Novel plate stamping mechanical equipment convenient for stamping

A technology of mechanical equipment and new type of sheet metal, applied in the field of new sheet metal stamping machinery and equipment, can solve problems such as limited hand-held area, personal injury to workers, and danger, and achieve the effect of improving product quality, reasonable structure, and increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

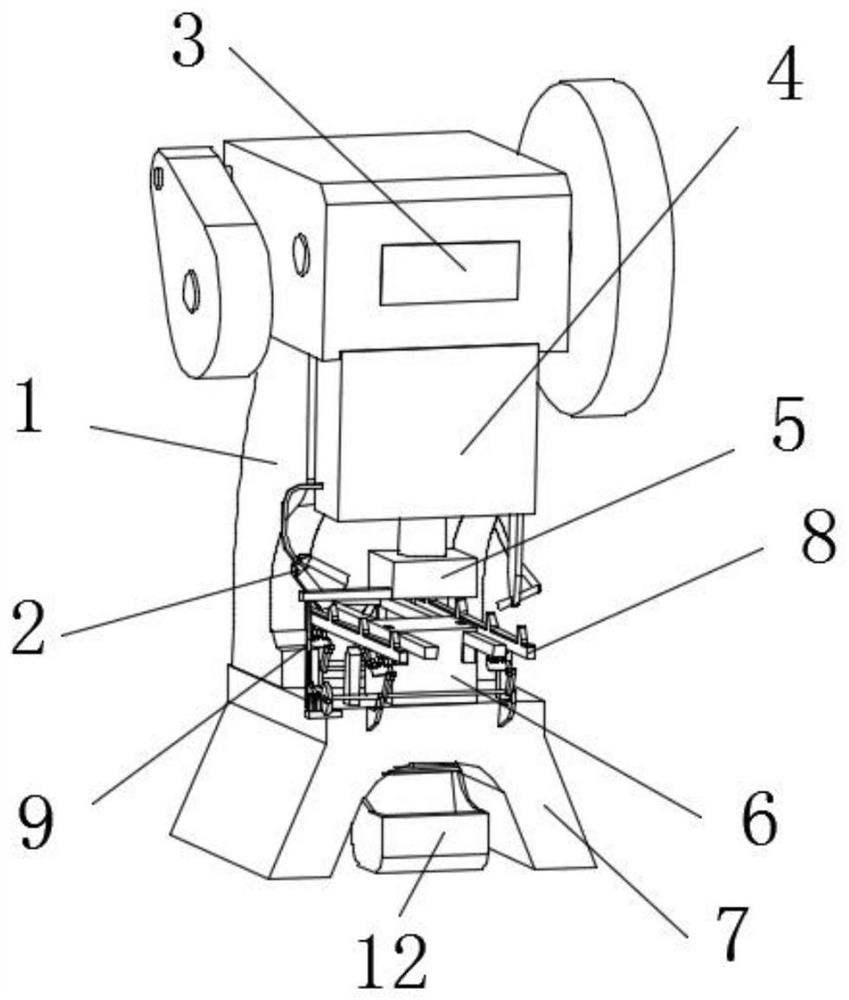

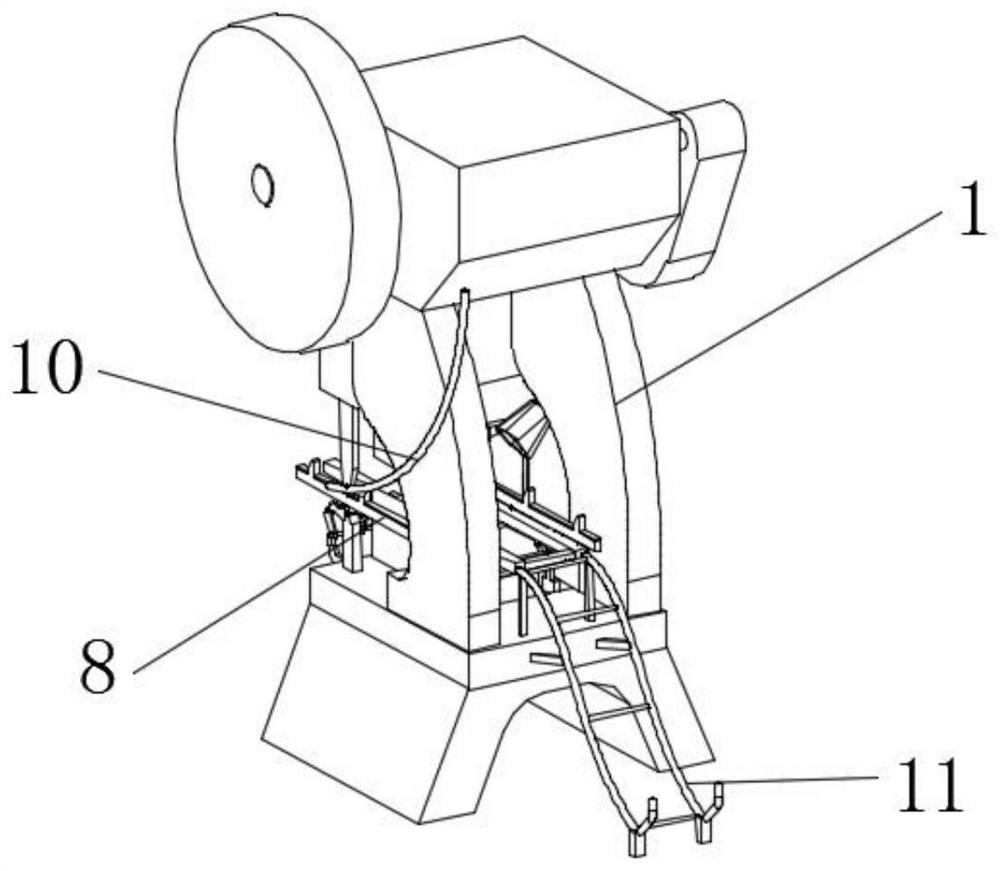

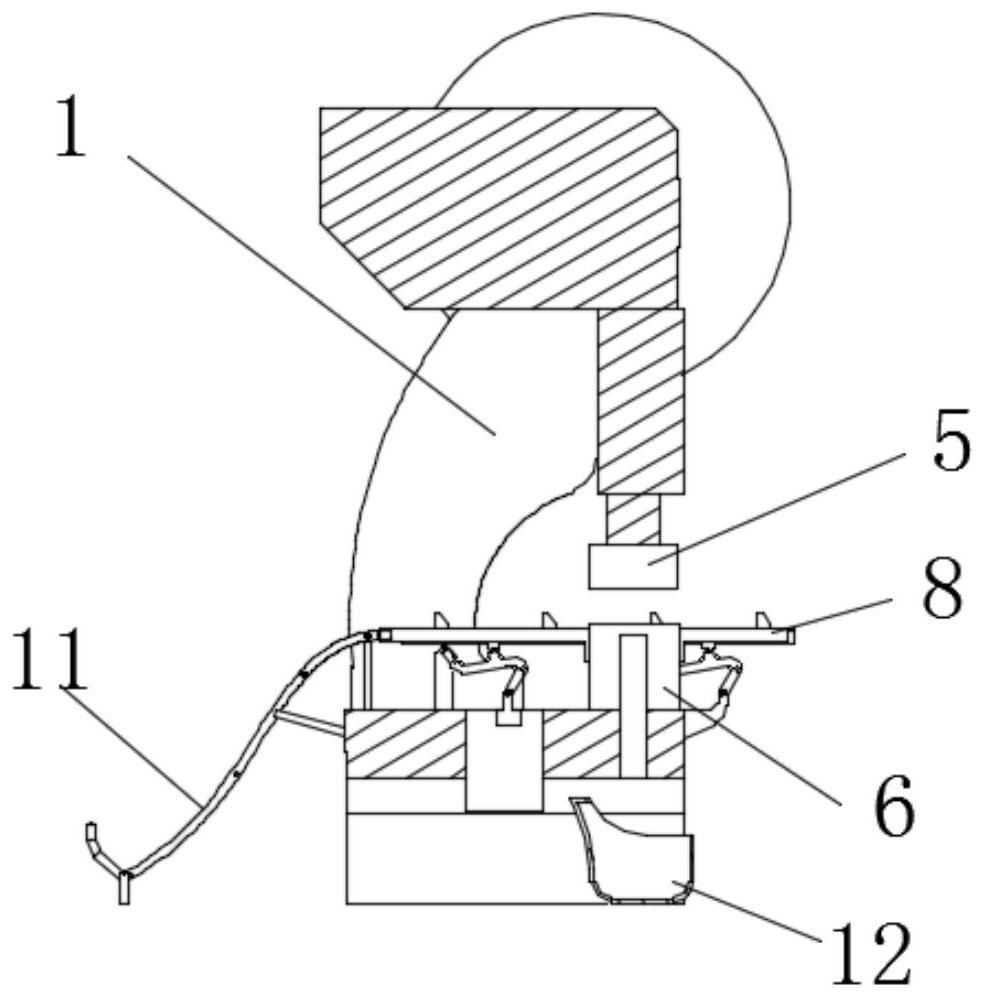

[0042] Example: Reference Figure 1-9 A new type of sheet metal stamping mechanical equipment that is convenient for stamping is shown, including a body 1, a support platform 7 is fixedly installed on the bottom side of the body 1, the top side of the support platform 7 is a support plane, and the bottom side is a stamping equipment supporting foot. One side is provided with a receiving rack 11, and the receiving rack 11 is used to collect the plate products after production. The side opposite to the receiving rack 11 on the body 1 is fixed with a telescopic chamber 4, and a punch is slidably installed in the telescopic chamber 4. The bottom end of the punch is fixedly equipped with an upper formwork 5, and the top side of the support platform 7 is fixedly equipped with a lower formwork 6, the upper formwork 5 and the lower formwork 6 are compatible, and the upper formwork 5 and the lower formwork 6 are respectively the parts of the plate stamping die. Upper mold and lower mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com