in a re-pressing state through the fresh air assembly, the smoke dust and the molten slag are discharged from the lower end of the equipment, damage of the smoke dust to workers is reduced, the adjusting assembly is used for controlling the size of the discharging groove, and finished products and waste materials can be conveniently and separately collected.

Owner:苏艺

Drying device for zinc oxide preparation

ActiveCN114111254ASimple structureReasonable designChemical industryDrying gas arrangementsComposite materialChemical preparation

The invention belongs to the technical field of chemical preparation, and particularly relates to a drying device for zinc oxide preparation, which comprises a base and a hollow rotating shaft rotationally assembled between two supporting columns, the hollow rotating shaft is fixedly connected with a drying cylinder, the drying cylinder is obliquely arranged on the surface of the hollow rotating shaft, and the supporting columns are provided with air inlet mechanisms matched with the hollow rotating shaft. The lower side of the feeding hopper is provided with a discharging pipe, the outer side of the discharging pipe is sleeved with a connecting pipe, a springback mechanism is arranged between the mounting plate and the lower side of the feeding hopper, the lower side of the feeding hopper is provided with an electromagnet, the outer surface of the higher side of the drying cylinder is fixedly connected with a fixing ring concentric with the hollow rotating shaft, and the inner wall of the drying cylinder is provided with an abutting blocking mechanism matched with the feeding port. The zinc oxide nanoparticle drying device is simple in structure and reasonable in design, the drying effect on zinc oxide nanoparticles is improved, meanwhile, connection between the feeding hopper and the drying cylinder is facilitated, and the design is ingenious.

Owner:ZHONGKAI UNIV OF AGRI & ENG

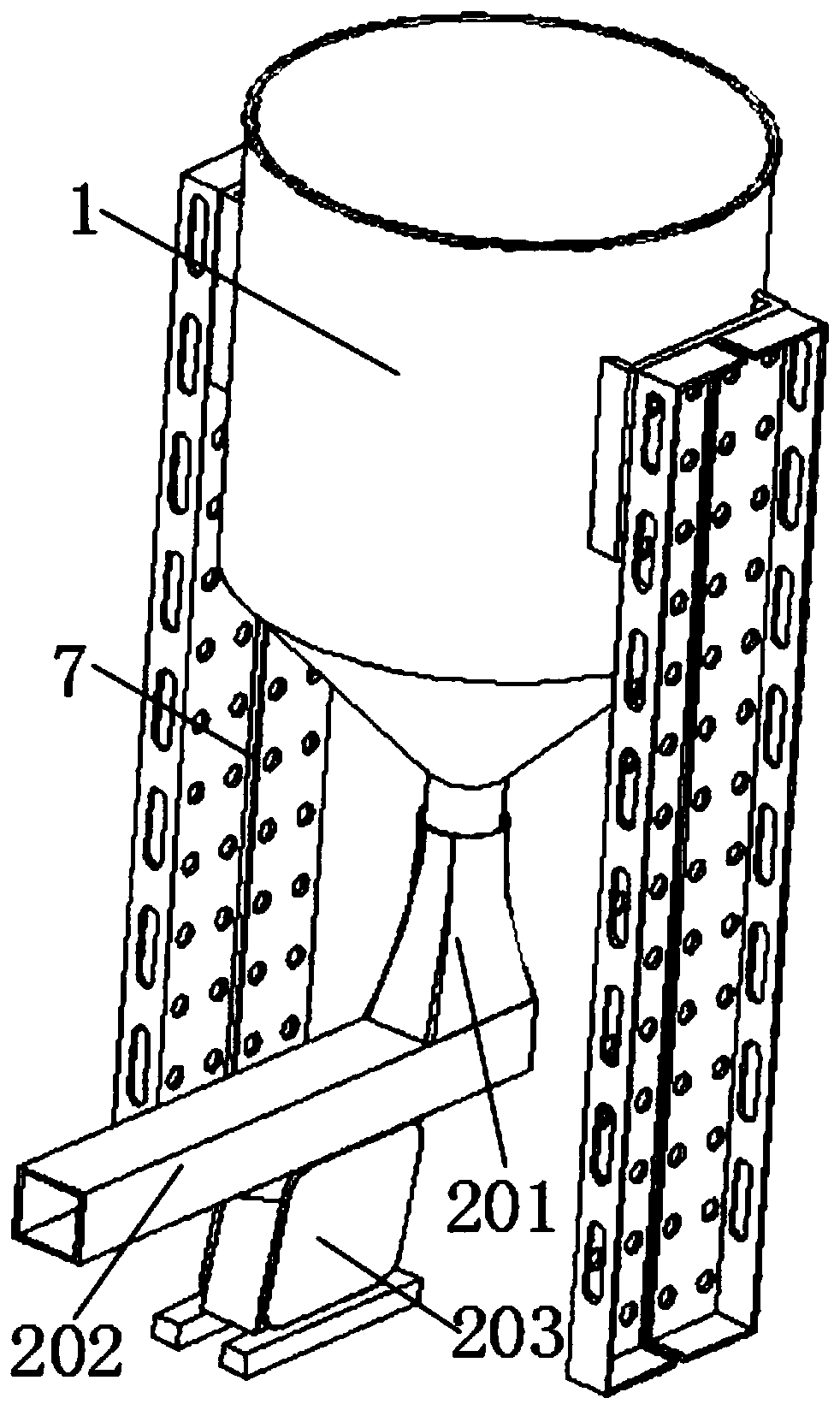

Novel special batching machine for food heating bags

PendingCN110052196AConvenient blankingAvoid dustRotary stirring mixersTransportation and packagingPurchase costEngineering

The invention discloses a novel special batching machine for food heating bags. The novel special batching machine for food heating bags comprises a first support frame, a second support frame is arranged at the upper end of the first support frame, a storage barrel is arranged in the second support frame, and a linear feeding mechanism is connected to the lower end of the storage barrel. The novel special batching machine for food heating bags has the advantages that an original feeding and weighing mode is changed to prevent flying dust during feeding and weighing, so that materials are weighed and metered more accurately and can be stirred quickly, and a stirring mechanism can be separated from a stirring box; a cover of the rapid stirring mechanism can prevent the flying dust during stirring, feeding and stirring can be alternatively carried out, the materials inside the stirring box can discharge conveniently to prevent the flying dust during stirring and bagging, and accordinglyboth labor and time cost are saved effectively; a stirring and discharging alternating mechanism substitutes for a stirring device and a screw feeder in the prior art, and accordingly purchased cost of equipment can be saved.

