Movable assembly type large-scale stone feeding crushing and screening device

A screening equipment and assembled technology, which is applied in the field of mobile assembled large-scale stone feeding crushing and screening equipment, can solve problems such as troublesome, easy accumulation and cleaning of materials, and labor-intensive problems, so as to reduce manufacturing costs, avoid unsafe, and not easy to jam Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

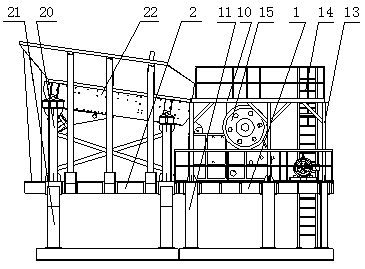

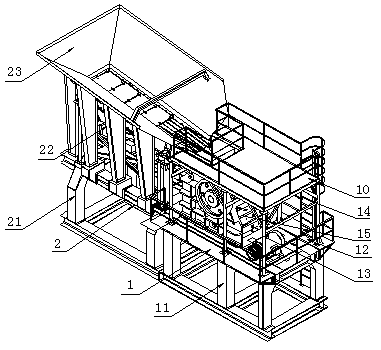

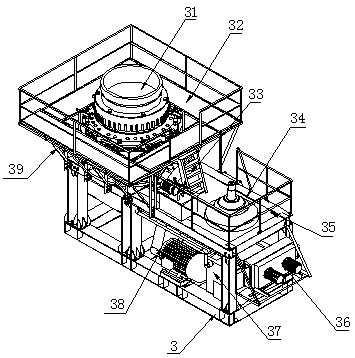

[0024] Embodiment 1: with reference to attached Figure 1~5 . A mobile assembled large-scale stone material crushing and screening equipment, at least including a combined feeding module, a combined crushing module and a combined screening module; the combined feeding module includes a feeder supporting three-dimensional steel structure frame 2, a feeding Machine 22, as well as the three-dimensional steel structure frame 1 supported by the jaw breaker and the jaw breaker 15, the four hinged columns 20 are installed on the frame surface of the three-dimensional steel structure frame 2 supported by the feeder, and the feeder 22 is hinged to the upper ends of the four hinged columns 20 Connection; the jaw crusher 15 is located on the shelf surface of the jaw crusher supporting three-dimensional steel structure frame 1 and there is a maintenance walkway 12 around the jaw crusher 15, and the jaw crusher maintenance platform 10 is supported on the jaw crusher supporting three-dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com