Full-automatic cell separation device based on cell machining

A cell, fully automatic technology, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of high processing cost, easy breakage, time-consuming and labor-intensive, etc., and achieve high processing efficiency, stable quality, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

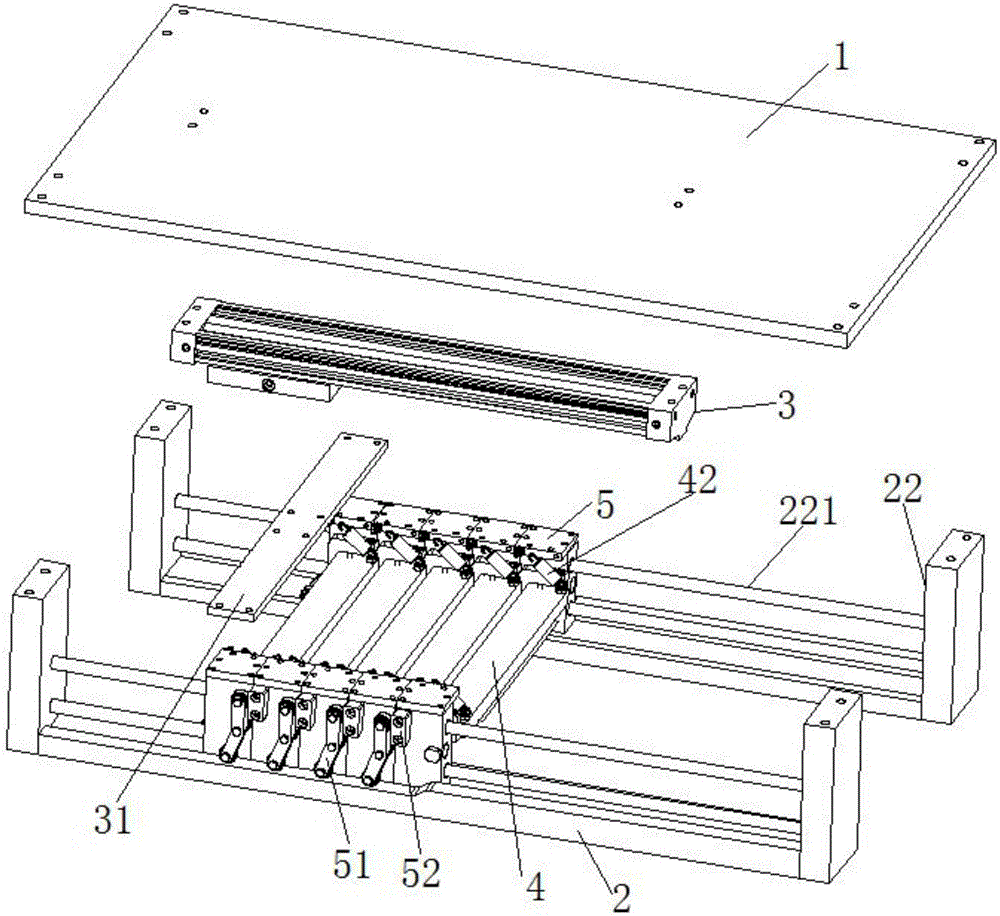

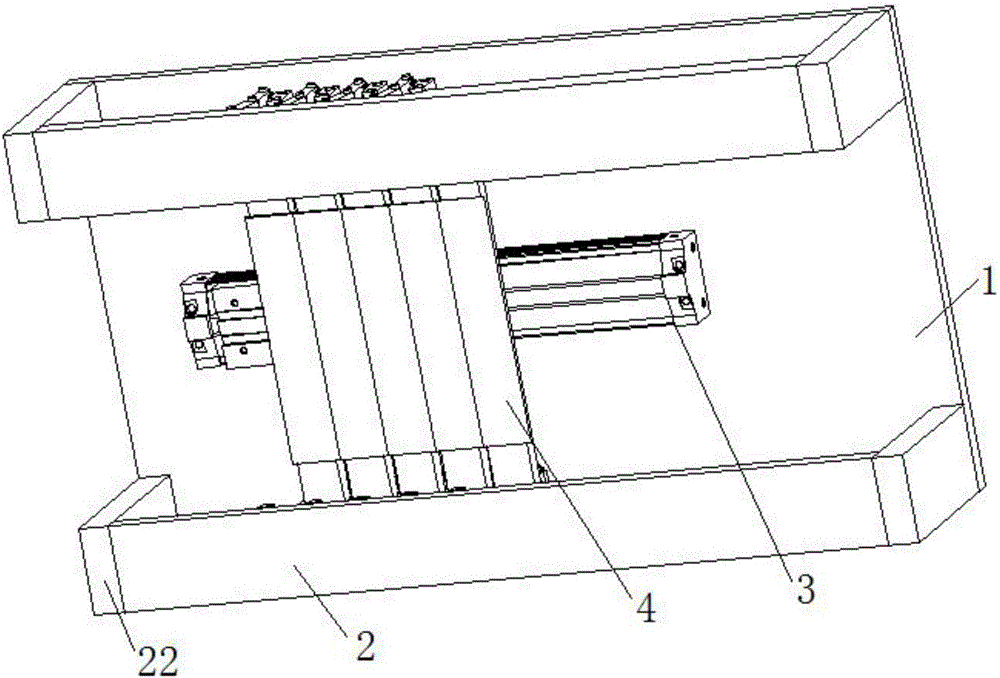

[0036] Example: such as Figures 1 to 4 As shown, the fully automatic chip breaking device based on cell processing in this embodiment includes a mounting plate 1, two linear guide rails 2, a linear drive device 3 and a plurality of chip breaking suction cups 4;