Owner:长兴顶盛科技有限公司

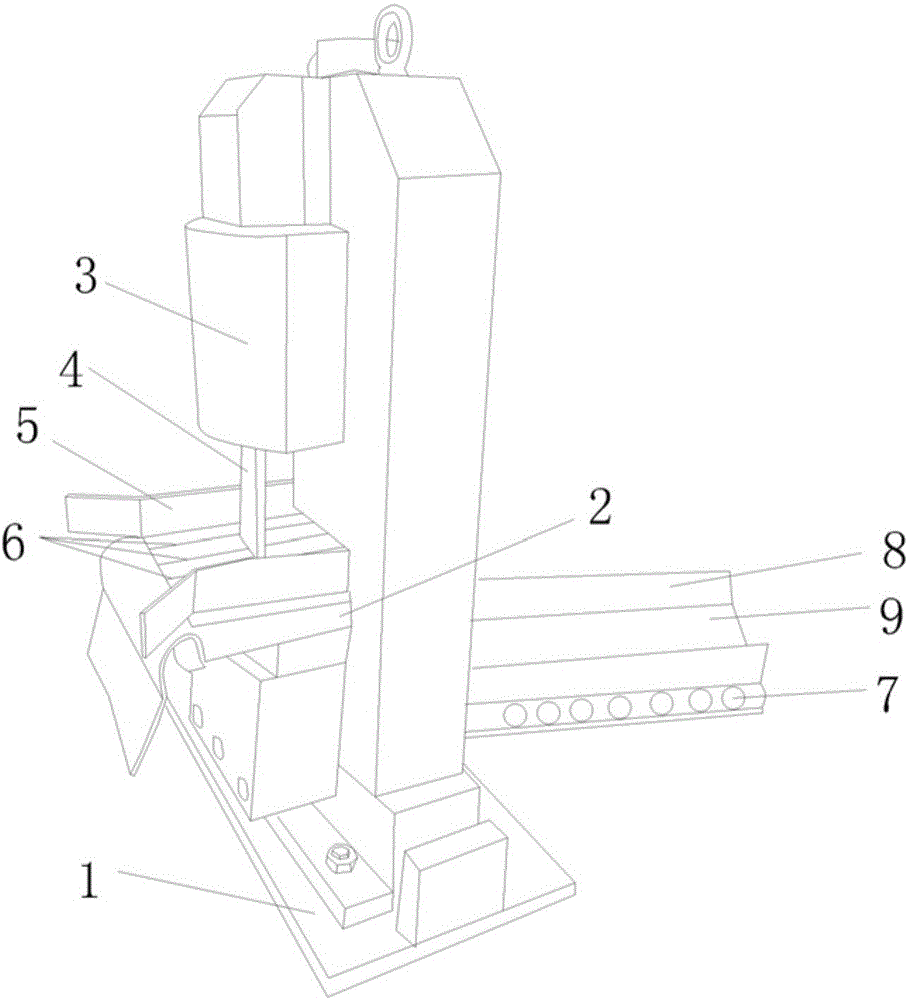

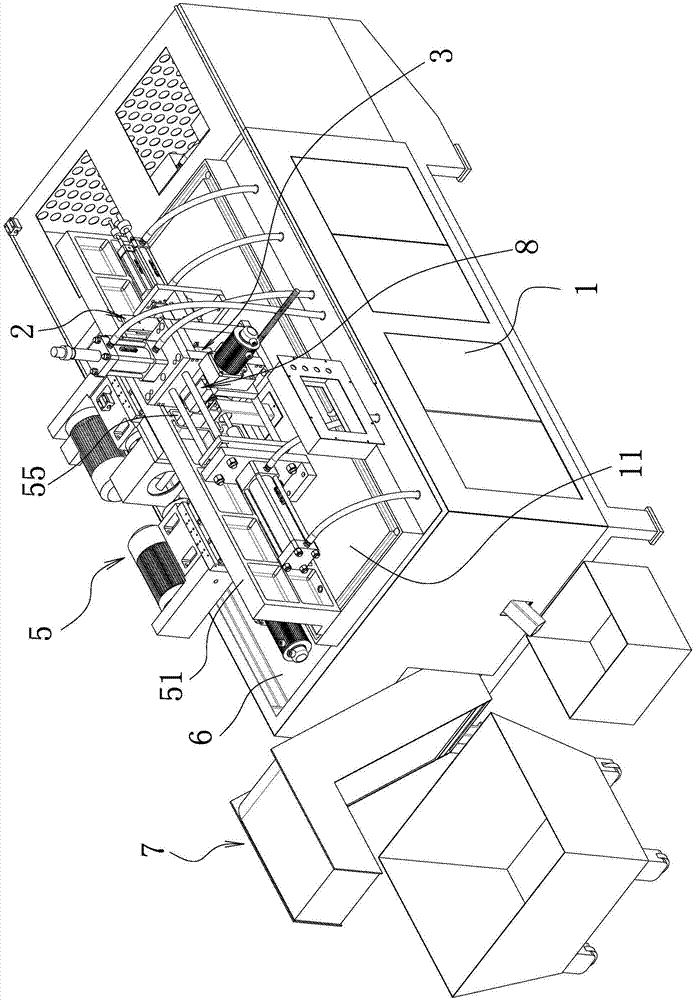

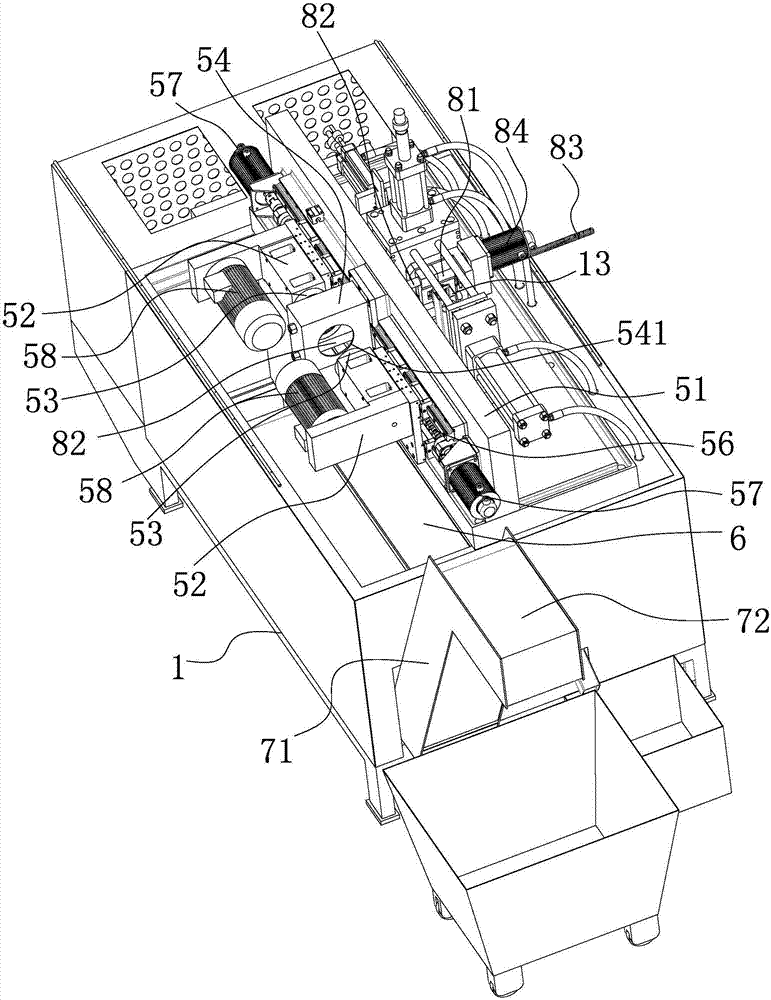

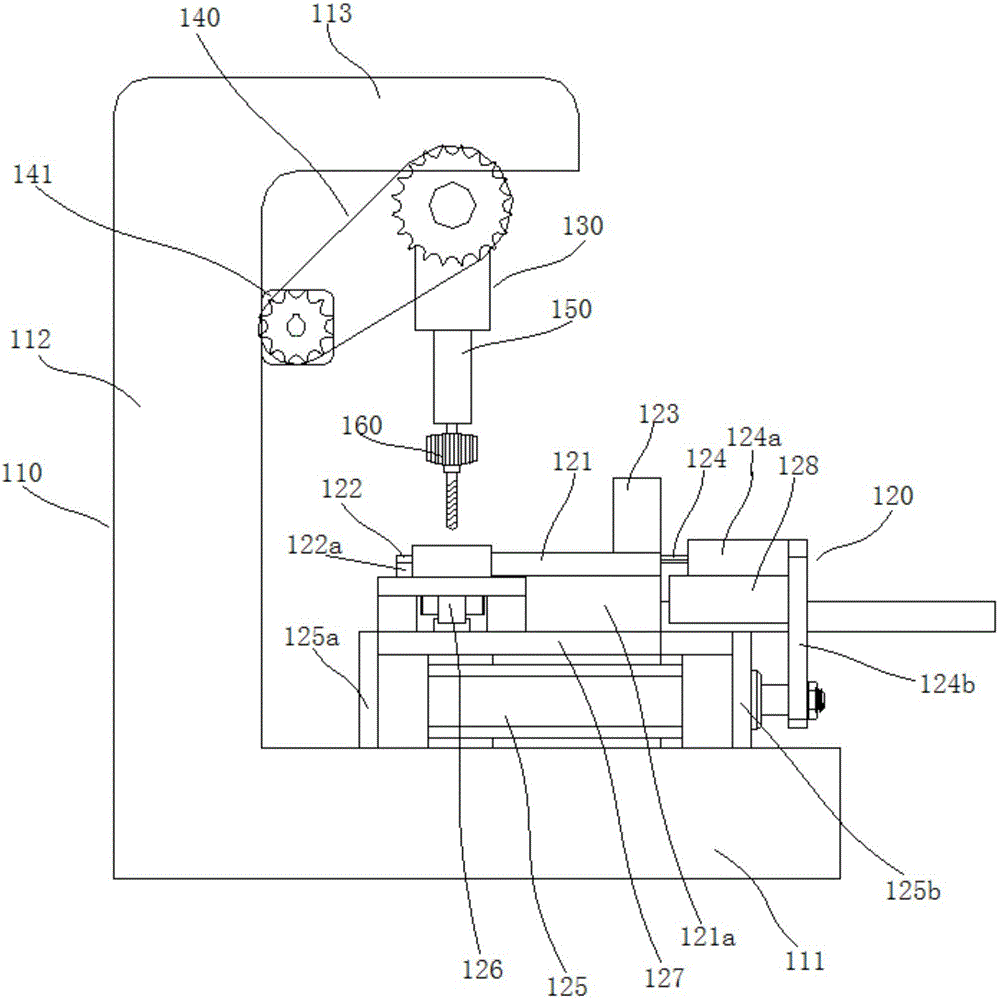

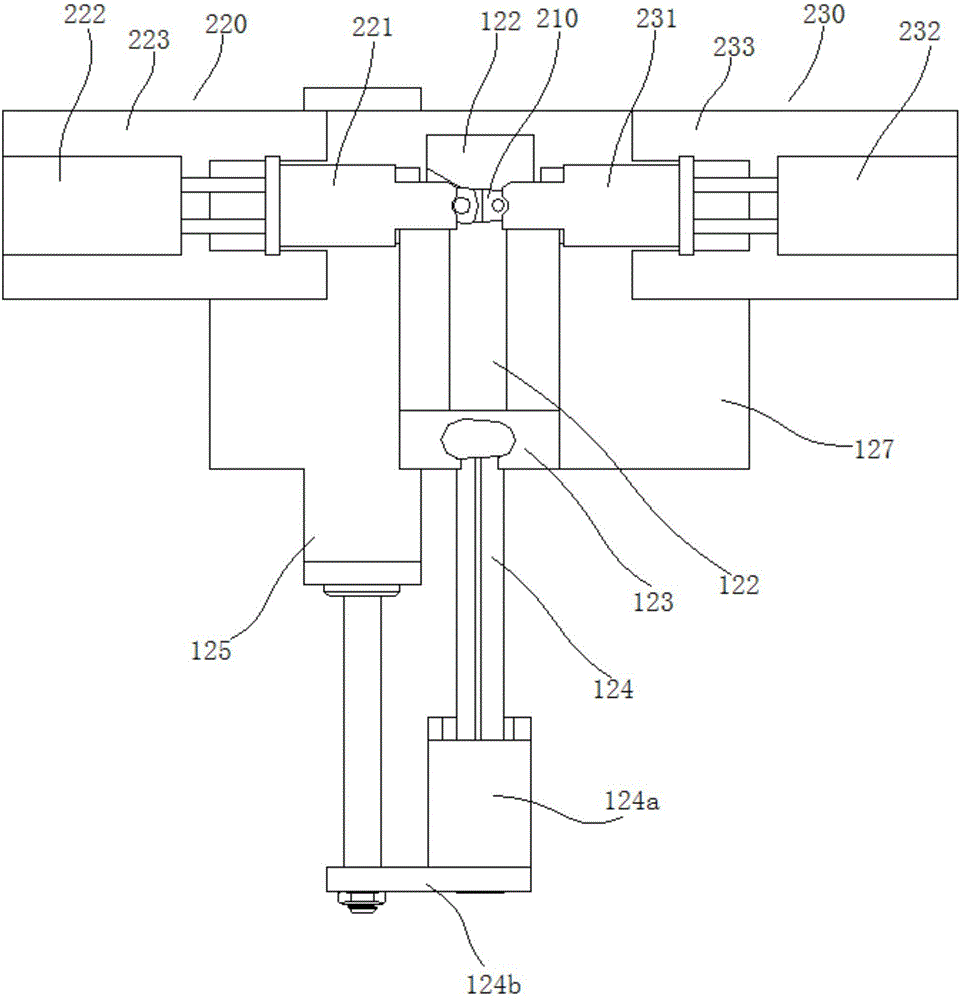

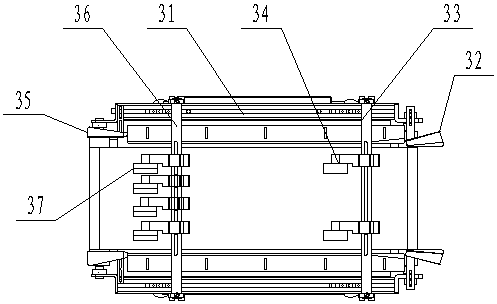

Automatic reaming machine of transition chain plates

ActiveCN105798388AAutomated reamingImprove efficiencyReaming devicesMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of chain manufacturing equipment, and relates to an automatic reaming machine of transition chain plates. The machine comprises a C-shaped frame; the frame includes a baseplate; a top plate is arranged above the baseplate through a connecting plate; a feeding mechanism is arranged on the baseplate; a perforating mechanism is arranged on the top plate; the feeding mechanism includes a feeding chute; a positioning plate is arranged at one end of the feeding chute; a piece cylinder for storing the transition chain plates is arranged at the other end of the feeding chute, and is matched with a feeding plate; the feeding plate is driven by a feeding cylinder to push the transition chain plates in the piece cylinder to the positioning plate along the feeding chute; the perforating mechanism includes a transmission mechanism, a lifting mechanism and a drilling and reaming mechanism; the drilling and reaming mechanism is connected with the lifting mechanism, and is positioned rightly above the transition chain plates pushed to the positioning plate; and the transmission mechanism is used for driving the lifting mechanism to lift. The machine can preferably realize automatic reaming of the transition chain plates.

