Automatic reaming machine of transition chain plates

A technology of reaming machine and chain plate, which is applied in the direction of reaming device, reaming device, metal processing, etc., can solve the problems of lack of automatic reaming device, deformation of connecting holes in the plate, low production efficiency, etc., and achieve the improvement of precision, Reasonable structure and effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

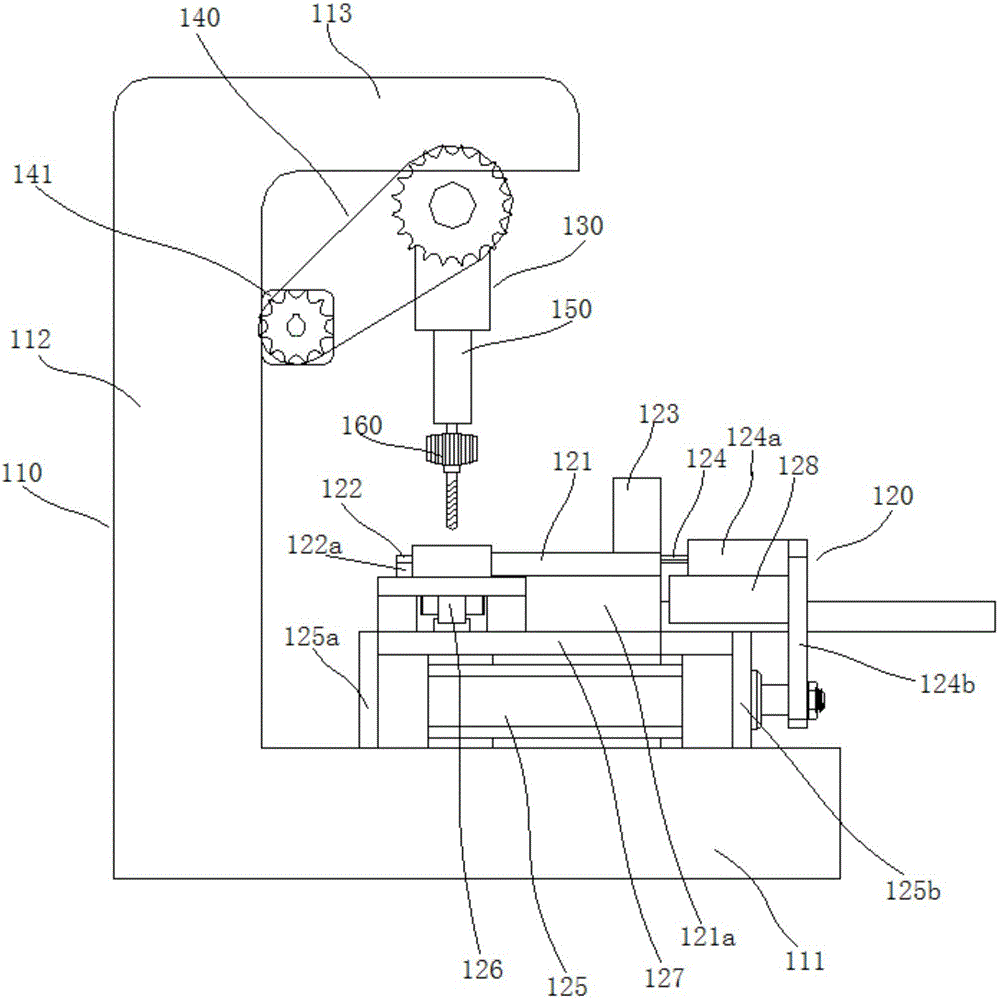

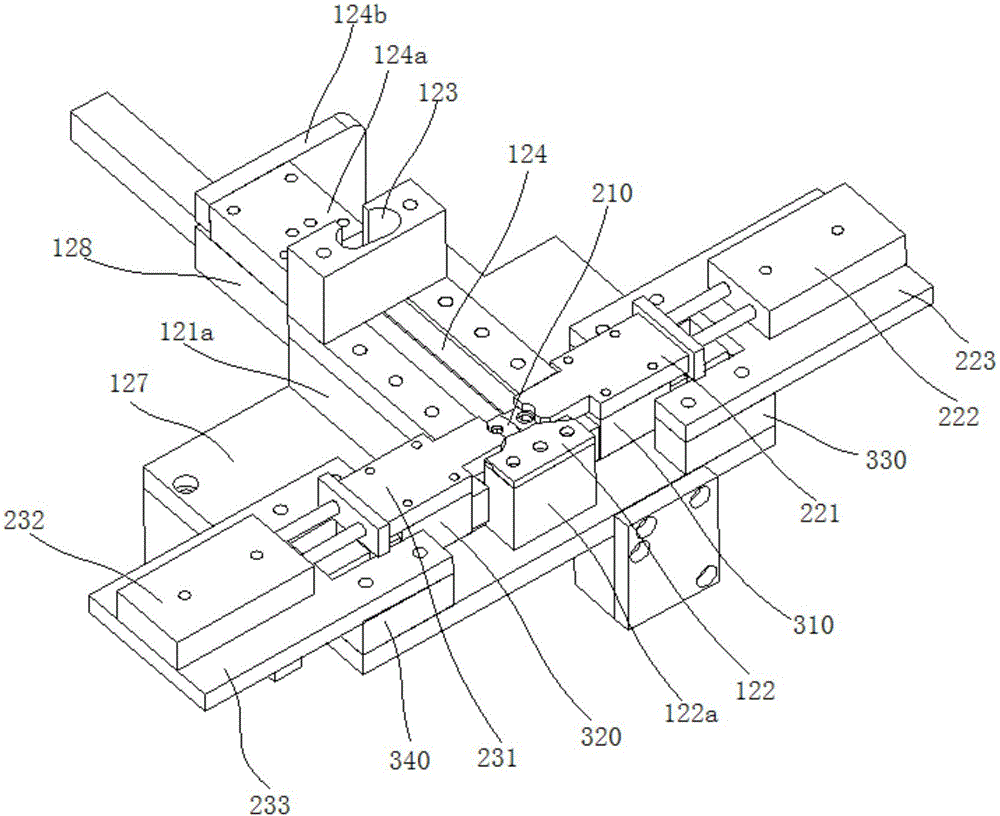

[0026] Such as figure 1 , 2 As shown in , 3, this embodiment provides an automatic reaming machine for transition chain plates, which can preferably replace manual reaming operations on transition chain plates, thus having better production efficiency, low cost and high precision .

