Mixer

A technology of mixer and mixing hopper, which is applied to mixers, mixers with rotary mixing devices, mixer accessories, etc., can solve the problems of unclean discharge, residual material in mixing hoppers, scattered mixing containers, etc., to prevent scattering , The effect of clean blanking and convenient blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

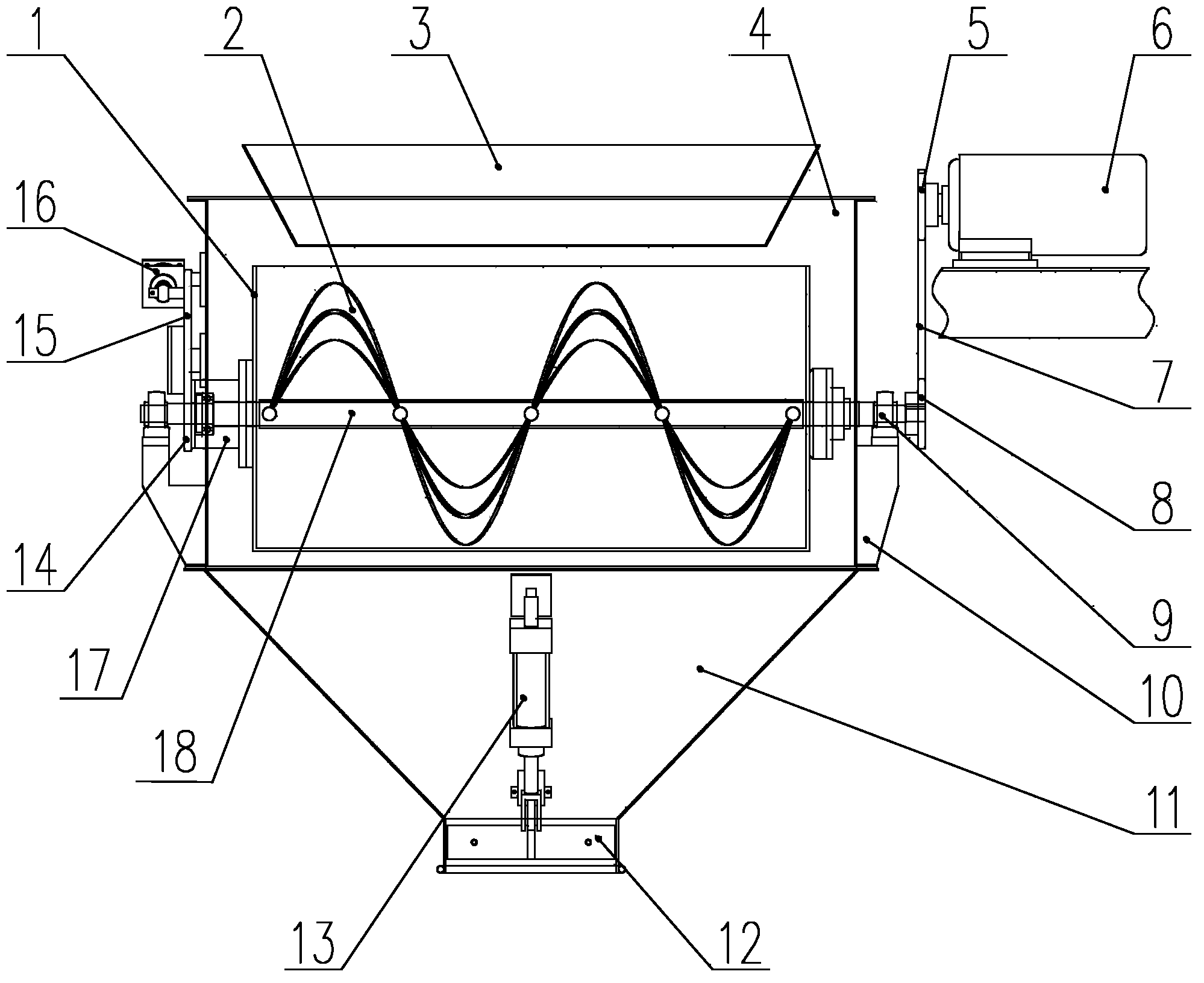

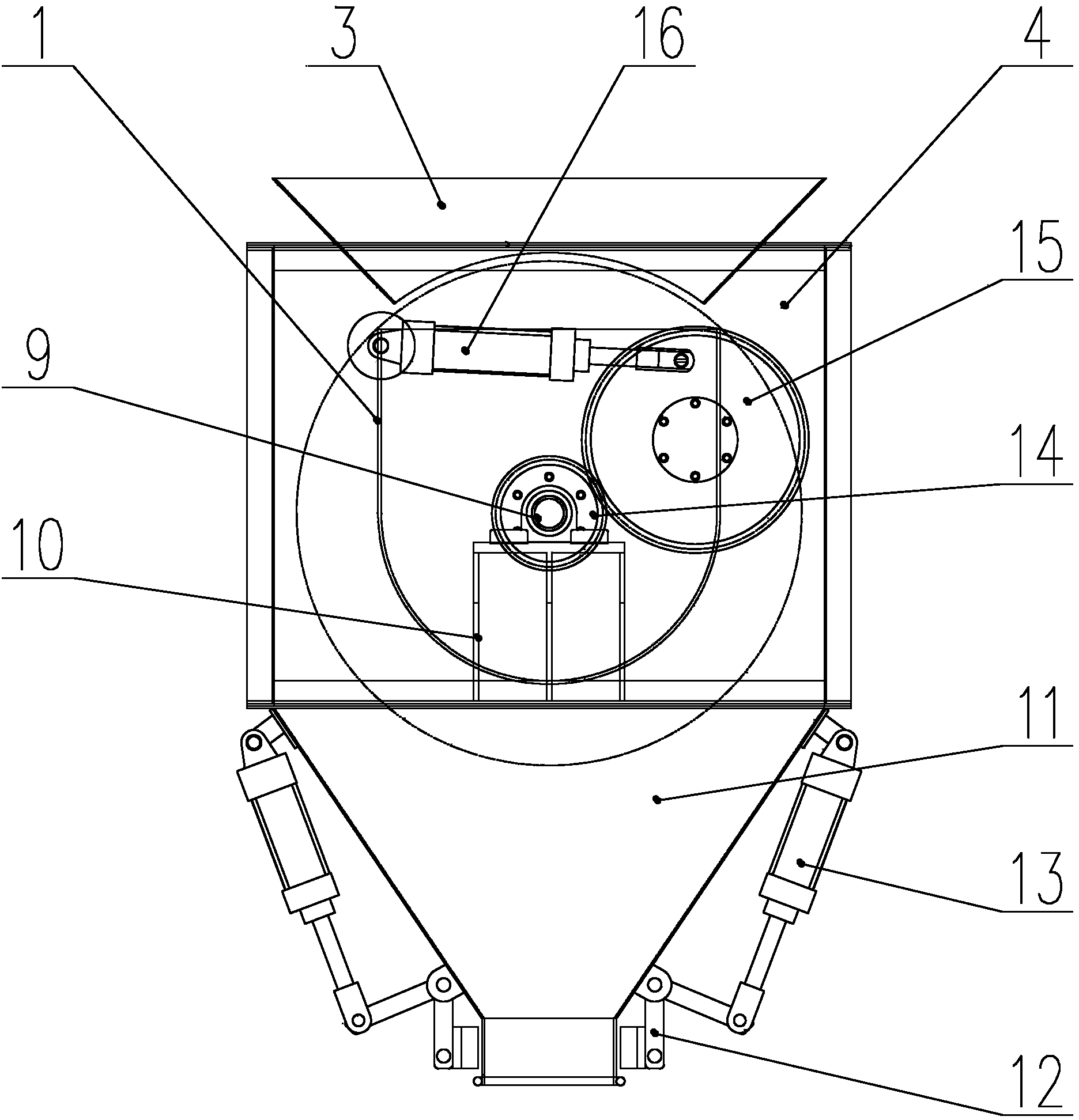