Owner:HANGZHOU SHIELD CHAIN

Novel plate stamping mechanical equipment convenient for stamping

InactiveCN112517710AEasy to identifyEasy to manageShaping toolsMetal-working feeding devicesReciprocating motionEngineering

The invention discloses novel plate stamping mechanical equipment convenient for stamping, and relates to the technical field of plate stamping mechanical equipment. The novel plate stamping mechanical equipment comprises a machine body, wherein a telescopic cavity is fixedly arranged in one side of the machine body; a punch is slidably arranged in the telescopic cavity; an upper die plate is fixedly arranged at the bottom end of the punch; a lower die plate is fixedly arranged at the top side of a supporting platform; the upper die plate is matched with the lower die plate; a driving mechanism is arranged at one side of the upper die plate; the driving mechanism is fixedly connected to the upper die plate; and material conveying rods are arranged at the two sides of the lower die plate. The novel plate stamping mechanical equipment is reasonable in structure and easy to operate, movement of the upper die plate is used for driving a multi-link mechanism to move, the two material conveying rods do parallel surrounding reciprocating motion, a stamped plate is jacked up by the material conveying rods and then continuously moves towards one side by a certain distance step by step, theaction that automatic feeding is conducted through the two material conveying rods and then automatic discharging is conducted is achieved, and the operation safety is improved.

Owner:德清县杰创机械有限公司

Multifunctional cooking unit and cooking device with cooking unit

PendingCN109527973ASimple structureEasy to make and useHousehold cleanersCooking vessel constructionsEngineeringMechanical engineering

The invention discloses a multifunctional cooking unit and a cooking device with the cooking unit. The multifunctional cooking unit comprises a cooking body, the cooking body is provided with a feeding port and a discharging port, and a cooking cavity and a feeding cavity are formed in the cooking body from top to bottom in sequence; a rotation cooking mechanism is arranged in the cooking cavity,and a rotation feeding structure is arranged in the feeding cavity and comprises a sealing plate and a feeding channel, wherein the sealing plate and the cooking cavity are matched to form a sealing cooking cavity, and the feeding channel is used for introducing materials in the cooking cavity to the discharging port. The multifunctional cooking unit is simple in structure, convenient to manufacture and use, small in size and capable of occupying small space, and processing and feeding of various kinds of food can be achieved.