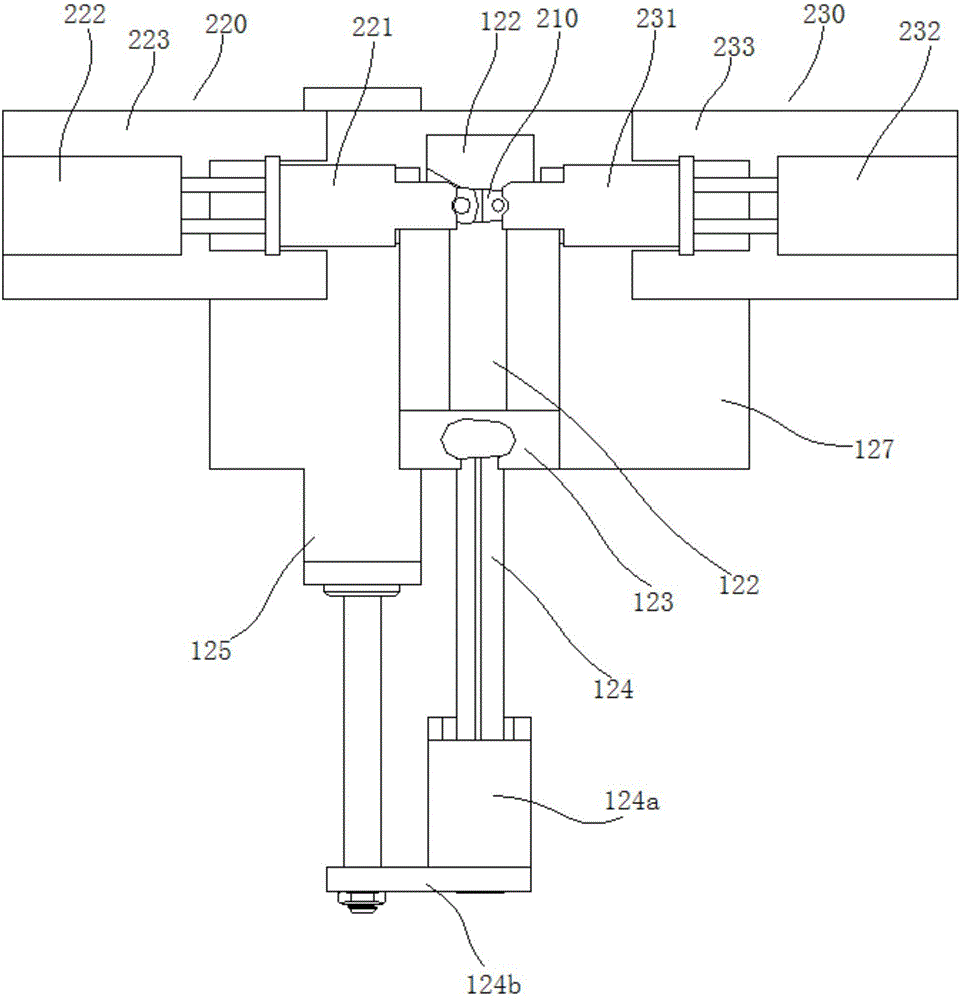

[0027] The automatic reaming machine for the transition chain plate in the present embodiment includes a frame 110 constructed into a "C" shape, and the frame 110 includes a bottom plate 111, and a top plate 113 is set through a connecting plate 112 above the bottom plate 111; the bottom plate 111 is provided with The feeding mechanism 120 is provided with a punching mechanism 130 at the top plate 113 .

[0028] Feeding mechanism 120 comprises feeding chute 121, and feeding chute 121 one end is provided with positioning plate 122, and feeding chute 121 other end is provided with sheet tube 123 for storing transition chain plate 210; Sheet tube 123 cooperates with a feeding plate 124, feeds Driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com