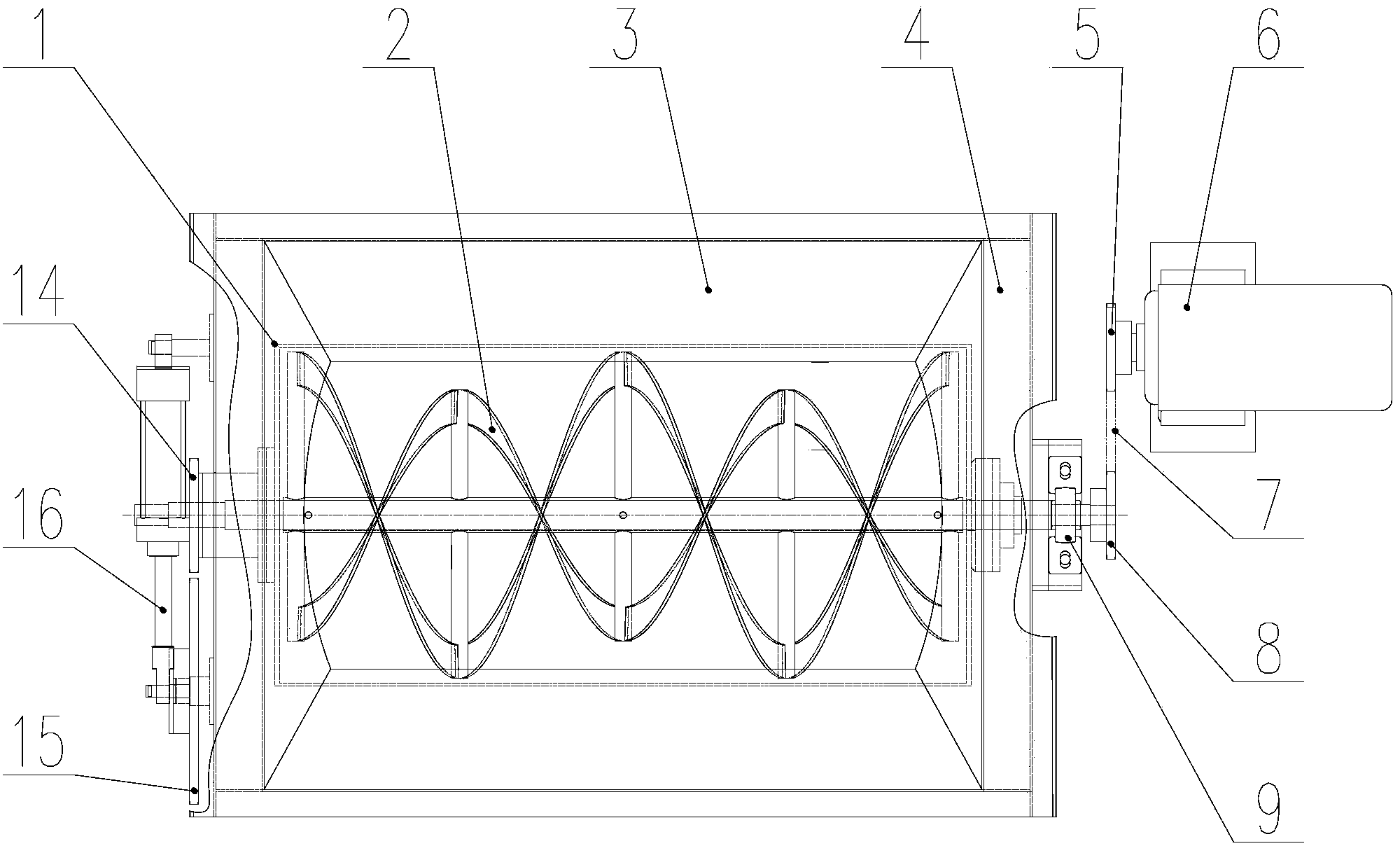

[0024] Such as Figures 1 to 3 Shown are the front, side and top views of a mixer in this embodiment, respectively, and the dotted lines represent structures that block the line of sight. A kind of embodiment of mixing machine, comprises outer cover 4, is provided with collection hopper 3 above outer cover 4, and is provided with packing bucket 11 below outer cover 4, and packing bucket 11 and outer cover 4 are movably connected, and the inner chamber of outer cover 4 and packing The inner cavities of the bucket 11 communicate with each other to form a continuous inner cavity.

[0025] The upper part of the collecting hopper 3 is a feed port, and the lower part is a discharge port, and the discharge port is aligned with the inner cavity of the outer cover 4 .

[0026] It also includes a mixing bucket 1 , which is arranged in the inner cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com