Owner:赵星

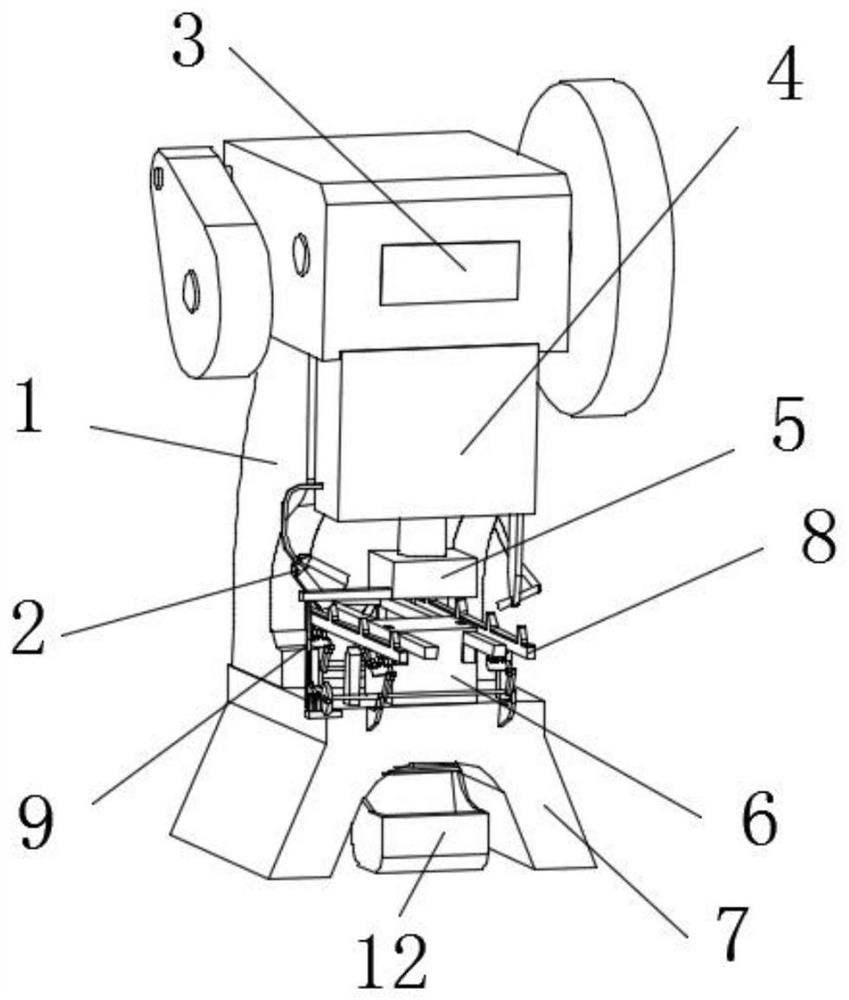

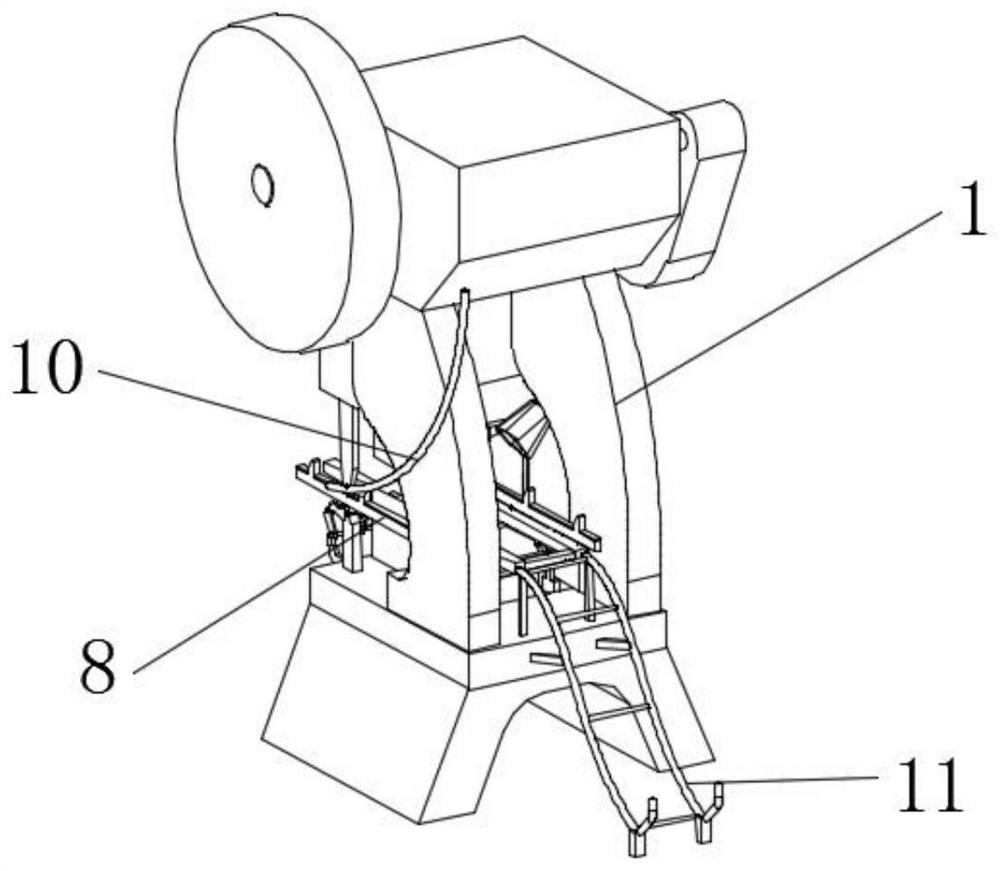

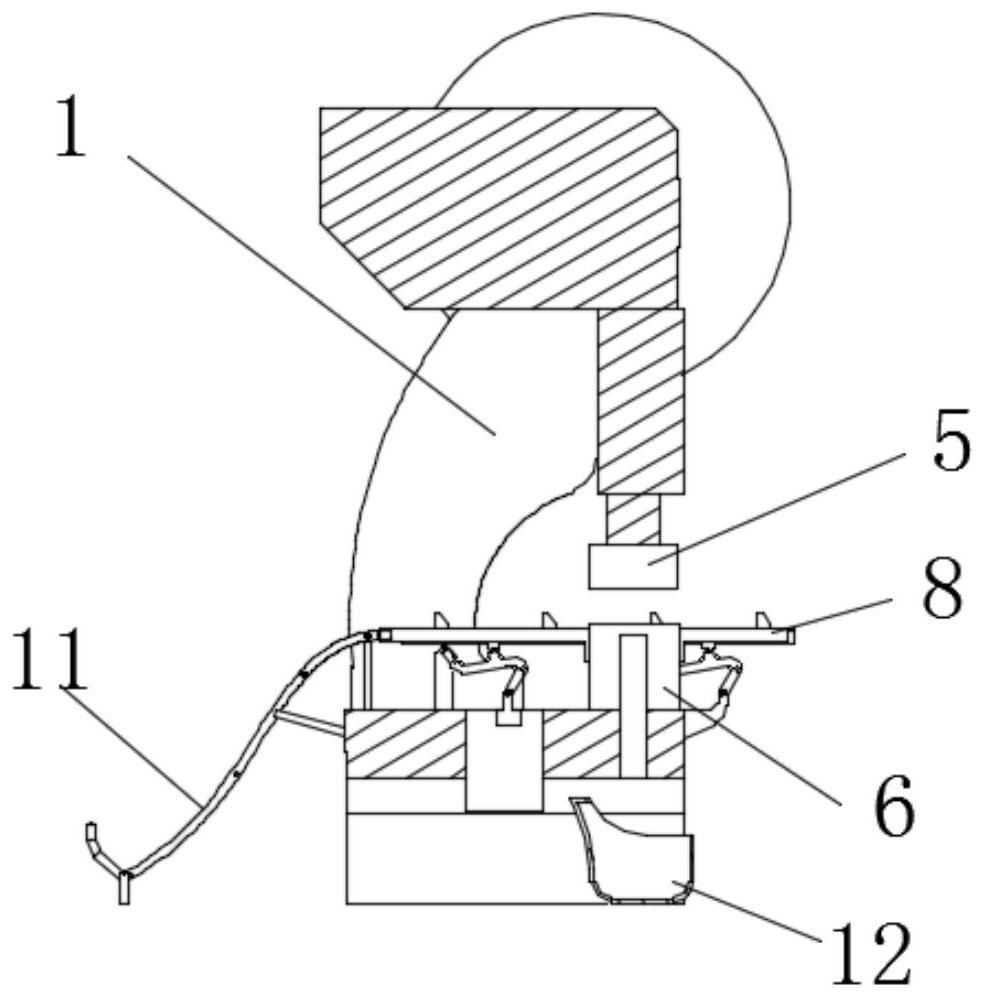

Wing surface punching device of automobile U-shaped beam

ActiveCN103433357ALow powerSmall passive inertiaPerforating toolsMetal-working feeding devicesPunchingShaped beam

The invention discloses a wing surface punching device of an automobile U-shaped beam, and belongs to the field of punching machine tools. The wing surface punching device of the automobile U-shaped beam comprises a main sliding block arranged on a machine frame. A die assembly is arranged corresponding to the main sliding block, the die assembly comprises a plurality of male dies and a plurality of female dies which correspond to one another, and the male dies are arranged inside a male die guide holder. Male die push rods which abut against one ends of the male dies respectively are arranged inside the male die guide holder. The male die guide holder and the female dies are mounted on a die holder support. The main sliding block is fixedly connected with a cylinder support, the cylinder support is provided with a plurality of die selection cylinders, the lower ends of piston rods of the die selection cylinders are connected with die selection push blocks, and the die selection push blocks are correspondingly arranged between the sliding block and the male dies. A die set guide plate is arranged at the position, corresponding to the side face of the die holder support, of the machine frame. A blanking channel is arranged in the position, corresponding to the positions of the female dies, of the die set guide plate. A lifting motor is arranged on the lower side of the die holder support on the machine frame, and the upper end of a spindle of the lifting motor is connected with the bottom of the die holder support through a ball screw mechanism. By means of the wing surface punching device of the automobile U-shaped beam, waste blanking is convenient, feeding can not be affected, and machining energy consumption is low.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

Pigeon feeder and mounting method thereof

The invention relates to a pigeon feeder, which comprises a feed box for storing feed and a feed trough for feeding pigeons. The feed trough is communicated with the feed box and fixed below the feed box. A baffle is arranged at a discharge hole of the feed box and provided with an opening as wide as the feed. The invention further relates to a mounting method of the pigeon feeder, which is characterized in that a left pigeon cage and a right pigeon cage are abutted to each other, the pigeon feeder is mounted on the left pigeon cage and the right pigeon cage trough hooks, one part of the pigeon feeder directly faces the left pigeon cage, the other part of the pigeon directly faces the right pigeon cage, and the bottom of each pigeon cage is 11-12cm away from the upper end of the baffle. The pigeon feeder has the advantages of material economization, labor saving, simple structure, cleanness, durability, low price, operational convenience and the like.

Owner:黄镜明

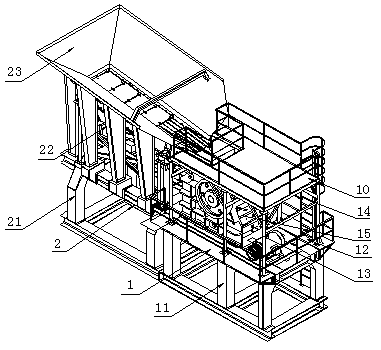

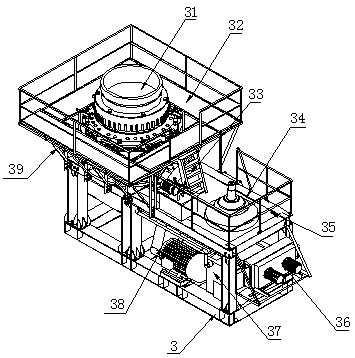

Movable assembly type large-scale stone feeding crushing and screening device

The invention relates to a movable assembly type large-scale stone feeding crushing and screening device capable of rapidly assembling and forming and rapidly disassembly, assembly and moving. The stone feeding crushing and screening device is characterized in that a combined feeding module comprises a feeding machine supporting three-dimensional steel structure framework, a feeding machine, a jaw-breaking supporting three-dimensional steel structure frame and a jaw breaker; a combined crushing module comprises a cone crusher supporting three-dimensional steel structure framework, a cone crusher and a movable cone maintenance platform, wherein the cone crusher is installed on the cone crusher supporting three-dimensional steel structure framework, the movable cone maintenance platform is located on a supporting three-dimensional steel structure frame surface on one side of the cone crusher, and a maintenance simulation seat is arranged in the center of the movable cone maintenance platform; and a combined screening module comprises a vibration screen supporting three-dimensional steel structure framework, a vibrating screen, a vibrating screen discharging hopper and a vibrating screen dropping hopper, wherein the height of front supporting stand columns is lower than the height of rear supporting stand columns in the vibration screen supporting three-dimensional steel structureframework, so that the vibrating screen located on the front supporting stand columns and the rear supporting stand columns is obliquely distributed, and the vibrating screen discharging hopper is matched with a vibrating screen discharging opening and is horizontally supported by the multiple front supporting columns.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

