Wing surface punching device of automobile U-shaped beam

A punching device, U-shaped technology, applied in the field of plate processing devices, can solve problems affecting processing, affecting feeding, accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

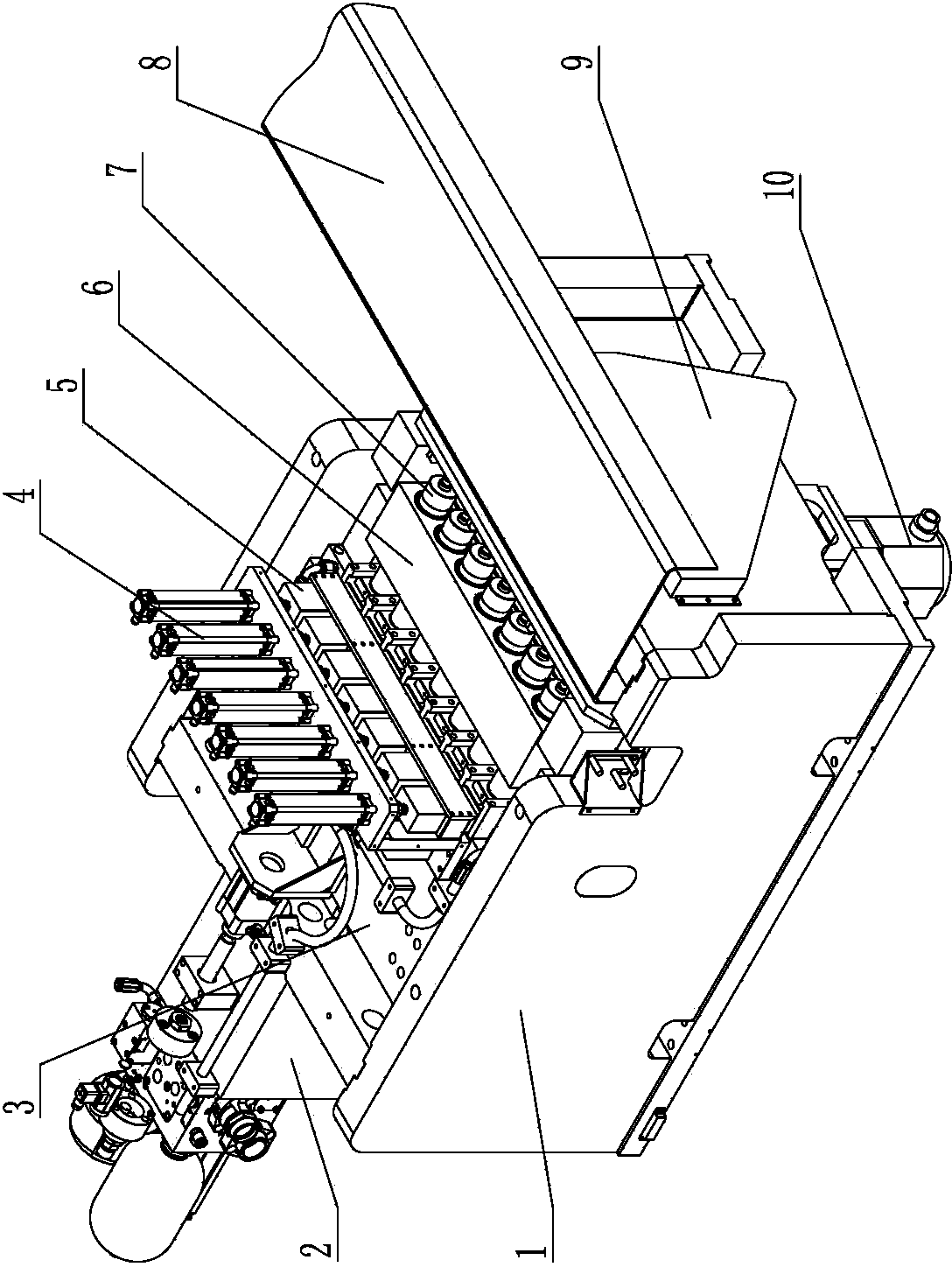

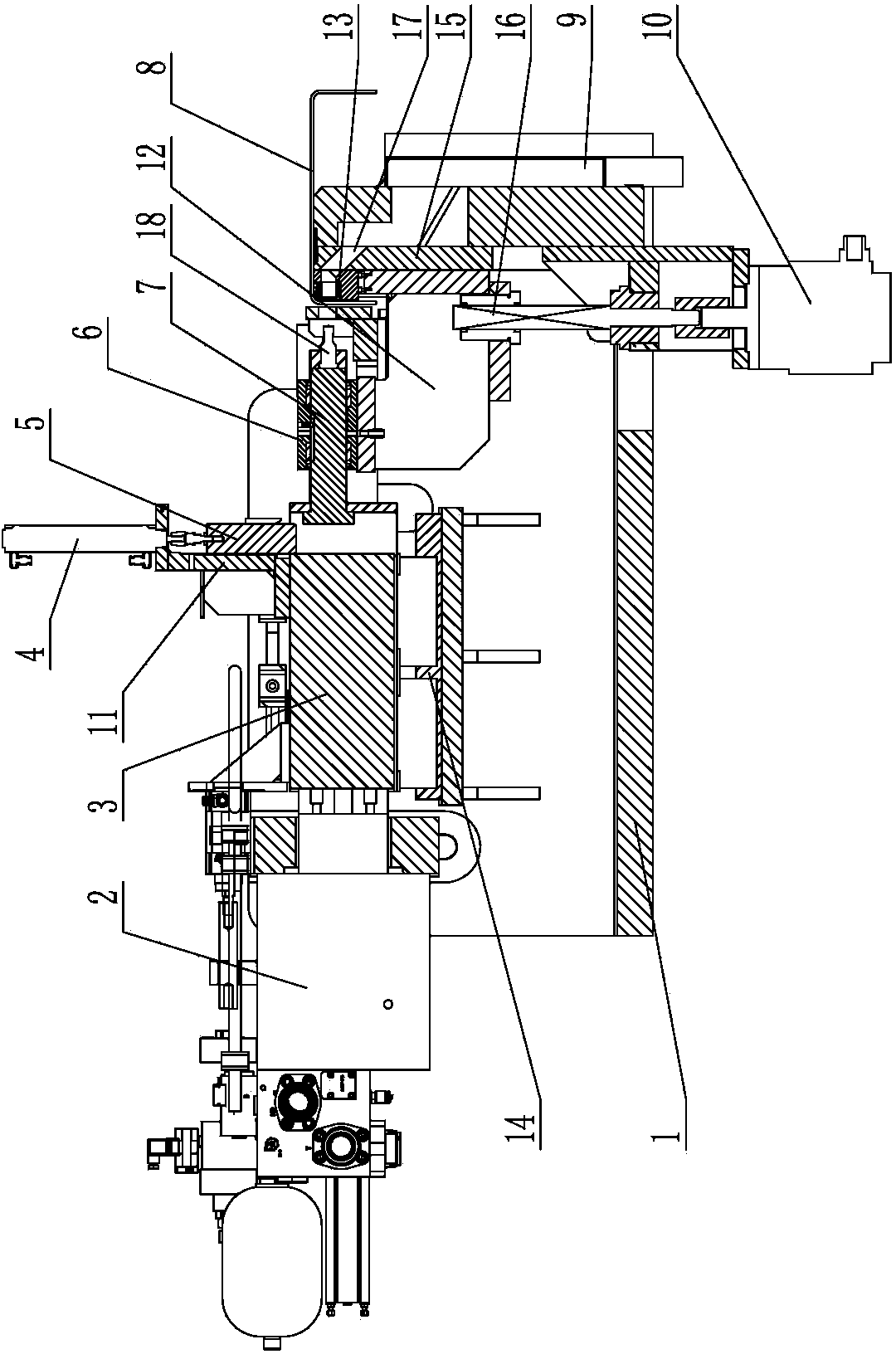

[0011] Such as figure 1 with 2 Shown, is a kind of automobile U-beam airfoil punching device, comprises frame 1, is provided with guide rail 14 horizontally on frame 1, is provided with main slider 3 that can slide along guide rail 14 in guide rail 14, and main slider 3 is provided with a hydraulic punch 2 at one end, and the other end of the main slider 3 is correspondingly provided with a mold assembly, the mold assembly includes a corresponding number of punches 18 and dies 13, and the punches 18 are arranged in the punch guide seat 6, The punch guide seat 6 is slidingly provided with a punch push rod 7, and the punch push rod 7 is in contact with one end of each punch 18 one by one, and the punch guide seat 6 and each die 13 are installed on the die holder bracket 12 , the main slider 3 is fixed with a cylinder bracket 11, and several mold selection cylinders 4 are vertically arranged side by side on the cylinder bracket 11, and the piston rod of the mold selection cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com