[0037] The two above-mentioned linear guide rails 2 are arranged side by side and in parallel, and are respectively fixed on the lower end of the above-mentioned mounting plate 1;

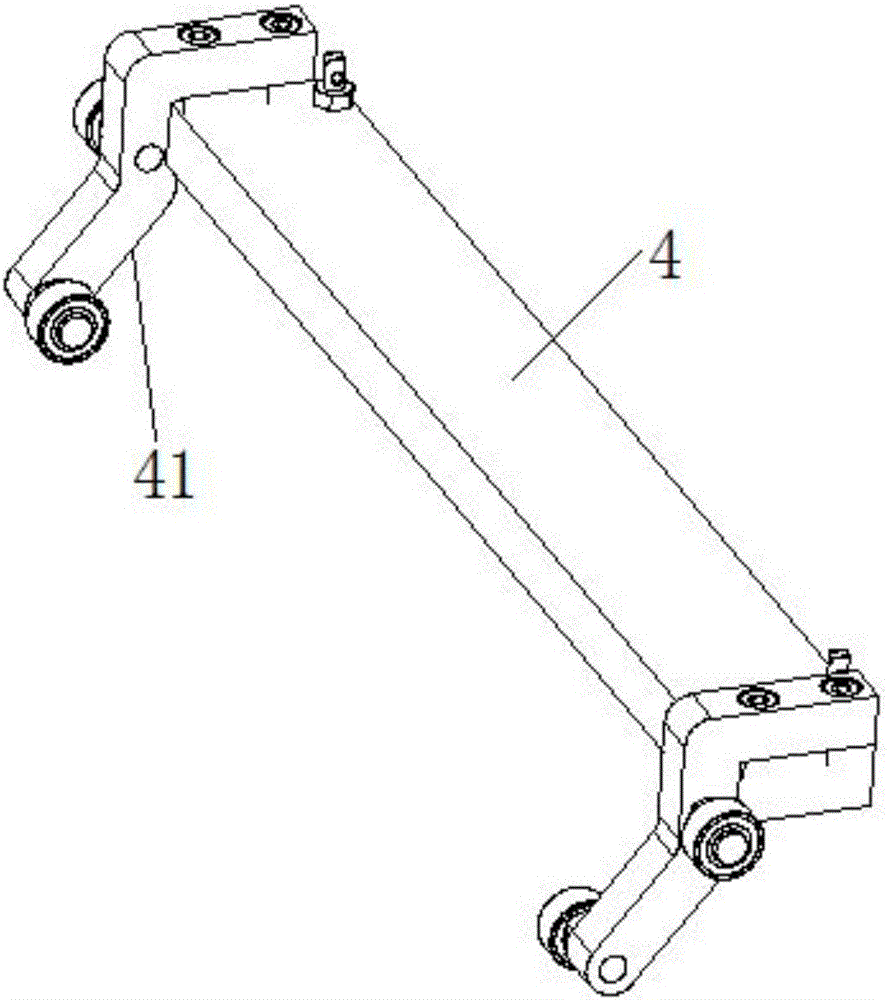

[0038] A plurality of above-mentioned piece-breaking suction cups 4 are all horizontally arranged and distributed side by side between the two above-mentioned linear guide rails 2, and are perpendicular to the above-mentioned linear guide rails 2 respectively, and the two ends of each above-mentioned piece-breaking suction cup 4 are respectively passed through slides connected to it in rotation. The block 5 is slidably installed on the corresponding linear guide rail 2, the lower end surfaces of the above-mentioned sheet-breaking suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com