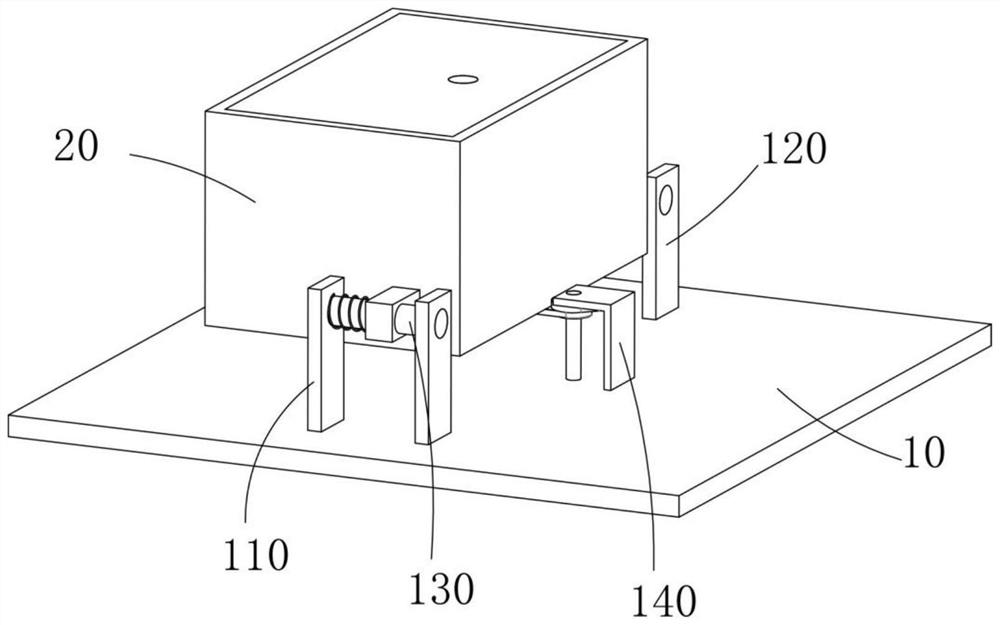

Glucosamine hydrochloric acid crystallization equipment

InactiveCN113893571AConvenient blankingSugar derivativesSolution crystallizationPhysicsComposite material

The invention discloses glucosamine hydrochloric acid crystallization equipment, which comprises a base, two first supporting plates, two second supporting plates, a guide rod and a crystallization box body, wherein the first supporting plates and the second supporting plates are vertically arranged on the base, the first supporting plates and the second supporting plates are oppositely arranged, the guide rod is horizontally connected between the two first supporting plates, the guide rod is horizontally connected between the two second supporting plates, the crystallization box body is a cuboid shell, the two ends, in the length direction, of the crystallization box body are arranged on the guide rod in a sleeving mode through connecting lugs, the guide rod is sleeved with a spring, the bottom of a bottom disc communicates with a communicating pipe, hot air can be introduced into the bottom disc through the communicating pipe to heat the bottom disc, a material removing mechanism is arranged in the crystallization box body, glucosamine hydrochloric acid enters the crystallization box body through a feeding port and is located on the bottom disc, the bottom discheats the glucosamine hydrochloric acid to obtain a concentrated saturated solution, cooling crystallization is conducted to obtain a crystal, the crystal is located on the bottom disc, and the crystal can be removed and collected through the material removing mechanism.

Owner:许妙飞

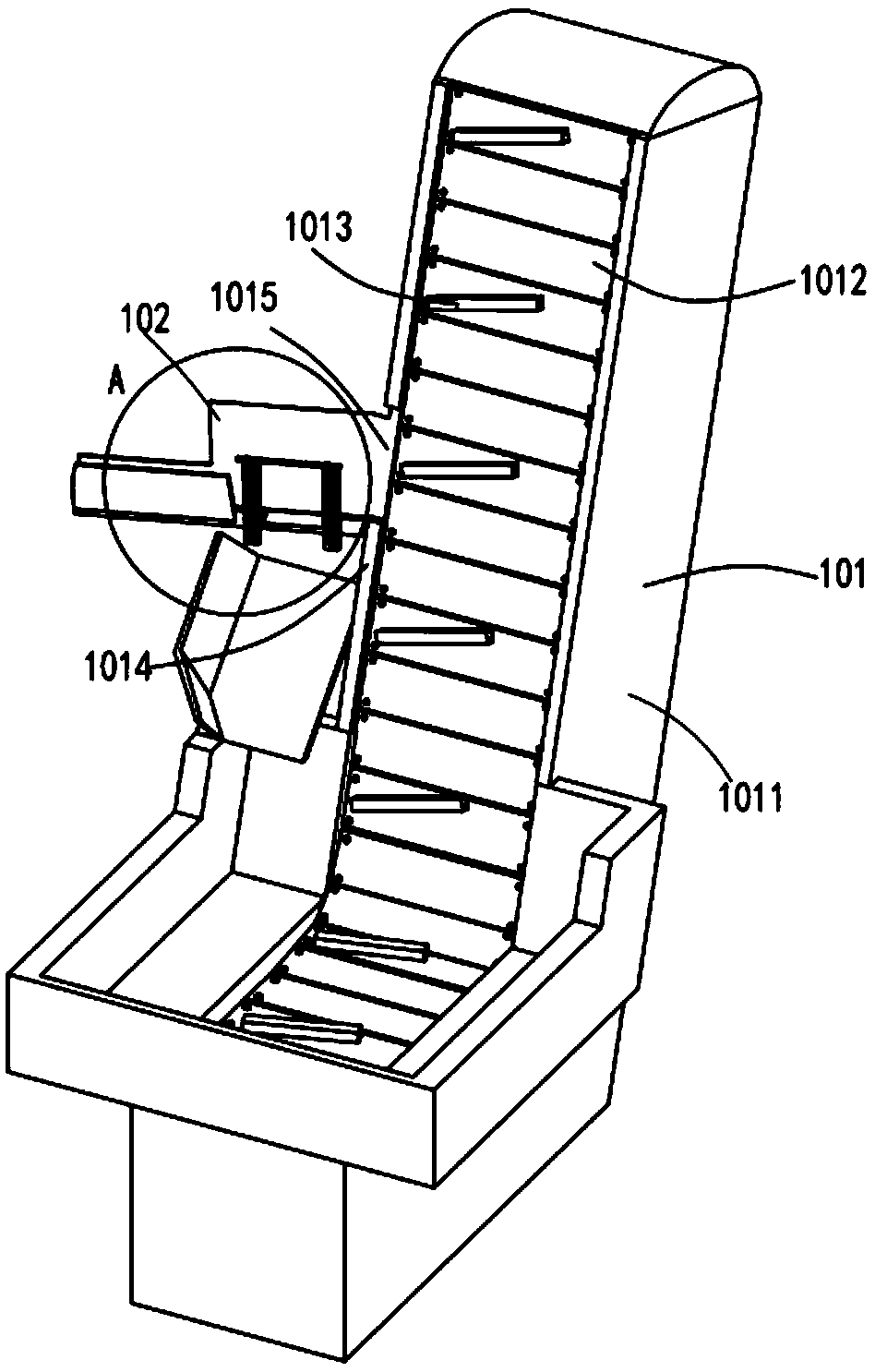

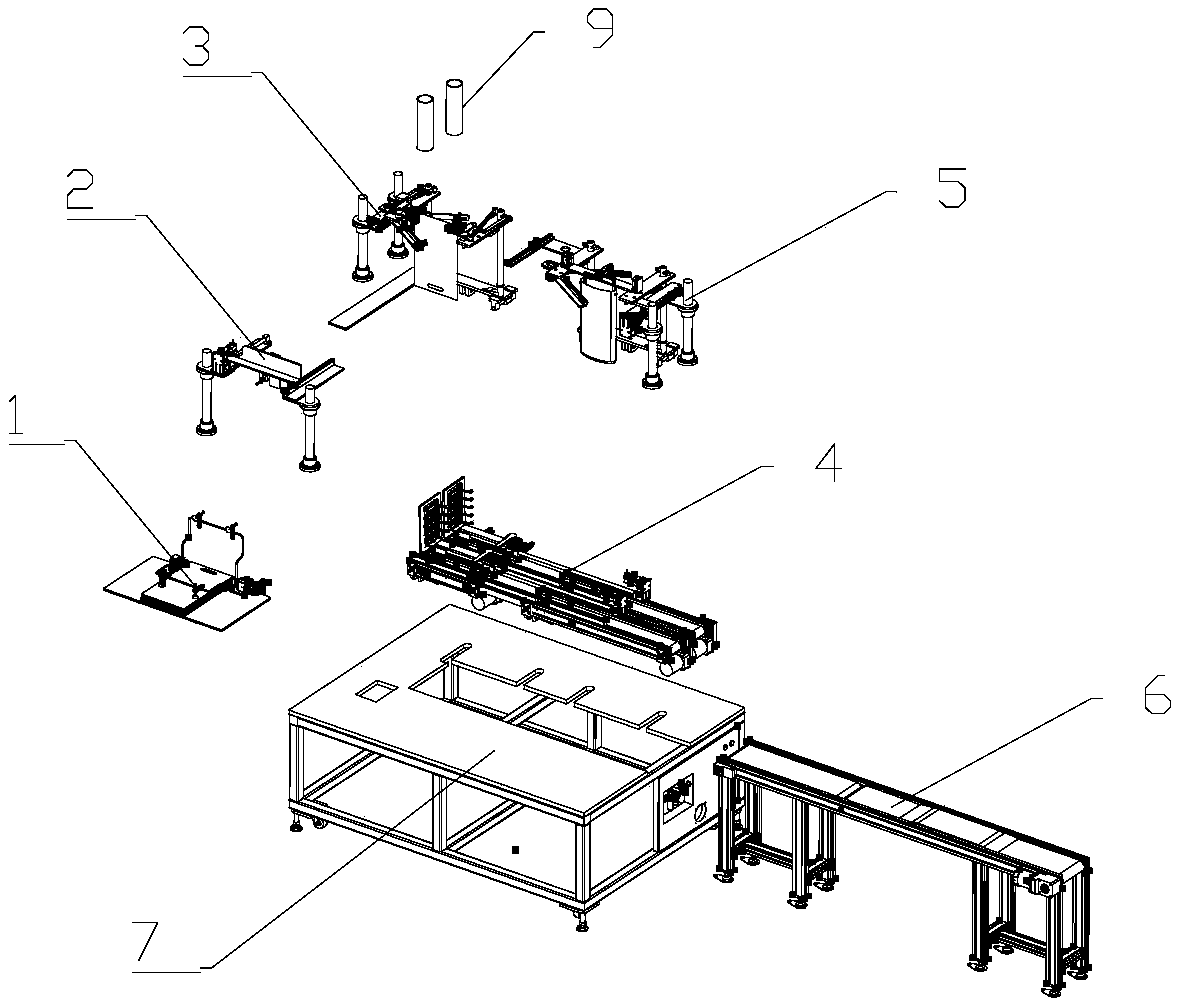

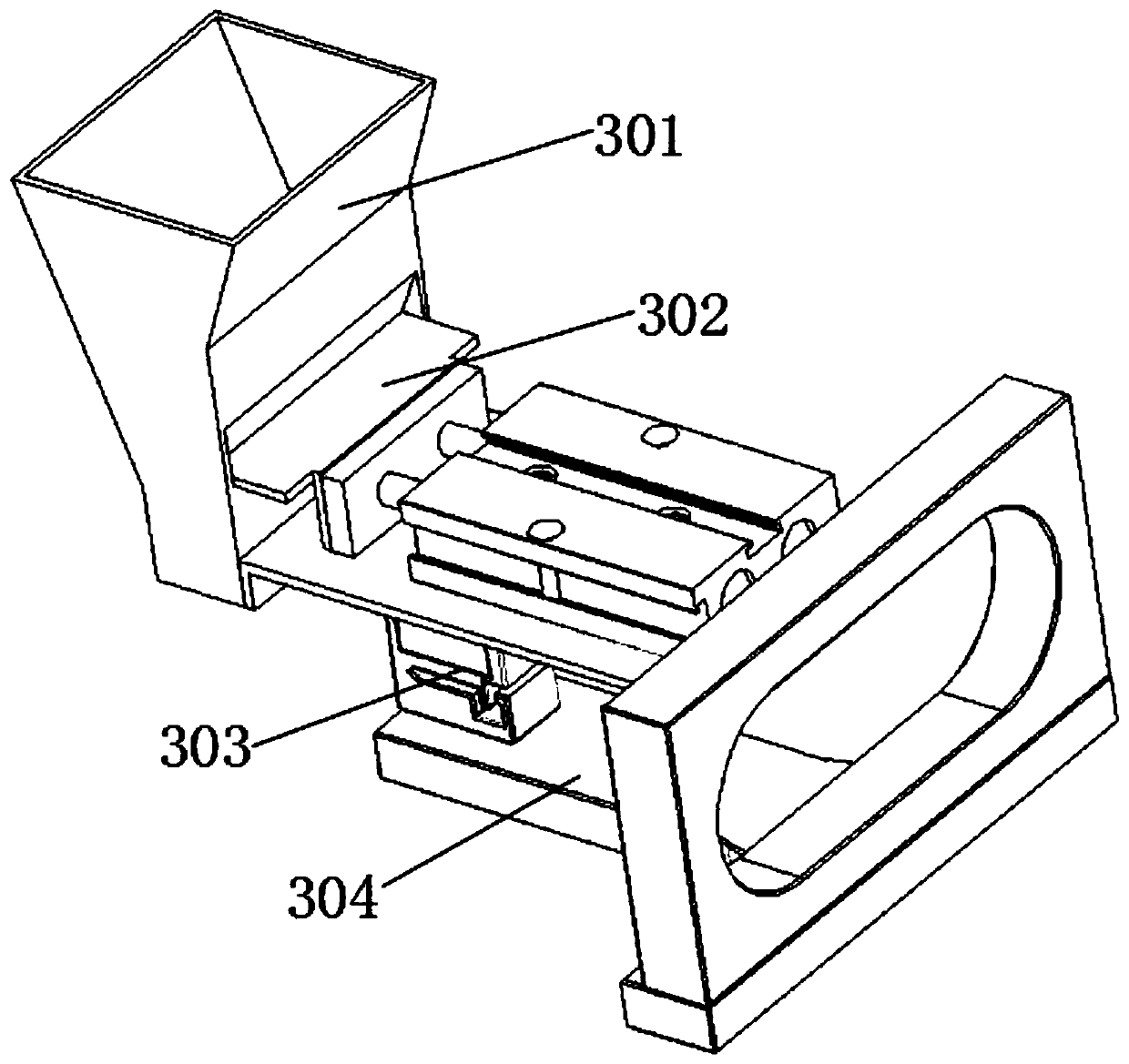

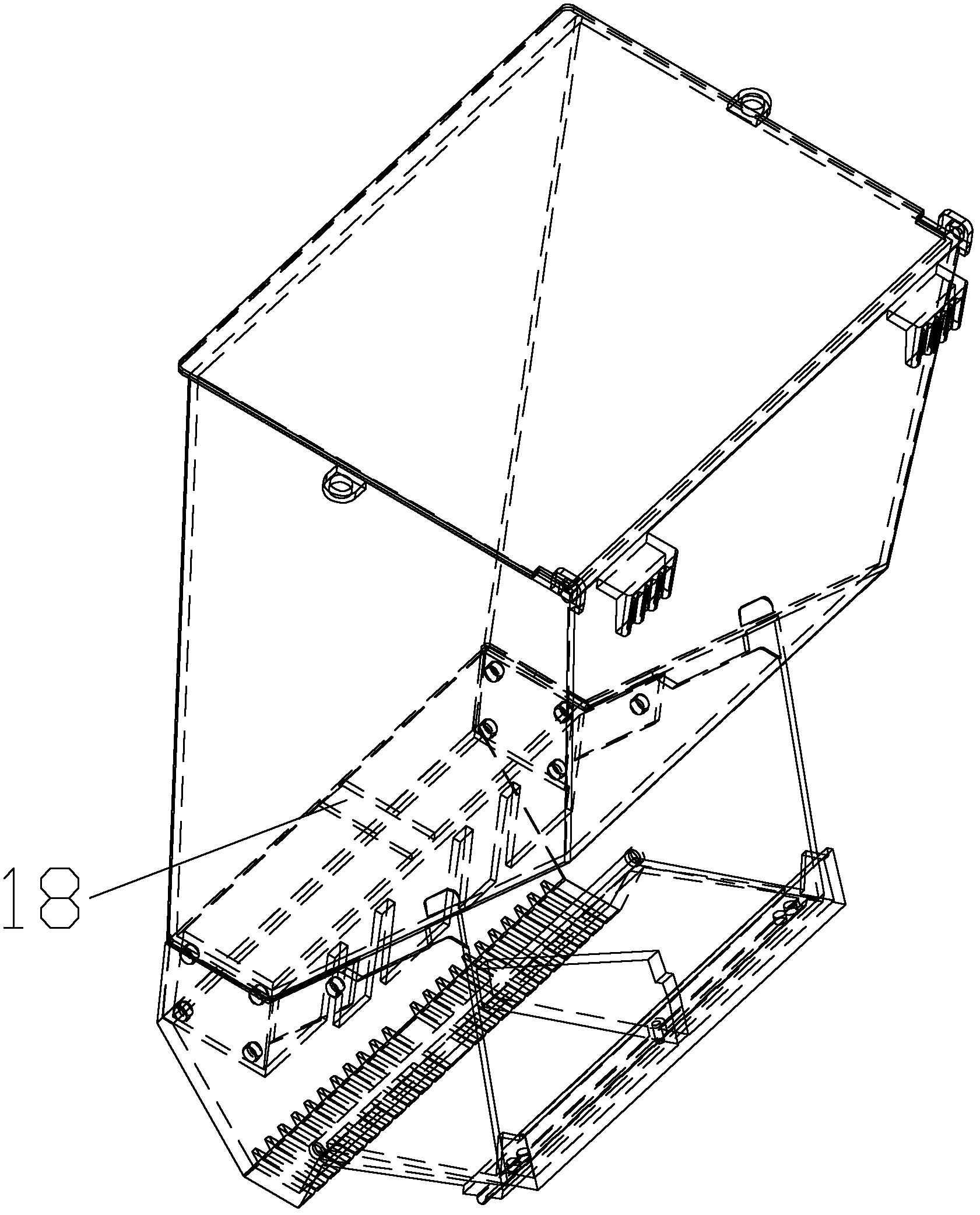

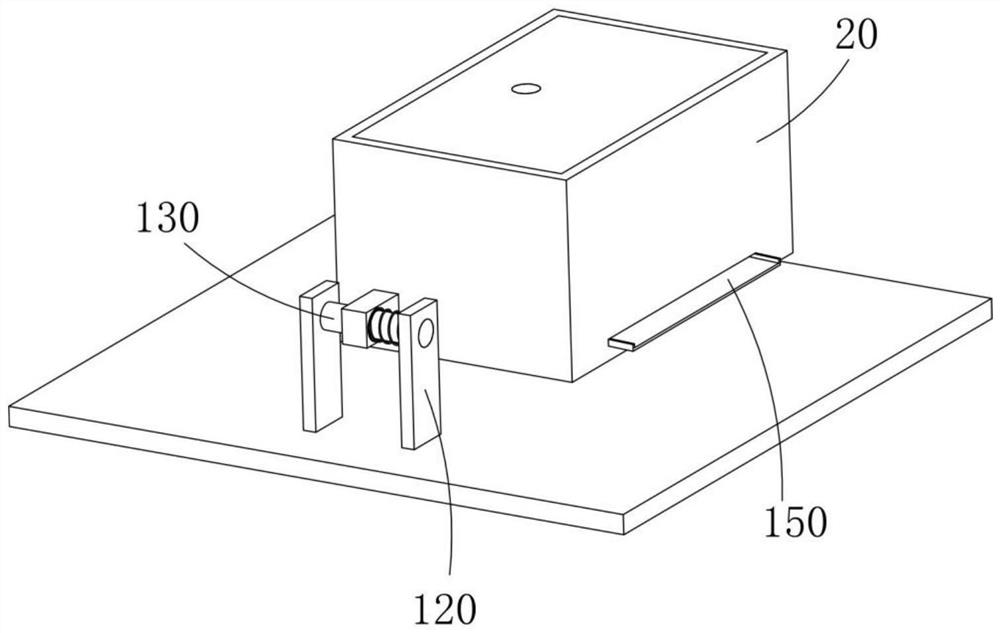

Single-piece taking structure for automatic flattening and shaping collection system of cigarette bar box leather

PendingCN109204975AEasy to take outConvenient blankingPackagingArticle feedersCollection systemEngineering

The invention discloses a single-piece taking structure for an automatic flattening and shaping collection system of a cigarette bar box leather, and the structure comprises a laying-off control mechanism, a sucking disc mechanism and a material pushing mechanism. The laying-off control mechanism comprises a left baffle plate and a right baffle plate which are located below a material warehouse and are respectively located at the left and right sides of the material warehouse. The left and right baffle plates extend in the front-back surface, and are respectively disposed above a conveying machine frame through a support. The left baffle plate is rotatingly connected with the corresponding support, and achieves the reciprocating swinging through a laying-off drive mechanism. The right baffle plate is fixedly connected with the corresponding support. The sucking disc mechanism comprises at least two columns of sucking disc assemblies, and the corresponding column of sucking disc assemblies are located at the gaps at two sides of an air sucking belt, and are sunken into the conveying machine frame. The material pushing mechanism is located at the right side of the single-piece takingstructure, and a material pushing plate points to the left side. The structure provided by the invention can automatically take out a single box leather from the material warehouse and place the single box leather on a conveying structure.

Owner:CHINA TOBACCO HENAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com